设计简介

四速轮 锻模和切边冲孔复合模设计

摘要

本文介绍了锻造加工技术加工金属零件,重点介绍了模锻。模锻是在锻锤压力机上使用专门的模具使坯料在模膛中成形获得所需形状和尺寸的锻件。它适用于成批或大量生产。锻造加工生产率最高,锻件形状、尺寸稳定性好,并有最佳的综合力学性能。。锻件的最大优势是韧性高、显微组织合理,件与件之间性能变化小。

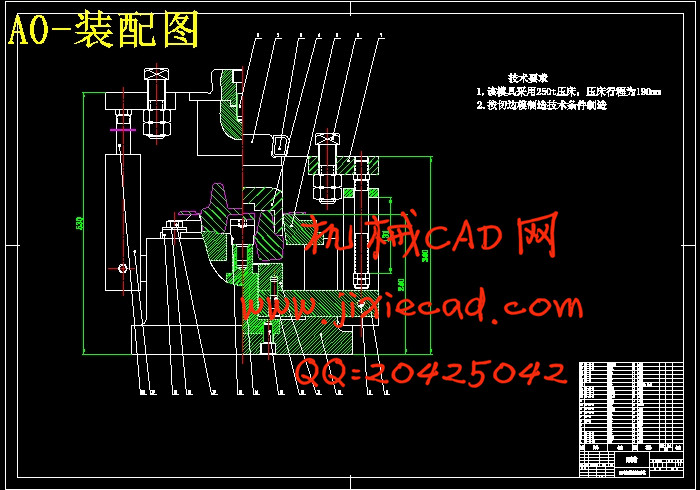

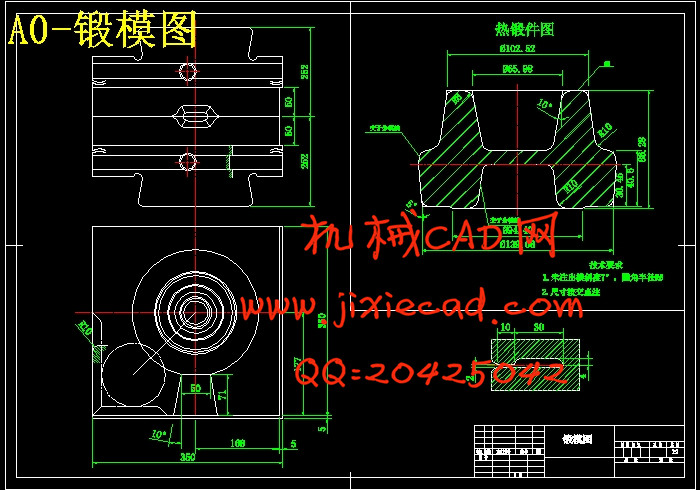

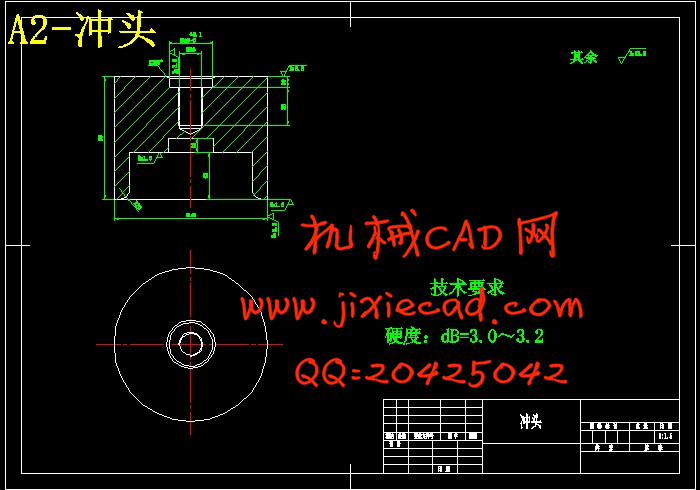

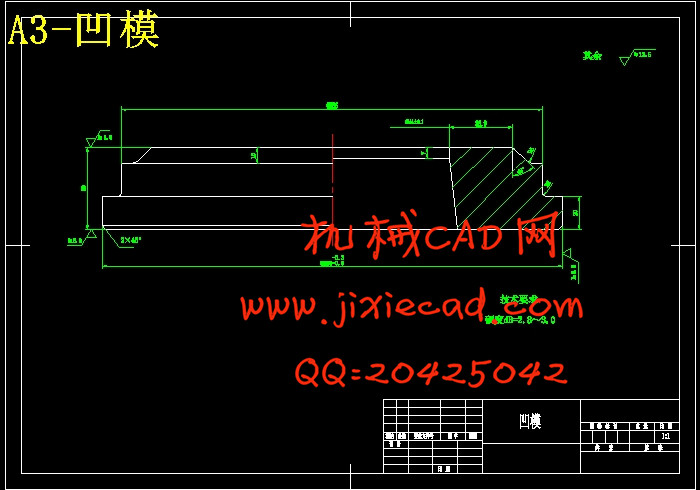

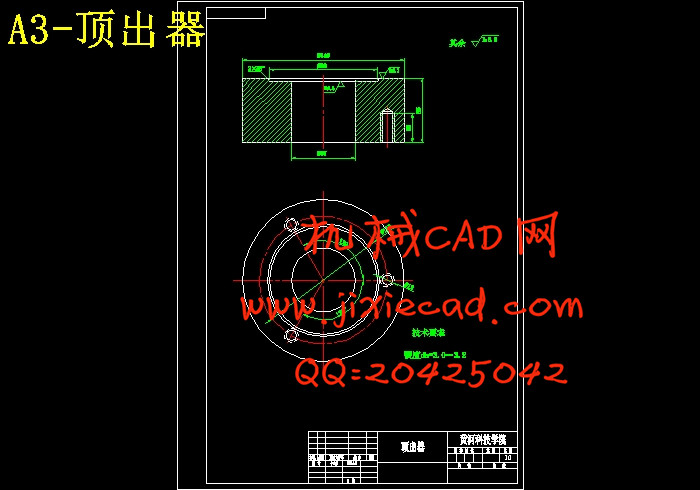

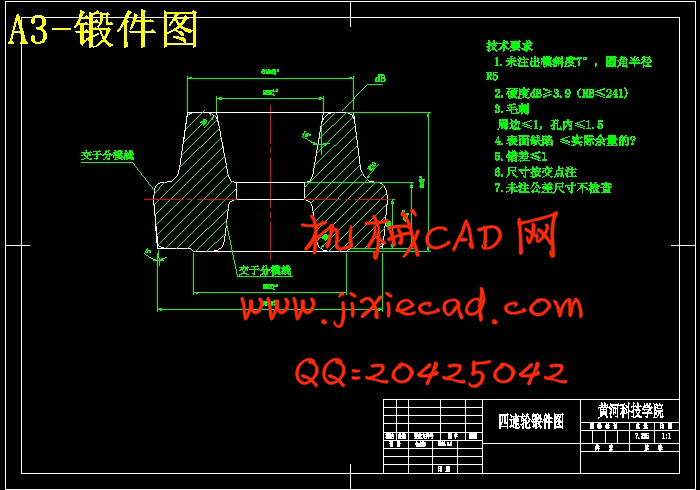

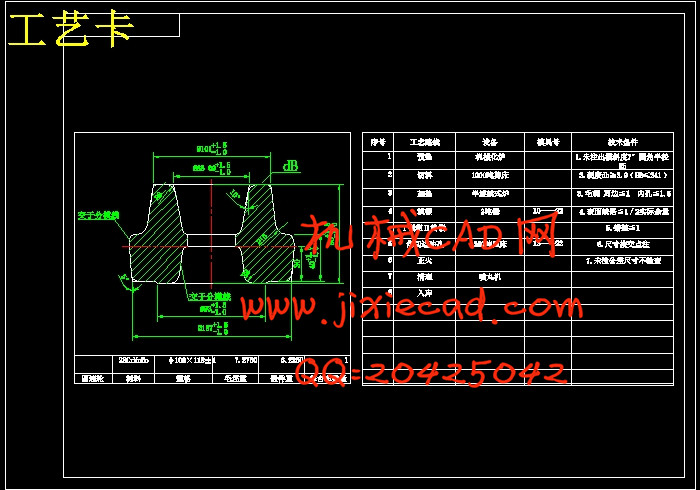

本次毕业设计具体进行了以四速轮作为零件的锻模设计。包括四速轮的锻件图、锤锻模图和切边冲孔复合模图的详尽设计。并简要介绍了模锻的后续工艺,包括切边冲连皮,锻件的冷却,锻件的热处理,及锻件的表面清理等,其中重点介绍了切边冲连皮工艺,切边冲孔复合模较连续模具有效率高、质量好,减少设备台数等优点。

关键词:锻造,模具设计,切边冲连皮,热处理,表面清理

Four Speed Gear Forging Die and Trimming and Piercing Compound Die Design

This paper introduces the forging processing metal parts processing technology, introduces die forging. Forging hammer is in press using specialized mold making the blank in the mold bore forming to obtain the required shape and size of the forgings. It is suitable for batch or mass production. Forging forging shape, high productivity, good size stability, and has the best comprehensive mechanical properties.. Forging is the biggest advantage of high toughness, microstructure and properties of reasonable, between small changes.

. This graduation design is specific to four speed gear as part of forging die design. Including four speed wheel forging drawing, the hammer forging die drawing and trimming and piercing compound die for the detailed design drawings. And briefly introduces the forging of the follow-up process, including trimming punching, forging cooling, forgings and forging heat treatment, surface cleaning, which focuses on the cutting edge of punching process, trimming and punching compound die of a mold continuous high efficiency, good quality, decreasing equipments etc.

Key words: Design of die forging, punching, cutting, heat treatment, surface cleaning

目录

1绪论 1

2四速轮锤上锻模设计 2

2.1制定锻件图 2

2.2确定锻件的基本数据 4

2.3确定设备吨位 4

2.4确定飞边槽尺寸 5

2.5终锻模膛设计 5

2.6确定制坯工步 6

2.7确定坯料尺寸 6

2.8镦粗台设计 7

2.9锻模结构设计 7

3模锻后续工序 12

3.1切边与冲连皮 12

3.2锻件冷却与热处理 13

3.2.1锻件的冷却 13

3.2.2锻件的热处理 13

3.3锻件的表面清理 14

结论 15

致谢 16

设计总结 17

参考文献 18

摘要

本文介绍了锻造加工技术加工金属零件,重点介绍了模锻。模锻是在锻锤压力机上使用专门的模具使坯料在模膛中成形获得所需形状和尺寸的锻件。它适用于成批或大量生产。锻造加工生产率最高,锻件形状、尺寸稳定性好,并有最佳的综合力学性能。。锻件的最大优势是韧性高、显微组织合理,件与件之间性能变化小。

本次毕业设计具体进行了以四速轮作为零件的锻模设计。包括四速轮的锻件图、锤锻模图和切边冲孔复合模图的详尽设计。并简要介绍了模锻的后续工艺,包括切边冲连皮,锻件的冷却,锻件的热处理,及锻件的表面清理等,其中重点介绍了切边冲连皮工艺,切边冲孔复合模较连续模具有效率高、质量好,减少设备台数等优点。

关键词:锻造,模具设计,切边冲连皮,热处理,表面清理

Four Speed Gear Forging Die and Trimming and Piercing Compound Die Design

This paper introduces the forging processing metal parts processing technology, introduces die forging. Forging hammer is in press using specialized mold making the blank in the mold bore forming to obtain the required shape and size of the forgings. It is suitable for batch or mass production. Forging forging shape, high productivity, good size stability, and has the best comprehensive mechanical properties.. Forging is the biggest advantage of high toughness, microstructure and properties of reasonable, between small changes.

. This graduation design is specific to four speed gear as part of forging die design. Including four speed wheel forging drawing, the hammer forging die drawing and trimming and piercing compound die for the detailed design drawings. And briefly introduces the forging of the follow-up process, including trimming punching, forging cooling, forgings and forging heat treatment, surface cleaning, which focuses on the cutting edge of punching process, trimming and punching compound die of a mold continuous high efficiency, good quality, decreasing equipments etc.

Key words: Design of die forging, punching, cutting, heat treatment, surface cleaning

目录

1绪论 1

2四速轮锤上锻模设计 2

2.1制定锻件图 2

2.2确定锻件的基本数据 4

2.3确定设备吨位 4

2.4确定飞边槽尺寸 5

2.5终锻模膛设计 5

2.6确定制坯工步 6

2.7确定坯料尺寸 6

2.8镦粗台设计 7

2.9锻模结构设计 7

3模锻后续工序 12

3.1切边与冲连皮 12

3.2锻件冷却与热处理 13

3.2.1锻件的冷却 13

3.2.2锻件的热处理 13

3.3锻件的表面清理 14

结论 15

致谢 16

设计总结 17

参考文献 18