设计简介

围板冲压复合模设计

摘要

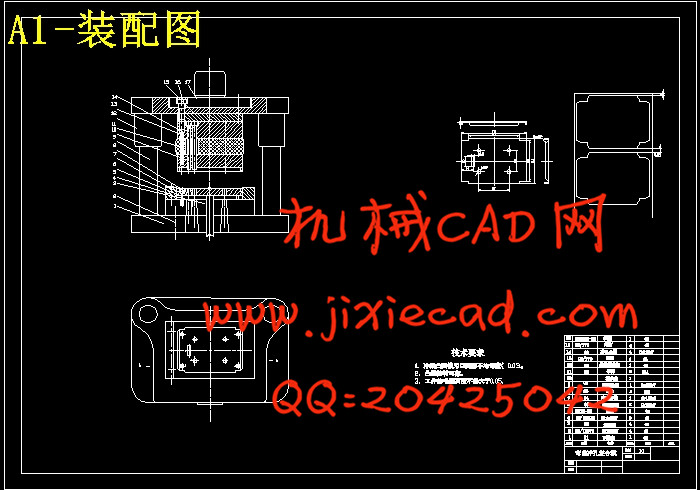

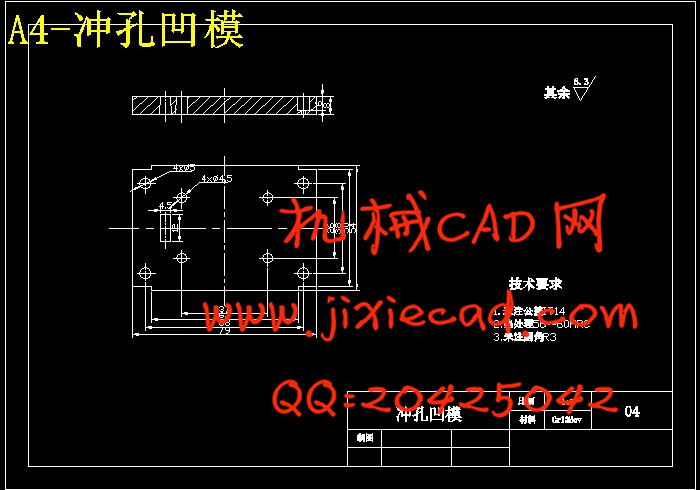

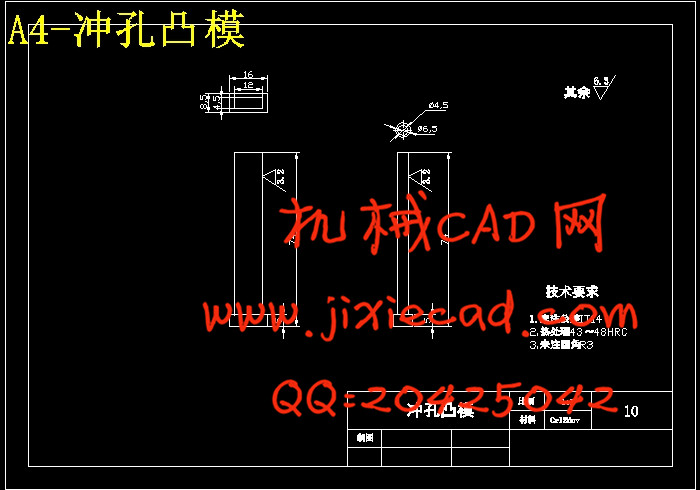

本模具为喂板冲孔弯曲复合模, 在设计时:1 、接受任务书;2 、调研消化原始资料;3 、选择成形设备;4 、拟定模具结构方案;5 、方案的讨论与论证;7 、绘制模具装配图;8 、绘制零件图;9 、编写设计说明书;10 、模具制造试模与图纸修改。正确的确定模具成形零件的尺寸。冲孔凸模、落料凹模、凸凹模等零件是确定制件形状、尺寸和表面质量的直接因素,关系甚大,要特别注意。模具的设计应制造方便, 尽量做道使设计的模具制造容易、造价便宜。特别是比较复杂的成形零件,必须考虑是采用一般的机械加工方法加工还是采用特殊的加工方法加工。模具的设计应当效率高、安全、可靠。模具零件应耐磨耐用。

关键词:模具、成形、冲孔凸模、落料凹模、凸凹模。

Piercing and Blanking Characteristic of Compound Die of Conditioner Shim

This molding tool is a piercing and blanking characteristic of compound die of conditioner shim, while designing:1, accept the mission book.2 , the investigation digests the primitive data.3 , choose to the forming equipments.4 , draft the molding tool construction project.5 , the discussion of the project and argument.7 , drawing the molding tool assembles the diagram.8 , draw the spare parts diagram.9 , weave to write to design the manual.10 , the molding tool manufacturing tries the mold and diagram paper modification.The exactitude really settles size of the forming spare parts. piercing punch , blanking die, piercing punch & blanking die etc spare parts that molding tool forming spare parts is a direct factor that certain system a shape, size relate to with the surface quantity very big, want to be specially attention.The design of the molding tool should make the convenience, doing a molding tool manufacturing that make design easy and build the price cheapness to the best.Model the spare parts especially more complicatedly, must consider is to adopt the general machine process the method processes to adopt still to process specially the method processes.The design of the molding tool shoulds the efficiency high, safety, dependable.The molding tool spare parts should bear to whet enduring.

Key Words: Molding tool, forming, piercing punch , blanking die ,piercing punch & blanking die .

目 录

绪论.......................................................................................................................................1

1.国内模具的现状与发展趋势........................................................................1

1.1 国内模具的现状...................................................................................................1

1.2 国内模具发展趋势.............................................................................................2

2. 国外模具的现状与发展趋势............................................................................3

第一章 冲裁件的工艺分析及排样....................................................................4

1.1冲裁件的工艺分析........................................................................5

1.2制件的外形分析............................................................................5

1.3冲裁件的尺寸精度和表面粗糙度................................................5

第二章 工艺方案的确定.....................................................................6

第三章 主要工艺参数计算…….........................................................7

3.1冲裁的工艺计算..............................................................................8

3.2 排样的设计与计算..........................................................................8

3.3 冲裁力的计算….............................................................................10

3.4 压力机的公称压力的计算………………………………………11

3.5 压力中心的确定及相关计算……………………………………11

3.6 工作部分的尺寸计算…………………………………………….12

第四章 模具总体设计................... ...................................................14

第五章 模具主要零部件的设计................ ......................................14

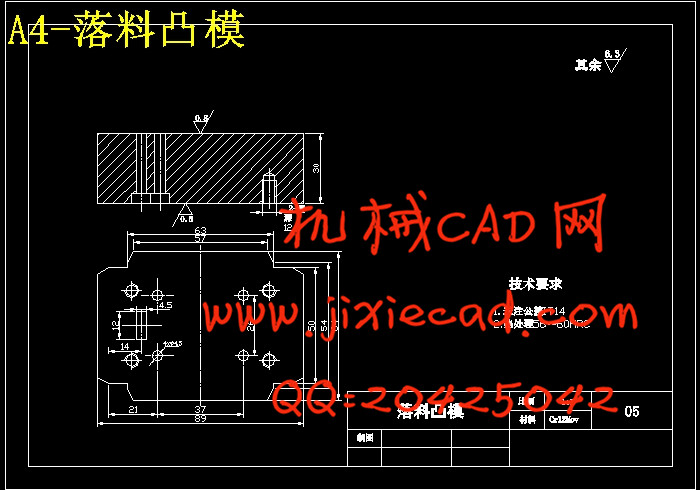

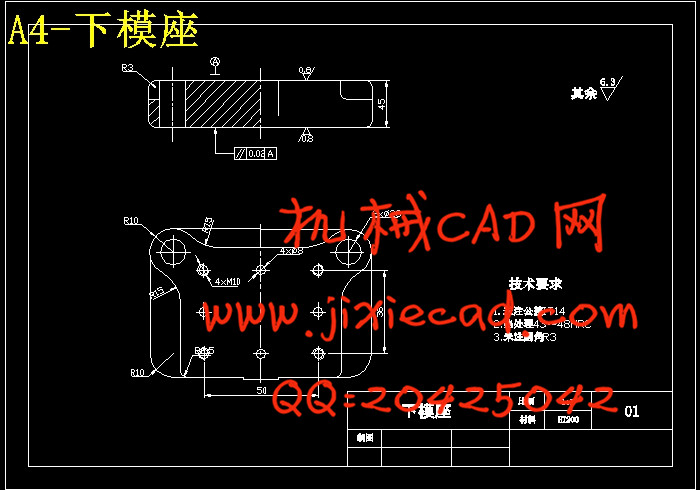

5.1 工作零件的结构设计....................................................................14

5.2 定位零件的设计................... .......................................................16

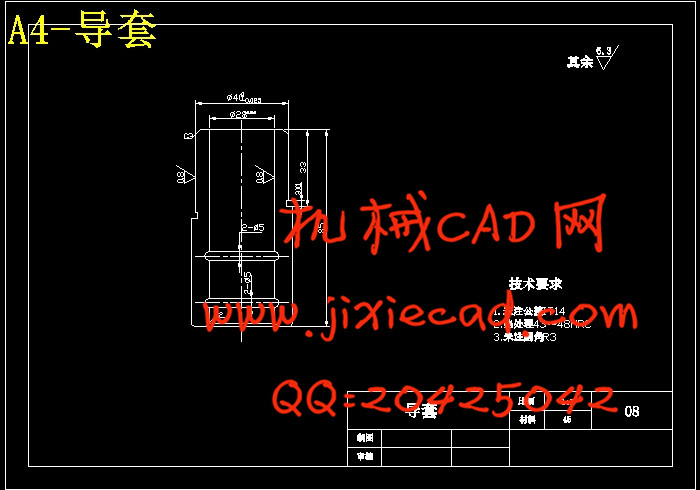

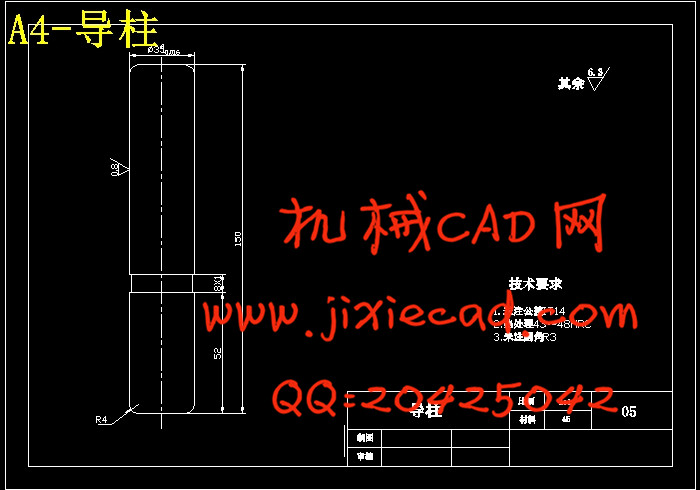

5.3 导向装置的设计.............................................................................17

5.4 打料装置是设计................................ ................... ........................17

5.5 顶件装置的设计............................................................................17

5.6 连接装置是设计............................................................................18

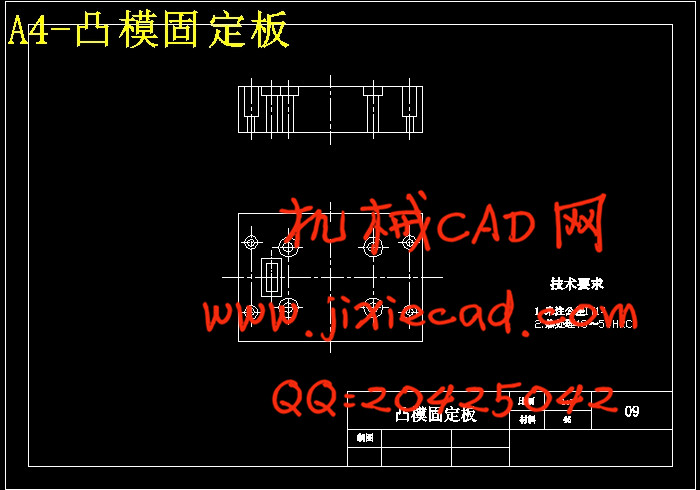

5.7 固定板是设计........................................................................... .. ..19

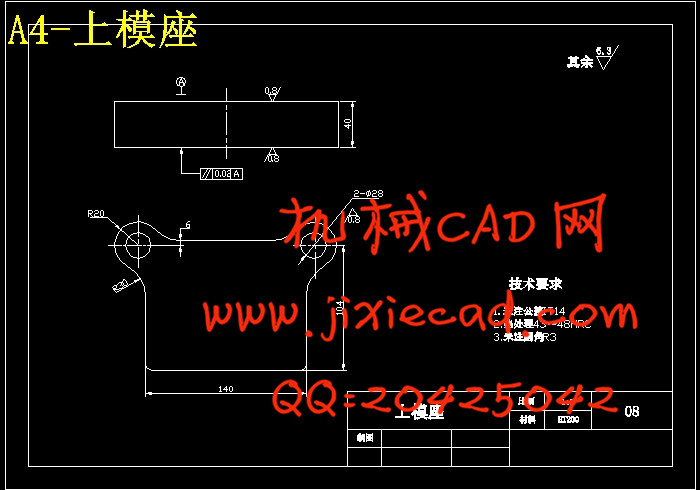

5.8 模架及组成零件的确定. ...............................................................19

第六章 模具工作原理.........................................................................20

第七章 模具的装配.............................. .............................. ................21

7.1 装配前是准备..................................................................... ............22

7.2装配模柄......................................................... .................................22

7.3装配凸凹模.............................................................. ........................23

第二部分

第一章 零件结构工艺性分析................................................. .............24

1.1 弯曲是直边高度................................................. ............................24

1.2 孔边距................................................. ...........................................24

1.3 最小弯曲半径................................................. ................................24

第二章 主要工艺参数计算................................................. .................24

2.1 弯曲力的计算................................................. ...............................24

2.2 压力机是压力确定................................................. .....................25

2.3 回弹量是计算................................................. ..................... ........25

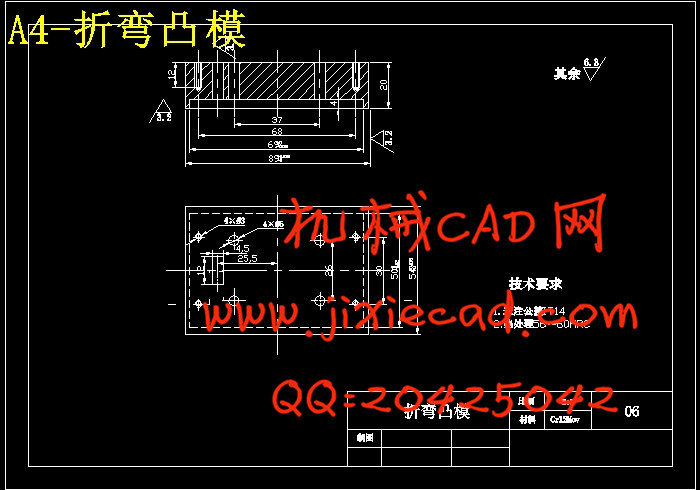

第三章 弯曲模工零部分设计............ ............ ............ ............ .........25

3.1 凸凹模的间隙是计算............................................. ...................25

第四章 模具总体设计............................................. ..........................26

第五章 设备是选定............................ ......................... ........................27

总结........................................................................................................28

致谢........................................................................................................29

参考文献................................................................................................30

摘要

本模具为喂板冲孔弯曲复合模, 在设计时:1 、接受任务书;2 、调研消化原始资料;3 、选择成形设备;4 、拟定模具结构方案;5 、方案的讨论与论证;7 、绘制模具装配图;8 、绘制零件图;9 、编写设计说明书;10 、模具制造试模与图纸修改。正确的确定模具成形零件的尺寸。冲孔凸模、落料凹模、凸凹模等零件是确定制件形状、尺寸和表面质量的直接因素,关系甚大,要特别注意。模具的设计应制造方便, 尽量做道使设计的模具制造容易、造价便宜。特别是比较复杂的成形零件,必须考虑是采用一般的机械加工方法加工还是采用特殊的加工方法加工。模具的设计应当效率高、安全、可靠。模具零件应耐磨耐用。

关键词:模具、成形、冲孔凸模、落料凹模、凸凹模。

Piercing and Blanking Characteristic of Compound Die of Conditioner Shim

This molding tool is a piercing and blanking characteristic of compound die of conditioner shim, while designing:1, accept the mission book.2 , the investigation digests the primitive data.3 , choose to the forming equipments.4 , draft the molding tool construction project.5 , the discussion of the project and argument.7 , drawing the molding tool assembles the diagram.8 , draw the spare parts diagram.9 , weave to write to design the manual.10 , the molding tool manufacturing tries the mold and diagram paper modification.The exactitude really settles size of the forming spare parts. piercing punch , blanking die, piercing punch & blanking die etc spare parts that molding tool forming spare parts is a direct factor that certain system a shape, size relate to with the surface quantity very big, want to be specially attention.The design of the molding tool should make the convenience, doing a molding tool manufacturing that make design easy and build the price cheapness to the best.Model the spare parts especially more complicatedly, must consider is to adopt the general machine process the method processes to adopt still to process specially the method processes.The design of the molding tool shoulds the efficiency high, safety, dependable.The molding tool spare parts should bear to whet enduring.

Key Words: Molding tool, forming, piercing punch , blanking die ,piercing punch & blanking die .

目 录

绪论.......................................................................................................................................1

1.国内模具的现状与发展趋势........................................................................1

1.1 国内模具的现状...................................................................................................1

1.2 国内模具发展趋势.............................................................................................2

2. 国外模具的现状与发展趋势............................................................................3

第一章 冲裁件的工艺分析及排样....................................................................4

1.1冲裁件的工艺分析........................................................................5

1.2制件的外形分析............................................................................5

1.3冲裁件的尺寸精度和表面粗糙度................................................5

第二章 工艺方案的确定.....................................................................6

第三章 主要工艺参数计算…….........................................................7

3.1冲裁的工艺计算..............................................................................8

3.2 排样的设计与计算..........................................................................8

3.3 冲裁力的计算….............................................................................10

3.4 压力机的公称压力的计算………………………………………11

3.5 压力中心的确定及相关计算……………………………………11

3.6 工作部分的尺寸计算…………………………………………….12

第四章 模具总体设计................... ...................................................14

第五章 模具主要零部件的设计................ ......................................14

5.1 工作零件的结构设计....................................................................14

5.2 定位零件的设计................... .......................................................16

5.3 导向装置的设计.............................................................................17

5.4 打料装置是设计................................ ................... ........................17

5.5 顶件装置的设计............................................................................17

5.6 连接装置是设计............................................................................18

5.7 固定板是设计........................................................................... .. ..19

5.8 模架及组成零件的确定. ...............................................................19

第六章 模具工作原理.........................................................................20

第七章 模具的装配.............................. .............................. ................21

7.1 装配前是准备..................................................................... ............22

7.2装配模柄......................................................... .................................22

7.3装配凸凹模.............................................................. ........................23

第二部分

第一章 零件结构工艺性分析................................................. .............24

1.1 弯曲是直边高度................................................. ............................24

1.2 孔边距................................................. ...........................................24

1.3 最小弯曲半径................................................. ................................24

第二章 主要工艺参数计算................................................. .................24

2.1 弯曲力的计算................................................. ...............................24

2.2 压力机是压力确定................................................. .....................25

2.3 回弹量是计算................................................. ..................... ........25

第三章 弯曲模工零部分设计............ ............ ............ ............ .........25

3.1 凸凹模的间隙是计算............................................. ...................25

第四章 模具总体设计............................................. ..........................26

第五章 设备是选定............................ ......................... ........................27

总结........................................................................................................28

致谢........................................................................................................29

参考文献................................................................................................30