设计简介

内 容 提 要

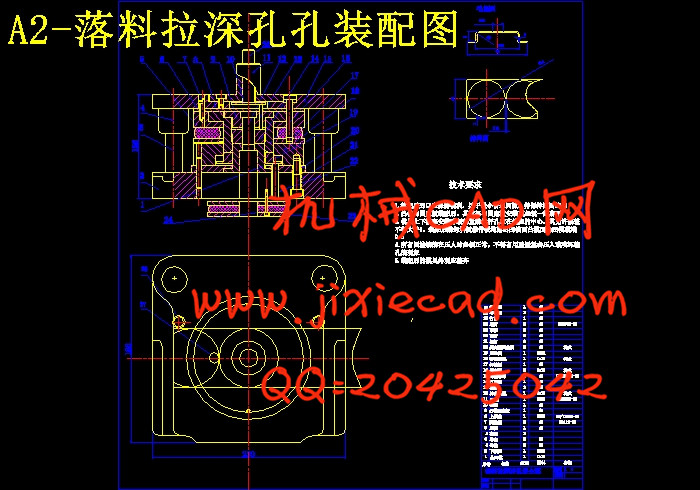

这次设计的是一次成型的落料-冲孔-拉深-切边复合模。通过学习了冲压与模具设计等相关专业书之后,我自己自行设计的一套集落料-冲孔-拉深-切边的模具。本次设计的目的不是检验产品是否能够使用,而是掌握如何来设计模具,了解模具设计的关键所在,因为本人是第一次设计模具,所以这次论文是基于我的经验和基础和在指导老师以及同学的帮助下完成的,从零件工艺的分析到确定工艺方按,然后到模具设计步骤,最后装配成一套模具。针对凸凹模,复合模的结构特点,采用基于参数化的自动和交互设计相结合的方法对凸凹模进行了设计。为实现凸凹模结构的CAD系统商品化,适用化奠定了基础。

Summary:This time design of model once of fall to anticipate- hurtle the bore- pull deep- slice the compound mold in side.Passed to study to wash to press after designing with molding tool the related profession in etc. book, myself design by oneself a set of to gather to fall to anticipate- hurtle the bore- pull deep- slice the molding tool of the side.

The purpose of this design is not a key to examine the product whether can use, but control how come to design the molding tool, understand the molding tool design place, because oneself design the molding tool for the first time, so this time the thesis is a help to base on my experience with the foundation with at guide teacher and classmates to descend to complete of, analyze the certain craft from the spare parts craft the square press, then arrive the molding tool the design the step, assembling finally a set of molding tools.Aim at the convex and cave mold, the construction characteristics of the compound mold, adopt according to the auto that parameter turn with hand over to designed the method that combine together to proceed the design to the convex and cave mold with each other

目 录

前言………………………………………………………………………1

摘要………………………………………………………………………2.

第一章 零件工艺性分析及确定工艺方案……………………………3

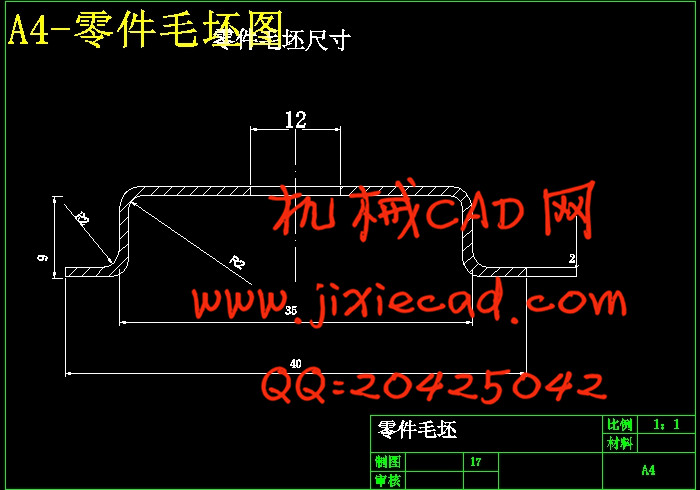

. 零件工艺分析………………………………………………………3

第1.2节 工艺方案确定……………………………………………4

第1.3节 排样确定…………………………………………………4

第二章 工艺与设计计算…………………………………………………5

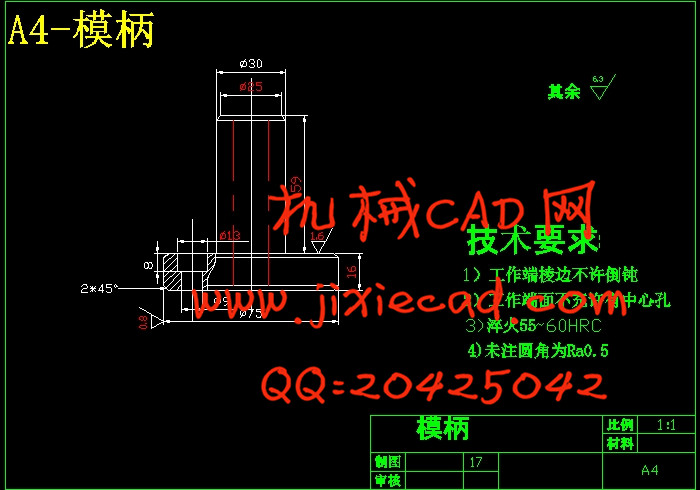

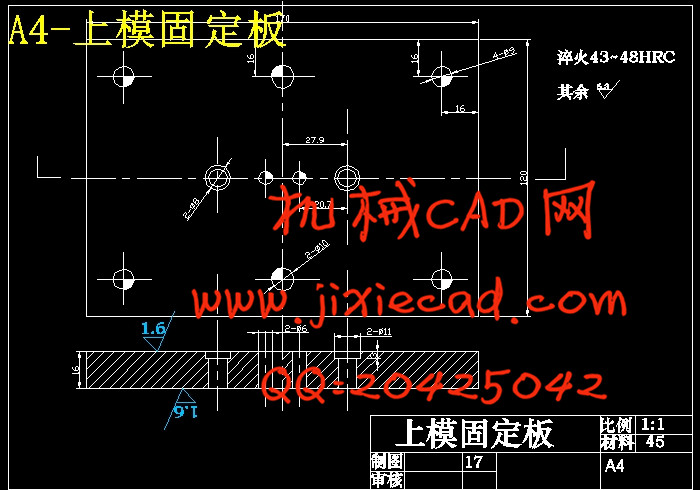

第2.1节 模具的设计和加工………………………………………5

第2.2节 冲裁力的计算……………………………………………6

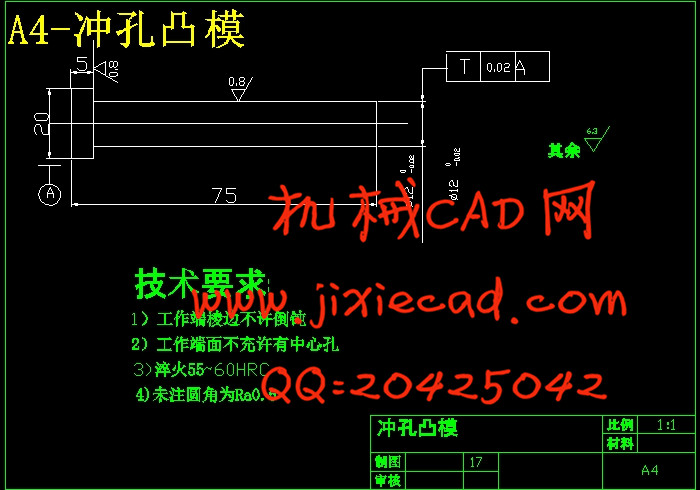

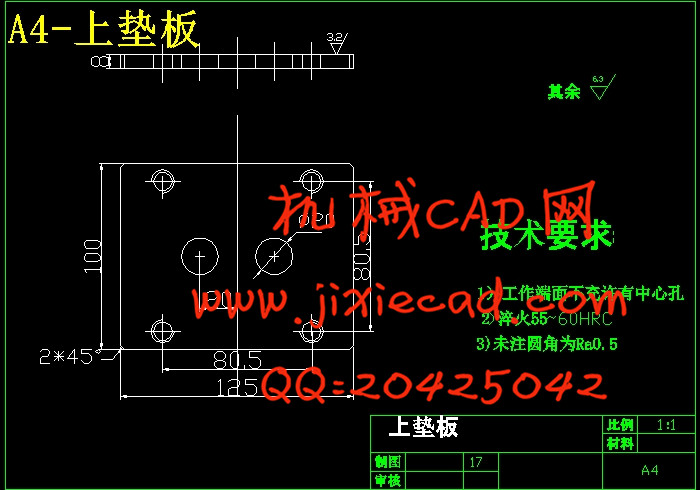

第2.3节 计算各主要零件的尺寸…………………………………8

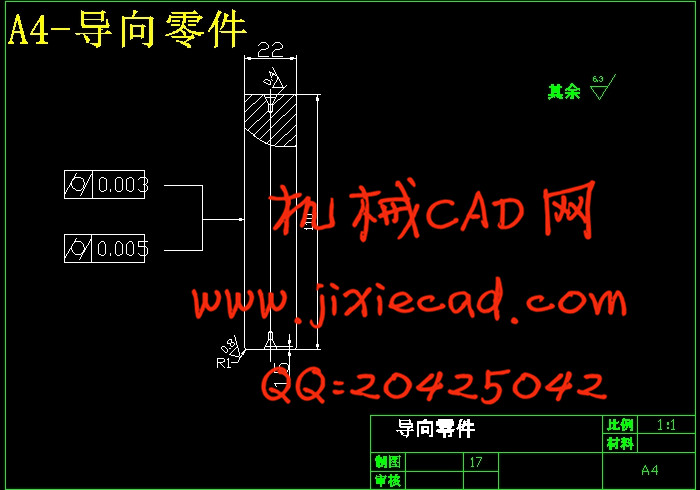

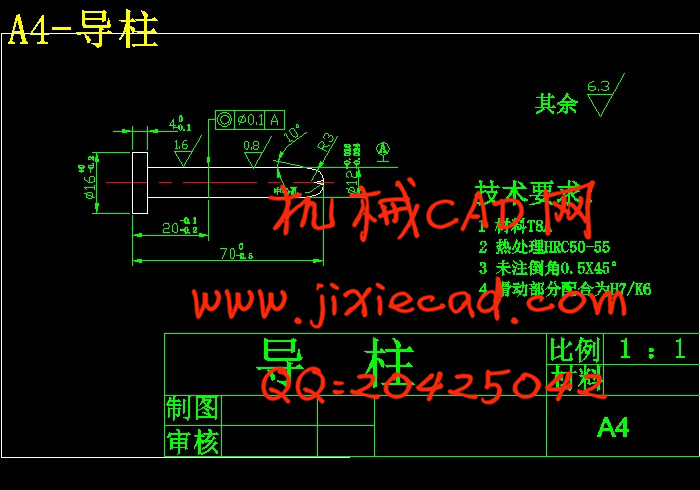

第2.4节 定位零件的设计…………………………………………17

第三章 模具的装配 …………………………………………………21

第四章 结论与展望 …………………………………………………….24

结束语…………………………………………………………………… 25

谢鸣 ………………………………………………………………………26

参考文献………………………………………………………………… 27

这次设计的是一次成型的落料-冲孔-拉深-切边复合模。通过学习了冲压与模具设计等相关专业书之后,我自己自行设计的一套集落料-冲孔-拉深-切边的模具。本次设计的目的不是检验产品是否能够使用,而是掌握如何来设计模具,了解模具设计的关键所在,因为本人是第一次设计模具,所以这次论文是基于我的经验和基础和在指导老师以及同学的帮助下完成的,从零件工艺的分析到确定工艺方按,然后到模具设计步骤,最后装配成一套模具。针对凸凹模,复合模的结构特点,采用基于参数化的自动和交互设计相结合的方法对凸凹模进行了设计。为实现凸凹模结构的CAD系统商品化,适用化奠定了基础。

Summary:This time design of model once of fall to anticipate- hurtle the bore- pull deep- slice the compound mold in side.Passed to study to wash to press after designing with molding tool the related profession in etc. book, myself design by oneself a set of to gather to fall to anticipate- hurtle the bore- pull deep- slice the molding tool of the side.

The purpose of this design is not a key to examine the product whether can use, but control how come to design the molding tool, understand the molding tool design place, because oneself design the molding tool for the first time, so this time the thesis is a help to base on my experience with the foundation with at guide teacher and classmates to descend to complete of, analyze the certain craft from the spare parts craft the square press, then arrive the molding tool the design the step, assembling finally a set of molding tools.Aim at the convex and cave mold, the construction characteristics of the compound mold, adopt according to the auto that parameter turn with hand over to designed the method that combine together to proceed the design to the convex and cave mold with each other

目 录

前言………………………………………………………………………1

摘要………………………………………………………………………2.

第一章 零件工艺性分析及确定工艺方案……………………………3

. 零件工艺分析………………………………………………………3

第1.2节 工艺方案确定……………………………………………4

第1.3节 排样确定…………………………………………………4

第二章 工艺与设计计算…………………………………………………5

第2.1节 模具的设计和加工………………………………………5

第2.2节 冲裁力的计算……………………………………………6

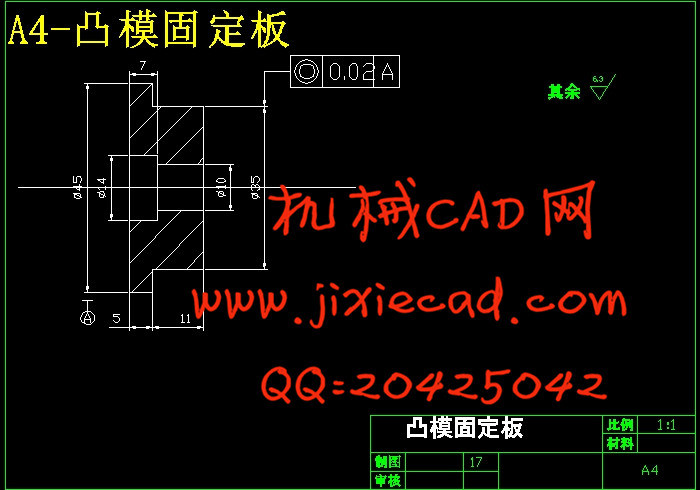

第2.3节 计算各主要零件的尺寸…………………………………8

第2.4节 定位零件的设计…………………………………………17

第三章 模具的装配 …………………………………………………21

第四章 结论与展望 …………………………………………………….24

结束语…………………………………………………………………… 25

谢鸣 ………………………………………………………………………26

参考文献………………………………………………………………… 27