设计简介

摘要

本课题生产的制件为空调垫片,材料为纯铝,制件厚度为1mm,采用冲孔落料级进模具大批量生产。设计采用先冲孔,后落料形式。开始时的第一个定位采用始用挡料销,由导料板和活动挡料销粗定位后冲出 Φ

Φ 孔,然后由此孔做为导正孔,做精确定位,落料成品。采用这种定位冲孔落料方式,可以保证之间的精度。条料的排样方式采用直对排,材料利用率可以达到85%。模架选用中间导柱导套形式,可以保证模具运行精度和模具寿命。这套模具加工简单,安装和调整也很方便,生产效率也很高,可以满足设计要求。模具中的主要工作零件加工时才用热处理,以保证其有适用的机械性能。

孔,然后由此孔做为导正孔,做精确定位,落料成品。采用这种定位冲孔落料方式,可以保证之间的精度。条料的排样方式采用直对排,材料利用率可以达到85%。模架选用中间导柱导套形式,可以保证模具运行精度和模具寿命。这套模具加工简单,安装和调整也很方便,生产效率也很高,可以满足设计要求。模具中的主要工作零件加工时才用热处理,以保证其有适用的机械性能。

由于设计水平和实践经验的局限性,设计当中难免有错误和不足之处。在老师和同学帮助之下完成了这次设计课程,设计了一套空调垫片冲孔落料级进模具,使自己积累了一定的设计经验。

关键词:空调垫片 冲孔落料级进模具 始用挡料销 导料板 活动挡料销

Abstract

What subject this produce make piece air conditioner spacer , material pure aluminium , make a thickness 1mm, adopt and wash the hole blanking grade and enter the mould to produce in enormous quantities. Design and adopt washing holes , and then blanking form first . The first localization at the beginning adopts the beginning to sell by blocking the material, go out of ¦µ hole after being led material board and activity and blocked the material and sold and made a reservation thickly, then therefore the hole is made in order to lead the straight hole, make and make a reservation accurately, the blanking finished product. Adopt the localization wash hole blanking way , can guarantee precision during. One kind of ways of arranging of a piece of material is adopted straight to arranging , the material utilization ratio can be up to 85%. The mould shelf leads the post to lead one set of forms while selecting for use, can guarantee the mould operation precision and life-span of mould . This set of moulds are processed simply, it is very convenient to install and adjust, production efficiency is very high, can meet the designing requirement . The groundwork part in the mould just uses the heat treatment while processing, so as to ensure that there is suitable mechanical performance in it.

Because of designing the limitation of competence and practical experience, unavoidably there are a mistake and weak point in the middle to design. Finish the course of designing under teacher and classmate help , design one air conditioner spacer wash hole blanking magnitude enter mould, make oneself accumulate certain design experience.

Keywords:Air conditioner spacer Wash the hole blanking grade and enter the mould The beginning is by blocking the material and selling Lead the material board The activity blocks the material to sell

1, 冲压件的工艺分析

冲压件的工艺分析……………………………………………………………………………1

2, 冲压工艺方案的确定

冲压工艺方案的确定…………………………………………………………………………2

3, 主要设计计算

3.1,排样方式的确定及其计算………………………………………………………………3

3.2,冲压力的计算……………………………………………………………………………4

3.3,压力中心的确定及相关计算……………………………………………………………5

3.4,工作零件刃口尺寸的计算………………………………………………………………7

3.5,卸料橡胶的计算…………………………………………………………………………7

4, 模具的总体设计

4.1,模具类型的选择…………………………………………………………………………9

4.2,定位方式的选择…………………………………………………………………………9

4.3,卸料、出件方式的选择…………………………………………………………………9

4.4,导向方式的选择…………………………………………………………………………9

5, 主要工作零件设计

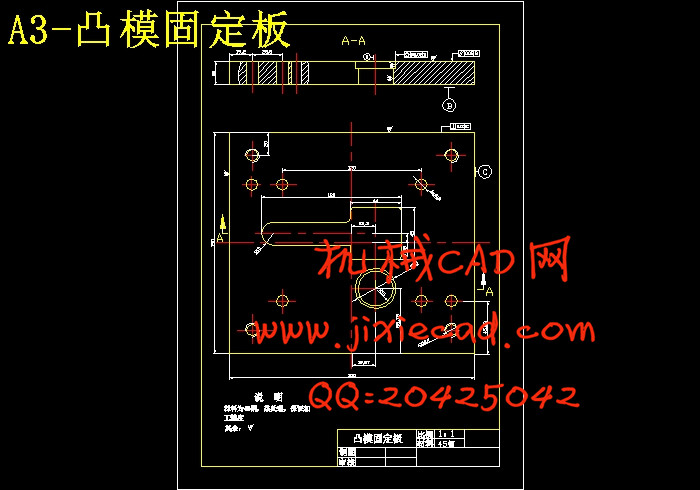

5.1,工作零件的结构设计…………………………………………………………………10

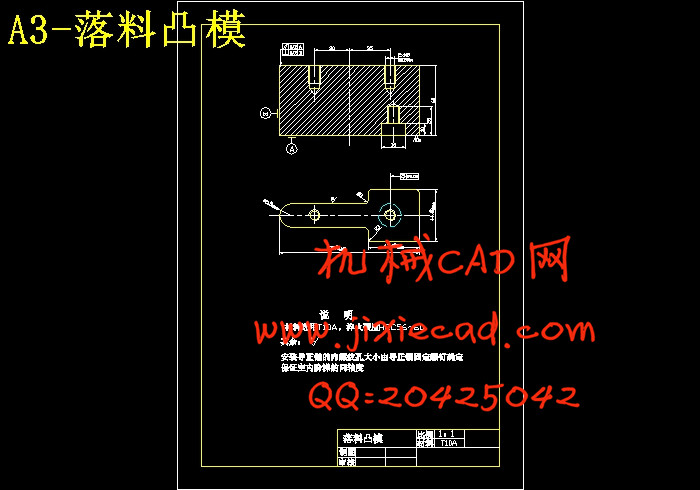

5.1.1,落料凸模………………………………………………………………………10

5.1.2,冲孔凸模………………………………………………………………………11

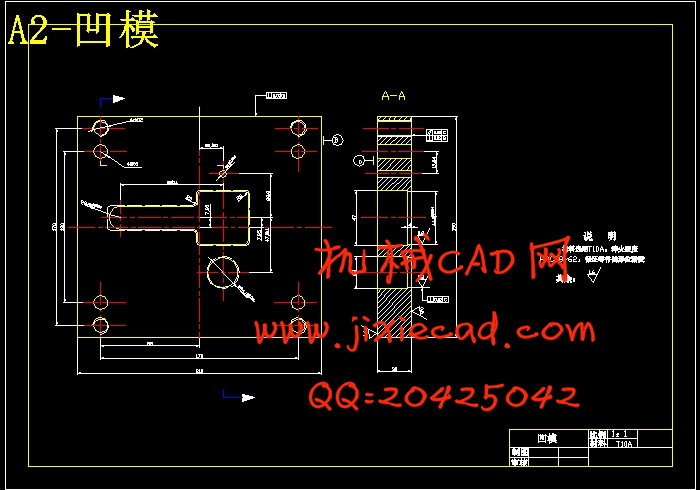

5.1.3,凹模……………………………………………………………………………11

5.2,定位零件的设计………………………………………………………………………13

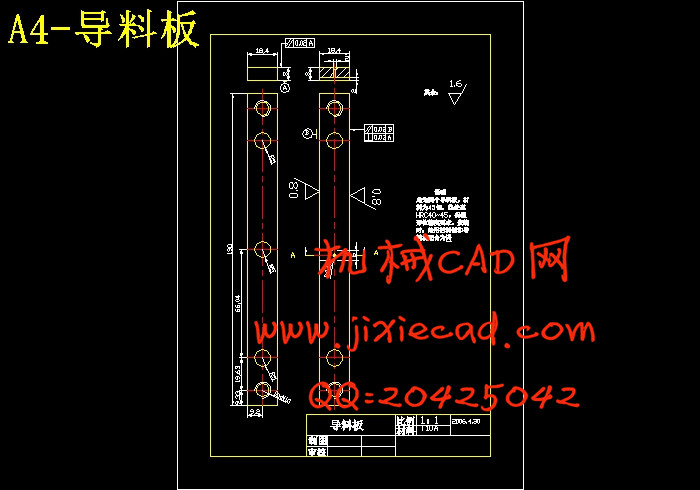

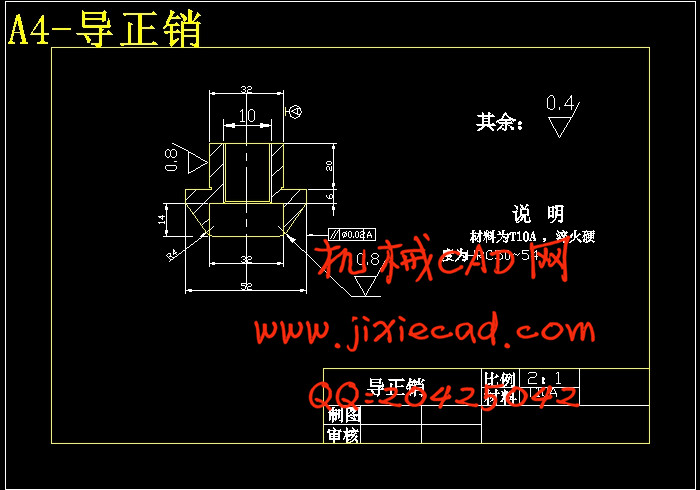

5.3,导料板的设计…………………………………………………………………………13

5.4,卸料部件的设计………………………………………………………………………13

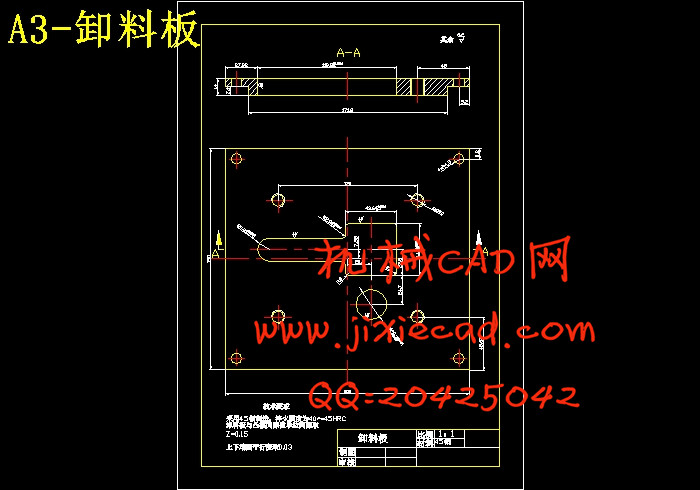

5.4.1,卸料板的设计…………………………………………………………………13

5.4.2,卸料螺钉的选用………………………………………………………………14

5.5,模架及其它零件的设计…………………………………………………………………14

6, 模具总装图

模具总装图……………………………………………………………………………………15

7, 冲压设备的选定

冲压设备的选定………………………………………………………………………………16

8, 模具零件加工工艺

模具零件加工工艺……………………………………………………………………………17

9, 模具的装配

9.1,模柄的装配………………………………………………………………………………17

9.2,凸模的装配………………………………………………………………………………17

9.3,弹压卸料板的装配………………………………………………………………………17

9.4,凸凹模的预配……………………………………………………………………………17

9.5,凸模的装配………………………………………………………………………………18

9.6,装配下模…………………………………………………………………………………18

9.7,装配上模…………………………………………………………………………………18

9.8,试冲与调试………………………………………………………………………………18

9.9,冲压模常见的试冲问题与调试方法……………………………………………………19

10, 设计总结

设计总结……………………………………………………………………………………20

本课题生产的制件为空调垫片,材料为纯铝,制件厚度为1mm,采用冲孔落料级进模具大批量生产。设计采用先冲孔,后落料形式。开始时的第一个定位采用始用挡料销,由导料板和活动挡料销粗定位后冲出

由于设计水平和实践经验的局限性,设计当中难免有错误和不足之处。在老师和同学帮助之下完成了这次设计课程,设计了一套空调垫片冲孔落料级进模具,使自己积累了一定的设计经验。

关键词:空调垫片 冲孔落料级进模具 始用挡料销 导料板 活动挡料销

Abstract

What subject this produce make piece air conditioner spacer , material pure aluminium , make a thickness 1mm, adopt and wash the hole blanking grade and enter the mould to produce in enormous quantities. Design and adopt washing holes , and then blanking form first . The first localization at the beginning adopts the beginning to sell by blocking the material, go out of ¦µ hole after being led material board and activity and blocked the material and sold and made a reservation thickly, then therefore the hole is made in order to lead the straight hole, make and make a reservation accurately, the blanking finished product. Adopt the localization wash hole blanking way , can guarantee precision during. One kind of ways of arranging of a piece of material is adopted straight to arranging , the material utilization ratio can be up to 85%. The mould shelf leads the post to lead one set of forms while selecting for use, can guarantee the mould operation precision and life-span of mould . This set of moulds are processed simply, it is very convenient to install and adjust, production efficiency is very high, can meet the designing requirement . The groundwork part in the mould just uses the heat treatment while processing, so as to ensure that there is suitable mechanical performance in it.

Because of designing the limitation of competence and practical experience, unavoidably there are a mistake and weak point in the middle to design. Finish the course of designing under teacher and classmate help , design one air conditioner spacer wash hole blanking magnitude enter mould, make oneself accumulate certain design experience.

Keywords:Air conditioner spacer Wash the hole blanking grade and enter the mould The beginning is by blocking the material and selling Lead the material board The activity blocks the material to sell

1, 冲压件的工艺分析

冲压件的工艺分析……………………………………………………………………………1

2, 冲压工艺方案的确定

冲压工艺方案的确定…………………………………………………………………………2

3, 主要设计计算

3.1,排样方式的确定及其计算………………………………………………………………3

3.2,冲压力的计算……………………………………………………………………………4

3.3,压力中心的确定及相关计算……………………………………………………………5

3.4,工作零件刃口尺寸的计算………………………………………………………………7

3.5,卸料橡胶的计算…………………………………………………………………………7

4, 模具的总体设计

4.1,模具类型的选择…………………………………………………………………………9

4.2,定位方式的选择…………………………………………………………………………9

4.3,卸料、出件方式的选择…………………………………………………………………9

4.4,导向方式的选择…………………………………………………………………………9

5, 主要工作零件设计

5.1,工作零件的结构设计…………………………………………………………………10

5.1.1,落料凸模………………………………………………………………………10

5.1.2,冲孔凸模………………………………………………………………………11

5.1.3,凹模……………………………………………………………………………11

5.2,定位零件的设计………………………………………………………………………13

5.3,导料板的设计…………………………………………………………………………13

5.4,卸料部件的设计………………………………………………………………………13

5.4.1,卸料板的设计…………………………………………………………………13

5.4.2,卸料螺钉的选用………………………………………………………………14

5.5,模架及其它零件的设计…………………………………………………………………14

6, 模具总装图

模具总装图……………………………………………………………………………………15

7, 冲压设备的选定

冲压设备的选定………………………………………………………………………………16

8, 模具零件加工工艺

模具零件加工工艺……………………………………………………………………………17

9, 模具的装配

9.1,模柄的装配………………………………………………………………………………17

9.2,凸模的装配………………………………………………………………………………17

9.3,弹压卸料板的装配………………………………………………………………………17

9.4,凸凹模的预配……………………………………………………………………………17

9.5,凸模的装配………………………………………………………………………………18

9.6,装配下模…………………………………………………………………………………18

9.7,装配上模…………………………………………………………………………………18

9.8,试冲与调试………………………………………………………………………………18

9.9,冲压模常见的试冲问题与调试方法……………………………………………………19

10, 设计总结

设计总结……………………………………………………………………………………20