设计简介

菱形垫片冲压模具设计

摘 要

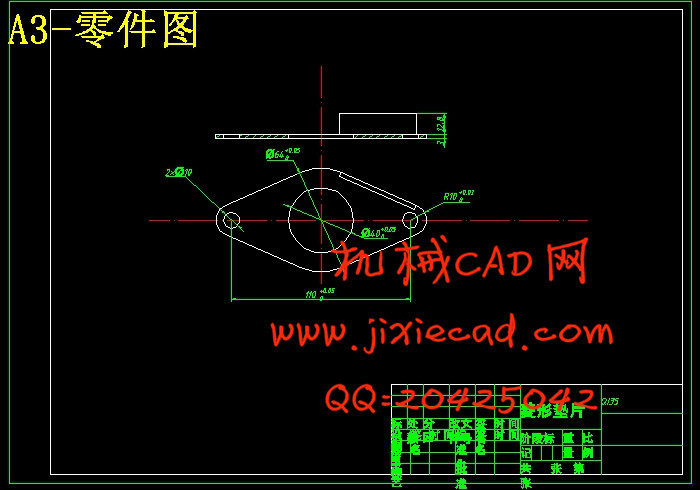

全文对菱形垫片的工艺分析确定与模具设计进行具体的论证设计。通过工艺分析确定需要设计四套模具,分别是落料模、冲空模1、弯曲模、冲孔模2。

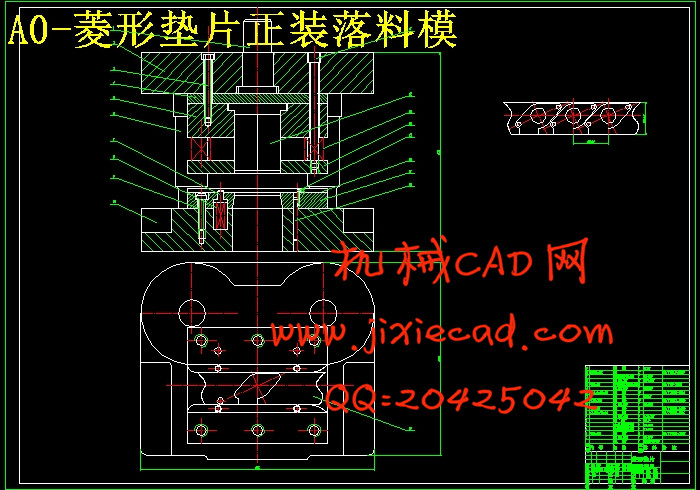

根据工艺分析与确定,第一套模具进行落料,相应的设计出落料模。从产品零件图看出其外形不规则,对落零件的排样和材料利用率给予相应的确定和计算,采用弹性卸料、自然落料方式。

工件的第二道工序须要冲出中心的大孔,对定位的设计带来了一定的难题。对于工件固定也有一定的要求。

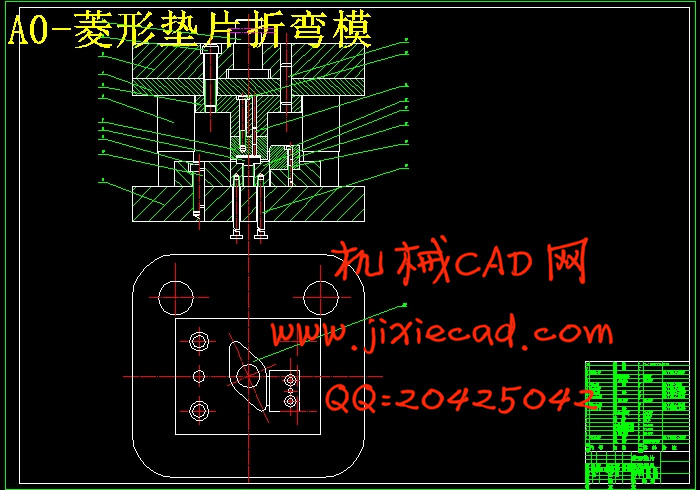

工件的第三道工序需要弯曲工件边缘的矩形,模具采用孔和边缘定位,对卸料装置的设计,和凹凸模的计算设计。

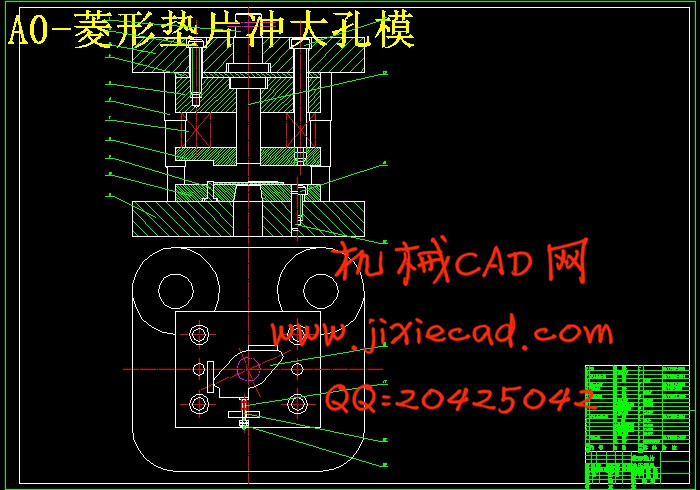

工件的第四道工序为冲出两个对称的圆孔,两个圆孔的位置度有要求,所以定位采用孔和弯曲面定位。

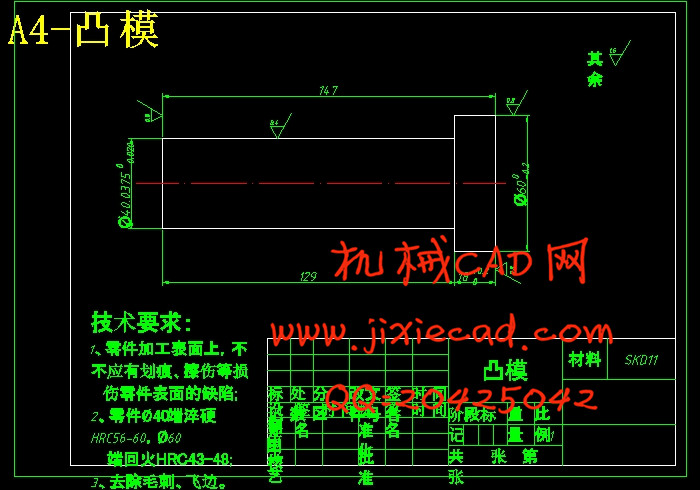

关键词:定位;冲孔;弯曲;凹模;凸模。

Hardware Research on the Measurement System of Ring Laser Resonant Cavity

摘 要

全文对菱形垫片的工艺分析确定与模具设计进行具体的论证设计。通过工艺分析确定需要设计四套模具,分别是落料模、冲空模1、弯曲模、冲孔模2。

根据工艺分析与确定,第一套模具进行落料,相应的设计出落料模。从产品零件图看出其外形不规则,对落零件的排样和材料利用率给予相应的确定和计算,采用弹性卸料、自然落料方式。

工件的第二道工序须要冲出中心的大孔,对定位的设计带来了一定的难题。对于工件固定也有一定的要求。

工件的第三道工序需要弯曲工件边缘的矩形,模具采用孔和边缘定位,对卸料装置的设计,和凹凸模的计算设计。

工件的第四道工序为冲出两个对称的圆孔,两个圆孔的位置度有要求,所以定位采用孔和弯曲面定位。

关键词:定位;冲孔;弯曲;凹模;凸模。

Hardware Research on the Measurement System of Ring Laser Resonant Cavity

Abstract

Full text of the analysis of the technology of diamond gasket set and mold design specific demonstration design. Through the analysis of the technology to design four sets of mould to determine, respectively is blanking mold, blunt empty mode 1, bending modulus, punching mould 2.

According to process analysis and determination, the first set of mould for blanking, corresponding design ChuLa materials moulds. From product parts graph see the appearance is irregular, on falling blank layout and material utilization give corresponding determination and calculation, using elastic and unloading, natural blanking way.

The second procedure need workpiece out the big hole in the center of the design of positioning brings some problems. For the fixed also to have certain requirements.

The third procedure need workpieces bending workpiece, the edges of the rectangular mould adopts the hole and edge localization, to unloader device design, and bump mould calculation design.

The fourth procedure for workpiece out two symmetrical round hole, two round hole position degree have demands, so the positioning hole and bending face positioning.

KeyWords: Positioning;Punchedhole ;Flection; Convex mold;cave mold.

Full text of the analysis of the technology of diamond gasket set and mold design specific demonstration design. Through the analysis of the technology to design four sets of mould to determine, respectively is blanking mold, blunt empty mode 1, bending modulus, punching mould 2.

According to process analysis and determination, the first set of mould for blanking, corresponding design ChuLa materials moulds. From product parts graph see the appearance is irregular, on falling blank layout and material utilization give corresponding determination and calculation, using elastic and unloading, natural blanking way.

The second procedure need workpiece out the big hole in the center of the design of positioning brings some problems. For the fixed also to have certain requirements.

The third procedure need workpieces bending workpiece, the edges of the rectangular mould adopts the hole and edge localization, to unloader device design, and bump mould calculation design.

The fourth procedure for workpiece out two symmetrical round hole, two round hole position degree have demands, so the positioning hole and bending face positioning.

KeyWords: Positioning;Punchedhole ;Flection; Convex mold;cave mold.

目录

1绪 论 1

1.1冲压的概念、特点及应用 1

1.2 冲压的基本工序及模具 2

1.3 冲压技术的现状及发展方向 2

1.3.1 冲压成形理论及冲压工艺方面 3

1.3.2 冲模是实现冲压生产的基本条件 3

1.3.3 冲压设备和冲压生产自动化方面 5

1.3.4 冲压标准化及专业化生产方面 5

2设计的具体内容 7

3工艺分析与方案确定 8

3.1 零件的工艺分析 8

3.2 工艺方案及模具结构类型 8

3.3排样设计 8

4模具的设计及计算 12

4.1落料模具的设计及计算 12

4.1.1 冲压力计算 12

4.1.2 凸、凹模刃口尺寸及公差计算 15

4.1.3 落料模具装配简图 16

4.2 冲

4.2.1 冲压力计算 17

4.2.2 凹凸模刃口尺寸及公差计算 18

4.2.3 孔

4.3 弯曲模的设计及计算 21

4.3.1 弯曲力计算 21

4.3.2 凹、凸模刃口尺寸及公差计算 22

4.3.3 弯曲模具装配简图 23

4.4 冲

4.4.1 冲压力计算 24

4.4.2 凹凸模刃口尺寸及公差计算 25

4.4.3 冲

5结 论 27

5.1总结 27

5.2体会 27

参考文献 28

致 谢 29