设计简介

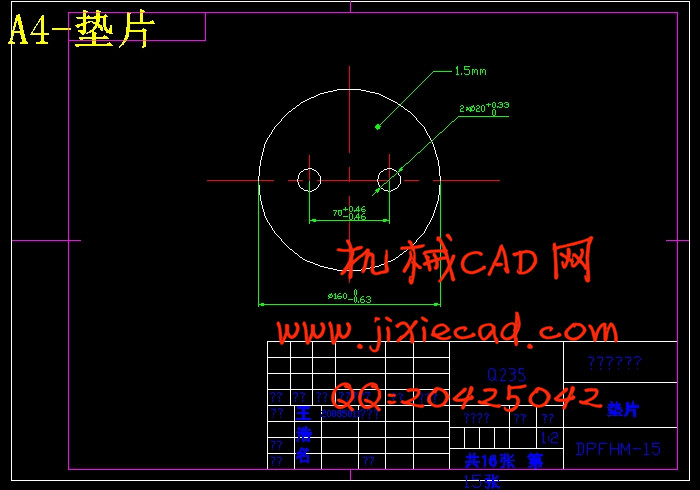

垫片落料冲孔复合模

摘 要

模具是现代工业生产中重要的工艺装备之一。在铸造、锻造、冲压、塑料、橡胶、玻璃、粉末冶金、陶瓷等生产行业中得到广泛应用。某些发达国家的模具总产值以超过机床工业的总产值,在这些国家,模具工业已摆脱了从属地位而发展成为独立的行业。近年来,我国的模具工业也有了较大的发展,模具制造工艺和生产装备智能化程度越来越高,极大地提高了模具制造的精度、质量和生产率。

本次毕业设计的模具的主要作用是垫片的落料和冲孔,该模具在设计时不仅要根据冲裁件的材料选择模具的材料,还要根据冲裁件的形状、尺寸和精度来确定模具的类型和冲裁的工艺方案。其中确定合理的冲裁间隙是本次设计的重点,它不仅影响冲裁件的形状、尺寸和精度,还影响模具的使用寿命。模具材料的选择时应注意材料的性能和强度,应尽量选择标准件,这样不仅可以提高模具的寿命还可以缩短模具的制造周期。

在模具设计时不仅要考虑做出的零件能满足工作要求,还要保证它的使用寿命。本次设计中主要是考虑它的实际工作环境和必须完成的设计任务,模架采用中间导柱模架,凹模采用洞口形状凹模,这样可以一次完成全部的工序加工,在设计中要考虑到很多关于我所设计零件的知识,包括它的使用场合,外观等。通过这次的设计使我深深的体会到怎样才能把所学的东西更好的运用到实践中,设计过程中应注意的问题,使自己在冲压模方面有了更深更多的了解。模具的精度比较高时在使用的过程中要合理的保养,发现问题要及时的修复,这样才能保证产品的质量,提高模具寿命。

关键词:垫片,落料,冲孔,复合模。

Abstract

̥ mold is the modern industrial production in one of the important process equipment. In casting, forging, stamping, plastic, rubber, glass, powder metallurgy, ceramic production such as widely used in industry. Some developed countries with more than machine tool industry mold output value of the total output value, in these countries, die and mold industry is already out of a subordinate position and become independent of the industry. In recent years, our country mold industry also has larger development, mold manufacturing process and production equipment intelligence more and more high, greatly improve the precision of the mold manufacture, quality and productivity.

The graduation design of the mold is the main purpose of the gasket blanking and punching, this mold in the design not only according to the material blanking pieces of selecting mold material, and according to the blanking pieces of the shape, size and precision of the type and to determine the mold cutting process scheme. Among them the determination of reasonable cutting clearance is this the point of design, it not only affects the cutting piece of the shape, size and precision, still affect the service life of the die. Die material choice should pay attention to the material properties and strength, should try to choose standard parts, such not only can improve the service life of mold can shorten the mold manufacturing cycle.

In the mold design not only should consider when a parts can meet the job requirements, it also ensures that its service life. The design of the main consideration of its actual work environment and must complete design task, formwork among the guide post formwork, concave die adopt the mouth of the cave shape concave die, so can a complete the process, in the design considerations to a lot about what I design of the knowledge of the parts, including the use of occasions, appearance, etc. Through this design makes my deep experience how can better use what they have learned into practice, design the problems in the process, make oneself in progressive metal stamping has a deeper understanding of the more. The accuracy is higher in the process of use to the reasonable maintenance, found that the problem should be timely repair, so that we can guarantee the quality of the product, improve die life.

Keywords: gaskets, dropping material, punching, compound mold。

目录

中文摘要............................................................1

英文摘要............................................................2

1 绪论..............................................................5

2 冲压工艺分析......................................................5

2.1 产品的结构和工艺分析...........................................5

2.2 产品尺寸精度、粗糙度、断面质量分析.............................6

2.2.1 尺寸精度.....................................................6

2.2.2 产量.........................................................6

2.2.3 产品材料分析.................................................6

3 冲压工艺方案的确定................................................6

4 垫片冲模结构的确定................................................8

4.1 模具的选择.....................................................8

4.2 定位装置.......................................................8

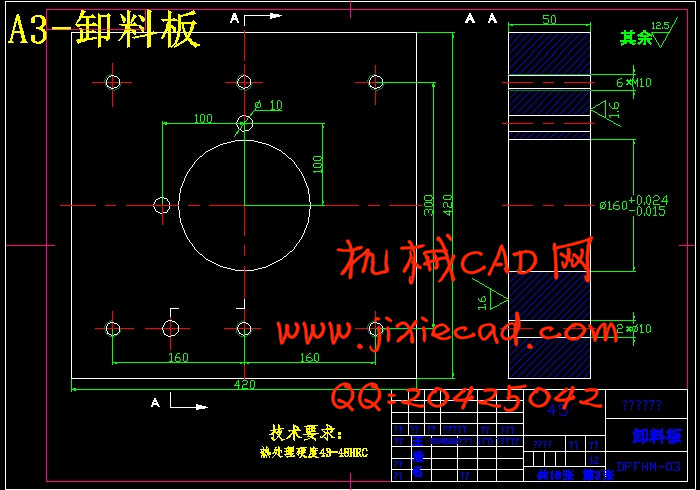

4.3 卸料装置.......................................................9

4.4 废料切刀卸料...................................................9

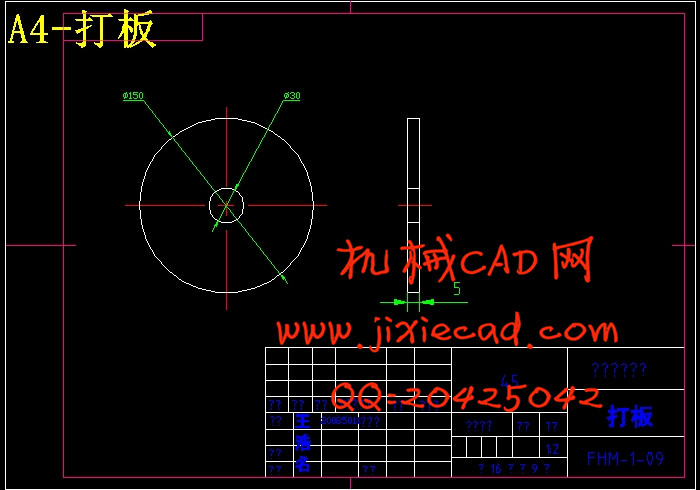

4.5 推件装置.......................................................9

4.6 弹性装置.......................................................9

4.7 导向及支撑固定装置.............................................9

4.8 模架...........................................................9

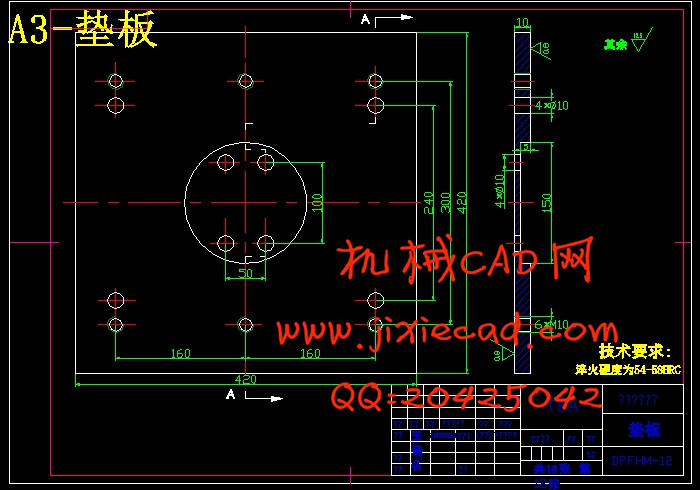

4.9 垫板..........................................................10

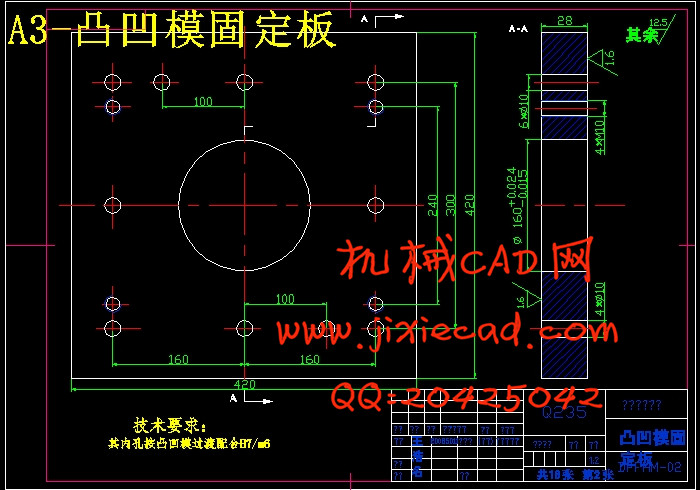

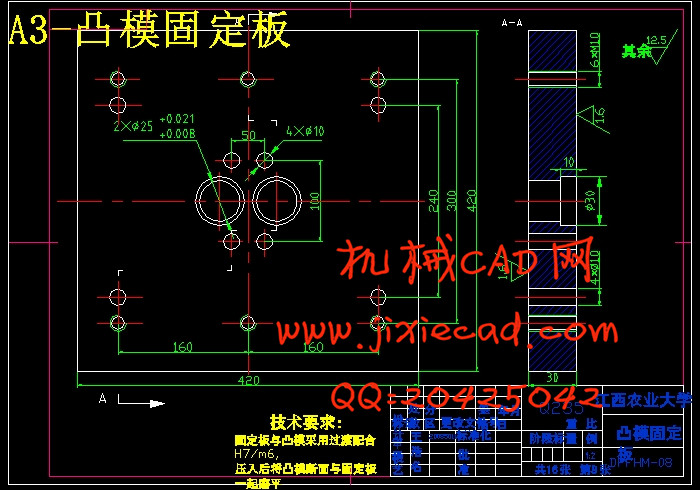

4.10 固定板.......................................................10

4.11 紧固件.......................................................10

5 冲压工艺的计算...................................................10

5.1 排样..........................................................10

5.1.1 排样设计原则................................................10

5.1.2 排样的分类..................................................11

5.2 搭边..........................................................11

5.3 送料步距......................................................11

5.4 条料宽度和导料板间距的计算....................................11

5.5 材料利用率的计算..............................................12

5.6 制件的排样....................................................12

6 模具冲压工艺的计算...............................................13

6.1 冲裁力的计算..................................................13

6.2 卸料力,推件力,顶件力的计算.................................14

6.3 压力机公称压力的确定..........................................15

6.4 初选压力机....................................................16

6.5 确定模具的压力中心............................................16

7 计算模具的刃口尺寸...............................................16

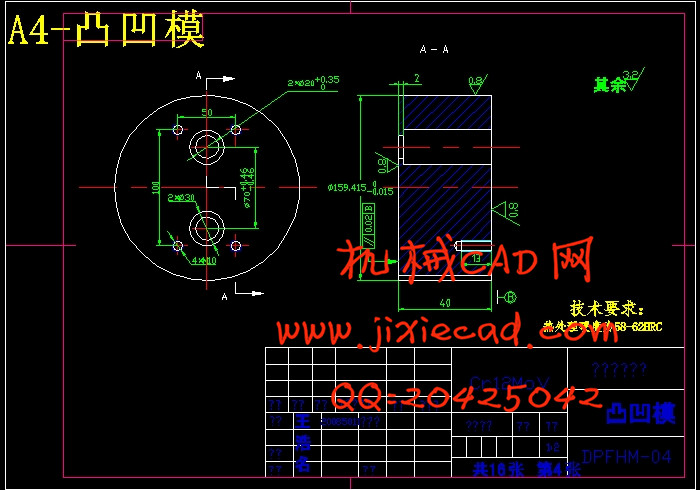

7.1 凸凹模刃口尺寸计算的依据和计算原则............................16

7.2 凸凹模刃口尺寸的计算..........................................17

7.2.1 冲孔凸凹模的刃口尺寸计算...................................18

7.2.2 落料凸凹模刃口尺寸的计算...................................18

8 冲裁模零部件的设计...............................................18

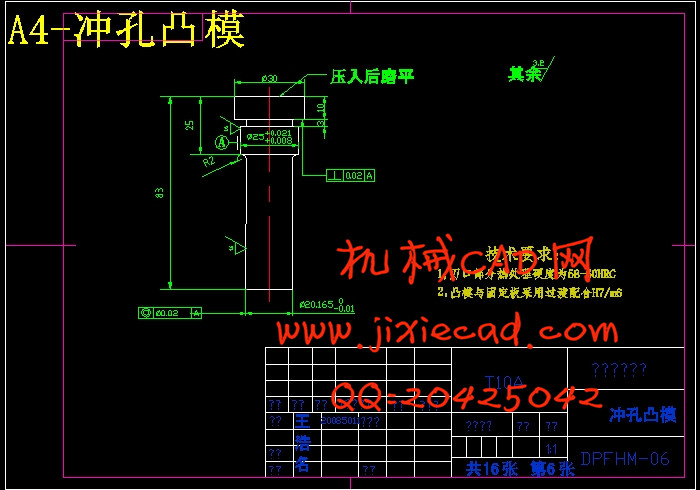

8.1 凸模结构设计..................................................18

8.1.1 凸模的结构形式.............................................18

8.1.2 凸模长度的计算.............................................19

8.1.3 凸模的强度和刚度校核.......................................20

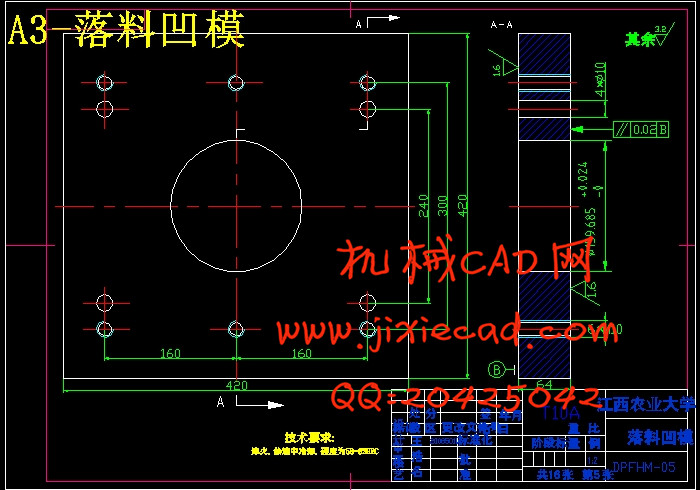

8.2 凹模结构设计.................................................20

8.3 卸料装置的设计................................................21

8.3.1 卸料板的有关尺寸的计算.....................................21

8.3.2 橡胶的选用和计算原则.......................................22

8.4 凸凹模长度确定,壁厚的校核....................................23

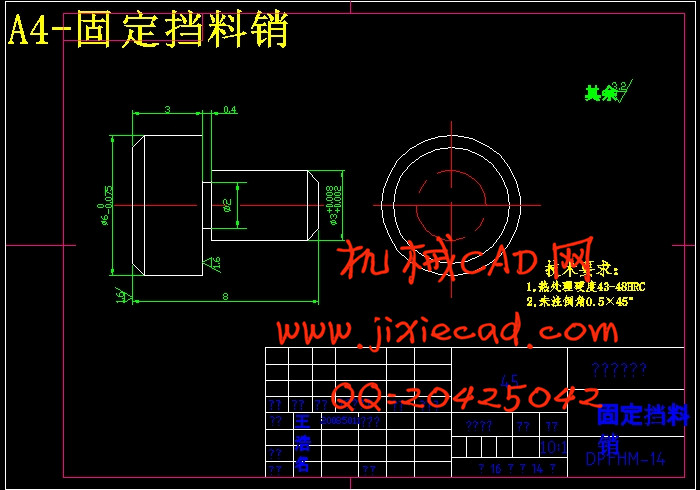

9 固定零件的设计...................................................24

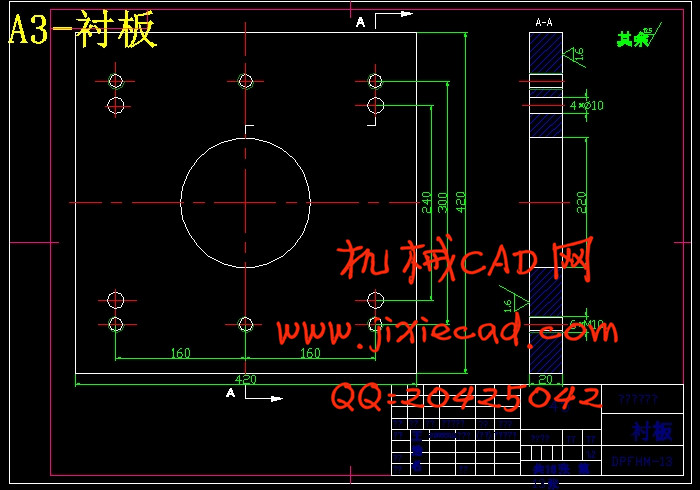

9.1 垫板..........................................................24

9.2 固定板........................................................25

9.3 紧固件........................................................25

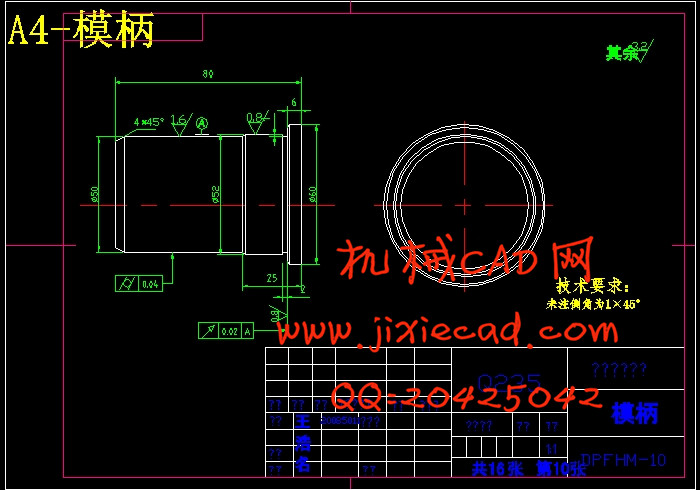

9.4 模柄..........................................................25

9.5 模架..........................................................26

9.5.1 对模架的基本要求...........................................26

9.5.2 模架形式...................................................26

10 模座的设计......................................................29

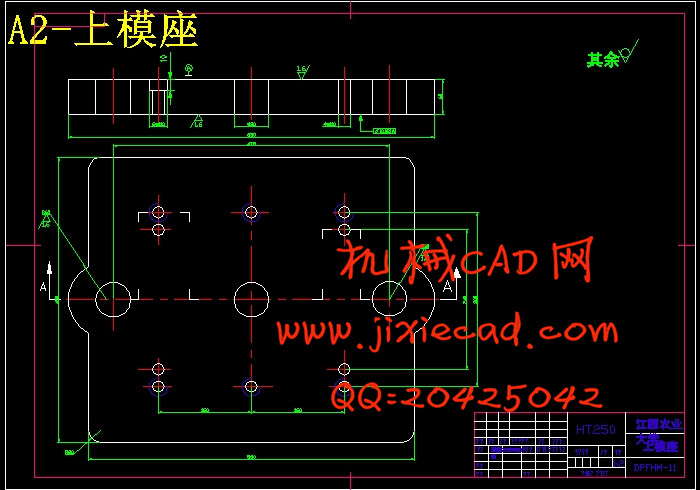

10.1 上模的设计..................................................29

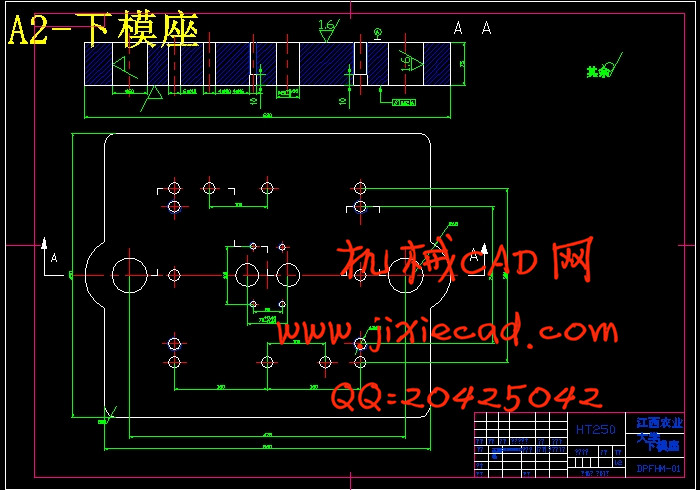

10.2 下模座的设计................................................30

11 冲模闭合高度的确定..............................................30

12 其他零件的选用..................................................31

12.1 选用中间导柱模架............................................31

12.2 选择导柱导套................................................31

12.3 定位元件的选择..............................................32

13 设计冲压模具时应该注意的事项....................................33

14 压力机的校核....................................................34

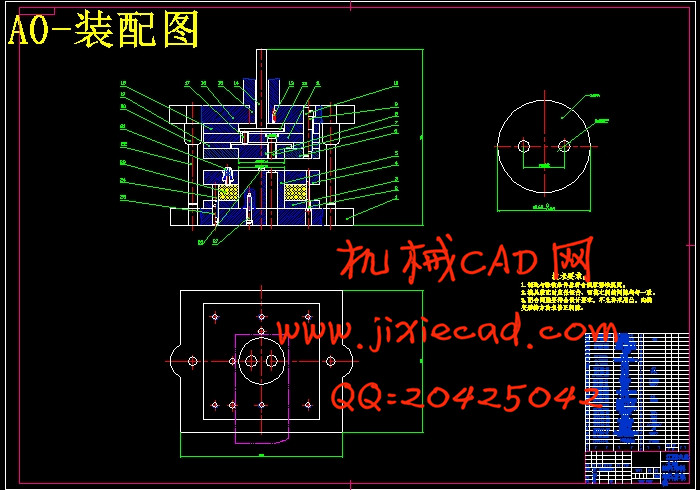

15 模具的装配图....................................................34

16 垫片落料冲孔复合模三维图........................................35

17 参考文献........................................................37

18 致谢............................................................38

摘 要

模具是现代工业生产中重要的工艺装备之一。在铸造、锻造、冲压、塑料、橡胶、玻璃、粉末冶金、陶瓷等生产行业中得到广泛应用。某些发达国家的模具总产值以超过机床工业的总产值,在这些国家,模具工业已摆脱了从属地位而发展成为独立的行业。近年来,我国的模具工业也有了较大的发展,模具制造工艺和生产装备智能化程度越来越高,极大地提高了模具制造的精度、质量和生产率。

本次毕业设计的模具的主要作用是垫片的落料和冲孔,该模具在设计时不仅要根据冲裁件的材料选择模具的材料,还要根据冲裁件的形状、尺寸和精度来确定模具的类型和冲裁的工艺方案。其中确定合理的冲裁间隙是本次设计的重点,它不仅影响冲裁件的形状、尺寸和精度,还影响模具的使用寿命。模具材料的选择时应注意材料的性能和强度,应尽量选择标准件,这样不仅可以提高模具的寿命还可以缩短模具的制造周期。

在模具设计时不仅要考虑做出的零件能满足工作要求,还要保证它的使用寿命。本次设计中主要是考虑它的实际工作环境和必须完成的设计任务,模架采用中间导柱模架,凹模采用洞口形状凹模,这样可以一次完成全部的工序加工,在设计中要考虑到很多关于我所设计零件的知识,包括它的使用场合,外观等。通过这次的设计使我深深的体会到怎样才能把所学的东西更好的运用到实践中,设计过程中应注意的问题,使自己在冲压模方面有了更深更多的了解。模具的精度比较高时在使用的过程中要合理的保养,发现问题要及时的修复,这样才能保证产品的质量,提高模具寿命。

关键词:垫片,落料,冲孔,复合模。

Abstract

̥ mold is the modern industrial production in one of the important process equipment. In casting, forging, stamping, plastic, rubber, glass, powder metallurgy, ceramic production such as widely used in industry. Some developed countries with more than machine tool industry mold output value of the total output value, in these countries, die and mold industry is already out of a subordinate position and become independent of the industry. In recent years, our country mold industry also has larger development, mold manufacturing process and production equipment intelligence more and more high, greatly improve the precision of the mold manufacture, quality and productivity.

The graduation design of the mold is the main purpose of the gasket blanking and punching, this mold in the design not only according to the material blanking pieces of selecting mold material, and according to the blanking pieces of the shape, size and precision of the type and to determine the mold cutting process scheme. Among them the determination of reasonable cutting clearance is this the point of design, it not only affects the cutting piece of the shape, size and precision, still affect the service life of the die. Die material choice should pay attention to the material properties and strength, should try to choose standard parts, such not only can improve the service life of mold can shorten the mold manufacturing cycle.

In the mold design not only should consider when a parts can meet the job requirements, it also ensures that its service life. The design of the main consideration of its actual work environment and must complete design task, formwork among the guide post formwork, concave die adopt the mouth of the cave shape concave die, so can a complete the process, in the design considerations to a lot about what I design of the knowledge of the parts, including the use of occasions, appearance, etc. Through this design makes my deep experience how can better use what they have learned into practice, design the problems in the process, make oneself in progressive metal stamping has a deeper understanding of the more. The accuracy is higher in the process of use to the reasonable maintenance, found that the problem should be timely repair, so that we can guarantee the quality of the product, improve die life.

Keywords: gaskets, dropping material, punching, compound mold。

目录

中文摘要............................................................1

英文摘要............................................................2

1 绪论..............................................................5

2 冲压工艺分析......................................................5

2.1 产品的结构和工艺分析...........................................5

2.2 产品尺寸精度、粗糙度、断面质量分析.............................6

2.2.1 尺寸精度.....................................................6

2.2.2 产量.........................................................6

2.2.3 产品材料分析.................................................6

3 冲压工艺方案的确定................................................6

4 垫片冲模结构的确定................................................8

4.1 模具的选择.....................................................8

4.2 定位装置.......................................................8

4.3 卸料装置.......................................................9

4.4 废料切刀卸料...................................................9

4.5 推件装置.......................................................9

4.6 弹性装置.......................................................9

4.7 导向及支撑固定装置.............................................9

4.8 模架...........................................................9

4.9 垫板..........................................................10

4.10 固定板.......................................................10

4.11 紧固件.......................................................10

5 冲压工艺的计算...................................................10

5.1 排样..........................................................10

5.1.1 排样设计原则................................................10

5.1.2 排样的分类..................................................11

5.2 搭边..........................................................11

5.3 送料步距......................................................11

5.4 条料宽度和导料板间距的计算....................................11

5.5 材料利用率的计算..............................................12

5.6 制件的排样....................................................12

6 模具冲压工艺的计算...............................................13

6.1 冲裁力的计算..................................................13

6.2 卸料力,推件力,顶件力的计算.................................14

6.3 压力机公称压力的确定..........................................15

6.4 初选压力机....................................................16

6.5 确定模具的压力中心............................................16

7 计算模具的刃口尺寸...............................................16

7.1 凸凹模刃口尺寸计算的依据和计算原则............................16

7.2 凸凹模刃口尺寸的计算..........................................17

7.2.1 冲孔凸凹模的刃口尺寸计算...................................18

7.2.2 落料凸凹模刃口尺寸的计算...................................18

8 冲裁模零部件的设计...............................................18

8.1 凸模结构设计..................................................18

8.1.1 凸模的结构形式.............................................18

8.1.2 凸模长度的计算.............................................19

8.1.3 凸模的强度和刚度校核.......................................20

8.2 凹模结构设计.................................................20

8.3 卸料装置的设计................................................21

8.3.1 卸料板的有关尺寸的计算.....................................21

8.3.2 橡胶的选用和计算原则.......................................22

8.4 凸凹模长度确定,壁厚的校核....................................23

9 固定零件的设计...................................................24

9.1 垫板..........................................................24

9.2 固定板........................................................25

9.3 紧固件........................................................25

9.4 模柄..........................................................25

9.5 模架..........................................................26

9.5.1 对模架的基本要求...........................................26

9.5.2 模架形式...................................................26

10 模座的设计......................................................29

10.1 上模的设计..................................................29

10.2 下模座的设计................................................30

11 冲模闭合高度的确定..............................................30

12 其他零件的选用..................................................31

12.1 选用中间导柱模架............................................31

12.2 选择导柱导套................................................31

12.3 定位元件的选择..............................................32

13 设计冲压模具时应该注意的事项....................................33

14 压力机的校核....................................................34

15 模具的装配图....................................................34

16 垫片落料冲孔复合模三维图........................................35

17 参考文献........................................................37

18 致谢............................................................38