设计简介

摘要

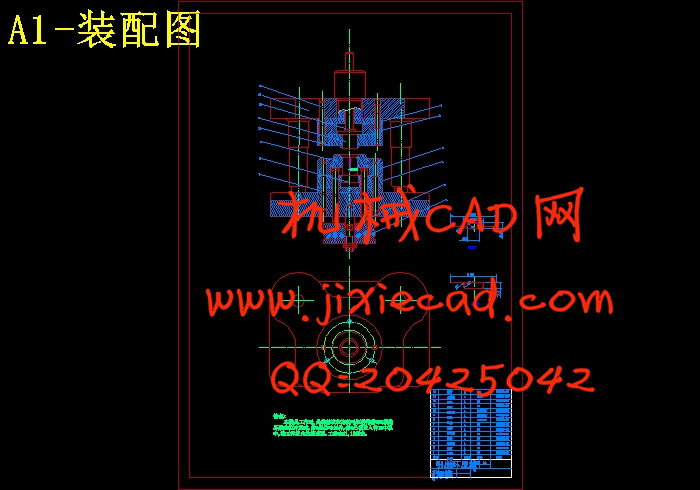

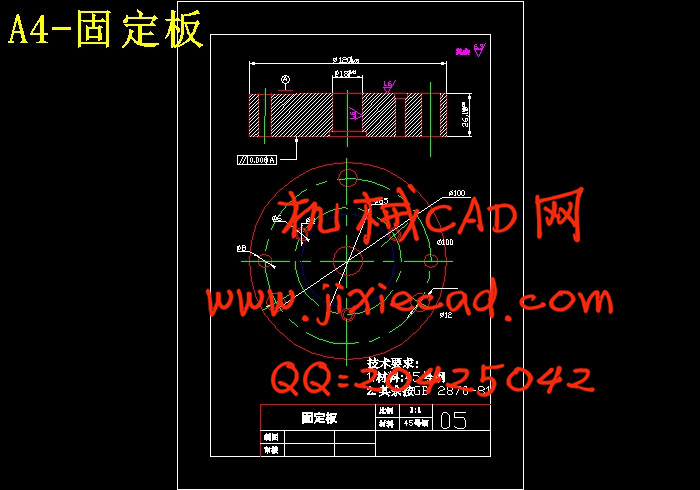

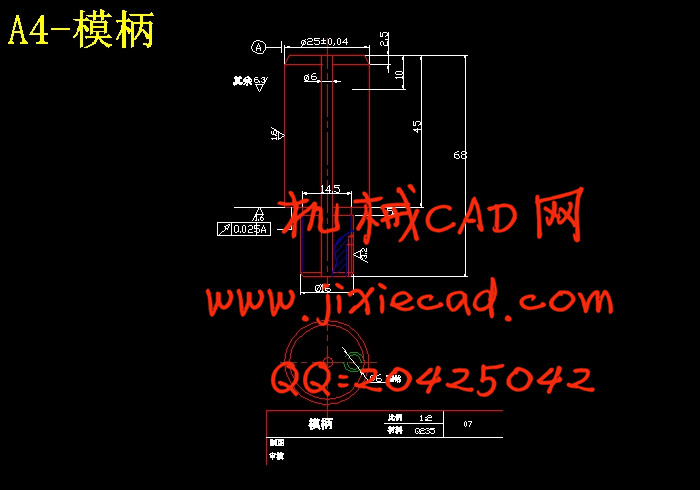

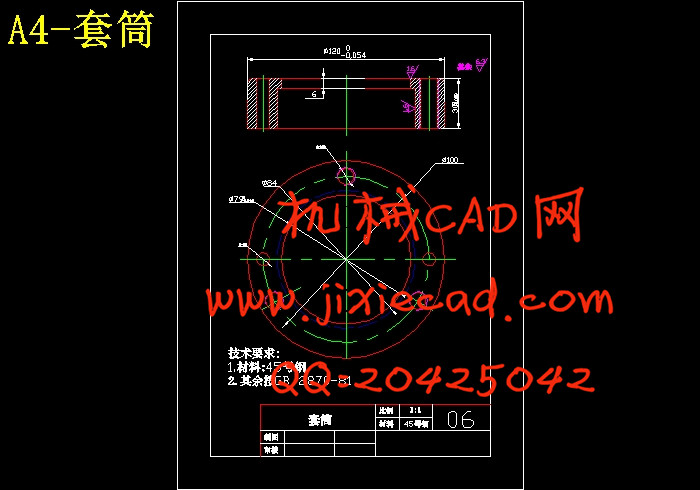

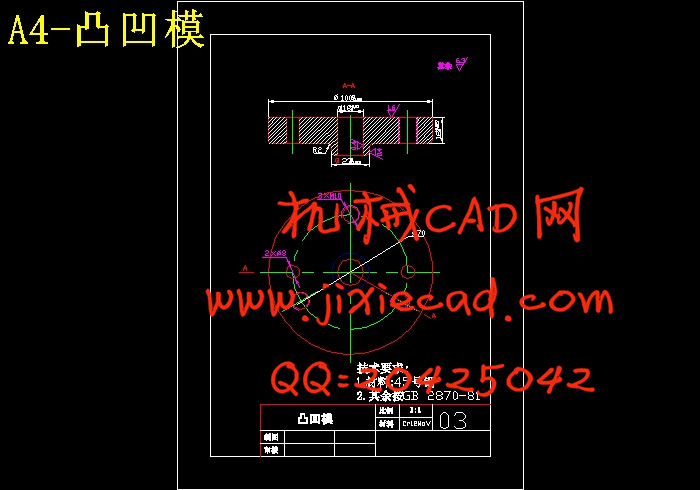

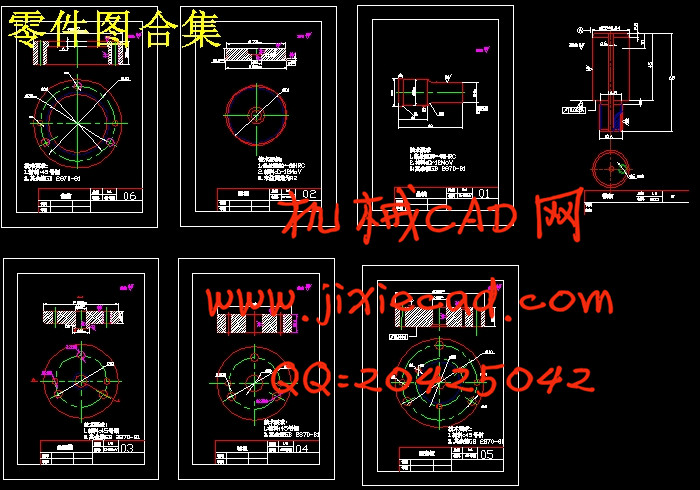

通过对制件的工艺计算及反拉深时的受力,应力及金属流动状态进行分析,设计并改进了反拉深模的结构,保证了零件尺寸的要求,消除了料厚变薄等缺陷,此模具结构简单,实用性强,提高劳动生产率,为保证模具冲裁间隙均匀性,凸模选用无机粘接剂,粘接固定,以消除制造误差,同时分析了该制件的工艺性。设计了拉深模具,并介绍了所用模具材料特点

关键词 拉深模 设计 料厚变薄 改进

Abstract

Through the technological calculation of the product and the analysis of the exerted force ,stree and metal flowing status when drawing for ward and backward,the back ward drawing die was desingal and improved in its structure,which ensured the requirement of the part dimensions and eliminated some defects such as the material thickness becoming thinner,The structure of the die for the technological process is simple and practical,it can increase the production efficiency,in order to ensure the uniformity of the blanking clearance of the die ,inorganic adhesive is used to bord and fix the punch to eliminate manufacturing errors,after an analysis of the technological property of the producte,the dimensions of the blank were determined and the drawing die for the part was designeal the characteristics of the die material were introduced at last.

Key words backward drawing die design material thickness getting thinner improvement

通过对制件的工艺计算及反拉深时的受力,应力及金属流动状态进行分析,设计并改进了反拉深模的结构,保证了零件尺寸的要求,消除了料厚变薄等缺陷,此模具结构简单,实用性强,提高劳动生产率,为保证模具冲裁间隙均匀性,凸模选用无机粘接剂,粘接固定,以消除制造误差,同时分析了该制件的工艺性。设计了拉深模具,并介绍了所用模具材料特点

关键词 拉深模 设计 料厚变薄 改进

Abstract

Through the technological calculation of the product and the analysis of the exerted force ,stree and metal flowing status when drawing for ward and backward,the back ward drawing die was desingal and improved in its structure,which ensured the requirement of the part dimensions and eliminated some defects such as the material thickness becoming thinner,The structure of the die for the technological process is simple and practical,it can increase the production efficiency,in order to ensure the uniformity of the blanking clearance of the die ,inorganic adhesive is used to bord and fix the punch to eliminate manufacturing errors,after an analysis of the technological property of the producte,the dimensions of the blank were determined and the drawing die for the part was designeal the characteristics of the die material were introduced at last.

Key words backward drawing die design material thickness getting thinner improvement