设计简介

摘 要

模具是工业生产中的重要工艺装备,是国民经济各部门发展的重要基础,是衡量一个国家的生产力水平的重要标志之一,模具已成为当代工业生产 的重要手段和工艺发展方向,也是机械制造业中技术先进、影响深远的重要工艺 装备,具有生产效率高、材料利用率高、制件质量优良、工艺适应性好等特点, 随着改革开放和国民经济的高速发展,推动了模具技术和工业的心发展势头,在仪器仪表、家用电器、交通、通讯等各行业中,被广泛应用于汽车、机械、航天、 航空、轻工、电子等行业。模具设计的水平高低、模具的制造能力强弱以及模具的质量的优劣,将直接影响各种产品的质量、经济效率的增长及整体工业水平的提高,现代工艺的发展和生产效益的提升,绝大程度上是取决于模具的发展和技术经济水平,模具工艺成为高新技术产业的重要组成部分,现代模具是高技术背景下的工艺密集型工业,其水平的高低,在很大程度上决定产品的质量、效益和产品的开发与制造能力。

冲压是利用安装在冲压设备上的模具对材料施加压力,使其产生分离或塑性变形,从而获得所需零件的一种压力加工方法。由于冲压加工具有许多突出的优点,因此在工业生产中,尤其是大批量生产中得到广泛应用。从精细的电子元件、仪表指针到汽车的覆盖件、高压容器封头以及航空航天器的蒙皮、机身等均需冲压加工。随着工业产品的不断发展和生产技术水平不断提高,不少过去用铸造、锻造、切削加工方法制造的零件,已被质量轻、刚度好的冲压件所代替。

关键词:模具,冲压

Abstract

Mold is the important industrial production technology and equipment, is sectors of the national economy development is the important base and the measure of a country's important mark of the level of productivity, mould has become an important means of modern industrial production and process development direction, and mechanical manufacturing technology advanced, profoundly important technology and equipment, high production efficiency, material with high efficiency and good quality product, process adaptability is good wait for a characteristic, along with the reform and opening-up and the high speed development of economy, promote the mould technology and industrial heart development momentum in instrumentation, household appliances, transportation, communication, and other industries, is widely used in motor vehicles, machinery, aerospace, aviation, light industry, electronic industry. Die design level, mould manufacturing capability of strength and the quality of the mould, the disadvantages of will directly affect the quality of the product, the economic efficiency of the growth and raise the level of the whole industry, the development of modern technology and production efficiency of ascension that is most extent depends on the development of the mould and the technical and economical level, mould technology has become the high and new technology industry is an important component of the modern mold is high technology background technology intensive industry, the level of high and low to a large extent, on the quality of the products, efficiency and product development and manufacturing ability.

Stamping is to use the equipment installed in stamping mould pressure on the material, make its produce separation or plastic deformation, and will obtain the needed parts stress of processing method. Due to the stamping process has many outstanding qualities, so in industrial production, especially mass production widely used. From fine electronic components, instrument pointer to the car's covering high pressure vessel, the head of the envelope, and aviation aircraft fuselage etc all needs to stamping processing. With the continuous development of industrial products and production technology level increases, many in the past by casting, forging, cutting processing method of parts manufacturing, has been light quality, good stiffness of stamping.

Keywords: mold, stamping

目 录

摘要………………………………………………………………………………………1

1 绪论……………………………………………………………………………………2

1.1 国内模具的现状和发展趋势 ……………………………………………………2

1.2 国外模具的现状和发展趋势 ……………………………………………………4

2 设计课题………………………………………………………………………………7

3 冲压件的工艺分析……………………………………………………………………8

4确定冲压工艺方案 ……………………………………………………………………9

5 模具结构形式选择与确定……………………………………………………………10

5.1排样及材料利用率 ………………………………………………………………10

6 工作零部件的计算……………………………………………………………………12

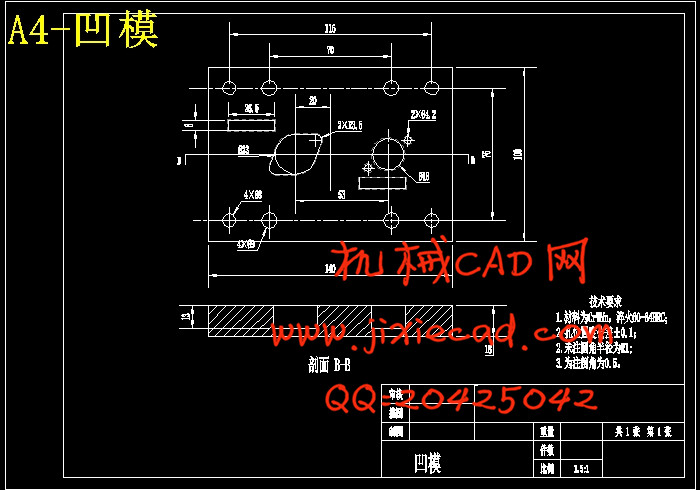

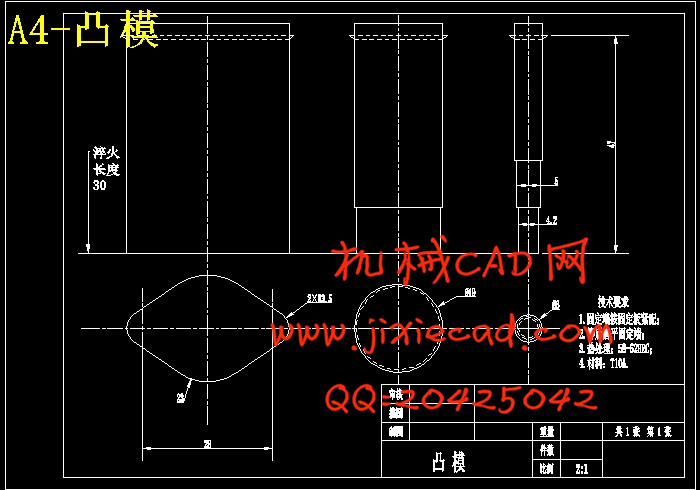

6.1冲孔凸模和落料凸模的加工………………………………………………………12

6.2侧刃位置计算………………………………………………………………………12

7 模具的设计与计算……………………………………………………………………13

7.1各部分工艺力的计算………………………………………………………………13

7.2冲压设备的初步选择………………………………………………………………14

7.3计算压力中心………………………………………………………………………14

7.4校核橡胶垫…………………………………………………………………………15

7.5模具总体结构的设计………………………………………………………………15

8模拟仿真…………………………………………………………………………………21

8.1 PRO/E介绍 …………………………………………………………………………21

8.2 PRO/E 基本建模……………………………………………………………………22

8.3 PRO/E 的装配………………………………………………………………………26

8.4 PRO/E 动画…………………………………………………………………………32

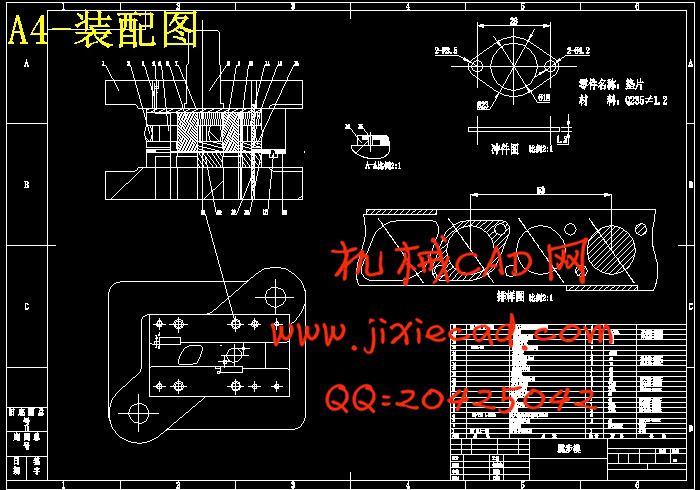

8.5 模具装配图…………………………………………………………………………35

设计总结 ……………………………………………………………………………39

致谢 ………………………………………………………………………………………40

参考文献 …………………………………………………………………………………41

模具是工业生产中的重要工艺装备,是国民经济各部门发展的重要基础,是衡量一个国家的生产力水平的重要标志之一,模具已成为当代工业生产 的重要手段和工艺发展方向,也是机械制造业中技术先进、影响深远的重要工艺 装备,具有生产效率高、材料利用率高、制件质量优良、工艺适应性好等特点, 随着改革开放和国民经济的高速发展,推动了模具技术和工业的心发展势头,在仪器仪表、家用电器、交通、通讯等各行业中,被广泛应用于汽车、机械、航天、 航空、轻工、电子等行业。模具设计的水平高低、模具的制造能力强弱以及模具的质量的优劣,将直接影响各种产品的质量、经济效率的增长及整体工业水平的提高,现代工艺的发展和生产效益的提升,绝大程度上是取决于模具的发展和技术经济水平,模具工艺成为高新技术产业的重要组成部分,现代模具是高技术背景下的工艺密集型工业,其水平的高低,在很大程度上决定产品的质量、效益和产品的开发与制造能力。

冲压是利用安装在冲压设备上的模具对材料施加压力,使其产生分离或塑性变形,从而获得所需零件的一种压力加工方法。由于冲压加工具有许多突出的优点,因此在工业生产中,尤其是大批量生产中得到广泛应用。从精细的电子元件、仪表指针到汽车的覆盖件、高压容器封头以及航空航天器的蒙皮、机身等均需冲压加工。随着工业产品的不断发展和生产技术水平不断提高,不少过去用铸造、锻造、切削加工方法制造的零件,已被质量轻、刚度好的冲压件所代替。

关键词:模具,冲压

Abstract

Mold is the important industrial production technology and equipment, is sectors of the national economy development is the important base and the measure of a country's important mark of the level of productivity, mould has become an important means of modern industrial production and process development direction, and mechanical manufacturing technology advanced, profoundly important technology and equipment, high production efficiency, material with high efficiency and good quality product, process adaptability is good wait for a characteristic, along with the reform and opening-up and the high speed development of economy, promote the mould technology and industrial heart development momentum in instrumentation, household appliances, transportation, communication, and other industries, is widely used in motor vehicles, machinery, aerospace, aviation, light industry, electronic industry. Die design level, mould manufacturing capability of strength and the quality of the mould, the disadvantages of will directly affect the quality of the product, the economic efficiency of the growth and raise the level of the whole industry, the development of modern technology and production efficiency of ascension that is most extent depends on the development of the mould and the technical and economical level, mould technology has become the high and new technology industry is an important component of the modern mold is high technology background technology intensive industry, the level of high and low to a large extent, on the quality of the products, efficiency and product development and manufacturing ability.

Stamping is to use the equipment installed in stamping mould pressure on the material, make its produce separation or plastic deformation, and will obtain the needed parts stress of processing method. Due to the stamping process has many outstanding qualities, so in industrial production, especially mass production widely used. From fine electronic components, instrument pointer to the car's covering high pressure vessel, the head of the envelope, and aviation aircraft fuselage etc all needs to stamping processing. With the continuous development of industrial products and production technology level increases, many in the past by casting, forging, cutting processing method of parts manufacturing, has been light quality, good stiffness of stamping.

Keywords: mold, stamping

目 录

摘要………………………………………………………………………………………1

1 绪论……………………………………………………………………………………2

1.1 国内模具的现状和发展趋势 ……………………………………………………2

1.2 国外模具的现状和发展趋势 ……………………………………………………4

2 设计课题………………………………………………………………………………7

3 冲压件的工艺分析……………………………………………………………………8

4确定冲压工艺方案 ……………………………………………………………………9

5 模具结构形式选择与确定……………………………………………………………10

5.1排样及材料利用率 ………………………………………………………………10

6 工作零部件的计算……………………………………………………………………12

6.1冲孔凸模和落料凸模的加工………………………………………………………12

6.2侧刃位置计算………………………………………………………………………12

7 模具的设计与计算……………………………………………………………………13

7.1各部分工艺力的计算………………………………………………………………13

7.2冲压设备的初步选择………………………………………………………………14

7.3计算压力中心………………………………………………………………………14

7.4校核橡胶垫…………………………………………………………………………15

7.5模具总体结构的设计………………………………………………………………15

8模拟仿真…………………………………………………………………………………21

8.1 PRO/E介绍 …………………………………………………………………………21

8.2 PRO/E 基本建模……………………………………………………………………22

8.3 PRO/E 的装配………………………………………………………………………26

8.4 PRO/E 动画…………………………………………………………………………32

8.5 模具装配图…………………………………………………………………………35

设计总结 ……………………………………………………………………………39

致谢 ………………………………………………………………………………………40

参考文献 …………………………………………………………………………………41