设计简介

摘 要:冲压是指板料经分离或成形而得到制件的方法。冲压利用冲压模具对板料进行加工。常温下进行的板料冲压加工称为冷冲压。模具工业是现代工业发展的基础,是大批生产同形产品的工具,是工业生产的主要工艺设备。冲压模具是模具工业的重要组成部分,模具工业是国民经济的基础工业。近年来,与机械相关的各个行业都越来越重视模具的设计与应用,不仅是因为模具已发展成为一项比较成熟的共性技术,同时还因为模具在现代工业中发挥越来越重要的作用,模具可保证冲压产品的尺寸精度,使产品质量稳定,而且加工中不破坏产品表面。

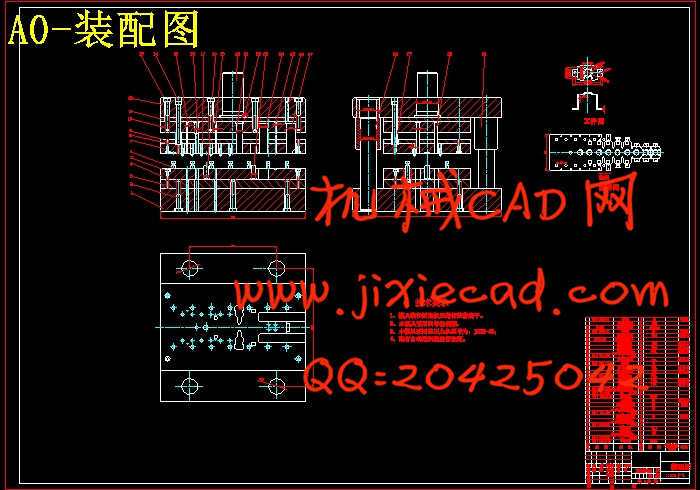

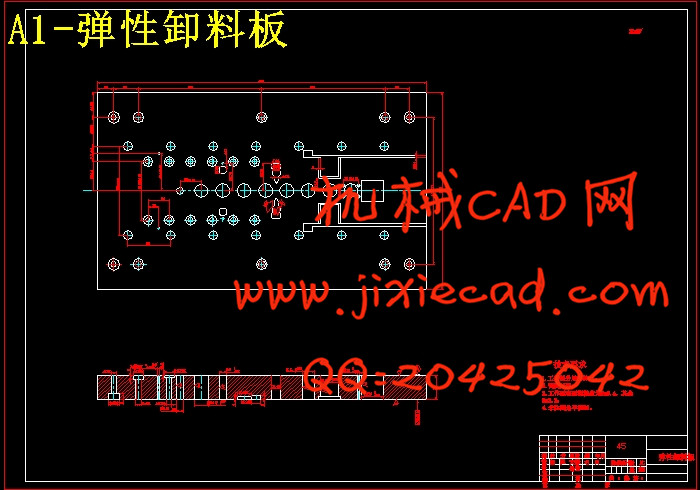

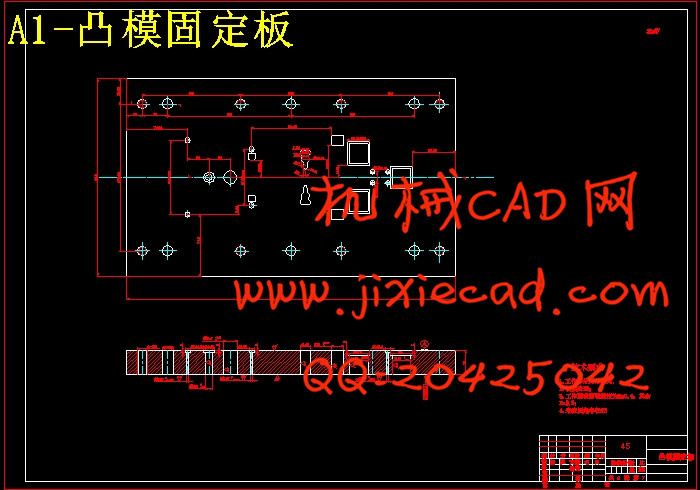

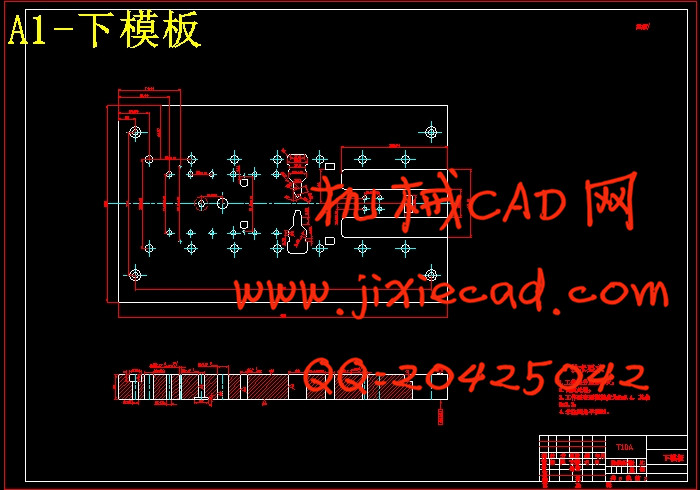

在这次毕业设计中,先介绍了马达支架的结构,对其工艺特点进行分析,再根据其结构特点对模具进行设计。其中重点阐述了成形该零件的级进模的排样设计、工位设计、模具总体结构设计、模具凸、凹模设计、固定板设计及抬顶料装置、卸料板结构及各零部件材料、热处理技术要求等。该模具虽然结构相对复杂,但加工质量好,生产效率高,适于工厂大批量生产。

设计过程中,不可避免的遇到一些困难,但是通过努力最终得以解决。这次设计是对模具设计的一次全面实践,相信对未来自己从事的工作一定会有相当大的帮助。

关键词:冲压模具,马达支架,级进模

Abstract: Stamping is refers to the sheet metal forming by separation or by stamping method. Stamping use of stamping dies for sheet metal processing. Room temperature for sheet metal stamping process called cold stamping. Mould industry is the basis for the development of modern industry, it is mass production tools, products of the same type is the main process equipment in industrial production. Stamping die is an important part of mold industry, mold industry is the basic industry of national economy. In recent years, with mechanical or related industries are pay more and more attention to mold the design and application, not only because the mould has developed into a relatively mature technology, but also because the mold plays more and more important role in modern industry, the mold to ensure the accuracy of the stamping product size, make the product quality is stable, and the processing surface without breaking the product.

In this graduation design, first introduced the structure of the motor bracket, analyzes its technological characteristics, according to the structure characteristics of mould design. Which expounds the forming of the parts of progressive die strip layout design, workstation design, convex, concave die mold overall structure design, mold design, fixed plate design, and carried lifter device, stripper plate structure and each parts material and heat treatment technical requirements, etc. The mold structure is relatively complex, but the processing quality well, high production efficiency, suitable for mass production in factories.

In the design process, will inevitably encounter some difficulties, but through hard work finally settled. This design is a comprehensive practice of mold design,I believe that there is a big help for my job in the future .

Keywords: Stamping mold,The motor bracket, Progressive mold

目 录

摘要…………………………………………………………………………………1

1前言………………………………………………………………………………2

2绪论………………………………………………………………………………3

2.1我国冲压模具的发展现状……………………………………………………3

2.2我国冲压模具制造技术发展趋势……………………………………………4

3零件工艺分析及确定工艺方案和模具结构类型………………………………5

3.1产品零件图……………………………………………………………………5

3.2工艺分析………………………………………………………………………6

3.2.1工艺审核……………………………………………………………………6

3.2.2工件的工艺分析……………………………………………………………7

3.3工艺方案及模具结构类型……………………………………………………7

3.3.1冷冲模具类型与结构………………………………………………………8

3.3.2冲裁模冲裁原理……………………………………………………………9

3.3.3零件冲压方案确定…………………………………………………………9

4级进模设计计算…………………………………………………………………10

4.1零件图…………………………………………………………………………10

4.2工艺方案及模具结构类型……………………………………………………11

4.3级进模的工作原理……………………………………………………………11

4.4多工位级进模的特点…………………………………………………………11

4.5排样设计………………………………………………………………………12

4.5.1排样的设计…………………………………………………………………12

4.5.2最小搭边值的选择…………………………………………………………13

4.5.3条料步距的计算……………………………………………………………14

4.5.4条料宽度计算………………………………………………………………14

4.6确定条料的利用率……………………………………………………………15

4.7计算冲裁力及弯曲力…………………………………………………………15

4.7.1冲裁力的计算………………………………………………………………15

4.7.2卸料力、推件力、顶件力的计算…………………………………………17

4.8压力机公称压力的确定及压力机的选用……………………………………18

4.9压力中心的确定………………………………………………………………19

5连续模零部件结构设计…………………………………………………………21

5.1凸、凹模结构设计……………………………………………………………21

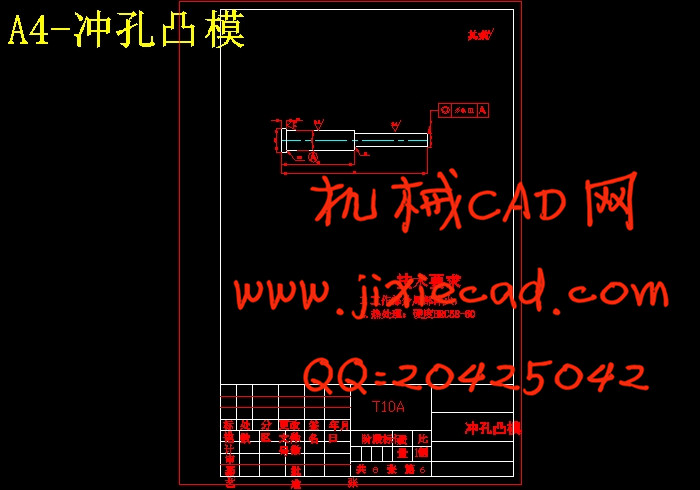

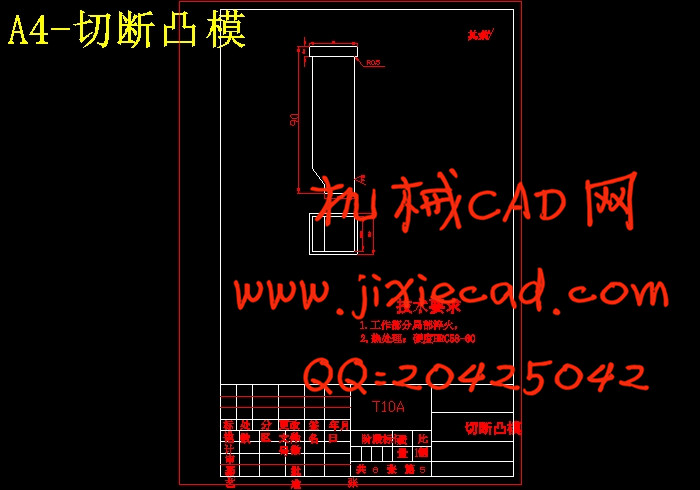

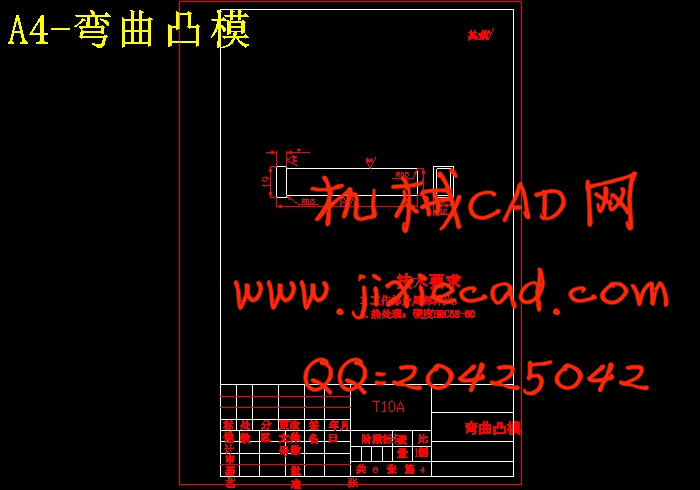

5.1.1凸模…………………………………………………………………………21

5.1.2凹模…………………………………………………………………………23

5.1.3凸、凹模工作尺寸计算……………………………………………………24

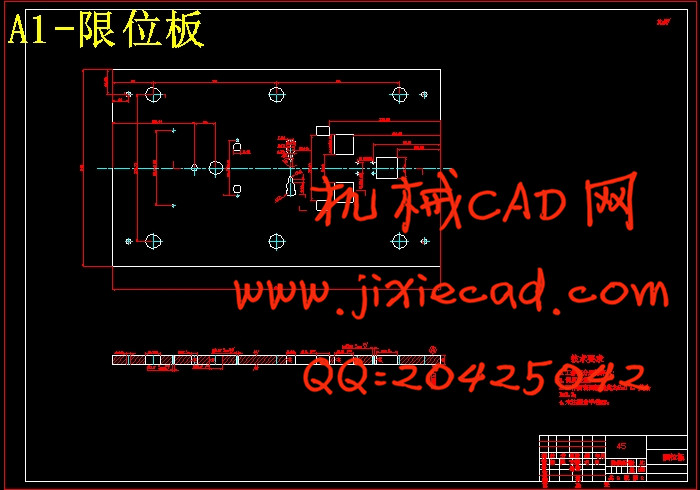

5.2定位形式与结构设计…………………………………………………………29

5.2.1设计原则……………………………………………………………………29

5.2.2定位零件机构与应用………………………………………………………30

5.3卸料结构的设计………………………………………………………………31

5.4连续模导向、安装和有关零部件……………………………………………30

5.4.1导向…………………………………………………………………………30

5.4.2结构件与安装………………………………………………………………31

5.4.3紧固件选用…………………………………………………………………31

5.4.4模具自制件的材料及热处理要求…………………………………………32

6模具装配…………………………………………………………………………32

7总结………………………………………………………………………………34

参考文献……………………………………………………………………………34

致谢…………………………………………………………………………………35

在这次毕业设计中,先介绍了马达支架的结构,对其工艺特点进行分析,再根据其结构特点对模具进行设计。其中重点阐述了成形该零件的级进模的排样设计、工位设计、模具总体结构设计、模具凸、凹模设计、固定板设计及抬顶料装置、卸料板结构及各零部件材料、热处理技术要求等。该模具虽然结构相对复杂,但加工质量好,生产效率高,适于工厂大批量生产。

设计过程中,不可避免的遇到一些困难,但是通过努力最终得以解决。这次设计是对模具设计的一次全面实践,相信对未来自己从事的工作一定会有相当大的帮助。

关键词:冲压模具,马达支架,级进模

Abstract: Stamping is refers to the sheet metal forming by separation or by stamping method. Stamping use of stamping dies for sheet metal processing. Room temperature for sheet metal stamping process called cold stamping. Mould industry is the basis for the development of modern industry, it is mass production tools, products of the same type is the main process equipment in industrial production. Stamping die is an important part of mold industry, mold industry is the basic industry of national economy. In recent years, with mechanical or related industries are pay more and more attention to mold the design and application, not only because the mould has developed into a relatively mature technology, but also because the mold plays more and more important role in modern industry, the mold to ensure the accuracy of the stamping product size, make the product quality is stable, and the processing surface without breaking the product.

In this graduation design, first introduced the structure of the motor bracket, analyzes its technological characteristics, according to the structure characteristics of mould design. Which expounds the forming of the parts of progressive die strip layout design, workstation design, convex, concave die mold overall structure design, mold design, fixed plate design, and carried lifter device, stripper plate structure and each parts material and heat treatment technical requirements, etc. The mold structure is relatively complex, but the processing quality well, high production efficiency, suitable for mass production in factories.

In the design process, will inevitably encounter some difficulties, but through hard work finally settled. This design is a comprehensive practice of mold design,I believe that there is a big help for my job in the future .

Keywords: Stamping mold,The motor bracket, Progressive mold

目 录

摘要…………………………………………………………………………………1

1前言………………………………………………………………………………2

2绪论………………………………………………………………………………3

2.1我国冲压模具的发展现状……………………………………………………3

2.2我国冲压模具制造技术发展趋势……………………………………………4

3零件工艺分析及确定工艺方案和模具结构类型………………………………5

3.1产品零件图……………………………………………………………………5

3.2工艺分析………………………………………………………………………6

3.2.1工艺审核……………………………………………………………………6

3.2.2工件的工艺分析……………………………………………………………7

3.3工艺方案及模具结构类型……………………………………………………7

3.3.1冷冲模具类型与结构………………………………………………………8

3.3.2冲裁模冲裁原理……………………………………………………………9

3.3.3零件冲压方案确定…………………………………………………………9

4级进模设计计算…………………………………………………………………10

4.1零件图…………………………………………………………………………10

4.2工艺方案及模具结构类型……………………………………………………11

4.3级进模的工作原理……………………………………………………………11

4.4多工位级进模的特点…………………………………………………………11

4.5排样设计………………………………………………………………………12

4.5.1排样的设计…………………………………………………………………12

4.5.2最小搭边值的选择…………………………………………………………13

4.5.3条料步距的计算……………………………………………………………14

4.5.4条料宽度计算………………………………………………………………14

4.6确定条料的利用率……………………………………………………………15

4.7计算冲裁力及弯曲力…………………………………………………………15

4.7.1冲裁力的计算………………………………………………………………15

4.7.2卸料力、推件力、顶件力的计算…………………………………………17

4.8压力机公称压力的确定及压力机的选用……………………………………18

4.9压力中心的确定………………………………………………………………19

5连续模零部件结构设计…………………………………………………………21

5.1凸、凹模结构设计……………………………………………………………21

5.1.1凸模…………………………………………………………………………21

5.1.2凹模…………………………………………………………………………23

5.1.3凸、凹模工作尺寸计算……………………………………………………24

5.2定位形式与结构设计…………………………………………………………29

5.2.1设计原则……………………………………………………………………29

5.2.2定位零件机构与应用………………………………………………………30

5.3卸料结构的设计………………………………………………………………31

5.4连续模导向、安装和有关零部件……………………………………………30

5.4.1导向…………………………………………………………………………30

5.4.2结构件与安装………………………………………………………………31

5.4.3紧固件选用…………………………………………………………………31

5.4.4模具自制件的材料及热处理要求…………………………………………32

6模具装配…………………………………………………………………………32

7总结………………………………………………………………………………34

参考文献……………………………………………………………………………34

致谢…………………………………………………………………………………35