设计简介

五速轮 锻模和切边冲孔复合模设计

摘要

目前,随着汽车及轻工业的迅速发展,模具设计制造日益受到人们的广泛关注,已成为一个行业。将高新技术应用于模具设计与制造,已成为快速制造优质模具的有力保证.国外工业先进国家都拥有上万个模具企业与支持模具企业或为模具企业提供生产装备的企业相组成的强大的产业基础。这是为适应社会产品工业化规模生产的重要条件和特点。本文介绍了模具设计的定义,模具的现状与未来走向,和模具设计的应用,模具设计的教育和改革。

关键词:模具;设计;应用;未来;教育

Five-speed Wheel Forging Die And Trimming Punching Composite Mold Design

Abstract

At present, along with rapid development of the automobile and light industry , mold design and manufacturing increase the wide attention of people.It has became an industry. High and new technology will be applied to the mold design and manufacturing.it has became the rapid manufacturing of die quality guarantee.foreign advanced industrial countries have tens of thousands of mould enterprises and supporting for die mold enterprises or providing production equipment enterprises They become strong industry base. This is in order to adapt to the social product of industrial scale production of important conditions and characteristics. This paper introduced the mold design definition, present situation and future trend of mold, and mold design, mold design education and reform.

Key words:Mold design;application; future; education

目录

绪论 1

1模锻件图设计 8

1.1 绘制锻件图的过程 8

1.1.1 确定分模位置 9

1.1.2 确定公差和加工余量 9

1.1.3 模锻斜度 10

1.1.4 圆角半径 10

1.1.5 技术条件 10

1.2 计算锻件的主要参数 10

2模锻变形工步的确定 11

2.1 绘制计算毛坯图 11

2.2 制坯工步选择 11

3确定坯料尺寸 14

3.1 坯料尺寸 14

4确定锻锤吨位 15

4.1 锻锤吨位设计 15

5锤锻模型槽设计 16

5.1 模锻工步型槽设计 16

5.1.1 确定毛边槽形式和尺寸 16

5.1.2 确定钳口 17

5.1.3 确定终锻型槽 18

5.1.4 设计预锻型槽 19

5.2 制坯型槽设计 20

5.2.1 滚挤型槽的设计 20

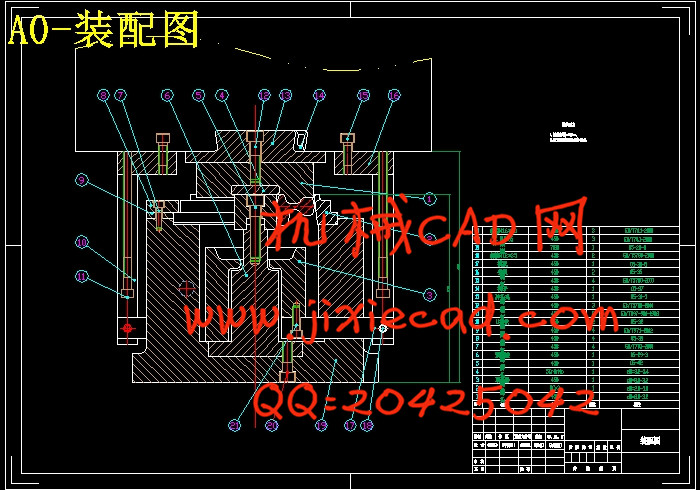

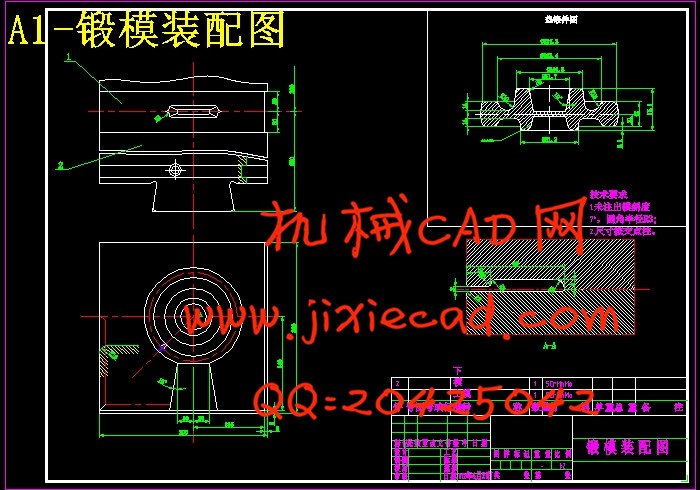

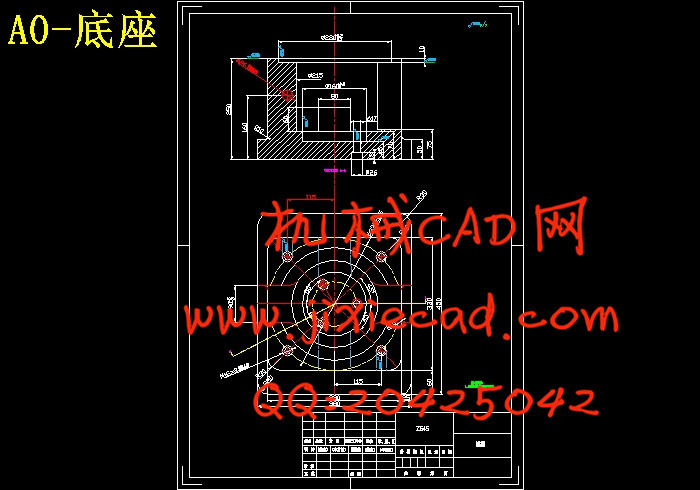

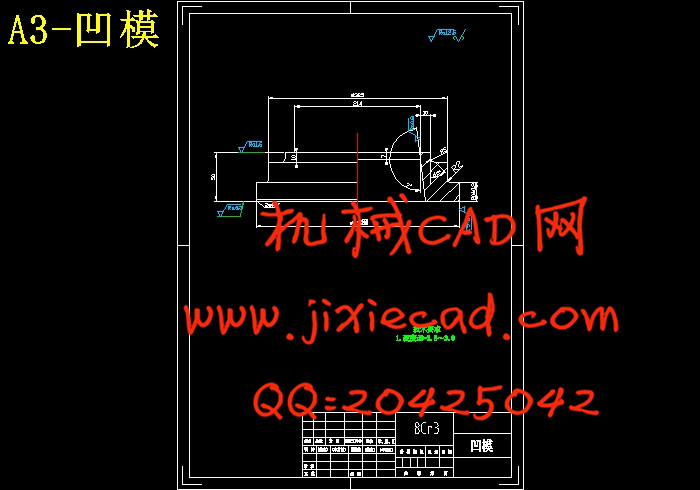

6锻模结构设计 21

7锻前加热、锻后冷却及热处理要求的确定 22

7.1 确定加热方式,及锻造温度范围 22

7.2 确定加热时间 22

7.3确定冷却方式及规范 22

结论 23

致谢 24

参考文献 25

摘要

目前,随着汽车及轻工业的迅速发展,模具设计制造日益受到人们的广泛关注,已成为一个行业。将高新技术应用于模具设计与制造,已成为快速制造优质模具的有力保证.国外工业先进国家都拥有上万个模具企业与支持模具企业或为模具企业提供生产装备的企业相组成的强大的产业基础。这是为适应社会产品工业化规模生产的重要条件和特点。本文介绍了模具设计的定义,模具的现状与未来走向,和模具设计的应用,模具设计的教育和改革。

关键词:模具;设计;应用;未来;教育

Five-speed Wheel Forging Die And Trimming Punching Composite Mold Design

Abstract

At present, along with rapid development of the automobile and light industry , mold design and manufacturing increase the wide attention of people.It has became an industry. High and new technology will be applied to the mold design and manufacturing.it has became the rapid manufacturing of die quality guarantee.foreign advanced industrial countries have tens of thousands of mould enterprises and supporting for die mold enterprises or providing production equipment enterprises They become strong industry base. This is in order to adapt to the social product of industrial scale production of important conditions and characteristics. This paper introduced the mold design definition, present situation and future trend of mold, and mold design, mold design education and reform.

Key words:Mold design;application; future; education

目录

绪论 1

1模锻件图设计 8

1.1 绘制锻件图的过程 8

1.1.1 确定分模位置 9

1.1.2 确定公差和加工余量 9

1.1.3 模锻斜度 10

1.1.4 圆角半径 10

1.1.5 技术条件 10

1.2 计算锻件的主要参数 10

2模锻变形工步的确定 11

2.1 绘制计算毛坯图 11

2.2 制坯工步选择 11

3确定坯料尺寸 14

3.1 坯料尺寸 14

4确定锻锤吨位 15

4.1 锻锤吨位设计 15

5锤锻模型槽设计 16

5.1 模锻工步型槽设计 16

5.1.1 确定毛边槽形式和尺寸 16

5.1.2 确定钳口 17

5.1.3 确定终锻型槽 18

5.1.4 设计预锻型槽 19

5.2 制坯型槽设计 20

5.2.1 滚挤型槽的设计 20

6锻模结构设计 21

7锻前加热、锻后冷却及热处理要求的确定 22

7.1 确定加热方式,及锻造温度范围 22

7.2 确定加热时间 22

7.3确定冷却方式及规范 22

结论 23

致谢 24

参考文献 25