设计简介

链 轮的冲压工艺及模具设计

摘 要

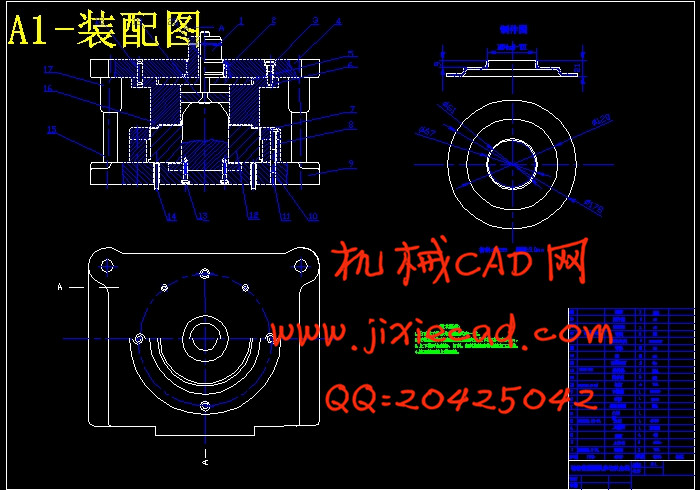

本次设计是对链轮的冲压工艺及模具设计的要求,分别对模具的工作零部件等六大类零部件作详细设计。设计的主要内容包括冲裁件的工艺分析及工艺方案的确定、工艺计算、冲裁模具的设计、模具的安装与调整等。

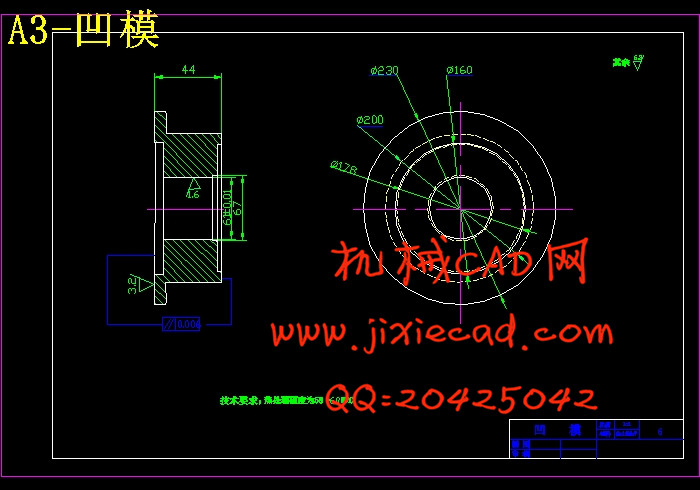

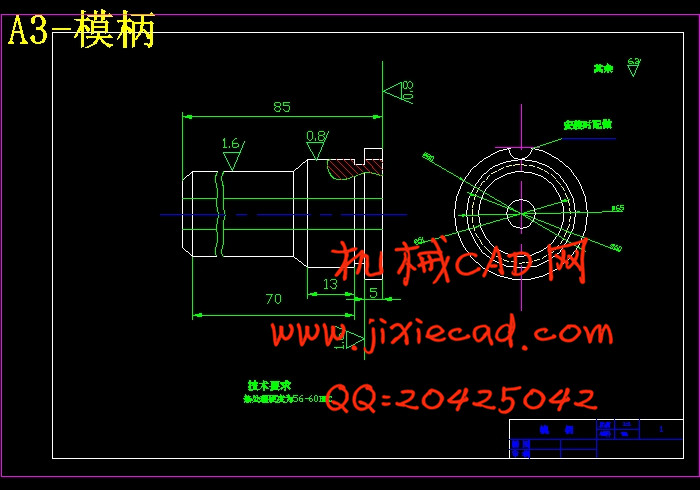

在工艺计算部分要对冲压力的计算、模具压力中心的确定、凸凹模尺寸并确定制造公差的计算、弹性元件的选取与计算等内容详细计算。必要时还要对模具的主要零件进行强度验算。

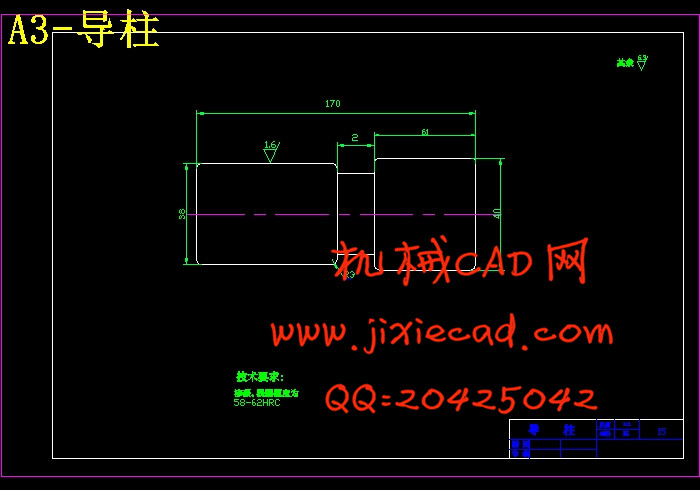

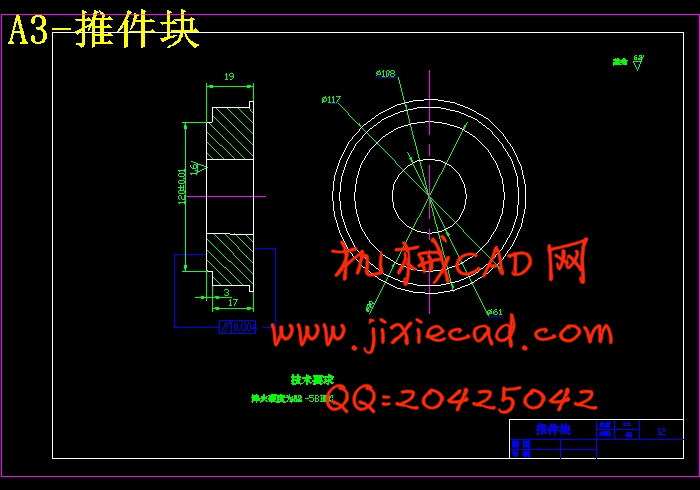

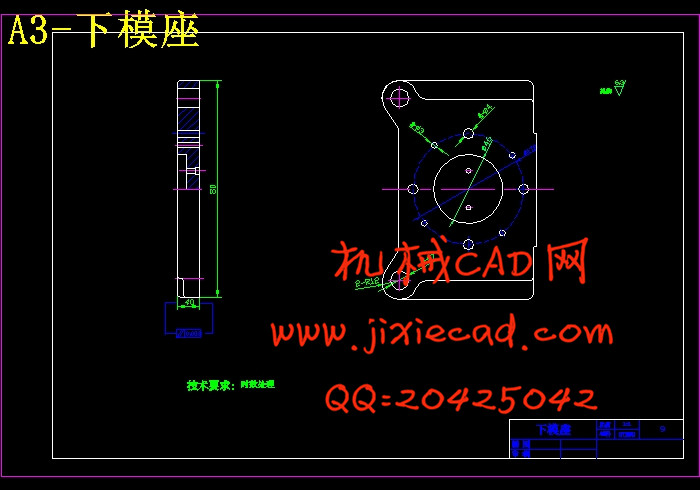

在冲裁模的设计部分要对工作零件、定位零件、卸料与顶件零件、导向零件连接与固定零件等结构进行详细的分析设计。要在设计过程中了解模具的工作过程和注意标准的选用。

模具的安装与调试部分要注意有导柱模具与无导柱模具的安装方法及顺序,通过模具的安装,了解模具的组成及各部分零部件的作用等。注意模具安装过后的试冲过程中常见的缺陷与解决方法等。

通过这次毕业设计要对模具有更近一步的了解,注意复合模与级进模之间的区别,两者虽然都是一副模具,在设计时要注意模具结构、模具使用方便、模具寿命高等问题。并且要提高生产效率,保证产品的质量。

关键词:复合模 级进模 试冲 间隙配合 过渡配合

n the process design part must to the ramming strength computation, the mold center of pressure determination, the convex-concave mold size and determines the manufacture common difference content detailed computations and so on computation, elastic part selection and computation。When necessity also must carry on the intensity checking calculation to the mold major parts.

In the punching die design part must to the work components, the localization components, the ex-denting and goes against components, the guidance components connection and fixed components is structuralism carries on the detailed analysis design.。Must understand the mold in the design process the work process and attention standard selection, has the further understanding to the single working procedure punching die structure.

The mold installment and the debugging part must pay attention have the guide pillar mold to install the method and the order with the non-guide pillar mold, Through mold installment,Understands the mold the composition and various part of spare part function and so on. The attention mold installment from now on will try to flush in the process the common flaw and the solution and so on。

Must have a nearer step understanding through the drawing dies for chain wheel, Pays attention to the superposable die with the level the difference, Two although all is a mold,When design must pay attention to the mold structure simply, the mold easy to operate, the mold life higher question. And must enhance the production efficiency, Guarantees the product the quality.

Key words: Superposable die The level enters the mold Tries to flush Gap coordination Transition fit

目 录

1 绪论…………………………………………………………………………………1

2 零件工艺性分析…………………………………………………………3

3 编制零件加工工艺 ……………………………………………………4

3.1分析比较和确定工艺方案……………………………………………4

3.2主要工艺技术参数的计算……………………………………………6

4 模具结构设计……………………………………………………………………9

4.1模具结构形式选择……………………………………………………9

4.2模具工作部分尺寸和公差计算 ……………………………………9

4.3模具其他零件的结构尺寸计算…………………………………… 11

4.4模具主要零件的材料选用………………………………………… 12

4.5凸凹模的工艺过程……………………………………………………12

5 模具的安装与调整……………………………………………………………15

5.1模具的安装 ……………………………………………………………15

5.2模具的调整 ……………………………………………………………16

设计总结………………………………………………………………………… 18

致谢……………………………………………………………………………… 19

参考文献 ……………………………………………………………………… 20

摘 要

本次设计是对链轮的冲压工艺及模具设计的要求,分别对模具的工作零部件等六大类零部件作详细设计。设计的主要内容包括冲裁件的工艺分析及工艺方案的确定、工艺计算、冲裁模具的设计、模具的安装与调整等。

在工艺计算部分要对冲压力的计算、模具压力中心的确定、凸凹模尺寸并确定制造公差的计算、弹性元件的选取与计算等内容详细计算。必要时还要对模具的主要零件进行强度验算。

在冲裁模的设计部分要对工作零件、定位零件、卸料与顶件零件、导向零件连接与固定零件等结构进行详细的分析设计。要在设计过程中了解模具的工作过程和注意标准的选用。

模具的安装与调试部分要注意有导柱模具与无导柱模具的安装方法及顺序,通过模具的安装,了解模具的组成及各部分零部件的作用等。注意模具安装过后的试冲过程中常见的缺陷与解决方法等。

通过这次毕业设计要对模具有更近一步的了解,注意复合模与级进模之间的区别,两者虽然都是一副模具,在设计时要注意模具结构、模具使用方便、模具寿命高等问题。并且要提高生产效率,保证产品的质量。

关键词:复合模 级进模 试冲 间隙配合 过渡配合

The Design of the Drawing Dies for Chain Wheel

Abstract

This graduation project is the request which designs to the drawing dies for chain wheel, separately and so on six big kind of spare parts makes the detailed design to the mold work spare part. Design primary coverage including blanking craft analysis and craft plan determination, process design, blanking mold design, mold installment and adjustment and so on.n the process design part must to the ramming strength computation, the mold center of pressure determination, the convex-concave mold size and determines the manufacture common difference content detailed computations and so on computation, elastic part selection and computation。When necessity also must carry on the intensity checking calculation to the mold major parts.

In the punching die design part must to the work components, the localization components, the ex-denting and goes against components, the guidance components connection and fixed components is structuralism carries on the detailed analysis design.。Must understand the mold in the design process the work process and attention standard selection, has the further understanding to the single working procedure punching die structure.

The mold installment and the debugging part must pay attention have the guide pillar mold to install the method and the order with the non-guide pillar mold, Through mold installment,Understands the mold the composition and various part of spare part function and so on. The attention mold installment from now on will try to flush in the process the common flaw and the solution and so on。

Must have a nearer step understanding through the drawing dies for chain wheel, Pays attention to the superposable die with the level the difference, Two although all is a mold,When design must pay attention to the mold structure simply, the mold easy to operate, the mold life higher question. And must enhance the production efficiency, Guarantees the product the quality.

Key words: Superposable die The level enters the mold Tries to flush Gap coordination Transition fit

目 录

1 绪论…………………………………………………………………………………1

2 零件工艺性分析…………………………………………………………3

3 编制零件加工工艺 ……………………………………………………4

3.1分析比较和确定工艺方案……………………………………………4

3.2主要工艺技术参数的计算……………………………………………6

4 模具结构设计……………………………………………………………………9

4.1模具结构形式选择……………………………………………………9

4.2模具工作部分尺寸和公差计算 ……………………………………9

4.3模具其他零件的结构尺寸计算…………………………………… 11

4.4模具主要零件的材料选用………………………………………… 12

4.5凸凹模的工艺过程……………………………………………………12

5 模具的安装与调整……………………………………………………………15

5.1模具的安装 ……………………………………………………………15

5.2模具的调整 ……………………………………………………………16

设计总结………………………………………………………………………… 18

致谢……………………………………………………………………………… 19

参考文献 ……………………………………………………………………… 20