设计简介

电动机端盖模具设计

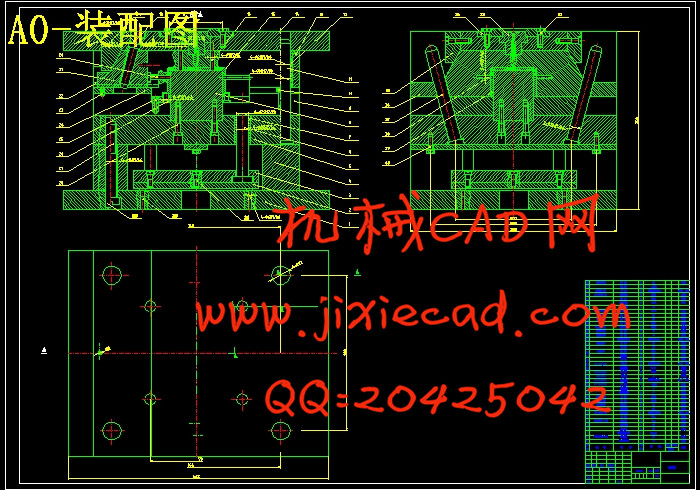

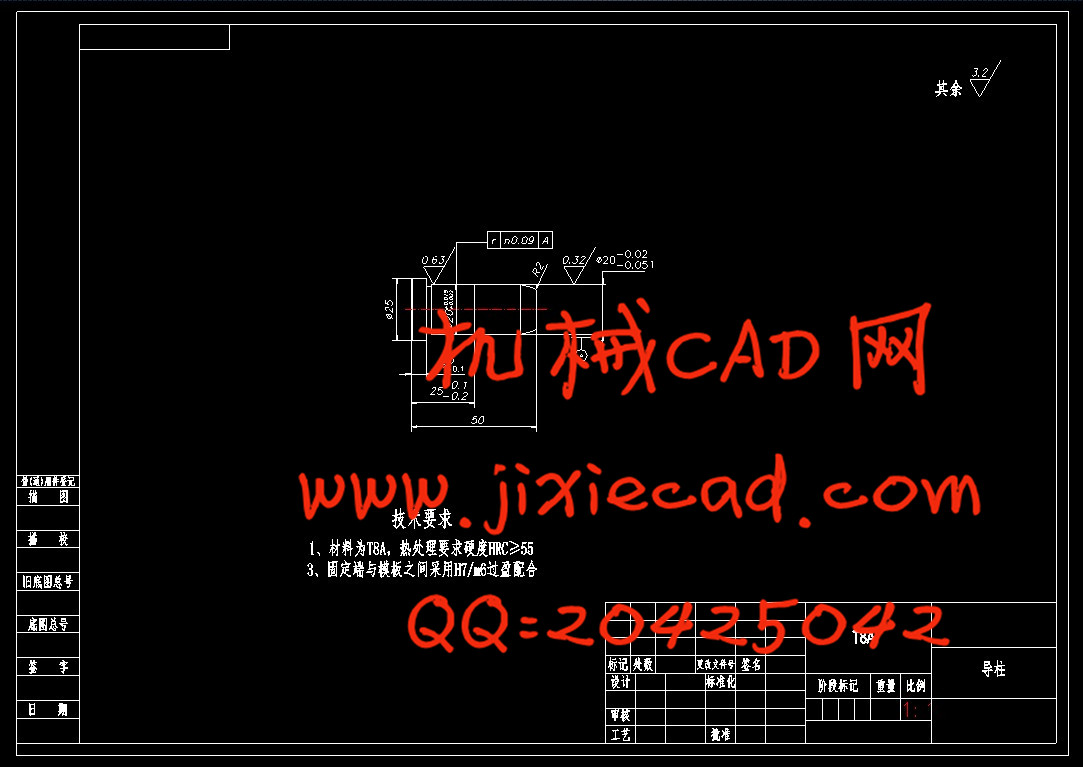

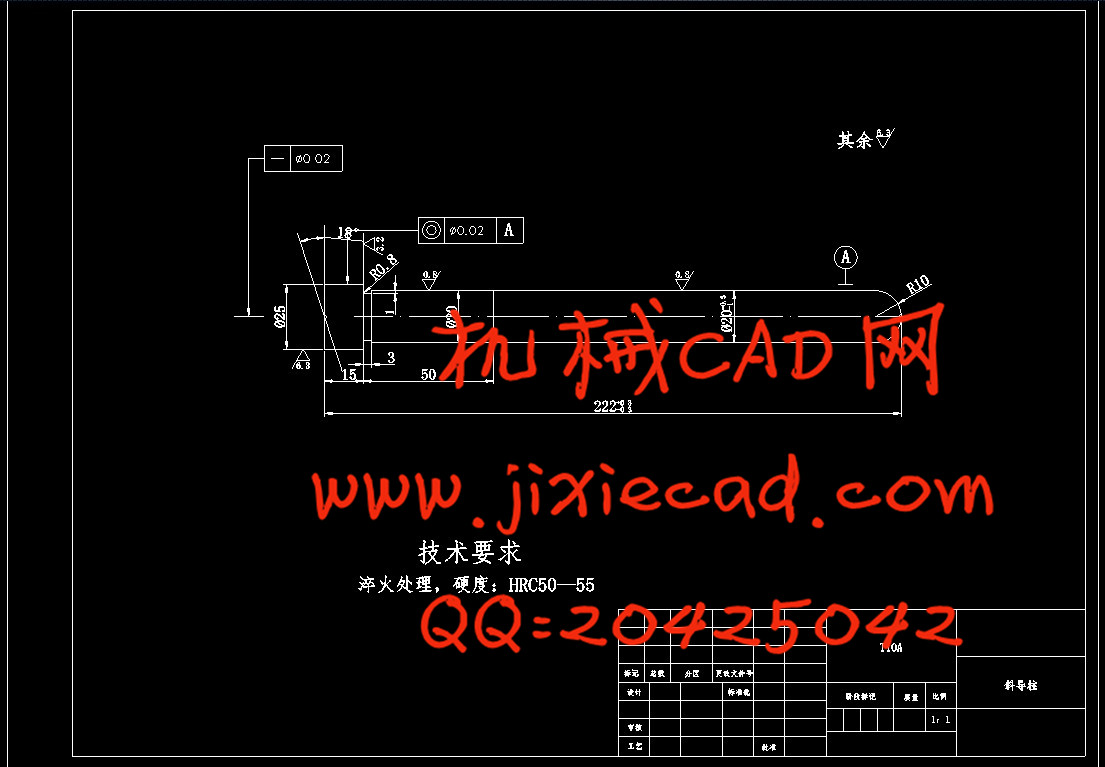

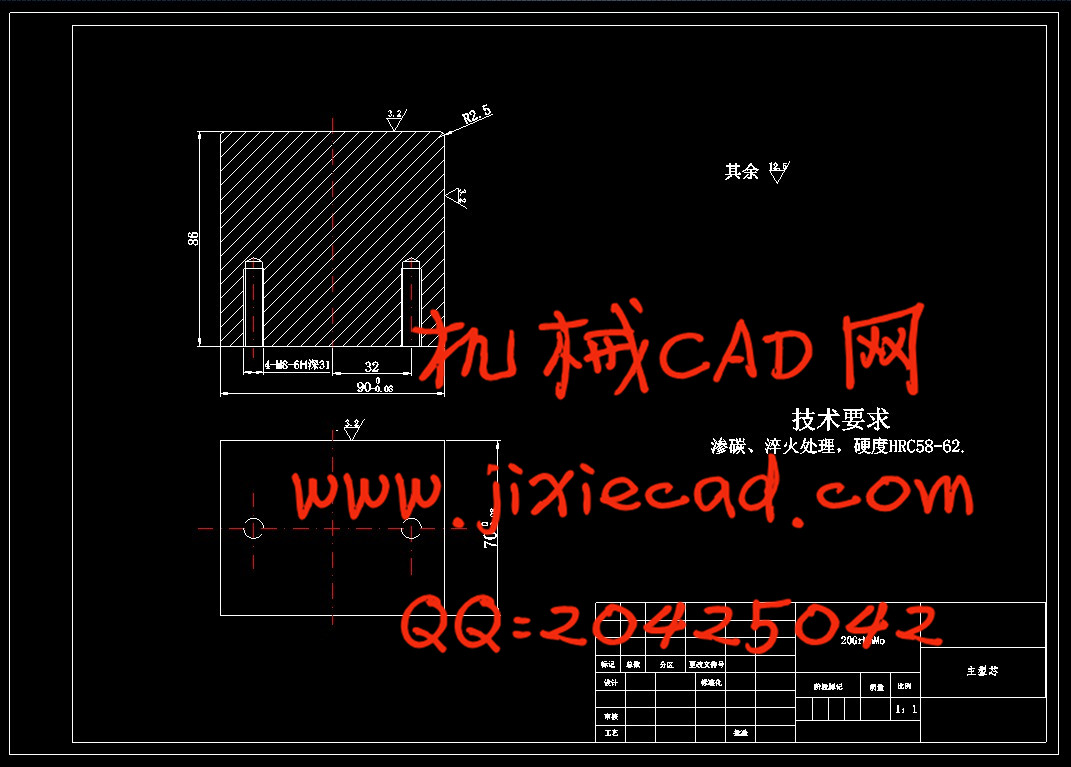

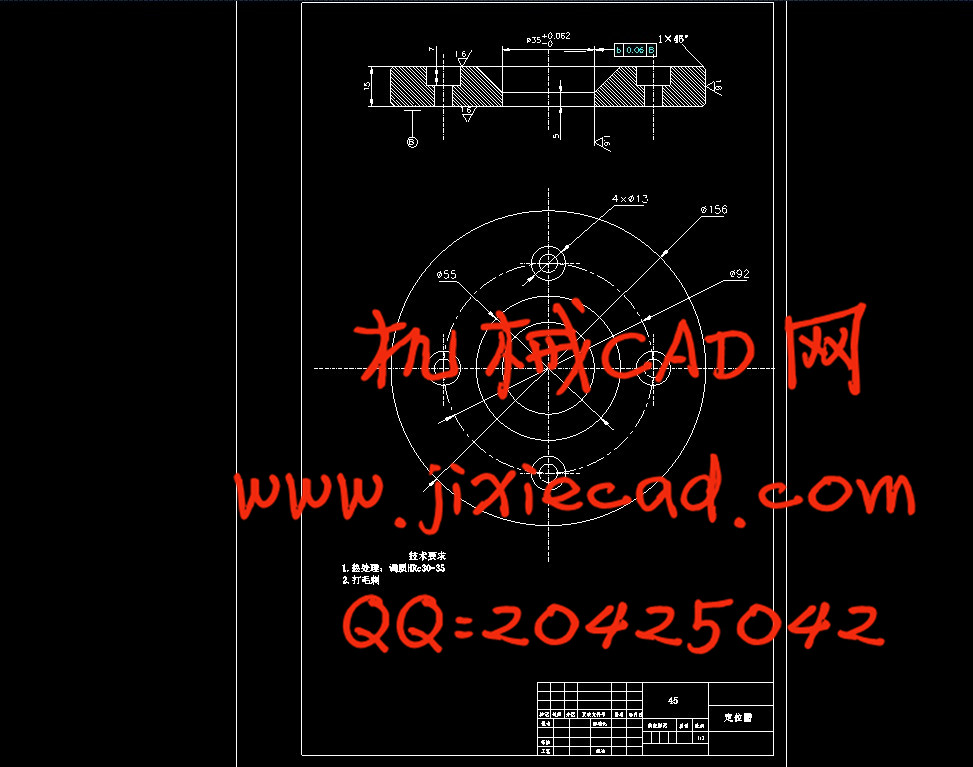

针对端盖压铸件结构及工艺要求,选择端盖口部大端面为动静模分型面。为了使动、定模能够准确地动作, 导向定位机构利用导柱与导套的配合。各成形小孔由动静模型芯对接组成,顶出机构是推杆推出的一次脱出机构,浇注系统采用中心浇道。

本模具考虑到年产量、设备及铸件的精度要求,选择一模二腔结构,并且采用UG来实现铝壳体端盖模具的三维设计及成型零件设计。

关键词:压铸模具;加工工艺分析;铝合金; 端盖;CAD

The Mold design of Motor cover

According to the structure and process requirement of cover die-casting piece ,we select the large end of cover mouth as the Parting surface between the static and dynamic model .In order to make the static and dynamic model can accurately move, we use the cooperation of the guide-post and guide-sleeve in oriented positioning system.The forming holes are formed by the core butt of the static and dynamic model,The knockouts uses once ejecting mechanism that lifter pushes out.,and the gating system adopts center runner.

Taking into account the annual production, equipment and the requirement of accuracy ,we select a second cavity mode,and use UG to achieve the three-dimensional design and molding parts design of aluminum shell cover mold.

Keywords: die-casting mould; processing technology analysis; aluminium alloy;

摘要

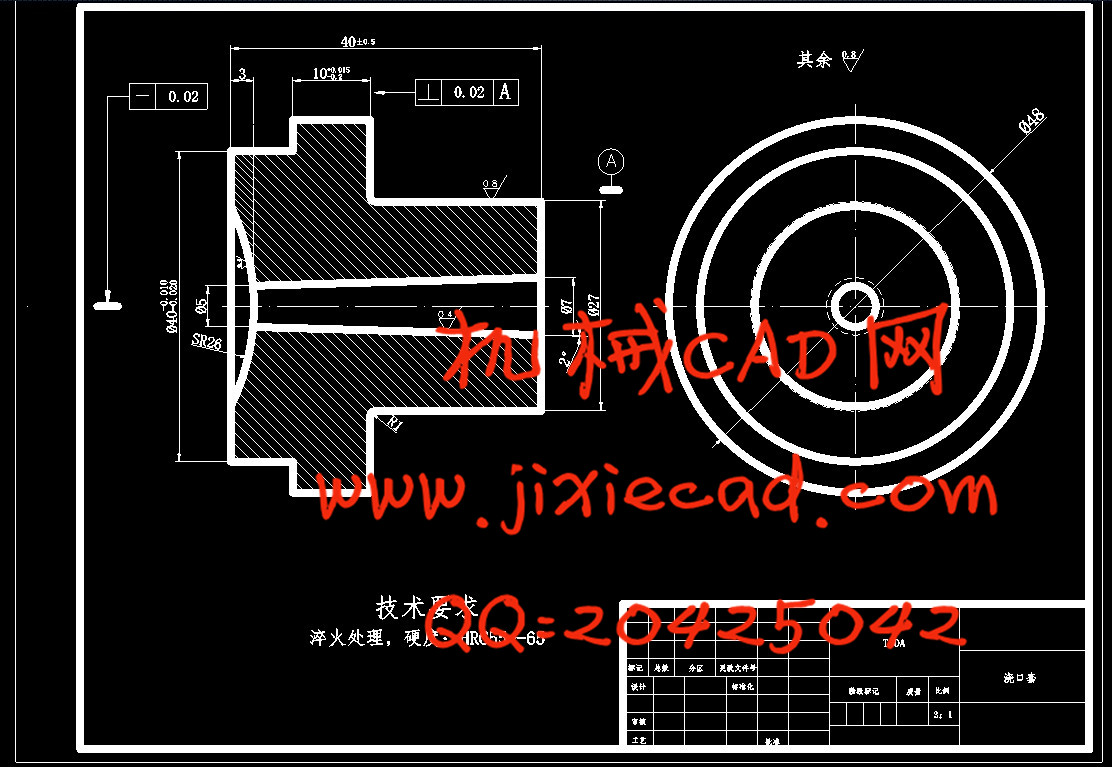

本次设计的端盖压铸件为圆形端盖类零件。最大外形尺寸为Ø64mm,内孔尺寸为Ø28mm,两侧有外加的半圆形。铸件壁厚局部不均匀,材料为铝合金。针对端盖压铸件结构及工艺要求,选择端盖口部大端面为动静模分型面。为了使动、定模能够准确地动作, 导向定位机构利用导柱与导套的配合。各成形小孔由动静模型芯对接组成,顶出机构是推杆推出的一次脱出机构,浇注系统采用中心浇道。

本模具考虑到年产量、设备及铸件的精度要求,选择一模二腔结构,并且采用UG来实现铝壳体端盖模具的三维设计及成型零件设计。

关键词:压铸模具;加工工艺分析;铝合金; 端盖;CAD

The Mold design of Motor cover

Abstract

The cover die-casting piece in this design is circular cover part. The maximum shape dimension is Ø64mm,and the inside hole dimension is Ø19mm, besides, both sides have additional semicircle .The casting has a partly uniform thickness ,and is made of aluminum alloy.According to the structure and process requirement of cover die-casting piece ,we select the large end of cover mouth as the Parting surface between the static and dynamic model .In order to make the static and dynamic model can accurately move, we use the cooperation of the guide-post and guide-sleeve in oriented positioning system.The forming holes are formed by the core butt of the static and dynamic model,The knockouts uses once ejecting mechanism that lifter pushes out.,and the gating system adopts center runner.

Taking into account the annual production, equipment and the requirement of accuracy ,we select a second cavity mode,and use UG to achieve the three-dimensional design and molding parts design of aluminum shell cover mold.

Keywords: die-casting mould; processing technology analysis; aluminium alloy;