设计简介

摘 要

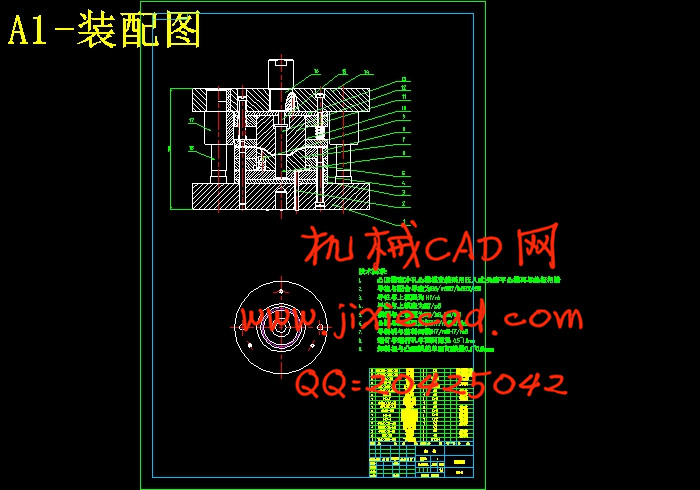

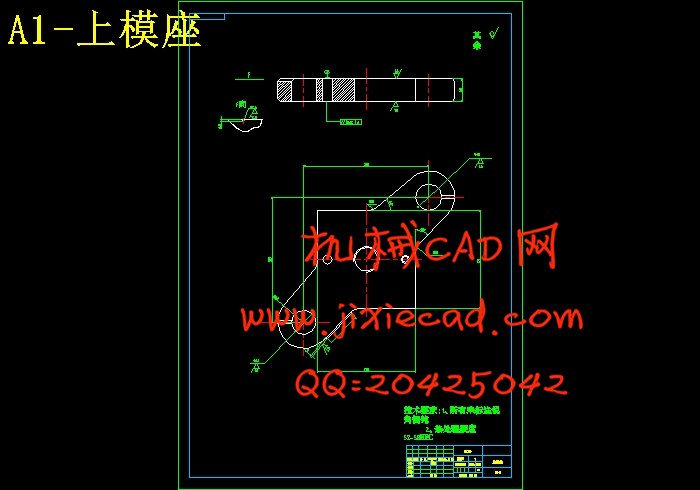

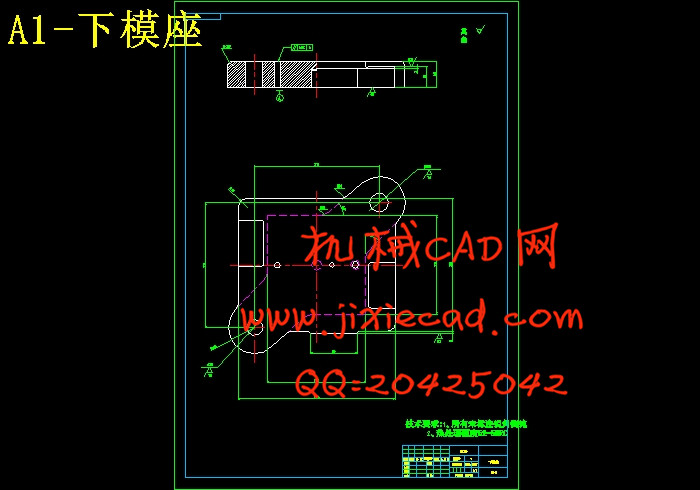

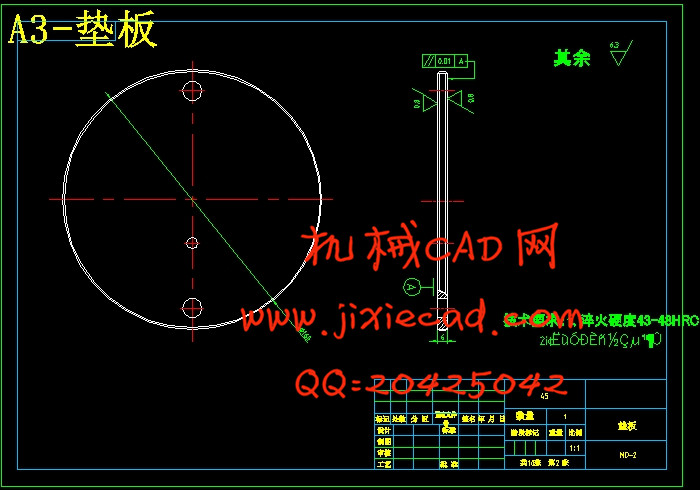

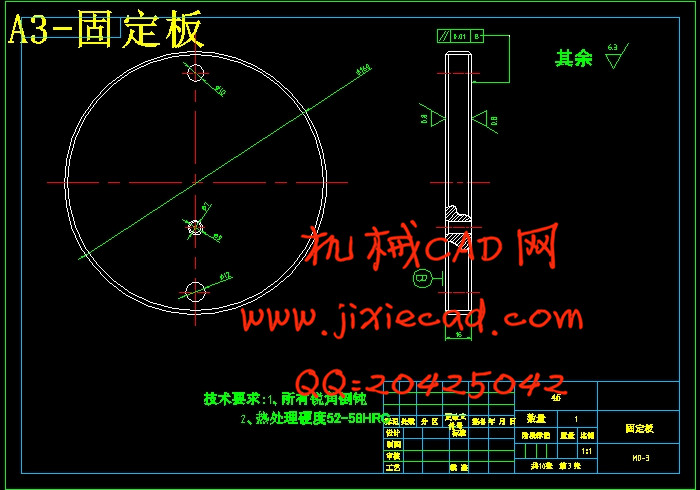

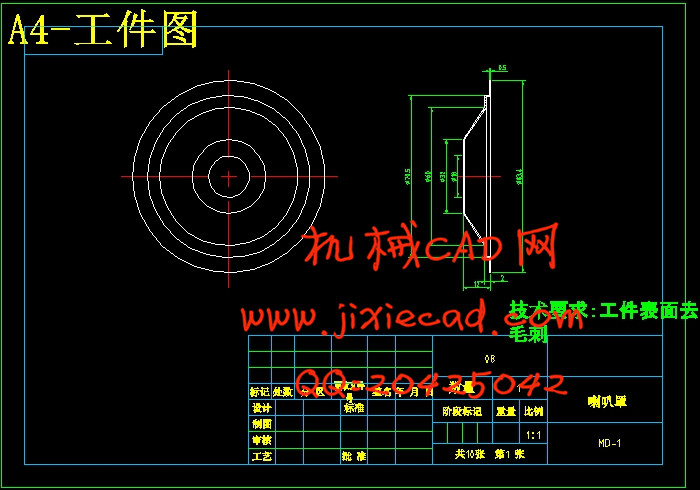

通过对拉深工件的正确分析,主要工艺参数的计算,编制了正确可行的工艺路线,在此基础上,设计了一副一模一腔的拉伸模。本设计详细地叙述了模具成型零件包括凸模、凹模及其它零件如卸料板、固定板、垫板、导柱、导套等的设计与加工工艺过程,需要零件的工艺参数的选择和计算,拉深机构与压边卸料装置以及其他结构的设计过程,并着重对模具的设计部分作了详细介绍。

关键词 模具设计 工艺卡片 复合模

Abstract

Through to the blanking work piece craft's correct analysis, the main technological parameter's computation, has established the correct feasible craft route, based on this, has designed a mold cavity drawing mold. This design narrated the mold formation components in detail including the plunger, the lower die and other components like unloads the yard lumber, the dead plate,the backing strip, the guide pillar, the guide sleeve and so design and the processing technological process, the important components' technological parameter's choice and the computation, the drawing organization with pressing nearby the dumping device as other structure's design process, and to has made the detailed introduction emphatically to mold's design part.

Key word mold design process chart superposable die

目 录

1、前言…………………………………………………………………………………5

2、绪论…………………………………………………………………………………6

3、冲件工艺分析及编制冲压工艺方案………………………………………………7

3.1、分析零件的工艺性 ……………………………………………………7

3.2、计算拉深件的工序尺寸 ………………………………………………7

3.3、编写冲压工艺过程卡片………………………………………………10

4、模具总体设计……………………………………………………………………11

4.1、模具结构形式的确定…………………………………………………11

4.2、拉深凸凹模间隙的计算………………………………………………11

4.3、拉深凸凹模圆角半径的计算…………………………………………11

4.4、各工序凸凹模工作部分尺寸的设计计算……………………………12

4.5、成形工作零件长度的确定……………………………………………13

4.6、复合模其他结构形式和标准…………………………………………14

4.7、计算拉伸模具闭合高度,校核压力机………………………………23

5、结束语……………………………………………………………………………25

参考文献 ……………………………………………………………………………26

致谢 …………………………………………………………………………………27

通过对拉深工件的正确分析,主要工艺参数的计算,编制了正确可行的工艺路线,在此基础上,设计了一副一模一腔的拉伸模。本设计详细地叙述了模具成型零件包括凸模、凹模及其它零件如卸料板、固定板、垫板、导柱、导套等的设计与加工工艺过程,需要零件的工艺参数的选择和计算,拉深机构与压边卸料装置以及其他结构的设计过程,并着重对模具的设计部分作了详细介绍。

关键词 模具设计 工艺卡片 复合模

Abstract

Through to the blanking work piece craft's correct analysis, the main technological parameter's computation, has established the correct feasible craft route, based on this, has designed a mold cavity drawing mold. This design narrated the mold formation components in detail including the plunger, the lower die and other components like unloads the yard lumber, the dead plate,the backing strip, the guide pillar, the guide sleeve and so design and the processing technological process, the important components' technological parameter's choice and the computation, the drawing organization with pressing nearby the dumping device as other structure's design process, and to has made the detailed introduction emphatically to mold's design part.

Key word mold design process chart superposable die

目 录

1、前言…………………………………………………………………………………5

2、绪论…………………………………………………………………………………6

3、冲件工艺分析及编制冲压工艺方案………………………………………………7

3.1、分析零件的工艺性 ……………………………………………………7

3.2、计算拉深件的工序尺寸 ………………………………………………7

3.3、编写冲压工艺过程卡片………………………………………………10

4、模具总体设计……………………………………………………………………11

4.1、模具结构形式的确定…………………………………………………11

4.2、拉深凸凹模间隙的计算………………………………………………11

4.3、拉深凸凹模圆角半径的计算…………………………………………11

4.4、各工序凸凹模工作部分尺寸的设计计算……………………………12

4.5、成形工作零件长度的确定……………………………………………13

4.6、复合模其他结构形式和标准…………………………………………14

4.7、计算拉伸模具闭合高度,校核压力机………………………………23

5、结束语……………………………………………………………………………25

参考文献 ……………………………………………………………………………26

致谢 …………………………………………………………………………………27