设计简介

摘 要

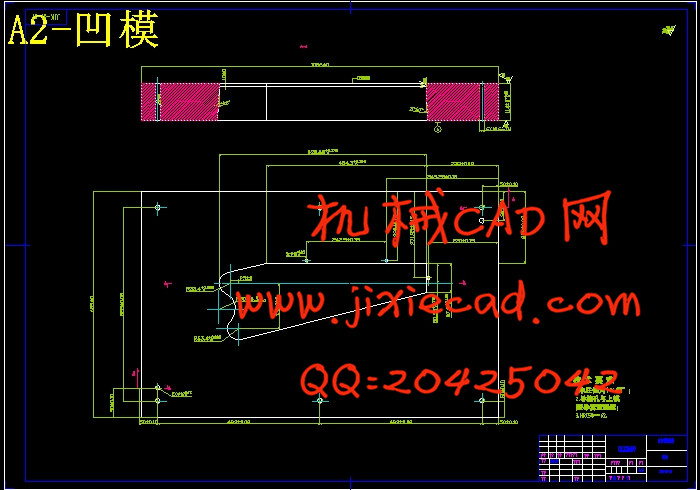

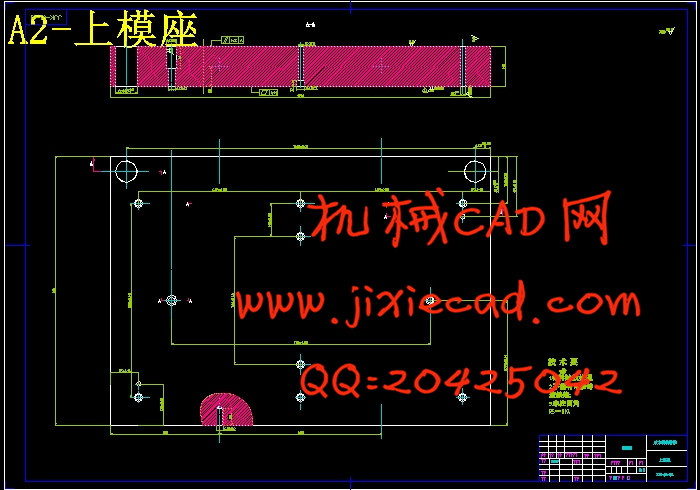

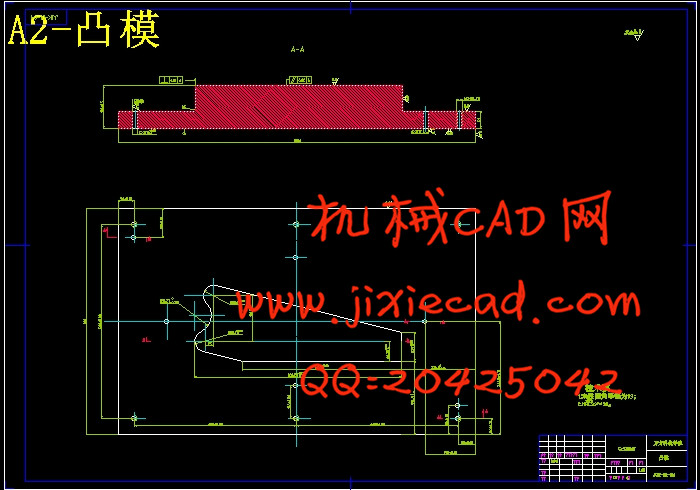

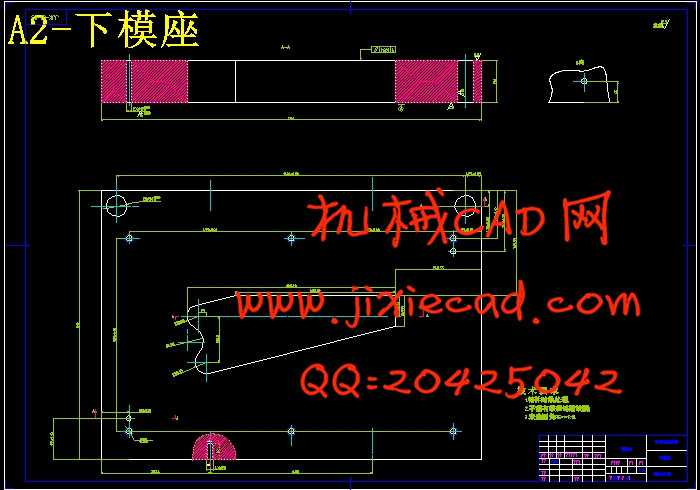

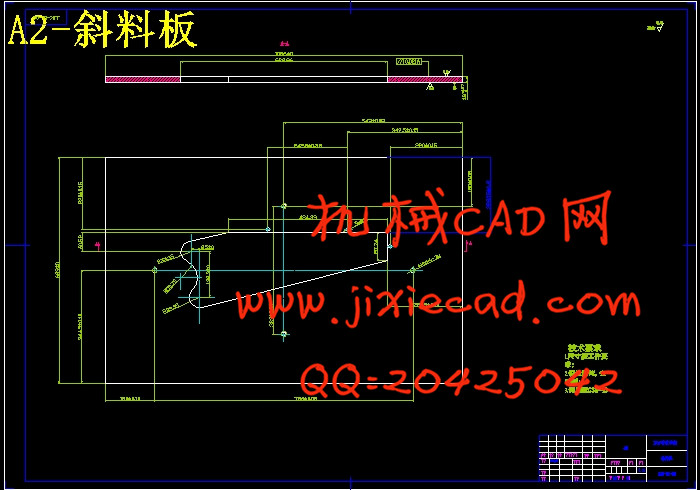

随着中国工业不断地发展,模具行业也显得越来越重要。本文针对拖拉机机架框的冲压工艺性,分析比较了成型过程不同冲压工艺,确定用三幅单模完成落料、冲孔、弯曲的工序过程。介绍了拖拉机机架框冷冲压成形过程,且重点分析了坯料形状、尺寸,落料模、冲孔模、弯曲模的工作原理、工艺性、圆角半径、精度、工序、力的计算、间隙及凸凹模深度、压力机的选择,并给出了合理的模具总体设计。还具体分析了模具的主要零部件(如凸凹模、卸料装置、拉深凸模、垫板、凸模固定板等)的设计与制造,冲压设备的选用,凸凹模间隙调整和编制一个重要零件的加工工艺过程。列出了模具所需零件的详细清单,并给出了合理的装配图。通过充分利用现代模具制造技术对传统机械零件进行结构改进、优化设计、优化工艺方法能大幅度提高生产效率,这种方法对类似产品具有一定的借鉴作用。

关键词:拖拉机机架框;冷冲压;模具装配图;三维建模

ABSTRACT

With China's industries continue to develop and die industry is also becoming increasingly important. This article in view of the tractor frame box stamping technology, analyses and compares the different forming process of stamping process, determine three photos with single mode complete blanking, punching, bending process process. Introduced the tractor frame box cold stamping process, and analyses the blank shape, size, blanking mold, punching die bending die, the working principle, technology, fillet radius, the precision and the working procedure, force calculation, clearance and die and punch depth, the choice of the press, and gives the rational mould overall design. For the process, the center of pressure, the die size and the tolerance of the calculation, design mold. Also analyzes the mold of the main components (such as punch and die and dump devices, drawing punch, slates, Punch plate, etc.) design and manufacturing, stamping equipment selection, punch-gap adjustment and establishment of a vital parts machining process. Die requirements set out a detailed list of parts, and gives a reasonable assembly. By fully utilizing modern manufacturing technology to mold traditional mechanical parts for structural improvements, design optimization, Process optimization methods can greatly enhance production efficiency, the method of similar products have some reference.

Keywords: Tractor frame dialog; Cold stamping; Mold assembly drawing; 3 d modeling

目 录随着中国工业不断地发展,模具行业也显得越来越重要。本文针对拖拉机机架框的冲压工艺性,分析比较了成型过程不同冲压工艺,确定用三幅单模完成落料、冲孔、弯曲的工序过程。介绍了拖拉机机架框冷冲压成形过程,且重点分析了坯料形状、尺寸,落料模、冲孔模、弯曲模的工作原理、工艺性、圆角半径、精度、工序、力的计算、间隙及凸凹模深度、压力机的选择,并给出了合理的模具总体设计。还具体分析了模具的主要零部件(如凸凹模、卸料装置、拉深凸模、垫板、凸模固定板等)的设计与制造,冲压设备的选用,凸凹模间隙调整和编制一个重要零件的加工工艺过程。列出了模具所需零件的详细清单,并给出了合理的装配图。通过充分利用现代模具制造技术对传统机械零件进行结构改进、优化设计、优化工艺方法能大幅度提高生产效率,这种方法对类似产品具有一定的借鉴作用。

关键词:拖拉机机架框;冷冲压;模具装配图;三维建模

ABSTRACT

With China's industries continue to develop and die industry is also becoming increasingly important. This article in view of the tractor frame box stamping technology, analyses and compares the different forming process of stamping process, determine three photos with single mode complete blanking, punching, bending process process. Introduced the tractor frame box cold stamping process, and analyses the blank shape, size, blanking mold, punching die bending die, the working principle, technology, fillet radius, the precision and the working procedure, force calculation, clearance and die and punch depth, the choice of the press, and gives the rational mould overall design. For the process, the center of pressure, the die size and the tolerance of the calculation, design mold. Also analyzes the mold of the main components (such as punch and die and dump devices, drawing punch, slates, Punch plate, etc.) design and manufacturing, stamping equipment selection, punch-gap adjustment and establishment of a vital parts machining process. Die requirements set out a detailed list of parts, and gives a reasonable assembly. By fully utilizing modern manufacturing technology to mold traditional mechanical parts for structural improvements, design optimization, Process optimization methods can greatly enhance production efficiency, the method of similar products have some reference.

Keywords: Tractor frame dialog; Cold stamping; Mold assembly drawing; 3 d modeling

摘 要 I

目 录 11 前言 1

1.1 题目的意义 1

2 冲压的基本知识 2

2.1 冲压的基本工序 2

2.2 冲压模具 4

2.2.1 冲模的要求 4

2.2.2 冲模的种类 5

2.2.3 冲模结构组成 5

2.2.4 国内外现状综述 6

3 冲压工艺分析与方案论证 8

3.1 冲压工艺分析 8

3.2 冲压方案论证 9

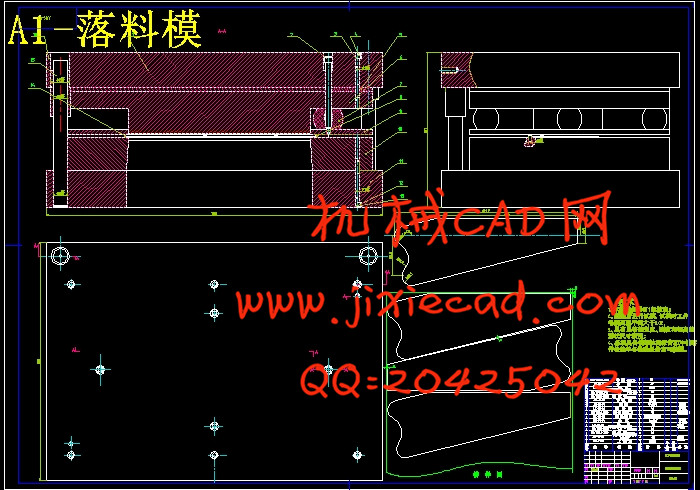

4 落料模设计 11

4.1 落料模的工作原理 11

4.2 冲压工艺分析,确定冲压工艺方案 11

4.3 排样 11

4.4 进行必要的工艺计算 12

4.4.1 落料力 12

4.4.2 卸料力 12

4.3.3推件力 13

4.4.3 选择冲床时的总压力 13

4.5 确定模具的压力中心 14

4.6 计算凸、凹模刃口尺寸 15

4.7 模具各主要零件设计 16

4.7.1 凹模的厚度、壁厚及材料 16

4.7.2 垫板的采用与厚度 18

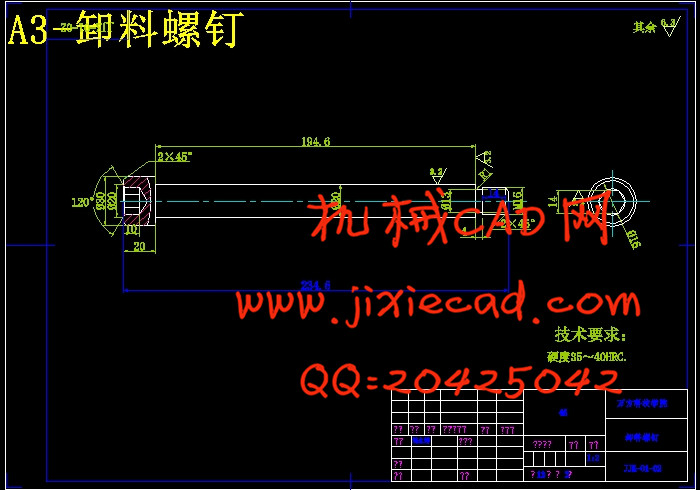

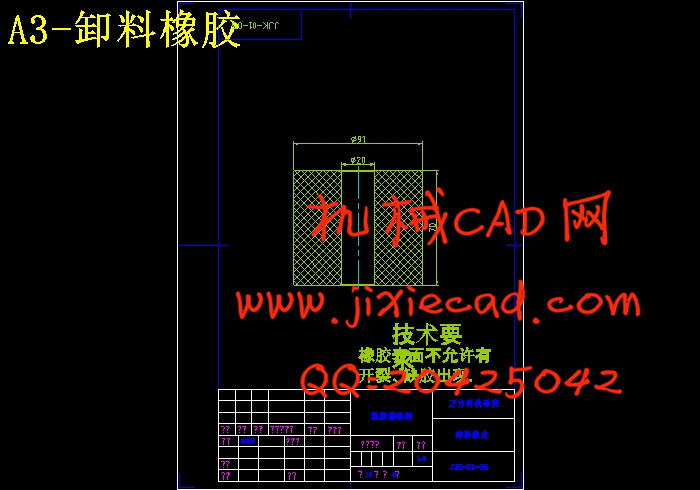

4.7.3 卸料橡胶的自由高度 19

4.7.4 上下模座的外形尺寸和厚度 20

4.7.5 上下模座的材料 20

4.7.6 模具的总体设计 20

4.8 选择冲压设备 21

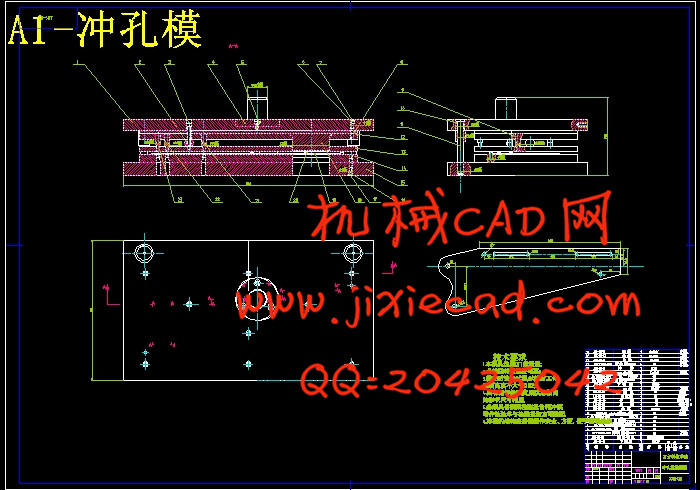

5 冲孔模的设计 23

5.1 冲孔模的工作原理 23

5.2 冲压件的工艺分析 23

5.3 计算冲压力 23

5.3.1 冲孔力 23

5.3.2 冲孔时的卸料力 24

5.3.3 推件力计算 24

5.3.4 选择冲床时的总压力 24

5.4 确定模具压力中心 25

5.5 计算凸模、凹模的刃口尺寸 25

5.6 模具总体设计主要零部件设计 27

5.6.1 模具主要零部件的设计 27

5.6.2 模具总体设计 30

5.6.3 模具的工作原理 30

5.7 凸模校核 31

5.7.1 圆形凸模的校核 31

5.7.2 非圆形凸模的强度校核 32

5.8 压力机的选择 32

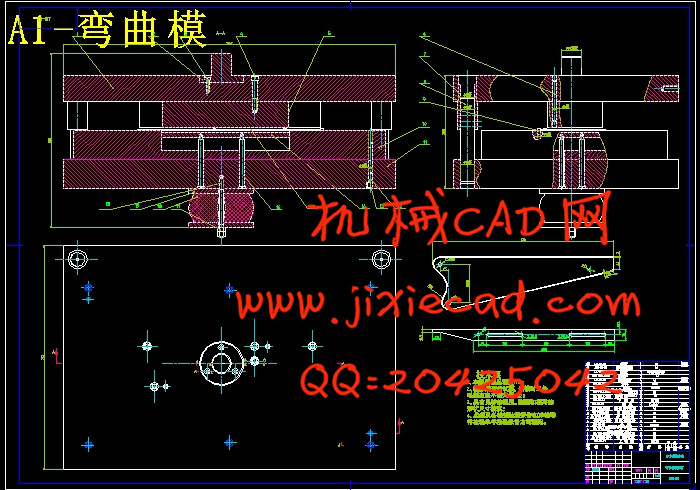

6 弯曲模的设计 34

6.1 弯曲模的工作原理 34

6.2 弯曲件的工艺性 34

6.2.1 弯曲件的工艺性 34

6.2.2 弯曲件的弯曲圆角半径 34

6.2.3 弯曲件的孔与弯曲处的最小距离 34

6.2.4 弯曲件的精度 35

6.3 弯曲件工序的确定原则 35

6.4 弯曲力的计算 36

6.4.1 自由弯曲力的计算 36

6.4.2 顶件力和卸料力的计算 36

6.4.3 弯曲时压力机压力的确定 37

6.5弯曲模工作部分的尺寸 37

6.5.1 凸凹模的圆角半径及凹模深度 37

6.5.2 弯曲模的间隙 39

6.5.3 压力机的选择 39

6.6 模具总体设计 40

7 结论 49

致 谢 50

参考文献 52