设计简介

摘 要

本课题是对无凸缘圆筒形件的冲压成形工艺及模具设计,其中分别对模具的工作零部件等六大类零部件作详细设计。设计的主要内容包括冲裁件的工艺分析及工艺方案的确定、工艺计算、冲裁模具的设计、模具的安装与调整等。

在工艺计算部分要对排样设计与计算、冲压力的计算、模具压力中心的确定、凸凹模尺寸并确定制造公差的计算与计算等内容详细计算。

在冲裁模的设计部分要对工作零件、定位零件、卸料与顶件零件、导向零件连接与固定零件等结构进行详细的分析设计。要在设计过程中了解模具的工作过程和注意标准的选用,对复合冲裁模的结构有进一步的了解。

模具的安装与调试部分要注意导柱模具与无导柱模具的安装方法及顺序,通过模具的安装,了解模具的组成及各部分零部件的作用等。注意模具安装过后的试冲过程中常见的缺陷与解决方法等。

通过这次设计要对复合模具有更近一步的了解,在设计时要注意模具结构简单、模具使用方便、模具寿命高等问题。并且要提高生产效率,保证产品的质量。

关键词:落料拉深 试冲 间隙配合 过渡配合

Abstract

This graduate design is to the request of the top dust sheet molding tool design, the difference wait to the work zero parts of the molding tool six the parts of big zeros make the detailed design.The main contents of designing includes to wash to cut a piece craft analysis and craft projects really settle, craft calculation, the gearing of the design, molding tool that wash to cut the molding tool and adjust etc..

Compute in the craft the part want to be to the row kind design and calculation, wash the calculation, molding tool pressure of the pressure center to really settle, convex and cave mold size and make sure the calculation that make the business trip and compute the detailed calculation in contents in etc..

Cut the mold to want at the design part that wash to the work spare parts, position the spare parts and unload to anticipate with a spare parts, lead to spare parts conjunction with fix spare parts etc. construction the proceeding the detailed analysis design.Want to be in design process work process of understanding the molding tool with notice to choose to use standardly, to reunite the construction that wash the understanding that cut the mold further have.

The gearing of the molding tool with adjust to try the part want to notice to lead the pillar molding tool to lead the pillar molding tool with gearing method and sequences that have nos, passing the gearing of the molding tool, understanding the molding tool constitute and function etc. of each parts of the parts of zeros.Noticing the molding tool installs to try to wash the familiar blemish of inside of process later on and solution method etc..

Pass this time graduate the design want to have the nearer and one-step understanding to the compound molding tool, while designing to notice the molding tool construction simple, molding tool usage convenience, high etc. in life span in molding tool problem.And increase production efficiency, guarantee the quantity of the product.

Key phrase:The compound mold tries to hurtle the cleft the match transition match

本课题是对无凸缘圆筒形件的冲压成形工艺及模具设计,其中分别对模具的工作零部件等六大类零部件作详细设计。设计的主要内容包括冲裁件的工艺分析及工艺方案的确定、工艺计算、冲裁模具的设计、模具的安装与调整等。

在工艺计算部分要对排样设计与计算、冲压力的计算、模具压力中心的确定、凸凹模尺寸并确定制造公差的计算与计算等内容详细计算。

在冲裁模的设计部分要对工作零件、定位零件、卸料与顶件零件、导向零件连接与固定零件等结构进行详细的分析设计。要在设计过程中了解模具的工作过程和注意标准的选用,对复合冲裁模的结构有进一步的了解。

模具的安装与调试部分要注意导柱模具与无导柱模具的安装方法及顺序,通过模具的安装,了解模具的组成及各部分零部件的作用等。注意模具安装过后的试冲过程中常见的缺陷与解决方法等。

通过这次设计要对复合模具有更近一步的了解,在设计时要注意模具结构简单、模具使用方便、模具寿命高等问题。并且要提高生产效率,保证产品的质量。

关键词:落料拉深 试冲 间隙配合 过渡配合

Abstract

This graduate design is to the request of the top dust sheet molding tool design, the difference wait to the work zero parts of the molding tool six the parts of big zeros make the detailed design.The main contents of designing includes to wash to cut a piece craft analysis and craft projects really settle, craft calculation, the gearing of the design, molding tool that wash to cut the molding tool and adjust etc..

Compute in the craft the part want to be to the row kind design and calculation, wash the calculation, molding tool pressure of the pressure center to really settle, convex and cave mold size and make sure the calculation that make the business trip and compute the detailed calculation in contents in etc..

Cut the mold to want at the design part that wash to the work spare parts, position the spare parts and unload to anticipate with a spare parts, lead to spare parts conjunction with fix spare parts etc. construction the proceeding the detailed analysis design.Want to be in design process work process of understanding the molding tool with notice to choose to use standardly, to reunite the construction that wash the understanding that cut the mold further have.

The gearing of the molding tool with adjust to try the part want to notice to lead the pillar molding tool to lead the pillar molding tool with gearing method and sequences that have nos, passing the gearing of the molding tool, understanding the molding tool constitute and function etc. of each parts of the parts of zeros.Noticing the molding tool installs to try to wash the familiar blemish of inside of process later on and solution method etc..

Pass this time graduate the design want to have the nearer and one-step understanding to the compound molding tool, while designing to notice the molding tool construction simple, molding tool usage convenience, high etc. in life span in molding tool problem.And increase production efficiency, guarantee the quantity of the product.

Key phrase:The compound mold tries to hurtle the cleft the match transition match

绪 论 1

一、零件及其冲压工艺分析 4

一、零件及其冲压工艺分析 4

1.1 工艺计算 4

1.2 毛坯尺寸的计算 5

1.3 拉深次数的确定 5

二、工艺方案的确定 6

三、主要工艺参数的计算 7

3.1 毛坯尺寸的计算 7

3.2 排样及相关尺寸的计算 8

3.3 冲压工序压力的计算 8

四、模具工作部分尺寸的计算 11

4.1 拉深模的间隙 11

4.2 拉深模的圆角半径 11

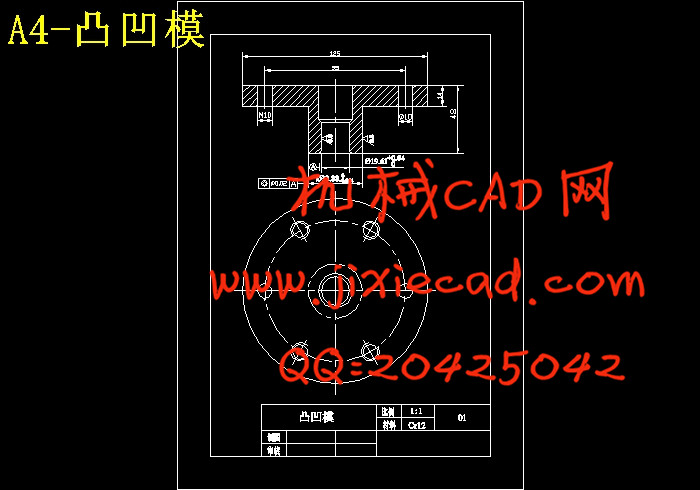

4.3 凸凹模工作部分的尺寸和公差 11

五、计算成型部件的尺寸 12

5.1 冲裁凸、凹模刃口尺寸的计算 12

六、模具总体设计 13

6.1 模具类型的选择 13

6.2 定位方式的选择 13

6.3 卸料、出件方式 13

6.4 连接与固定零件的选择 13

6.5 导向方式的选择 14

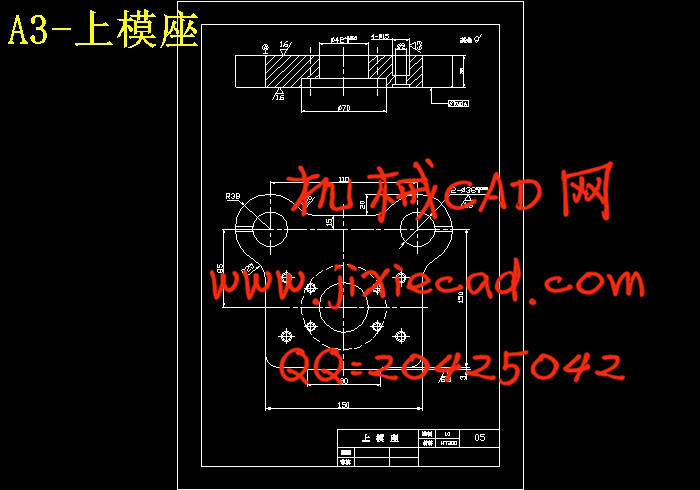

七、主要零部件设计 15

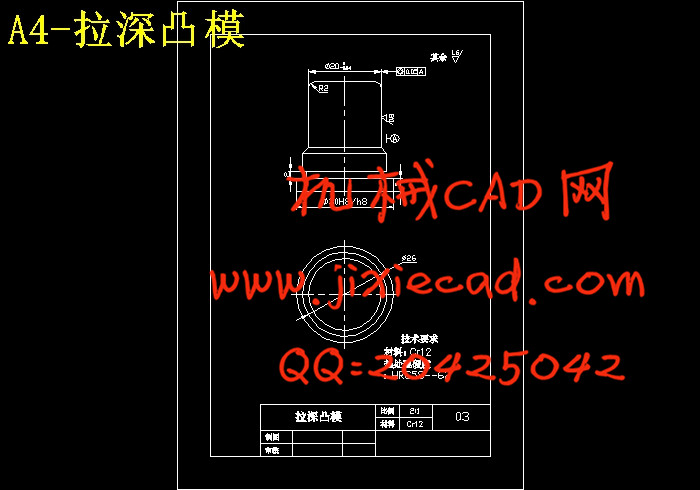

7.1 工作零件的结构设计 15

7.2 其他零部件的设计与选用 15

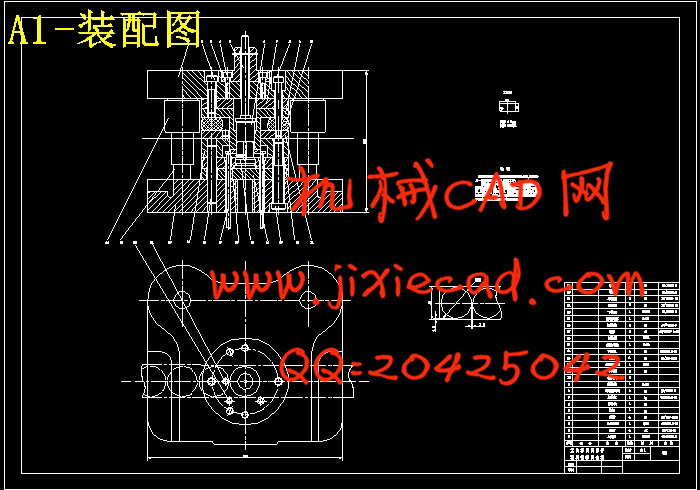

八、 模具总装图 17

九、 工作零件的加工工艺 18

9.1 冲裁凸凹模的主要技术要求 18

9.2 冲模工作零件的材料和热处理 18

9.3 凸模加工工艺过程 18

十、 模具的装配 19

10.1 装配下模部分 19

10.2 装配上模部分 19

10.3 冲裁模具的试冲 20

结 论 21

致 谢 22

参考文献 23

1.2 毛坯尺寸的计算 5

1.3 拉深次数的确定 5

二、工艺方案的确定 6

三、主要工艺参数的计算 7

3.1 毛坯尺寸的计算 7

3.2 排样及相关尺寸的计算 8

3.3 冲压工序压力的计算 8

四、模具工作部分尺寸的计算 11

4.1 拉深模的间隙 11

4.2 拉深模的圆角半径 11

4.3 凸凹模工作部分的尺寸和公差 11

五、计算成型部件的尺寸 12

5.1 冲裁凸、凹模刃口尺寸的计算 12

六、模具总体设计 13

6.1 模具类型的选择 13

6.2 定位方式的选择 13

6.3 卸料、出件方式 13

6.4 连接与固定零件的选择 13

6.5 导向方式的选择 14

七、主要零部件设计 15

7.1 工作零件的结构设计 15

7.2 其他零部件的设计与选用 15

八、 模具总装图 17

九、 工作零件的加工工艺 18

9.1 冲裁凸凹模的主要技术要求 18

9.2 冲模工作零件的材料和热处理 18

9.3 凸模加工工艺过程 18

十、 模具的装配 19

10.1 装配下模部分 19

10.2 装配上模部分 19

10.3 冲裁模具的试冲 20

结 论 21

致 谢 22

参考文献 23