设计简介

摘要

本文是关于消声器后盖复合模设计及制造工艺分析的研究。

消声器是允许气流通过,却又能阻止或减小声音传播的一种器件,是消除空气动力

性噪声的重要措施。消声器能够阻挡声波的传播,允许气流通过,是控制噪声的有效工

具。采用复合模是因为复合模具有生产效率高、冲压件质量高的特点。且使用复合摸能

在一个模具上完成整个零件的加工。而消声器的制造是通过将板类加工而成,将板类金

属加工成毛坯,然后经过冲孔、拉深、翻孔、翻边等工艺工序。而在研究过程中必须要

经过计算才能得出各冲孔、拉深、翻孔、翻边的凸凹模的尺寸,然后再结合使用寿命、

精度、拆装方便等要求确定凸凹模尺寸。然后再根据计算结果选用合适的模架、螺钉等

其他零件,并且根据要求选用合适的压力机设备,通过进一步的计算确定所选的零件是

否可以用,而压力机设备的选用必须考虑其过载情况,因为一旦过载就会造成人员和设

备的危险。本次零件外形简单对称,所有尺寸均为自由公差,对与零件在拉伸等变形后

的厚度变化没有要求,只要求表面不允许有皱着、划痕、开裂等缺陷,并且断裂口要求

平整因此该零件可以经过冷冲压加工成型。由于该零件是大批量生产,所以在进行设计

时应当要注意总体结构尺寸不能过大并且要简单。

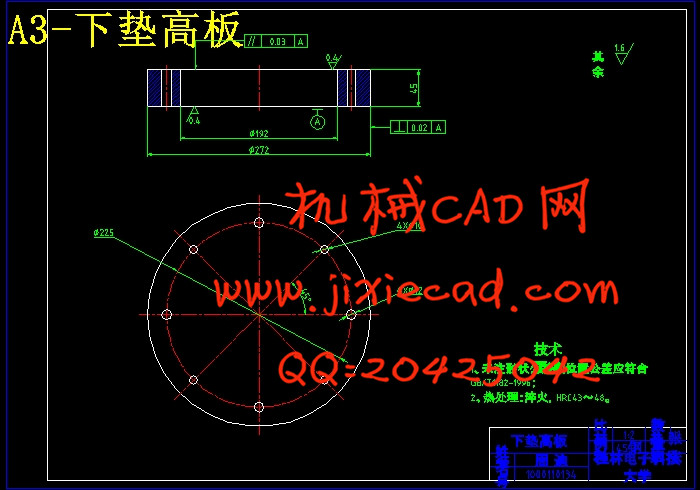

通过计算得到零件的尺寸后使用二维 CAD软件画出零件图,并通过零件图的装配

得到整个模具的装配图。最后经过修改得到总装配图。并制作出凹模加工工序、凸模加

工工序、凸凹模加工工序。最后编写出装配过程。

关键词:模具;冲压;拉深;翻孔;翻边;CAD画图

Abstract

This paper is about the muffler back cover compound die design and manufacturing

process analysis research.

Muffler is allowed to flow through, but also can prevent or reduce the spread of voice

device, is one of the important measures to eliminate the air dynamic noise. Muffler can

prevent the spread of sound waves, allowing the airflow through, is an effective tool to control

noise. Using composite die because composite modulus has the characteristics of the

production of high efficiency and high quality of stamping parts. And the use of composite

touch can complete the whole parts in a mold processing. And the manufacture of muffler is

by putting a plate type and plate type metal processing into blank, and then after punching and

deep drawing, turn over the hole and flanging process procedure. And in the process of

research must be calculated to various punching, deep drawing, double the size of the hole

flanging, intensive, and then combined with the service life, accuracy, the requirement of

dismantling is convenient wait for a convex concave die size. And then according to the

calculation results to choose appropriate die set, screws and other parts, and choose proper

press equipment according to the requirement, by further calculation to determine whether the

selected parts can be used, and the selection of press equipment must consider its overload

situation, because once the overload will cause the risk of personnel and equipment. The

simple parts shape is symmetrical, all size tolerance for freedom, the changes with the

thickness of the parts after the tensile deformation such as there is no requirement, only

require surface are not allowed to have a wrinkly, scratches, cracking and other defects, and

fracture require flat so the parts can pass cold stamping molding. Because the parts are mass

production, so in the design should pay attention to the overall structure size not too big and

simple.

Is obtained by computing the size of the parts after using A two-dimensional CAD

software draw the part drawing, and through the assembly to get the part drawing in the mold

assembly drawing. The last modified general assembly drawing. Machining process and

making the concave die, punch processing working procedure, intensive processing process.

The last write assembly process.

Keywords:mold;Stamping;Deep drawing;Double hole;Flanging;CAD drawing

目录

1引言.................................................................................................... 1

1.1模具的发展前景...................................................................................................................................1

1.1.1中国模具市场前景广阔....................................................................................................1

1.1.2模具产品市场竞争力不断提升........................................................................................1

1.1.3模具行业发展速度持续增长............................................................................................1

1.1.4模具行业机遇和挑战并存................................................................................................1

1.2冷冲模的发展........................................................................................................................................2

2工艺方案的分析...................................................................................3

2.1零件工艺性分析...................................................................................................................................3

2.2工艺方案的分析和确定......................................................................................................3

2.3确定排样方式........................................................................................................................................4

2.3.1计算材料利用率................................................................................................................4

2.3.2确定排样方案....................................................................................................................6

3消声器后盖展开形状及尺寸的确定...................................................... 7

3.1冲孔、翻边部分展开计算.................................................................................................................7

3.2拉深件展开计算....................................................................................................................................7

3.2.1确定修边余量....................................................................................................................8

3.2.2确定拉深工件毛坯直径....................................................................................................8

4拉深工序主要工艺参数计算.................................................................9

4.1确定是否用压边圈.............................................................................................................................. 9

4.2拉深次数和拉深系数的确定............................................................................................................9

4.3拉深模的圆角半径..............................................................................................................9

5四工序复合模的设计..........................................................................10

5.1计算总压力..........................................................................................................................................10

5.1.1冲裁力的计算..................................................................................................................10

5.1.2卸料力的计算..................................................................................................................10

5.1.3冲孔力的计算..................................................................................................................10

5.1.4顶件力的计算..................................................................................................................11

5.1.5拉深力的计算..................................................................................................................11

5.1.6压边力的计算..................................................................................................................12

5.1.7翻边力的计算..................................................................................................................13

5.1.8总压力的计算..................................................................................................................13

5.2压力机吨位的选择............................................................................................................................13

5.3确定模具压力中心............................................................................................................................13

5.4模具工作部分尺寸计算...................................................................................................................13

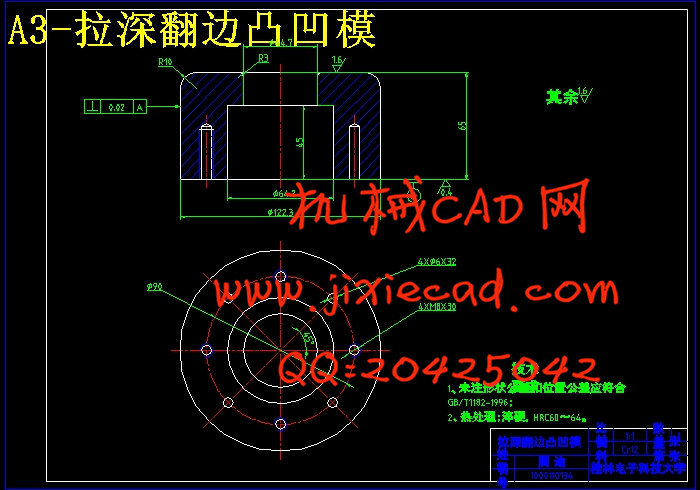

5.5四工序复合模结构的设计..............................................................................................................17

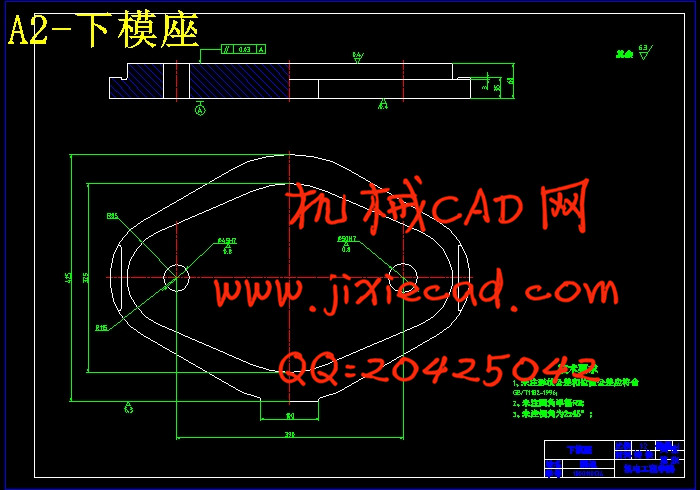

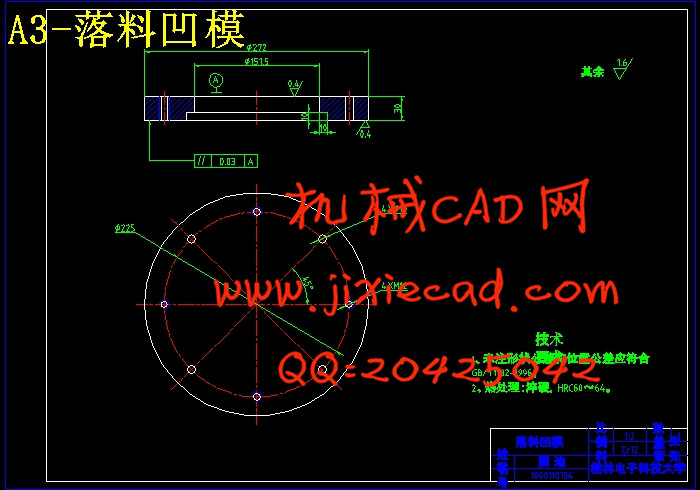

5.5.1凹模..................................................................................................................................17

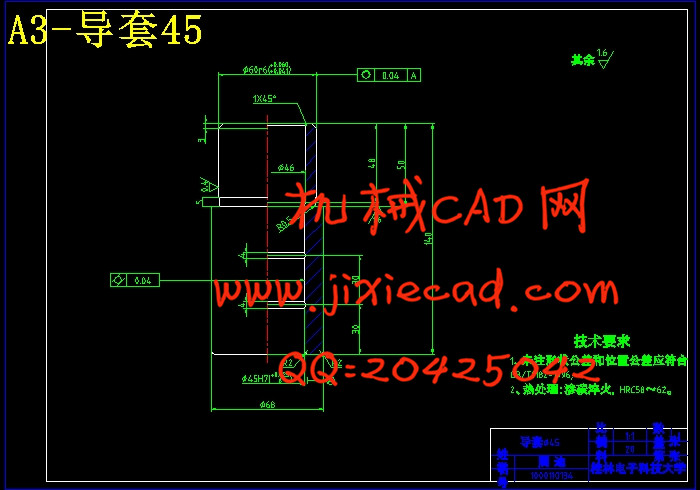

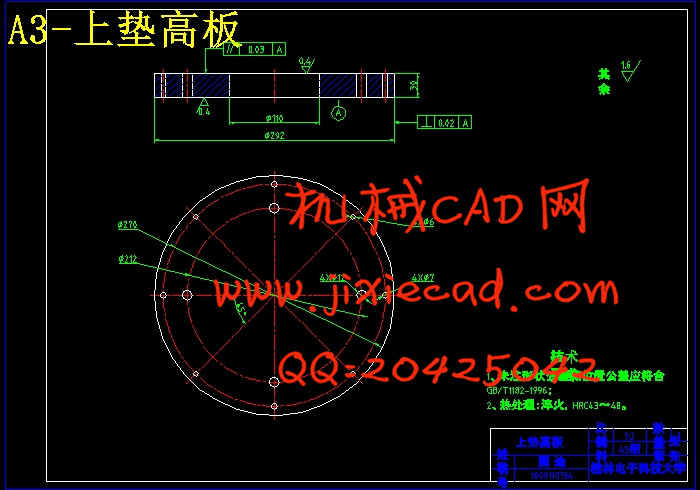

5.5.2选择模架及确定其他冲模零件......................................................................................19

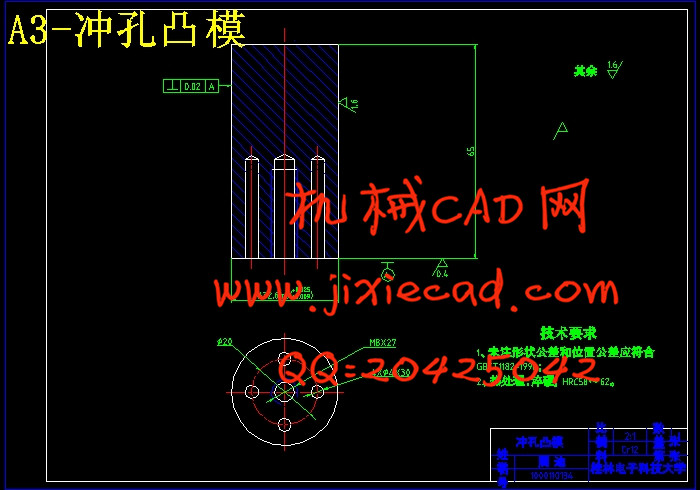

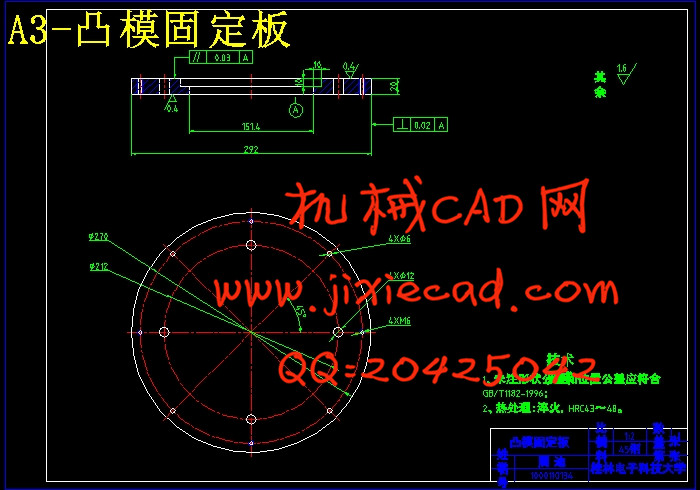

5.5.3凸模..................................................................................................................................21

5.5.4冲模各零件的材料及热处理要求..................................................................................22

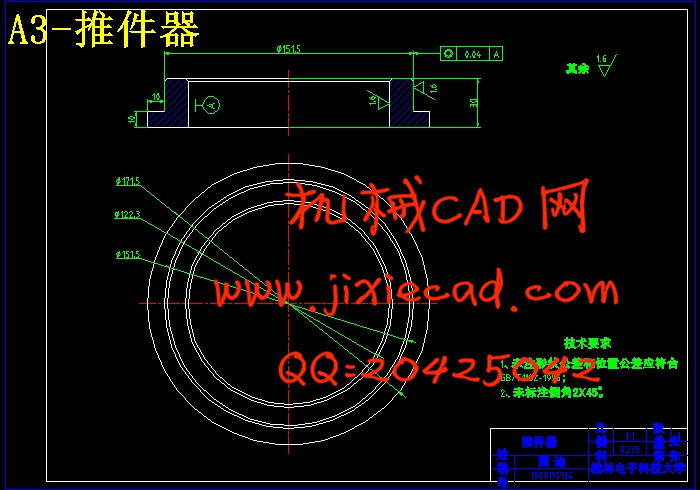

5.5.5卸料板确定......................................................................................................................23

5.5.6模具结构的计算..............................................................................................................24

5.5.7冲压设备的选择..............................................................................................................24

6四工序复合模的制造..........................................................................26

6.1冲模制造的概述..................................................................................................................................26

6.2冲模具体制造过程.............................................................................................................................27

6.2.1冷冲模模架的制造..........................................................................................................27

6.2.2冲模成形零件的加工......................................................................................................27

7四工序复合模的装配说明书............................................................... 30

总结.....................................................................................................34

谢辞.....................................................................................................35

参考文献.................................................................................................36

本文是关于消声器后盖复合模设计及制造工艺分析的研究。

消声器是允许气流通过,却又能阻止或减小声音传播的一种器件,是消除空气动力

性噪声的重要措施。消声器能够阻挡声波的传播,允许气流通过,是控制噪声的有效工

具。采用复合模是因为复合模具有生产效率高、冲压件质量高的特点。且使用复合摸能

在一个模具上完成整个零件的加工。而消声器的制造是通过将板类加工而成,将板类金

属加工成毛坯,然后经过冲孔、拉深、翻孔、翻边等工艺工序。而在研究过程中必须要

经过计算才能得出各冲孔、拉深、翻孔、翻边的凸凹模的尺寸,然后再结合使用寿命、

精度、拆装方便等要求确定凸凹模尺寸。然后再根据计算结果选用合适的模架、螺钉等

其他零件,并且根据要求选用合适的压力机设备,通过进一步的计算确定所选的零件是

否可以用,而压力机设备的选用必须考虑其过载情况,因为一旦过载就会造成人员和设

备的危险。本次零件外形简单对称,所有尺寸均为自由公差,对与零件在拉伸等变形后

的厚度变化没有要求,只要求表面不允许有皱着、划痕、开裂等缺陷,并且断裂口要求

平整因此该零件可以经过冷冲压加工成型。由于该零件是大批量生产,所以在进行设计

时应当要注意总体结构尺寸不能过大并且要简单。

通过计算得到零件的尺寸后使用二维 CAD软件画出零件图,并通过零件图的装配

得到整个模具的装配图。最后经过修改得到总装配图。并制作出凹模加工工序、凸模加

工工序、凸凹模加工工序。最后编写出装配过程。

关键词:模具;冲压;拉深;翻孔;翻边;CAD画图

Abstract

This paper is about the muffler back cover compound die design and manufacturing

process analysis research.

Muffler is allowed to flow through, but also can prevent or reduce the spread of voice

device, is one of the important measures to eliminate the air dynamic noise. Muffler can

prevent the spread of sound waves, allowing the airflow through, is an effective tool to control

noise. Using composite die because composite modulus has the characteristics of the

production of high efficiency and high quality of stamping parts. And the use of composite

touch can complete the whole parts in a mold processing. And the manufacture of muffler is

by putting a plate type and plate type metal processing into blank, and then after punching and

deep drawing, turn over the hole and flanging process procedure. And in the process of

research must be calculated to various punching, deep drawing, double the size of the hole

flanging, intensive, and then combined with the service life, accuracy, the requirement of

dismantling is convenient wait for a convex concave die size. And then according to the

calculation results to choose appropriate die set, screws and other parts, and choose proper

press equipment according to the requirement, by further calculation to determine whether the

selected parts can be used, and the selection of press equipment must consider its overload

situation, because once the overload will cause the risk of personnel and equipment. The

simple parts shape is symmetrical, all size tolerance for freedom, the changes with the

thickness of the parts after the tensile deformation such as there is no requirement, only

require surface are not allowed to have a wrinkly, scratches, cracking and other defects, and

fracture require flat so the parts can pass cold stamping molding. Because the parts are mass

production, so in the design should pay attention to the overall structure size not too big and

simple.

Is obtained by computing the size of the parts after using A two-dimensional CAD

software draw the part drawing, and through the assembly to get the part drawing in the mold

assembly drawing. The last modified general assembly drawing. Machining process and

making the concave die, punch processing working procedure, intensive processing process.

The last write assembly process.

Keywords:mold;Stamping;Deep drawing;Double hole;Flanging;CAD drawing

目录

1引言.................................................................................................... 1

1.1模具的发展前景...................................................................................................................................1

1.1.1中国模具市场前景广阔....................................................................................................1

1.1.2模具产品市场竞争力不断提升........................................................................................1

1.1.3模具行业发展速度持续增长............................................................................................1

1.1.4模具行业机遇和挑战并存................................................................................................1

1.2冷冲模的发展........................................................................................................................................2

2工艺方案的分析...................................................................................3

2.1零件工艺性分析...................................................................................................................................3

2.2工艺方案的分析和确定......................................................................................................3

2.3确定排样方式........................................................................................................................................4

2.3.1计算材料利用率................................................................................................................4

2.3.2确定排样方案....................................................................................................................6

3消声器后盖展开形状及尺寸的确定...................................................... 7

3.1冲孔、翻边部分展开计算.................................................................................................................7

3.2拉深件展开计算....................................................................................................................................7

3.2.1确定修边余量....................................................................................................................8

3.2.2确定拉深工件毛坯直径....................................................................................................8

4拉深工序主要工艺参数计算.................................................................9

4.1确定是否用压边圈.............................................................................................................................. 9

4.2拉深次数和拉深系数的确定............................................................................................................9

4.3拉深模的圆角半径..............................................................................................................9

5四工序复合模的设计..........................................................................10

5.1计算总压力..........................................................................................................................................10

5.1.1冲裁力的计算..................................................................................................................10

5.1.2卸料力的计算..................................................................................................................10

5.1.3冲孔力的计算..................................................................................................................10

5.1.4顶件力的计算..................................................................................................................11

5.1.5拉深力的计算..................................................................................................................11

5.1.6压边力的计算..................................................................................................................12

5.1.7翻边力的计算..................................................................................................................13

5.1.8总压力的计算..................................................................................................................13

5.2压力机吨位的选择............................................................................................................................13

5.3确定模具压力中心............................................................................................................................13

5.4模具工作部分尺寸计算...................................................................................................................13

5.5四工序复合模结构的设计..............................................................................................................17

5.5.1凹模..................................................................................................................................17

5.5.2选择模架及确定其他冲模零件......................................................................................19

5.5.3凸模..................................................................................................................................21

5.5.4冲模各零件的材料及热处理要求..................................................................................22

5.5.5卸料板确定......................................................................................................................23

5.5.6模具结构的计算..............................................................................................................24

5.5.7冲压设备的选择..............................................................................................................24

6四工序复合模的制造..........................................................................26

6.1冲模制造的概述..................................................................................................................................26

6.2冲模具体制造过程.............................................................................................................................27

6.2.1冷冲模模架的制造..........................................................................................................27

6.2.2冲模成形零件的加工......................................................................................................27

7四工序复合模的装配说明书............................................................... 30

总结.....................................................................................................34

谢辞.....................................................................................................35

参考文献.................................................................................................36