设计简介

摘 要

本设计题目为油箱盖冲压模设计,体现了拉深类零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者复合模设计的基础知识,为设计更复杂的复合模具做好了铺垫和吸取了更深刻的经验。

通过分析制件的工艺性可确定制件的成形加工需要一副复合模具完成。复合模是指冲床在一次行程中,完成落料、拉深、冲孔等多个工序的一种模具结构。相对其他冷冲压模具结构而言,它具有以下一些优点:①工件同轴度较好,表面平直,尺寸精度较高; ②生产效率高,受条料外形尺寸的精度限制较小。但需考虑的问题是:模具零部件加工制造比较困难,成本较高,并且凸凹模容易受到最小壁厚的限制

关键词:复合模 工艺性能 凸凹模 模具制造

Abstract

The requirement ,content and direction of the design of the deep thin wall plastic parts are embodied on this injection mould design of the plastic parts of long pipe box. The designer’s foundation knowledge of the injection mould design is reinforced and is able to design more complex injection mould through the design.

Through analyzes the workpiece the technology capability to bepossible to determine the workpiece the formed processing needs acompound mold to completeThe compound mold mean the punching machine is in a route of travel, completing to fall to anticipate, a kind of molding tool structure of several work prefaces of etc. of blunt bore.Opposite and other cold hurtle to press the molding tool structure but speeches, it has following some advantageses:The ① work piece is together the stalk degree is better, the surface is straight and even, the size accuracy is higher; The ② produces the efficiency high, be subjected to the anticipates the shape size of accuracy limit smaller.But need the problem of the consideration is:The molding tool zero partses process the manufacturing more difficulty, the cost is higher, and the convex and cave mold is subjected to the thick restrict of minimum wall easily.

Keyword:Compound mold craft function The convex and cave mold Molding tool manufacturing

目 录

1 绪论………………………………………………………………………1

1.1国内模具的现状和发展趋势…………………………………………1

1.1.1国内模具的现状……………………………………………………1

1.1.2国内模具的发展趋势………………………………………………3

1.2国外模具的现状和发展趋势…………………………………………5

2 冲压工艺分析 …………………………………………………………6

2.1油箱盖冲压工艺性分析 …………………………………………6

2.2冲压工艺方案的确定 ………………………………………………6

2.3主要设计计算 ………………………………………………………7

2.3.1 计算毛坯尺寸 ……………………………………………………7

2.3.2 翻边的工艺计算 ………………………………………………7

2.3.3成形次数的确定 …………………………………………………8

2.3.4排样…………………………………… …………………………8

2.3.5 冲压工序压力计算………………………………………………9

2.3.6 工作部分尺寸计算………………………………………………9

3 模具的总体设计………………………………………………………12

3.1模具类型的选择……………………………………………………12

3.2定位方式的选择……………………………………………………12

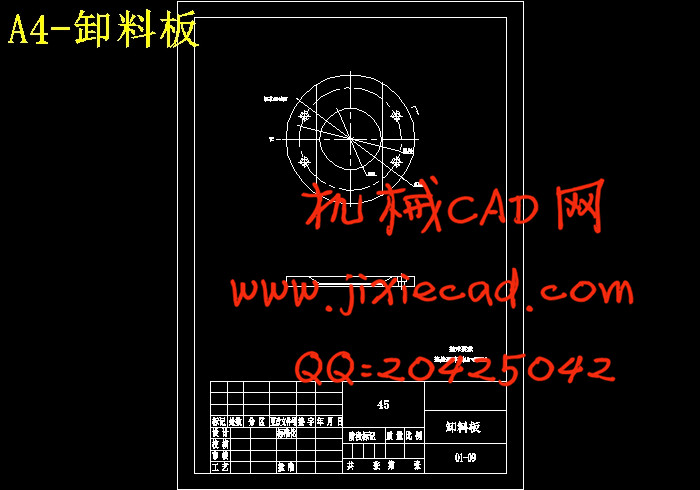

3.3卸料,出件方式的选择……………………………………………12

3.4导向方式的选择……………………………………………………13

4.主要零部件设计………………………… ……………………………14

4.1落料拉深凸凹模……………………………………………………14

4.2冲孔翻边凸凹模……………………………………………………15

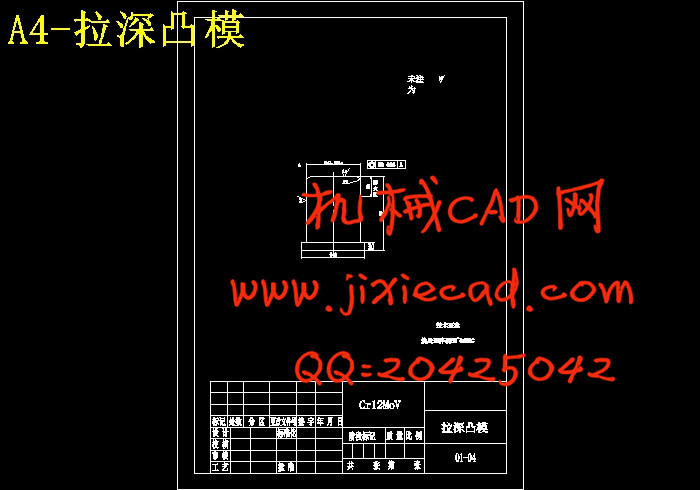

4.3拉深翻边凸凹模……………………………………………………16

4.4冲孔凸模……………………………………………………………16

4.5落料凹模……………………………………………………………17

4.6弹性元件的设计……………………………………………………17

4.7模架及其他零部件的选用 …………………………………………17

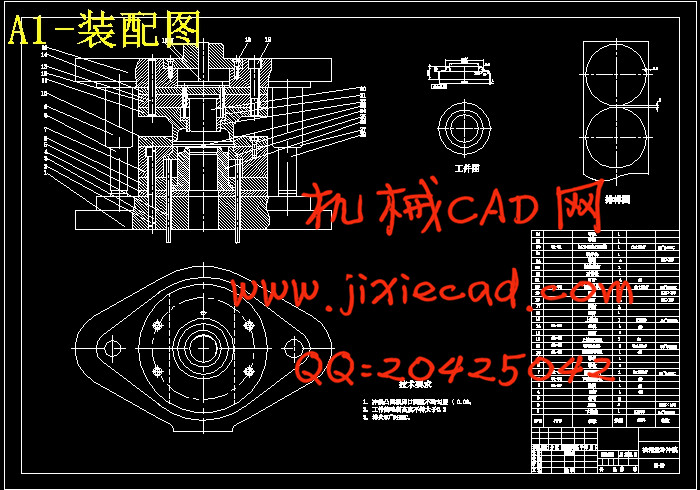

5.模具总装图………………………………………………………………17

6.工作零件的加工工艺……………………………………………………19

6.1 冲孔凸模加工工艺过程……………………………………………19

6.2 翻边冲孔凸凹模加工工艺过程……………………………………19

7 油箱盖模具的安装与调试………………………………………………19

7.1油箱盖模具的安装 …………………………………………………23

7.1.1拉深模的安装要求 ………………………………………………23

7.1.2拉深模的安装 ……………………………………………………24

7.2 深圆筒模具的调试…………………………………………………24

7.2.1 拉深模的调试要点………………………………………………24

7.2.1.1 进料阻力的调整………………………………………………24

7.2.1.2 拉深深度及间隙调整…………………………………………25

7.2.2 调整方法…………………………………………………………25

7.2.2.1 拉深时的破裂…………………………………………………25

7.2.2.2 拉深高度不够…………………………………………………25

7.2.2.3 制件底部被拉脱………………………………………………25

7.2.2.4 制品口缘折皱…………………………………………………26

7.2.2.5 拉深高度太大…………………………………………………26

7.2.2.6 零件拉深后壁厚与高度不均…………………………………26

结论…………………………………………………………………………27

致谢…………………………………………………………………………28

参考文献 …………………………………………………………………29

本设计题目为油箱盖冲压模设计,体现了拉深类零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者复合模设计的基础知识,为设计更复杂的复合模具做好了铺垫和吸取了更深刻的经验。

通过分析制件的工艺性可确定制件的成形加工需要一副复合模具完成。复合模是指冲床在一次行程中,完成落料、拉深、冲孔等多个工序的一种模具结构。相对其他冷冲压模具结构而言,它具有以下一些优点:①工件同轴度较好,表面平直,尺寸精度较高; ②生产效率高,受条料外形尺寸的精度限制较小。但需考虑的问题是:模具零部件加工制造比较困难,成本较高,并且凸凹模容易受到最小壁厚的限制

关键词:复合模 工艺性能 凸凹模 模具制造

Abstract

The requirement ,content and direction of the design of the deep thin wall plastic parts are embodied on this injection mould design of the plastic parts of long pipe box. The designer’s foundation knowledge of the injection mould design is reinforced and is able to design more complex injection mould through the design.

Through analyzes the workpiece the technology capability to bepossible to determine the workpiece the formed processing needs acompound mold to completeThe compound mold mean the punching machine is in a route of travel, completing to fall to anticipate, a kind of molding tool structure of several work prefaces of etc. of blunt bore.Opposite and other cold hurtle to press the molding tool structure but speeches, it has following some advantageses:The ① work piece is together the stalk degree is better, the surface is straight and even, the size accuracy is higher; The ② produces the efficiency high, be subjected to the anticipates the shape size of accuracy limit smaller.But need the problem of the consideration is:The molding tool zero partses process the manufacturing more difficulty, the cost is higher, and the convex and cave mold is subjected to the thick restrict of minimum wall easily.

Keyword:Compound mold craft function The convex and cave mold Molding tool manufacturing

目 录

1 绪论………………………………………………………………………1

1.1国内模具的现状和发展趋势…………………………………………1

1.1.1国内模具的现状……………………………………………………1

1.1.2国内模具的发展趋势………………………………………………3

1.2国外模具的现状和发展趋势…………………………………………5

2 冲压工艺分析 …………………………………………………………6

2.1油箱盖冲压工艺性分析 …………………………………………6

2.2冲压工艺方案的确定 ………………………………………………6

2.3主要设计计算 ………………………………………………………7

2.3.1 计算毛坯尺寸 ……………………………………………………7

2.3.2 翻边的工艺计算 ………………………………………………7

2.3.3成形次数的确定 …………………………………………………8

2.3.4排样…………………………………… …………………………8

2.3.5 冲压工序压力计算………………………………………………9

2.3.6 工作部分尺寸计算………………………………………………9

3 模具的总体设计………………………………………………………12

3.1模具类型的选择……………………………………………………12

3.2定位方式的选择……………………………………………………12

3.3卸料,出件方式的选择……………………………………………12

3.4导向方式的选择……………………………………………………13

4.主要零部件设计………………………… ……………………………14

4.1落料拉深凸凹模……………………………………………………14

4.2冲孔翻边凸凹模……………………………………………………15

4.3拉深翻边凸凹模……………………………………………………16

4.4冲孔凸模……………………………………………………………16

4.5落料凹模……………………………………………………………17

4.6弹性元件的设计……………………………………………………17

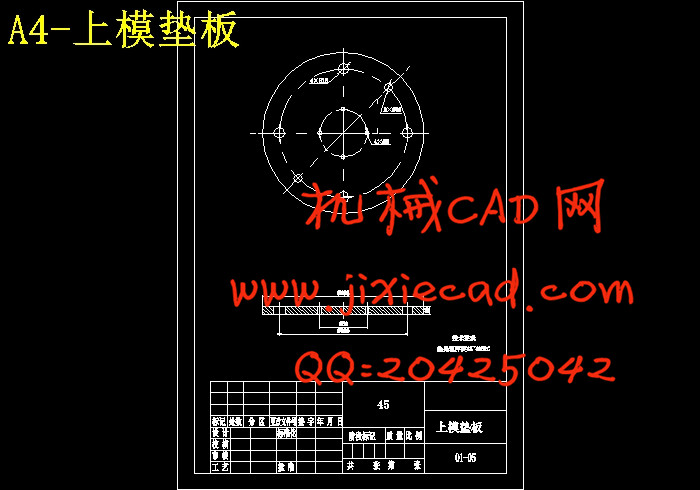

4.7模架及其他零部件的选用 …………………………………………17

5.模具总装图………………………………………………………………17

6.工作零件的加工工艺……………………………………………………19

6.1 冲孔凸模加工工艺过程……………………………………………19

6.2 翻边冲孔凸凹模加工工艺过程……………………………………19

7 油箱盖模具的安装与调试………………………………………………19

7.1油箱盖模具的安装 …………………………………………………23

7.1.1拉深模的安装要求 ………………………………………………23

7.1.2拉深模的安装 ……………………………………………………24

7.2 深圆筒模具的调试…………………………………………………24

7.2.1 拉深模的调试要点………………………………………………24

7.2.1.1 进料阻力的调整………………………………………………24

7.2.1.2 拉深深度及间隙调整…………………………………………25

7.2.2 调整方法…………………………………………………………25

7.2.2.1 拉深时的破裂…………………………………………………25

7.2.2.2 拉深高度不够…………………………………………………25

7.2.2.3 制件底部被拉脱………………………………………………25

7.2.2.4 制品口缘折皱…………………………………………………26

7.2.2.5 拉深高度太大…………………………………………………26

7.2.2.6 零件拉深后壁厚与高度不均…………………………………26

结论…………………………………………………………………………27

致谢…………………………………………………………………………28

参考文献 …………………………………………………………………29