设计简介

摘 要

模具是制造业的重要工艺基础,在我国,模具制造属于专用设备制造业。中国虽然很早就开始制造模具和使用模具,但长期未形成产业。直到20世纪80年代后期,中国模具工业才驶入发展的快车道。近年,不仅国有模具企业有了很大发展,三资企业、乡镇模具企业的发展也相当迅速。冷冲压模具在现代工业中具有很重要的作用,其在机械制造、电子、电器 等各行各业中都有广泛的应用。用冷冲压加工方法可以得到形状复杂、用其它加工方法难以加工的工件,如薄壳零件等。冷冲压的尺寸精度是由模具保证的,因此,尺寸稳定,互换性好。

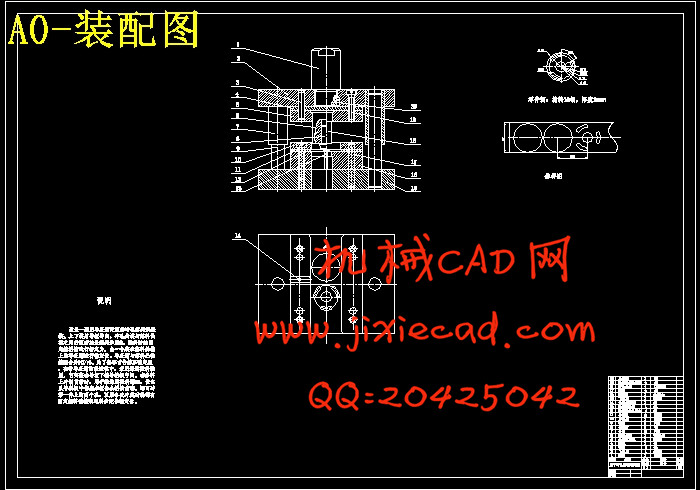

多工位级进模是在普通级进模的基础上发展起来的精密、高效、高寿命的先进模具。多工位级进模在不同的工位可以连续完成复杂零件的冲裁、弯曲、拉深、翻孔、翻边及其它成形等工序。主要用于生产批量大、材料厚度较薄、形状复杂、精度要求较高的中小型冲压件的生产。本文结合盖子零件的结构、工艺性来分析设计盖子模具结构、工艺性及工作原理,进行必要的计算,确定基本的参数、设计主体结构、排样图、工作零件、卸料装置、导料装置、安全装置、画装配图、零件图、编制模具零件加工工艺规程等。

本设计是盖子零件冲裁模具的设计,掌握模具工艺设计和模具结构设计的方法和步骤,掌握制造加工工艺的编制技术,进行盖子的设计,学习应用先进的方法,完成此课题的设计。

关键词:级进模;结构设计;模具制造; 模具;设计

Abstract

The mold is the manufacturing industry important craft foundation, in our country, the mold manufacture belongs to the special purpose equipment manufacturing industry. China although very already starts to make the mold and the use mold, but long-term has not formed the industry. Straight stabs 20 centuries 80's later periods, the Chinese mold industry only then drives into the development speedway. Recent years, not only the state-owned mold enterprise had the very big development, the three investments enterprise, the villages and towns the mold enterprise's development also quite rapid. Cold stamping die has a very important role in modern industry, machinery manufacturing, electronics, appliances and other industries. Cold stamping method can be complex shape, with other processing methods are difficult to process work pieces, such as the shell parts, etc. Cold stamping molds to ensure dimensional accuracy, therefore, dimensional stability, interchangeability.

Multi-position into modules are o-level into mode in the developed on the basis of precision, high efficiency, high life-span advanced mold. Multi-position into the mold in different location can continuously complete complex components cutting, bending, deep drawing, the hole flanging, flanging and other forming processes. Mainly for the production of batch big, material is very thin, complex shape, higher accuracy of small and medium-sized stamping production. This paper-reduction parts of the structure, to analyze the design process of reduction-die structure, process and principle of the necessary calculations to determine the basic parameters, the main structure design, layout plans, the working parts, unloading device I. Device, security installations, painting assembly, parts map, prepared mold parts processing technology, such as a point of order.

This design is process design master mold and mold structural design methods and steps to control the manufacturing processing techniques, the conduct of electronic lock-reset the design, study and application of advanced methods, to complete this task the design.

Keywords: Progressive Die ;The design of structural; Die manufacturing mold; design

目 录

1 冲压工艺设计概述 1模具是制造业的重要工艺基础,在我国,模具制造属于专用设备制造业。中国虽然很早就开始制造模具和使用模具,但长期未形成产业。直到20世纪80年代后期,中国模具工业才驶入发展的快车道。近年,不仅国有模具企业有了很大发展,三资企业、乡镇模具企业的发展也相当迅速。冷冲压模具在现代工业中具有很重要的作用,其在机械制造、电子、电器 等各行各业中都有广泛的应用。用冷冲压加工方法可以得到形状复杂、用其它加工方法难以加工的工件,如薄壳零件等。冷冲压的尺寸精度是由模具保证的,因此,尺寸稳定,互换性好。

多工位级进模是在普通级进模的基础上发展起来的精密、高效、高寿命的先进模具。多工位级进模在不同的工位可以连续完成复杂零件的冲裁、弯曲、拉深、翻孔、翻边及其它成形等工序。主要用于生产批量大、材料厚度较薄、形状复杂、精度要求较高的中小型冲压件的生产。本文结合盖子零件的结构、工艺性来分析设计盖子模具结构、工艺性及工作原理,进行必要的计算,确定基本的参数、设计主体结构、排样图、工作零件、卸料装置、导料装置、安全装置、画装配图、零件图、编制模具零件加工工艺规程等。

本设计是盖子零件冲裁模具的设计,掌握模具工艺设计和模具结构设计的方法和步骤,掌握制造加工工艺的编制技术,进行盖子的设计,学习应用先进的方法,完成此课题的设计。

关键词:级进模;结构设计;模具制造; 模具;设计

Abstract

The mold is the manufacturing industry important craft foundation, in our country, the mold manufacture belongs to the special purpose equipment manufacturing industry. China although very already starts to make the mold and the use mold, but long-term has not formed the industry. Straight stabs 20 centuries 80's later periods, the Chinese mold industry only then drives into the development speedway. Recent years, not only the state-owned mold enterprise had the very big development, the three investments enterprise, the villages and towns the mold enterprise's development also quite rapid. Cold stamping die has a very important role in modern industry, machinery manufacturing, electronics, appliances and other industries. Cold stamping method can be complex shape, with other processing methods are difficult to process work pieces, such as the shell parts, etc. Cold stamping molds to ensure dimensional accuracy, therefore, dimensional stability, interchangeability.

Multi-position into modules are o-level into mode in the developed on the basis of precision, high efficiency, high life-span advanced mold. Multi-position into the mold in different location can continuously complete complex components cutting, bending, deep drawing, the hole flanging, flanging and other forming processes. Mainly for the production of batch big, material is very thin, complex shape, higher accuracy of small and medium-sized stamping production. This paper-reduction parts of the structure, to analyze the design process of reduction-die structure, process and principle of the necessary calculations to determine the basic parameters, the main structure design, layout plans, the working parts, unloading device I. Device, security installations, painting assembly, parts map, prepared mold parts processing technology, such as a point of order.

This design is process design master mold and mold structural design methods and steps to control the manufacturing processing techniques, the conduct of electronic lock-reset the design, study and application of advanced methods, to complete this task the design.

Keywords: Progressive Die ;The design of structural; Die manufacturing mold; design

目 录

1.1冲压的概念、特点及应用 1

1.2冲压的基本工序及模具 2

1.3冲压技术的现状及发展方向 2

1.3.1冲压成形理论及冲压工艺方面 2

1.3.2冲模是实现冲压生产的基本条件 3

1.3.3冲压设备和冲压生产自动化方面 4

1.3.4冲压标准化及专业化生产方面 5

2 零件的工艺性分析 5

2.1 制件的工艺分析 6

2.1.1冲裁件的形状 6

2.1.2冲裁件内形及外形的转角 6

2.1.3冲裁件上凸出的悬臂和凹槽 6

2.1.4冲裁件的最小孔径 6

2.1.5制孔边距与孔间距 7

2.1.6提高材料利用率 7

2.2冲压工艺方案确认 7

3 模具结构的形式选择 8

4 标准的选用及必要的设计计算 8

4.1排样 计算材料利用率 8

4.2计算压力中心及冲裁力 9

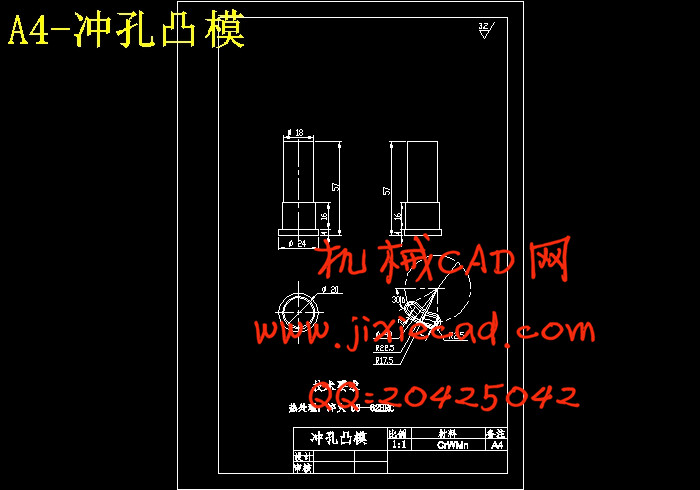

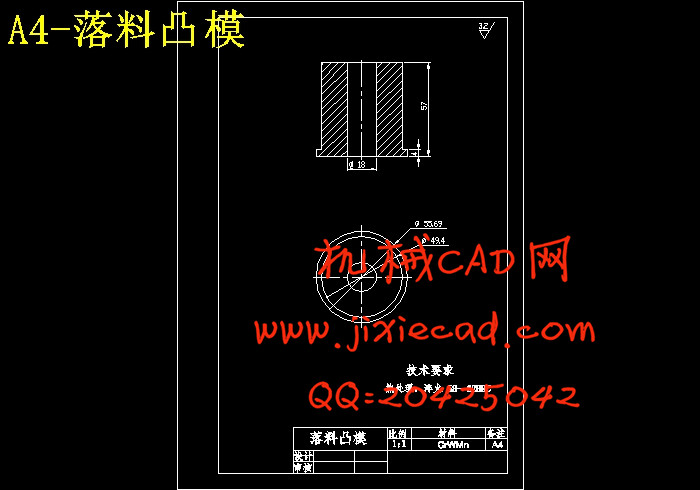

4.3 计算凸凹模尺寸 10

4.4 确定凹模外形尺寸 11

4.5 冲模闭合高度和压力机有关参数的校核 16

参考文献 17