设计简介

摘 要:本设计通过对卡板零件的工艺特点分析,确定了冲孔、压弯、翻边、切断等成形工艺,通过对所提出的不同设计方案的对比,最终确定了多工位级进模的冲压方案。本论文介绍了该卡板级进模具的设计要点、设计过程及模具的结构特点、工作过程。本卡板级进模具的设计目的在于提高卡板零件的生产效率,实现生产过程中的机械化和自动化,从而带来较好的经济和社会效益。

关键词:卡板零件;工艺分析;级进模;模具结构;

Abstract: This design aims at figuring out the forming process of punching, shearing, bending, flanging and cutting through the analysis on the technological characteristics of parts of card board. By comparing various proposed design proposal, the author ultimately determines to adopt the multi-station progressive die stamping as the processing scheme. In this paper, the author will introduce the design features and process of this model, meanwhile, its structural characteristics and machining process will also be involved.The board level of the card is designed to improve the production efficiency of the parts of the card boards, mechanize and automate the production process, resulting in better economic and social benefits.

Key words: Parts of card board; Industrial analysis; Progressive die; Mold structure

目 录

摘要………………………………………………………………………………1

关键词……………………………………………………………………………1

1前言……………………………………………………………………………1

2工件的冲压工艺分析…………………………………………………………2

2.1零件介绍………………………………………………………………………2

2.2工件的尺寸精度……………………………………………………………3

2.3审查零件材料选用是否得当…………………………………………3

2.4冲裁件结构工艺性分析………………………………………………3

2.5翻边工艺性分析…………………………………………………………3

3确定冲压工艺方案……………………………………………………4

3.1确定工艺方案………………………………………………………………4

3.2确定工位数………………………………………………………………6

3.3排样及材料利用率的计算……………………………………………6

3.3.1计算毛坯尺寸……………………………………………………………………7

3.3.2排样的设计…………………………………………………………………7

3.3.3材料利用率的计算………………………………………………………………8

4 主要工艺参数的确定……………………………………………………………9

4.1确定预冲孔直径尺寸……………………………………………………………9

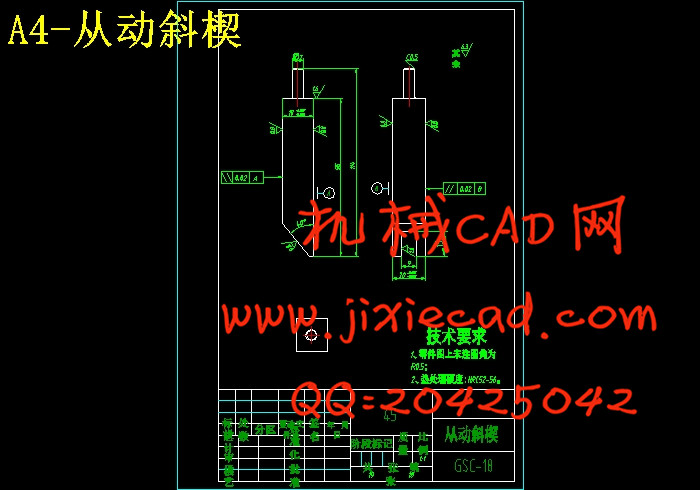

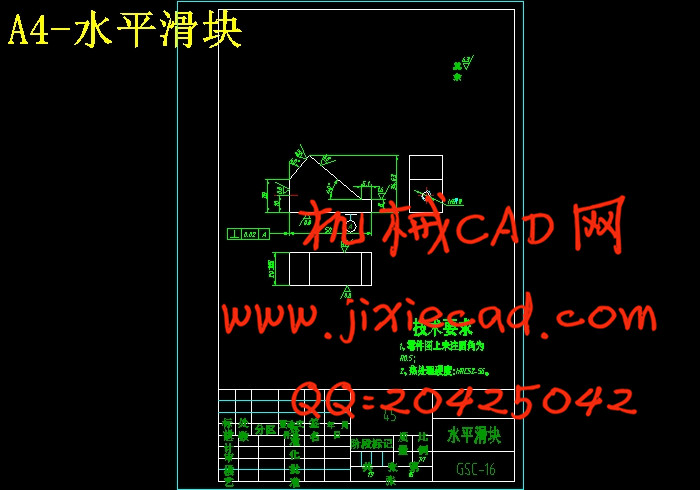

4.2确定双斜楔结构角度参……………………………………………………10

5 各部分工艺力的计算……………………………………………………………11

5.1冲裁力的计算……………………………………………………………………11

5.1.1冲裁力的计算公式……………………………………………………………11

5.1.2降低冲裁力的方法…………………………………………………12

5.2弯曲部分的力计算……………………………………………………………13

5.3翻孔部分的力计算…………………………………………………………13

5.4总压力…………………………………………………………………14

5.5压力中心的计算…………………………………………………………14

5.6冲压设备的选择………………………………………………………15

6计算凸、凹模刃口尺寸及公差…………………………………………………16

6.1计算原则………………………………………………………………16

6.2刃口尺寸计算…………………………………………………………17

6.2.1冲导正孔凸、凹模刃口尺寸计算………………………………………17

6.2.2冲预冲孔凸、凹模刃口尺寸计算…………………………………………18

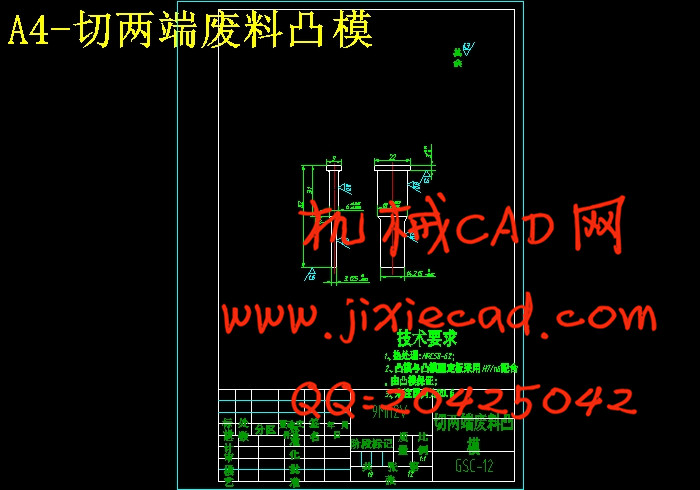

6.2.3切两端废料凸、凹模刃口尺寸计算………………………………………18

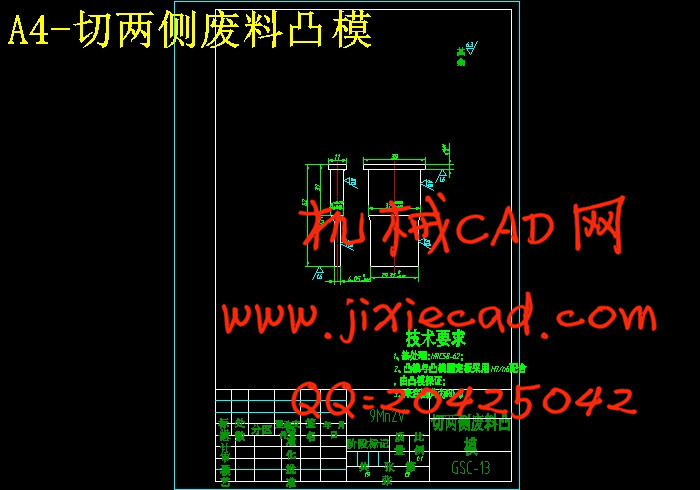

6.2.4切两侧废料凸、凹模刃口尺寸计算……………………………………19

6.2.5切断凸凹模刃口尺寸计算……………………………………………19

6.2.6翻边时凸凹模刃口尺寸计算……………………………………………20

6.2.7弯曲时凸凹模工作部位尺寸……………………………………………20

7模具主要零件设计与选择…………………………………………………21

7.1常用冲压模具材料的选取………………………………………………21

7.2冲孔圆形凸模的设计………………………………………………21

7.2.1冲孔凸模的结构设计………………………………………………21

7.2.2凸模长度的计算………………………………………………21

7.3切两端和两侧废料的凸模设计………………………………………………22

7.4翻孔凸模的设计………………………………………………………23

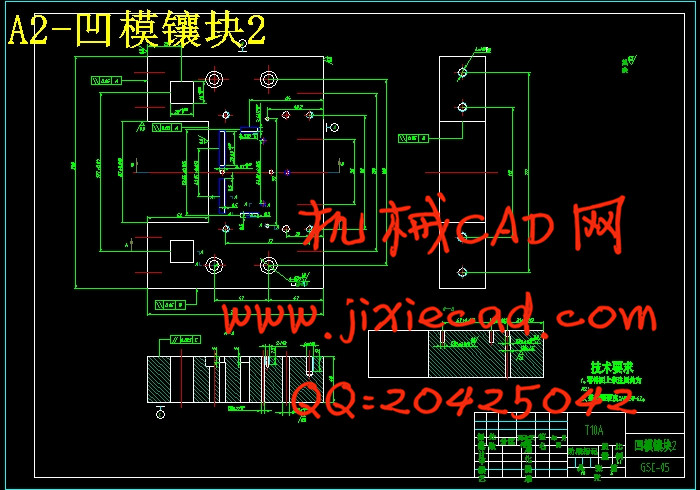

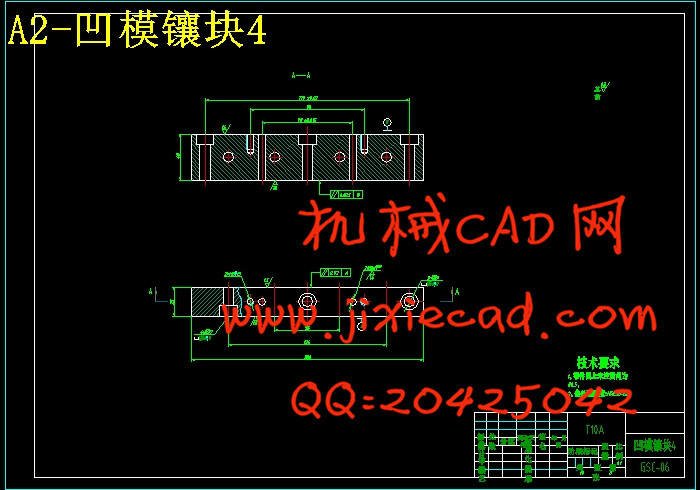

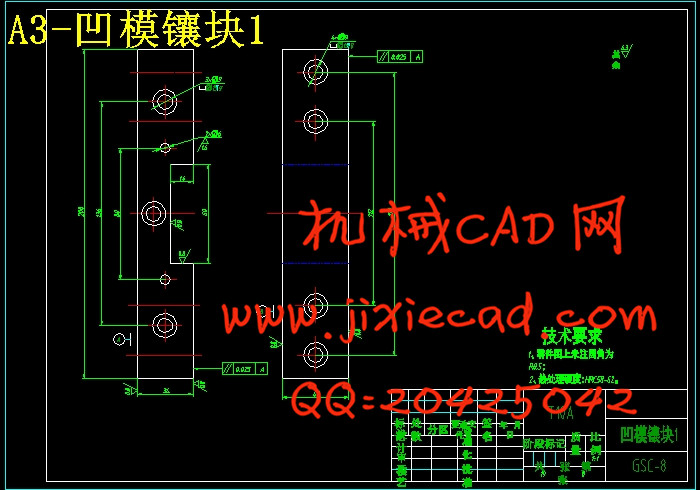

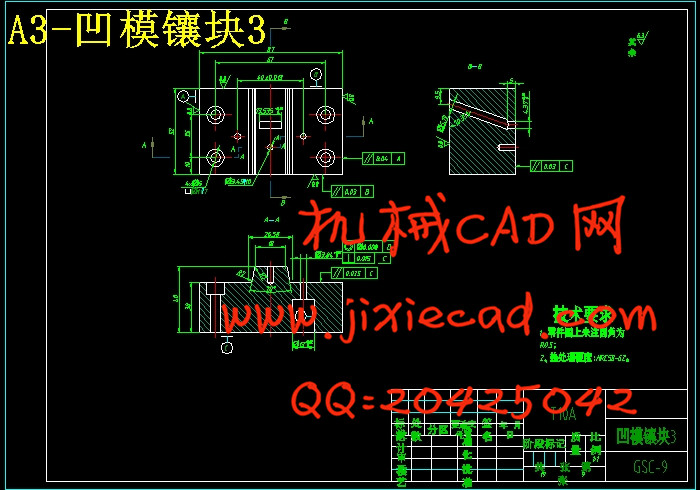

7.5凹模的设计………………………………………………………24

7.5.1凹模孔口形式及主要参数………………………………………………24

7.5.2凹模外形尺寸的确定………………………………………………24

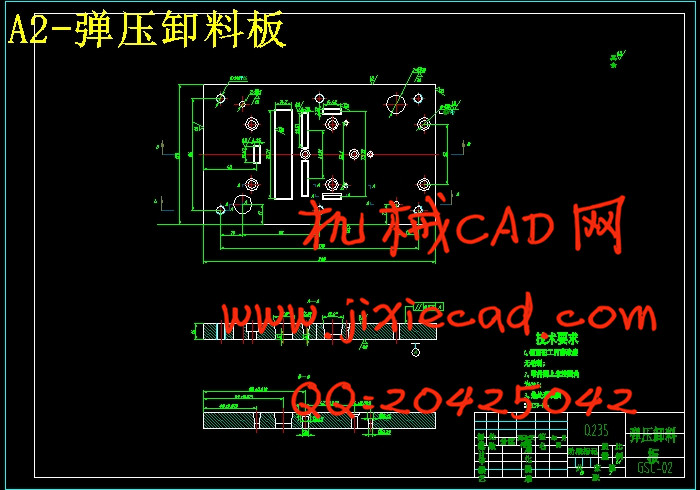

7.6卸料弹簧的设计和选用………………………………………………25

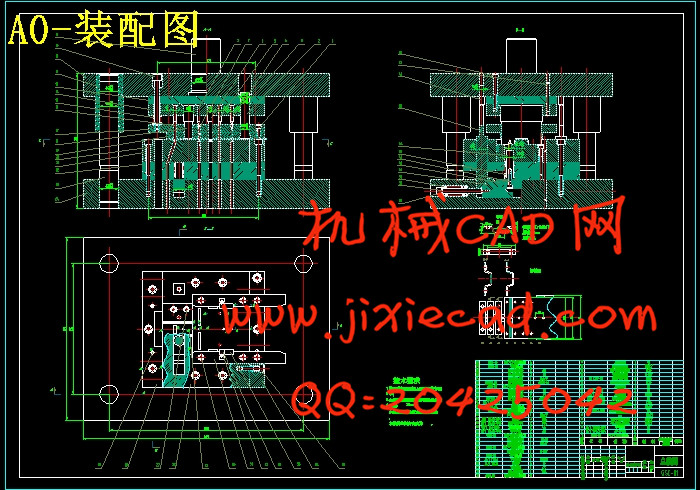

8 模具总体设计……………………………………………………………27

8.1 模架及模柄结构的设计及选择……………………………………………27

8.1.1 模架结构的设计和选择……………………………………………27

8.1.2模柄的选择…………………………………………………………27

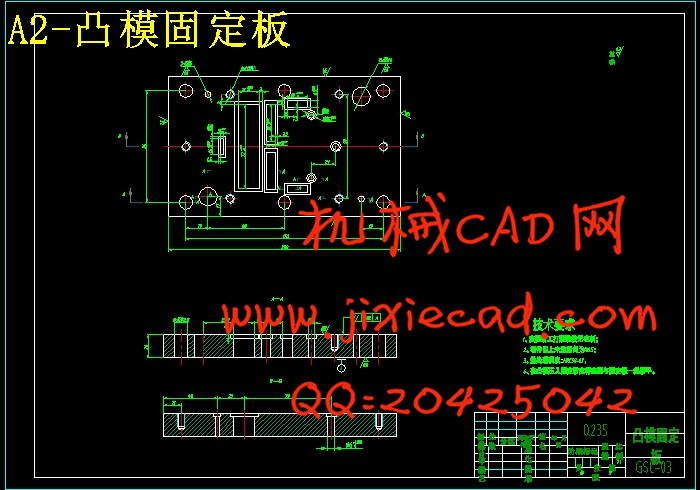

8.2 固定板结构设计…………………………………………………………28

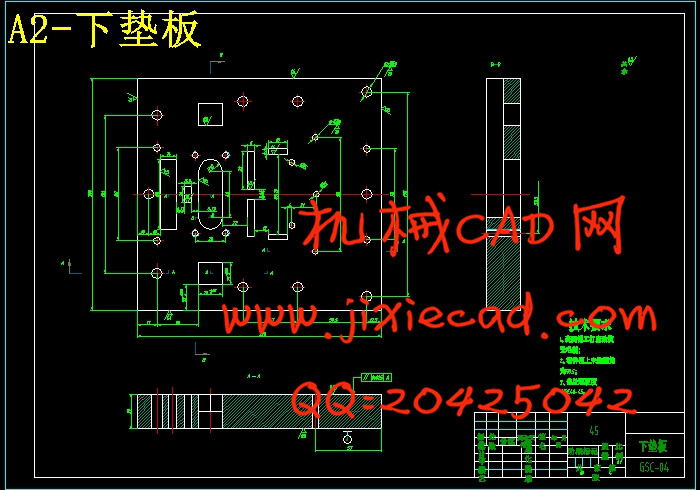

8.3 垫板结构设计…………………………………………………………29

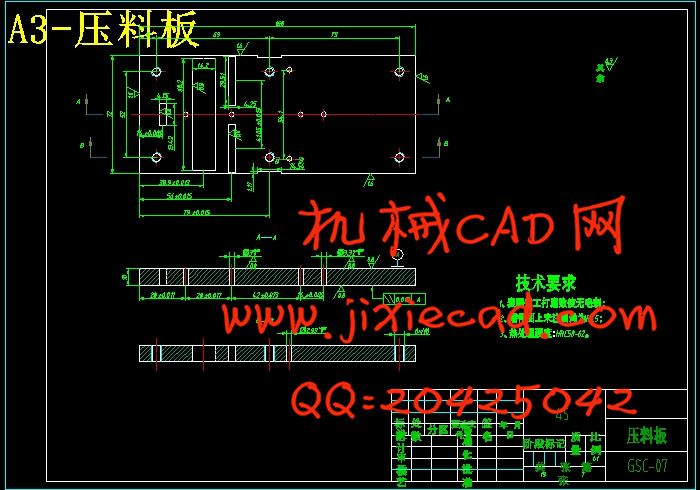

8.4 卸料板结构设计……………………………………………………30

8.5 导向机构设计…………………………………………………………32

8.6 翻边孔结构设计………………………………………………………………32

9绘制模具总装图……………………………………………………………33

10结束语 ……………………………………………………………………33

参考文献 …………………………………………………………………………34

致谢………………………………………………………………………… 35

关键词:卡板零件;工艺分析;级进模;模具结构;

Abstract: This design aims at figuring out the forming process of punching, shearing, bending, flanging and cutting through the analysis on the technological characteristics of parts of card board. By comparing various proposed design proposal, the author ultimately determines to adopt the multi-station progressive die stamping as the processing scheme. In this paper, the author will introduce the design features and process of this model, meanwhile, its structural characteristics and machining process will also be involved.The board level of the card is designed to improve the production efficiency of the parts of the card boards, mechanize and automate the production process, resulting in better economic and social benefits.

Key words: Parts of card board; Industrial analysis; Progressive die; Mold structure

目 录

摘要………………………………………………………………………………1

关键词……………………………………………………………………………1

1前言……………………………………………………………………………1

2工件的冲压工艺分析…………………………………………………………2

2.1零件介绍………………………………………………………………………2

2.2工件的尺寸精度……………………………………………………………3

2.3审查零件材料选用是否得当…………………………………………3

2.4冲裁件结构工艺性分析………………………………………………3

2.5翻边工艺性分析…………………………………………………………3

3确定冲压工艺方案……………………………………………………4

3.1确定工艺方案………………………………………………………………4

3.2确定工位数………………………………………………………………6

3.3排样及材料利用率的计算……………………………………………6

3.3.1计算毛坯尺寸……………………………………………………………………7

3.3.2排样的设计…………………………………………………………………7

3.3.3材料利用率的计算………………………………………………………………8

4 主要工艺参数的确定……………………………………………………………9

4.1确定预冲孔直径尺寸……………………………………………………………9

4.2确定双斜楔结构角度参……………………………………………………10

5 各部分工艺力的计算……………………………………………………………11

5.1冲裁力的计算……………………………………………………………………11

5.1.1冲裁力的计算公式……………………………………………………………11

5.1.2降低冲裁力的方法…………………………………………………12

5.2弯曲部分的力计算……………………………………………………………13

5.3翻孔部分的力计算…………………………………………………………13

5.4总压力…………………………………………………………………14

5.5压力中心的计算…………………………………………………………14

5.6冲压设备的选择………………………………………………………15

6计算凸、凹模刃口尺寸及公差…………………………………………………16

6.1计算原则………………………………………………………………16

6.2刃口尺寸计算…………………………………………………………17

6.2.1冲导正孔凸、凹模刃口尺寸计算………………………………………17

6.2.2冲预冲孔凸、凹模刃口尺寸计算…………………………………………18

6.2.3切两端废料凸、凹模刃口尺寸计算………………………………………18

6.2.4切两侧废料凸、凹模刃口尺寸计算……………………………………19

6.2.5切断凸凹模刃口尺寸计算……………………………………………19

6.2.6翻边时凸凹模刃口尺寸计算……………………………………………20

6.2.7弯曲时凸凹模工作部位尺寸……………………………………………20

7模具主要零件设计与选择…………………………………………………21

7.1常用冲压模具材料的选取………………………………………………21

7.2冲孔圆形凸模的设计………………………………………………21

7.2.1冲孔凸模的结构设计………………………………………………21

7.2.2凸模长度的计算………………………………………………21

7.3切两端和两侧废料的凸模设计………………………………………………22

7.4翻孔凸模的设计………………………………………………………23

7.5凹模的设计………………………………………………………24

7.5.1凹模孔口形式及主要参数………………………………………………24

7.5.2凹模外形尺寸的确定………………………………………………24

7.6卸料弹簧的设计和选用………………………………………………25

8 模具总体设计……………………………………………………………27

8.1 模架及模柄结构的设计及选择……………………………………………27

8.1.1 模架结构的设计和选择……………………………………………27

8.1.2模柄的选择…………………………………………………………27

8.2 固定板结构设计…………………………………………………………28

8.3 垫板结构设计…………………………………………………………29

8.4 卸料板结构设计……………………………………………………30

8.5 导向机构设计…………………………………………………………32

8.6 翻边孔结构设计………………………………………………………………32

9绘制模具总装图……………………………………………………………33

10结束语 ……………………………………………………………………33

参考文献 …………………………………………………………………………34

致谢………………………………………………………………………… 35