设计简介

上连接板模具设计

摘 要

本设计题目为弯曲模设计,体现了弯曲模的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者弯曲模设计的基础知识,为设计更复杂的弯曲模具做好了铺垫和吸取了更深刻的经验。本设计运用弯曲成型工艺及模具设计的基础知识,首先分析了板材的性能要求,为选取模具的类型做好了准备;然后计算了弯曲件的弯曲力,便于选取压力机吨位及确定压力机型号;最后分析了弯曲件的特征,确定模具的设计参数、设计要点及顶出装置的选取。成型原理可划分为两个阶段:首先,凸模与凹模共同作用成型U形件;凸模继续下行,最后成型制件,这种机构动作灵活可靠,设计方便,非常适合在本副模具中使用。

关键词:弯曲模 凸模 凹模

Abstract

The requirement ,content and direction of the design of the bending dies parts are embodied on this bending dies design. The designer’s foundation knowledge of the bending dies design is reinforced and is able to design more complex injection mould through the design.

Through the foundation knowledge, firstly, the composion and the perfourmance of the flat sheet is analyzed to choose the type of the mould. Secondly, the volume of the bend is estimated to choose the press molding machine and to detemine the type press machine and tonnage of press. Lastly the character of the part is analyzed to determine the mould design parameter and design point and choose the ejection assembly.

Especially fit for volume produce and hight precision produce.Moulding of the part is like this :Fist,behing punch and die’s together operation, the part is form to the fast bending ; punch is going down, swing block is flogged to work, and the second bending is begin. At last, the part is form to part. This device’s action credibly and design conveniencly. So, it is adapted to be used on this mould extraordinarily.

part. This device’s action credibly and design conveniencly. So, it is adapted to be used on this mould extraordinarily.

Keywords: bending dies punch dieg

目 录

摘要……………………………………………………………………………………1

第1章零件结构工艺性分析…………………………………………………………3

1.1 弯曲件的直边高度………………………………………………………………4

1.2 弯曲件的孔边距…………………………………………………………………4

1.3 最小弯曲半径……………………………………………………………………4

1.4 对称性工件圆角半径的设置……………………………………………………5

1.5 弯曲件的精度……………………………………………………………………5

第2章主要工艺参数的计算…………………………………………………………6

2.1 弯曲力的计算……………………………………………………………………6

2.2压力机公称压力的确定………………………………………………………… 6

2.3回弹量的计算…………………………………………………………………….7

2.4弯曲件毛坯尺寸的计算…………………………………………………………7

2.5弹顶力计算………………………………………………………………………7

第3章弯曲模工作部分设计…………………………………………………………8

3.1凸、凹模间隙值的确定…………………………………………………………8

3.2凸、凹模工作部分设计…………………………………………………………8

3.2.1凸、凹模刃口宽度尺寸的计算………………………………………………8

3.2.2凸模圆角半径的设置…………………………………………………………8

3.2.3凹模圆角半径的计算…………………………………………………………8

3.2.4凹模的深度及底部壁厚………………………………………………………9

第4章弯曲模总体设计………………………………………………………… … 10

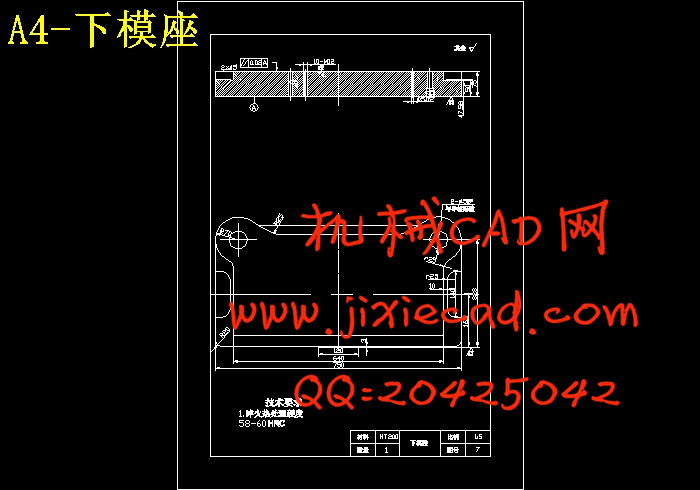

4.1 模具类型的选择……………………………………………………………… 10

4.2 定位方式的选择……………………………………………………………… 10

4.3 卸料出件方式的选择………………………………………………………… 10

4.4 导向方式的选择……………………………………………………………… 10

4.5连接与固定零件…………………………………………………………… …10

第5章 设备的选定…………………………………………………………… ….13

第6章 模具主要零部件的设计………………………………………………… …14

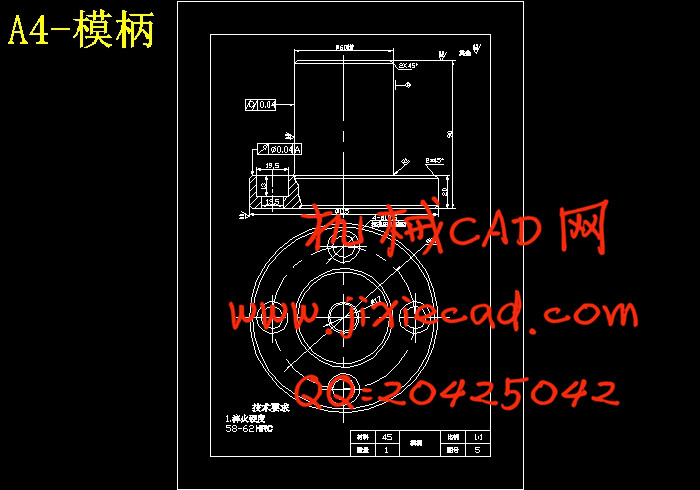

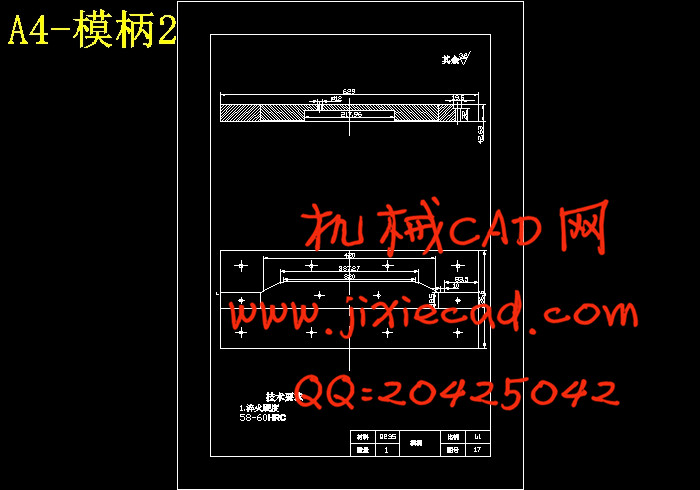

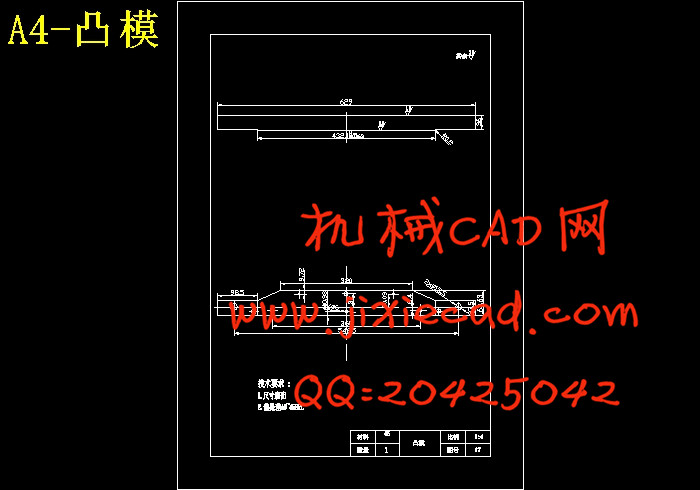

6.1 凸模部分…………………………………………………………………… …14

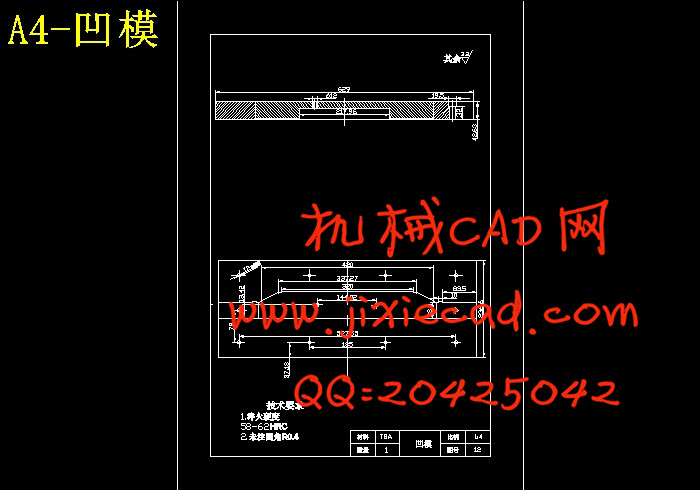

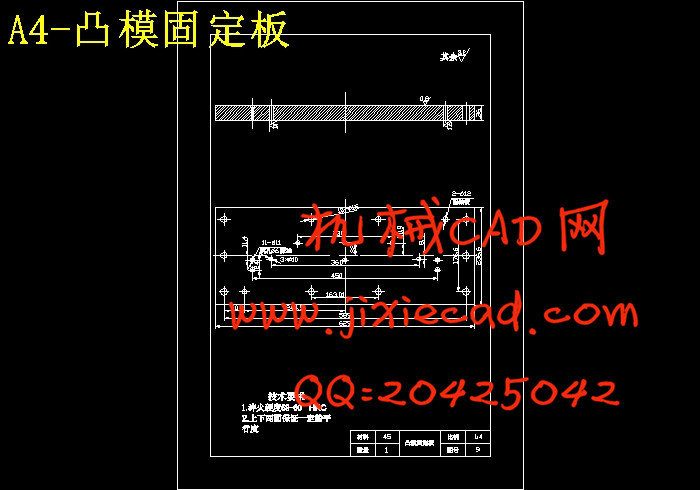

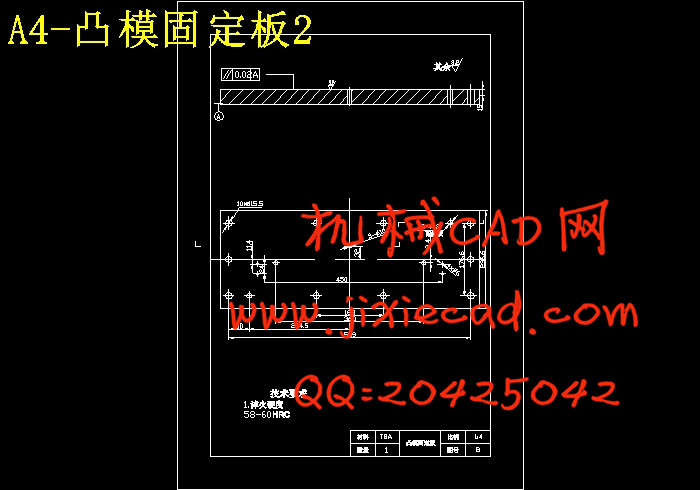

6.2 凹模部分……………………………………………………………… ………14

6.3连接零件的选用与标准化…………………………………………… …… …15

6.4 模具零件的加工工艺……………………………………………………… …16

6.5 模具试冲时常见的故障原因和调整方法……………………………… …….17

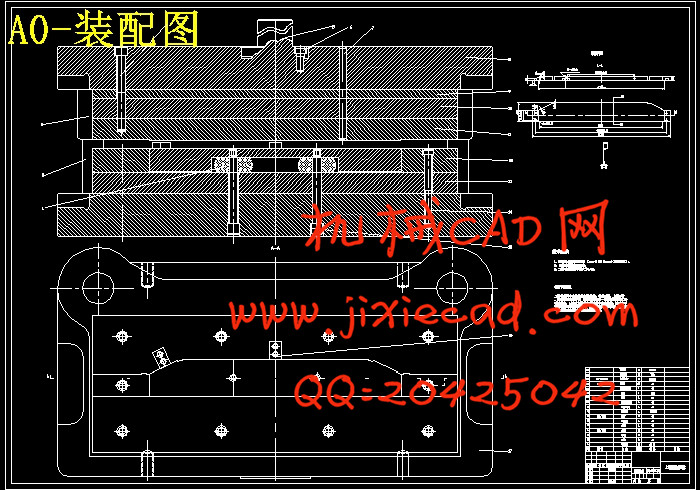

第7章 模具总装配………………………………………………………………18

结论…………………………………………………………………………… ……20

致谢…………………………………………………………………………… …….21

参考文献……………………………………………………………………… ……22

摘 要

本设计题目为弯曲模设计,体现了弯曲模的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者弯曲模设计的基础知识,为设计更复杂的弯曲模具做好了铺垫和吸取了更深刻的经验。本设计运用弯曲成型工艺及模具设计的基础知识,首先分析了板材的性能要求,为选取模具的类型做好了准备;然后计算了弯曲件的弯曲力,便于选取压力机吨位及确定压力机型号;最后分析了弯曲件的特征,确定模具的设计参数、设计要点及顶出装置的选取。成型原理可划分为两个阶段:首先,凸模与凹模共同作用成型U形件;凸模继续下行,最后成型制件,这种机构动作灵活可靠,设计方便,非常适合在本副模具中使用。

关键词:弯曲模 凸模 凹模

Abstract

The requirement ,content and direction of the design of the bending dies parts are embodied on this bending dies design. The designer’s foundation knowledge of the bending dies design is reinforced and is able to design more complex injection mould through the design.

Through the foundation knowledge, firstly, the composion and the perfourmance of the flat sheet is analyzed to choose the type of the mould. Secondly, the volume of the bend is estimated to choose the press molding machine and to detemine the type press machine and tonnage of press. Lastly the character of the part is analyzed to determine the mould design parameter and design point and choose the ejection assembly.

Especially fit for volume produce and hight precision produce.Moulding of the part is like this :Fist,behing punch and die’s together operation, the part is form to the fast bending ; punch is going down, swing block is flogged to work, and the second bending is begin. At last, the part is form to

Keywords: bending dies punch dieg

目 录

摘要……………………………………………………………………………………1

第1章零件结构工艺性分析…………………………………………………………3

1.1 弯曲件的直边高度………………………………………………………………4

1.2 弯曲件的孔边距…………………………………………………………………4

1.3 最小弯曲半径……………………………………………………………………4

1.4 对称性工件圆角半径的设置……………………………………………………5

1.5 弯曲件的精度……………………………………………………………………5

第2章主要工艺参数的计算…………………………………………………………6

2.1 弯曲力的计算……………………………………………………………………6

2.2压力机公称压力的确定………………………………………………………… 6

2.3回弹量的计算…………………………………………………………………….7

2.4弯曲件毛坯尺寸的计算…………………………………………………………7

2.5弹顶力计算………………………………………………………………………7

第3章弯曲模工作部分设计…………………………………………………………8

3.1凸、凹模间隙值的确定…………………………………………………………8

3.2凸、凹模工作部分设计…………………………………………………………8

3.2.1凸、凹模刃口宽度尺寸的计算………………………………………………8

3.2.2凸模圆角半径的设置…………………………………………………………8

3.2.3凹模圆角半径的计算…………………………………………………………8

3.2.4凹模的深度及底部壁厚………………………………………………………9

第4章弯曲模总体设计………………………………………………………… … 10

4.1 模具类型的选择……………………………………………………………… 10

4.2 定位方式的选择……………………………………………………………… 10

4.3 卸料出件方式的选择………………………………………………………… 10

4.4 导向方式的选择……………………………………………………………… 10

4.5连接与固定零件…………………………………………………………… …10

第5章 设备的选定…………………………………………………………… ….13

第6章 模具主要零部件的设计………………………………………………… …14

6.1 凸模部分…………………………………………………………………… …14

6.2 凹模部分……………………………………………………………… ………14

6.3连接零件的选用与标准化…………………………………………… …… …15

6.4 模具零件的加工工艺……………………………………………………… …16

6.5 模具试冲时常见的故障原因和调整方法……………………………… …….17

第7章 模具总装配………………………………………………………………18

结论…………………………………………………………………………… ……20

致谢…………………………………………………………………………… …….21

参考文献……………………………………………………………………… ……22