设计简介

摘 要

摘要:屏屏板工件采用冲孔落料级进模制造,级进模是一种工位多、效率高的冲模。在一副级进模上,根据冲压件的实际需要,按一定顺序安排了多个冲压工序(在级进模中称为工位)进行连续冲压。总之,级进模比单工序模生产率高,减少了模具和设备的数量,工件精度较高,便于操作和实现生产自动化。对于特别复杂或孔边距较小的冲压件,用简单模或复合模冲制有困难时,可用级进模逐步冲出。但级进模轮廓尺寸较大,制造较复杂,成本较高,一般适用于大批量生产小型冲压件。

关键词: 冲孔 落料 级进模 单工序模 冲压件

Abstract:The screen screen board work piece uses the punch holes to fall the material level to enter the mold manufacture, the level enters the mold is one kind of location are many, efficiency high dying. Enters on the mold in a level, according to the pressing part actual need, arranged many ramming working procedure according to the certain order (to enter in mold in level to be called location) to carry on the continual ramming. In brief, the level enters the mold compared to the single working procedure mawson production rate high, reduced the mold and the equipment quantity, the work piece precision is high, is advantageous for the operation and the realization production automation. Regarding is specially complex or the hole edge distance small pressing part, stamps out with the Jan single model or the superposable die when has the difficulty, may use the level to enter the mold gradually to run out. But the level enters the mold overall size in a big way, manufacture complex, the cost is high, is suitable generally for the mass production small pressing part.

Key Words:Punch holes Falls the material Enters the mold Single working procedure mold Pressing part

1 绪论………………………………………………………………………………1

2 冲裁件的工艺性分析……………………………………………………………3

3 冲压工艺方案的确定……………………………………………………………4

4 主要的设计计算…………………………………………………………………5

4.1 排样方式的确定及计算……………………………………………………5

4.2 冲压力的计算………………………………………………………………6

4.3 压力中心的确定及相关计算………………………………………………8

4.4 工作零件刃口尺寸的计算…………………………………………………9

4.5 卸料橡胶的设计……………………………………………………………10

5 模具的总体设计……………………………………………………………………12

5.1 模具类型的选择…………………………………………………………12

5.2 定位方式的选择…………………………………………………………12

5.3 卸料、出件方式的选择…………………………………………………12

5.4 导向方式的选择…………………………………………………………12

6 主要零件的结构设计………………………………………………………………13

6.1 工作零件的结构设计…………………………………………………………13

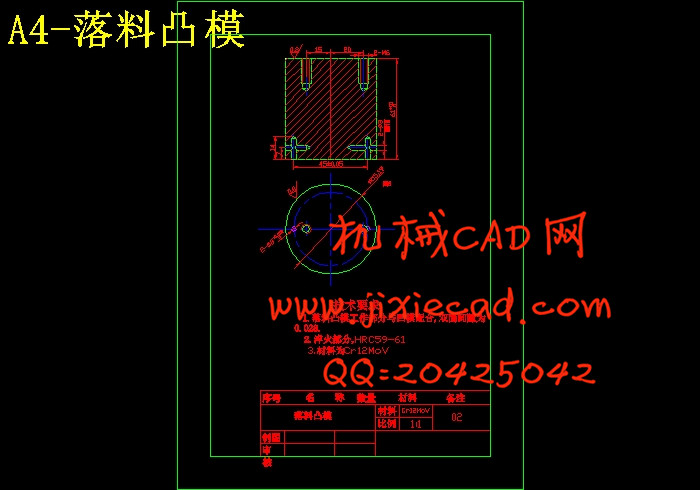

6.1.1 落料凸模………………………………………………………………………13

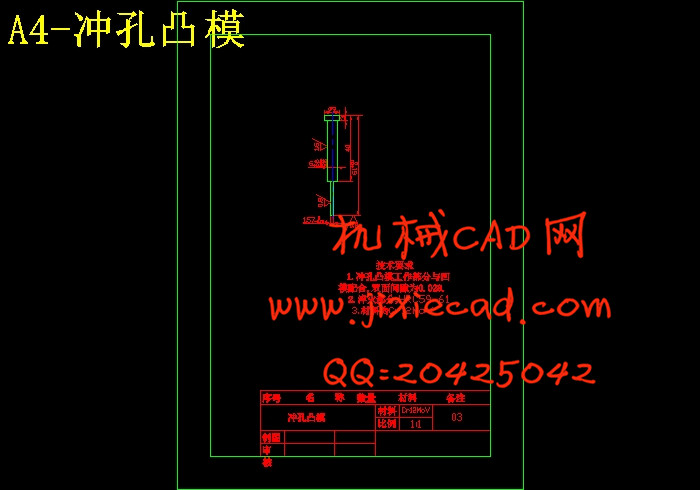

6.1.2 冲孔凸模………………………………………………………………………14

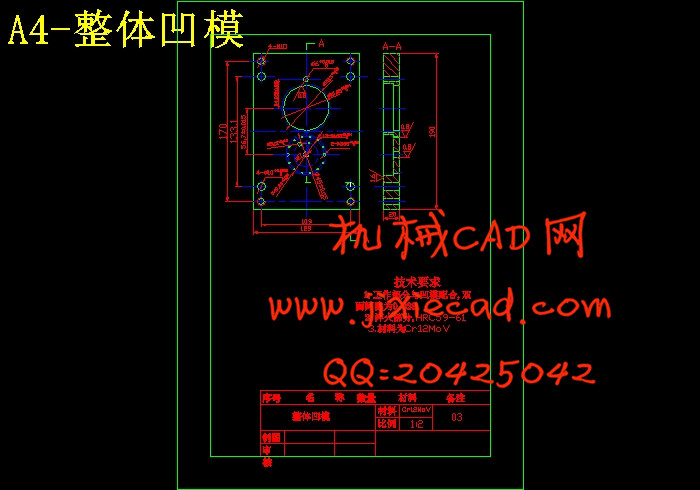

6.2 凹模………………………………………………………………………………16

6.3 定位零件的设计…………………………………………………………………17

6.4 导料板的设计……………………………………………………………………18

6.5 卸料部件的设计…………………………………………………………………18

6.5.1 卸料板的设计……………………………………………………………………19

6.5.2 卸料螺钉的选用…………………………………………………………………19

6.6 模架及其它零部件的设计………………………………………………………19

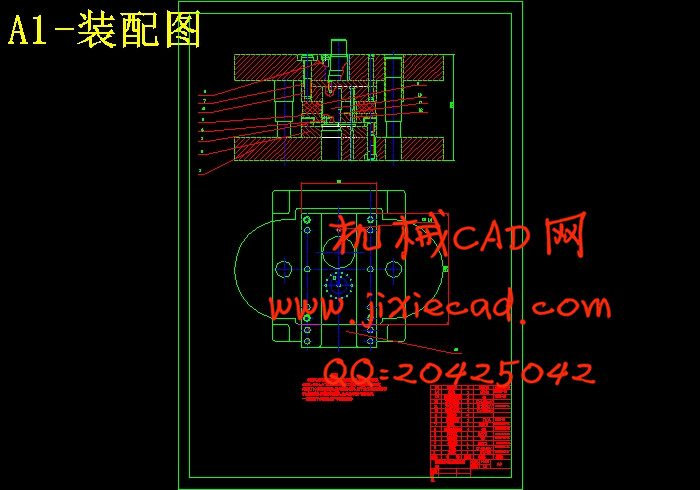

7 模具总装图………………………………………………………………………………22

8 冲压设备的选用…………………………………………………………………………23

9 模具零件加工工艺………………………………………………………………………24

10 模具的装配………………………………………………………………………………27

摘要:屏屏板工件采用冲孔落料级进模制造,级进模是一种工位多、效率高的冲模。在一副级进模上,根据冲压件的实际需要,按一定顺序安排了多个冲压工序(在级进模中称为工位)进行连续冲压。总之,级进模比单工序模生产率高,减少了模具和设备的数量,工件精度较高,便于操作和实现生产自动化。对于特别复杂或孔边距较小的冲压件,用简单模或复合模冲制有困难时,可用级进模逐步冲出。但级进模轮廓尺寸较大,制造较复杂,成本较高,一般适用于大批量生产小型冲压件。

关键词: 冲孔 落料 级进模 单工序模 冲压件

Abstract:The screen screen board work piece uses the punch holes to fall the material level to enter the mold manufacture, the level enters the mold is one kind of location are many, efficiency high dying. Enters on the mold in a level, according to the pressing part actual need, arranged many ramming working procedure according to the certain order (to enter in mold in level to be called location) to carry on the continual ramming. In brief, the level enters the mold compared to the single working procedure mawson production rate high, reduced the mold and the equipment quantity, the work piece precision is high, is advantageous for the operation and the realization production automation. Regarding is specially complex or the hole edge distance small pressing part, stamps out with the Jan single model or the superposable die when has the difficulty, may use the level to enter the mold gradually to run out. But the level enters the mold overall size in a big way, manufacture complex, the cost is high, is suitable generally for the mass production small pressing part.

Key Words:Punch holes Falls the material Enters the mold Single working procedure mold Pressing part

1 绪论………………………………………………………………………………1

2 冲裁件的工艺性分析……………………………………………………………3

3 冲压工艺方案的确定……………………………………………………………4

4 主要的设计计算…………………………………………………………………5

4.1 排样方式的确定及计算……………………………………………………5

4.2 冲压力的计算………………………………………………………………6

4.3 压力中心的确定及相关计算………………………………………………8

4.4 工作零件刃口尺寸的计算…………………………………………………9

4.5 卸料橡胶的设计……………………………………………………………10

5 模具的总体设计……………………………………………………………………12

5.1 模具类型的选择…………………………………………………………12

5.2 定位方式的选择…………………………………………………………12

5.3 卸料、出件方式的选择…………………………………………………12

5.4 导向方式的选择…………………………………………………………12

6 主要零件的结构设计………………………………………………………………13

6.1 工作零件的结构设计…………………………………………………………13

6.1.1 落料凸模………………………………………………………………………13

6.1.2 冲孔凸模………………………………………………………………………14

6.2 凹模………………………………………………………………………………16

6.3 定位零件的设计…………………………………………………………………17

6.4 导料板的设计……………………………………………………………………18

6.5 卸料部件的设计…………………………………………………………………18

6.5.1 卸料板的设计……………………………………………………………………19

6.5.2 卸料螺钉的选用…………………………………………………………………19

6.6 模架及其它零部件的设计………………………………………………………19

7 模具总装图………………………………………………………………………………22

8 冲压设备的选用…………………………………………………………………………23

9 模具零件加工工艺………………………………………………………………………24

10 模具的装配………………………………………………………………………………27