设计简介

支撑板冲压成形工艺及模具设计

摘 要:本设计课题介绍了弯曲、冲裁复合模的结构设计及工作过程。针对零件挤切后口部呈尖锐刃口状现象,改进了模具结构,消除部分加工缺陷,分体现了冲压工艺先进性和高效性,有一定的设计意义。通过对工艺零件的工艺分析及模具结构设计, 巩固所学的知识、熟悉有关资料,树立正确的设计思路,加强了对模具的整体认识,提高自己的实际模具设计工作能力。

本计运用了冲压成形模具设计的基本知识,首先对整个零件的了解分析工艺参数,冲压工艺性能,然后确定冲压模的结构形式,工零部件的设计与计算,弯曲和切边在一个工序上完成,本副模具优点结构简单紧凑,易于加工维修。

关键词:工艺分析; 弯曲成型;切边;模具结构。

Support plate stamping forming process and die design

Abstract: The design of the subject introducs the curved structure of blanking compound die design and working process. After cutting for parts crowded mouth like the phenomenon of sharp edge, and improve the structure of the mold to eliminate processing defects, sub-stamping process reflects the nature and efficiency, the design of a certain significance. Parts of the process technology and die structure design, the consolidation of knowledge, familiar with the relevant information, establish the correct design to enhance the overall understanding of the mold, to improve their ability to work the actual mold design.

The use of a stamping die design basic knowledge, the first part of understanding the whole analysis process parameters, the performance of stamping process, and then determine the structure of the form of stamping die, the parts of the design and calculation, bending and cutting-edge processes in a completed, the advantages of simple structure, deputy dies compact, easy maintenance processing.

Keywords: Process analysis; Bending; edge; die structure.

目录

1.绪论 ……………………………………………………………………1

2、支撑板工艺分析 ………………………………………………………6

2.1工艺分析 ………………………………………………………………6

2.2工艺方案的确定 ………………………………………………………7

2.3弯曲工艺计算 …………………………………………………………7

2.4弯曲工作部分尺寸计算 ………………………………………………9

2.4.1凸模圆角半径计算 …………………………………………………9

2.4.2凹模圆角半角计算 …………………………………………………9

2.4.3凹模工作部分深度的设计计算……………………………………10

2.4.4凸凹模间隙的确定…………………………………………………10

2.5弯曲件回弹值的计算…………………………………………………10

2.6弯曲力计算……………………………………………………………10

2.7冲孔φ10mm凸、凹刃口尺寸的计算…………………………………11

2.8外形落料凸、凹刃口尺寸的计算……………………………………12

2.9冲压力计算……………………………………………………………13

2.10压力中心的计算 ……………………………………………………13

2.11橡皮的选择 …………………………………………………………13

3、模架与压力机的选用 ………………………………………………16

3.1模架的选择 …………………………………………………………16

3.2压力机的选择 ………………………………………………………17

3.3压力机的校核 ………………………………………………………18

4、模具主要零部件的设计 ………………………………………………19

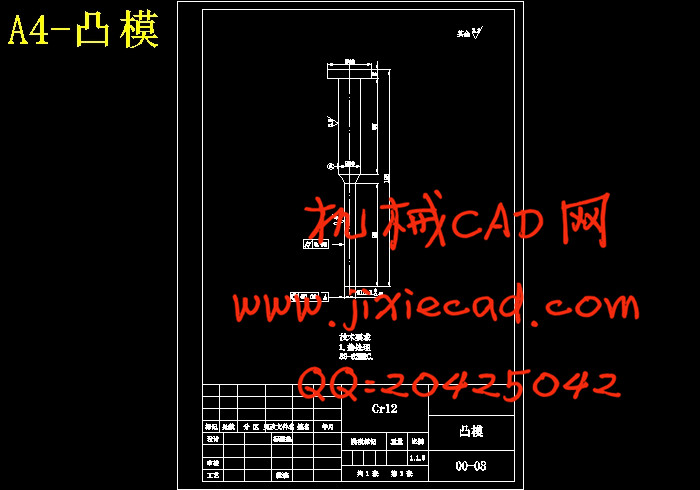

4.1冲孔Φ10凸模设计……………………………………………………19

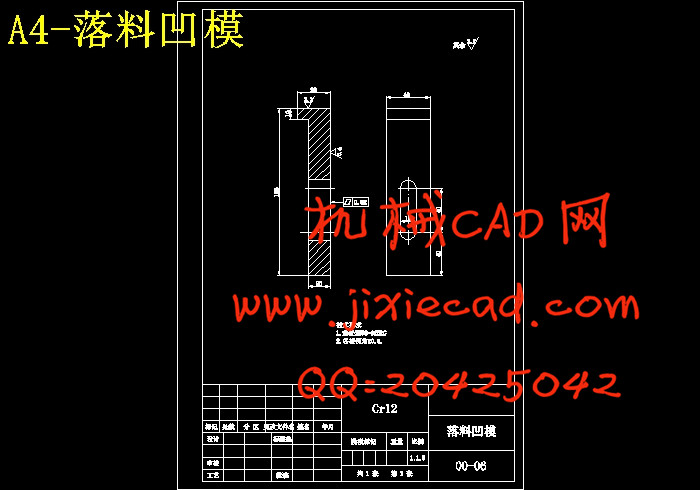

4.2落料凹模的设计 ………………………………………………………20

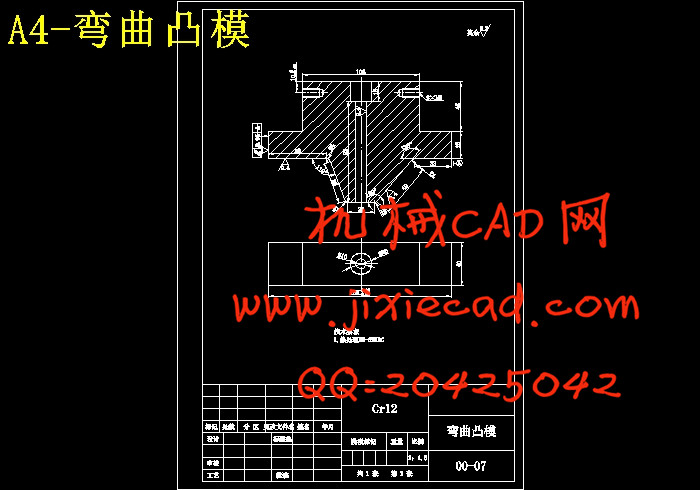

4.3凸凹模的设计 …………………………………………………………21

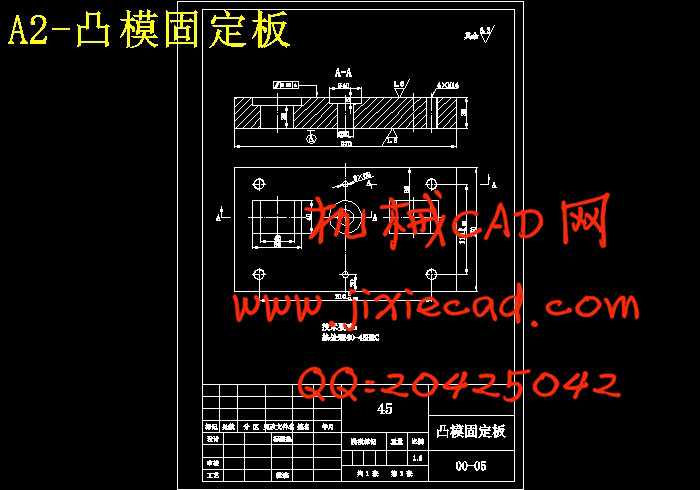

4.4凸模固定板的设计 ……………………………………………………21

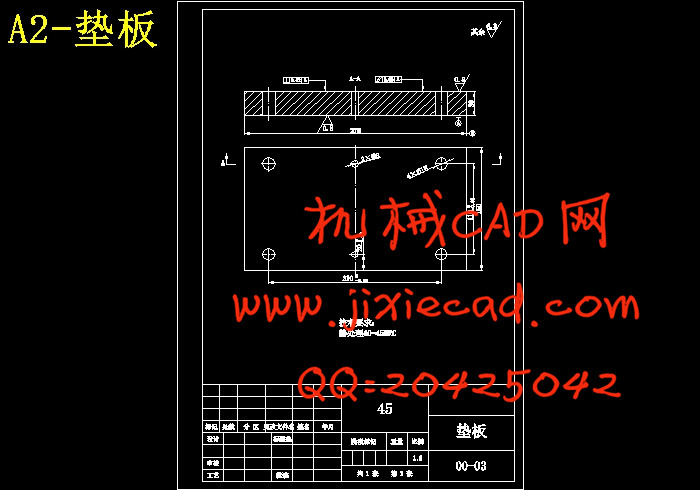

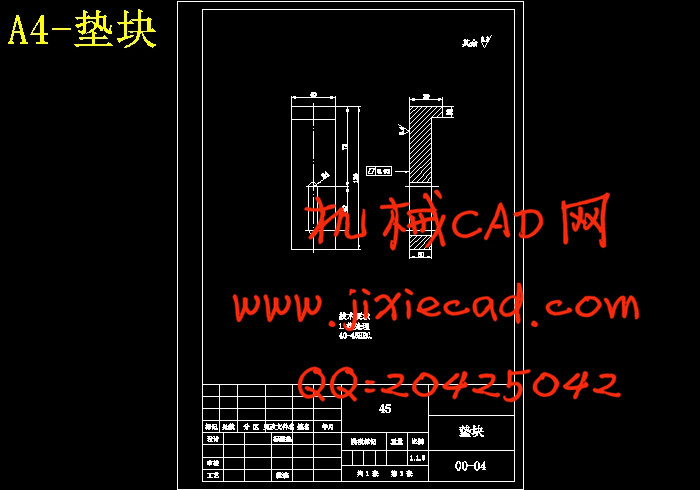

4.5垫板的设计 ……………………………………………………………22

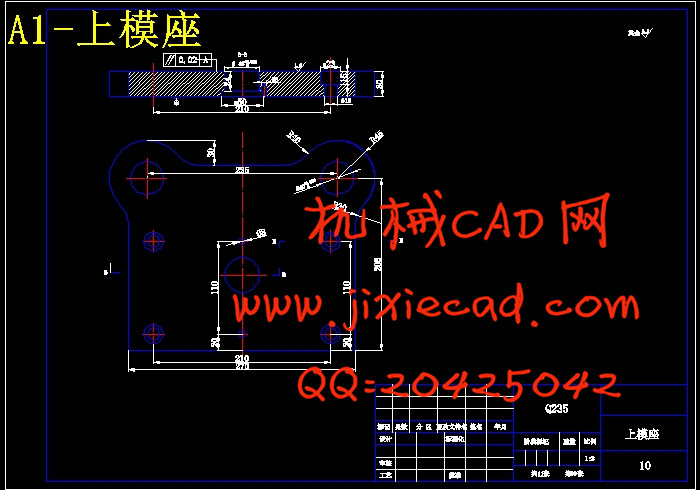

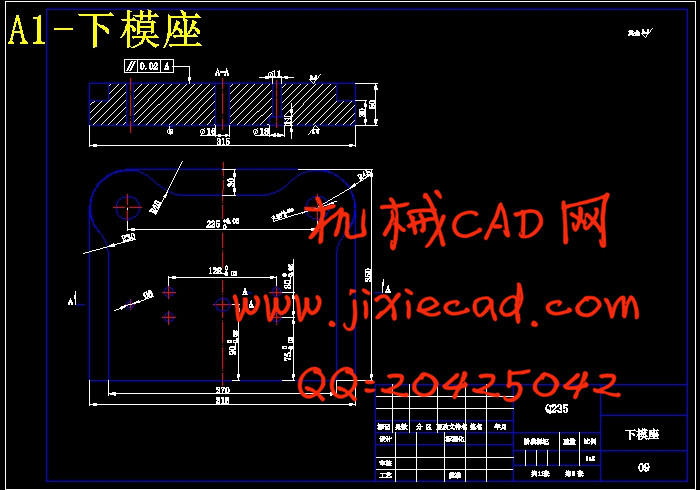

4.6模座的设计 ……………………………………………………………22

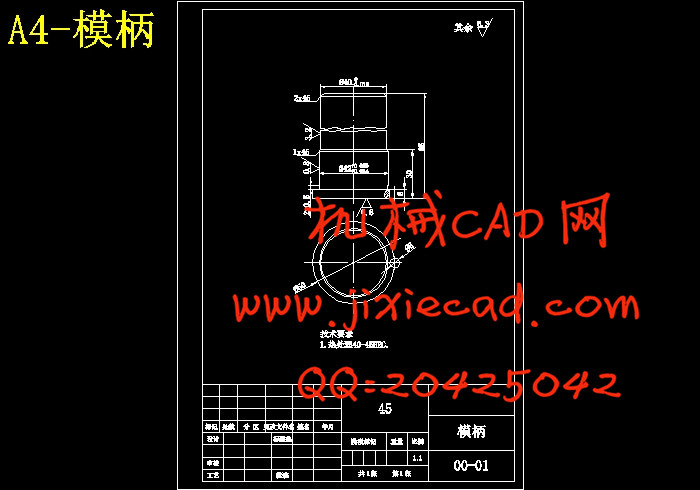

4.7模柄的设计 ……………………………………………………………22

4.8导柱、导套的选择 ……………………………………………………23

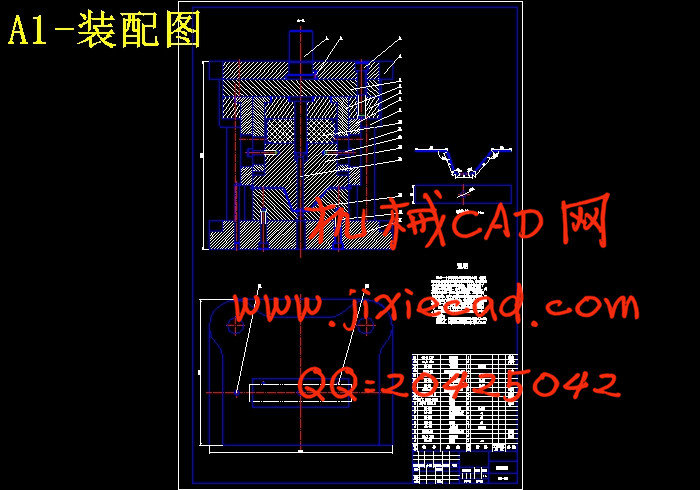

5、绘制模具总装配图………………………………………………………24

6、结束语……………………………………………………………………26

摘 要:本设计课题介绍了弯曲、冲裁复合模的结构设计及工作过程。针对零件挤切后口部呈尖锐刃口状现象,改进了模具结构,消除部分加工缺陷,分体现了冲压工艺先进性和高效性,有一定的设计意义。通过对工艺零件的工艺分析及模具结构设计, 巩固所学的知识、熟悉有关资料,树立正确的设计思路,加强了对模具的整体认识,提高自己的实际模具设计工作能力。

本计运用了冲压成形模具设计的基本知识,首先对整个零件的了解分析工艺参数,冲压工艺性能,然后确定冲压模的结构形式,工零部件的设计与计算,弯曲和切边在一个工序上完成,本副模具优点结构简单紧凑,易于加工维修。

关键词:工艺分析; 弯曲成型;切边;模具结构。

Support plate stamping forming process and die design

Abstract: The design of the subject introducs the curved structure of blanking compound die design and working process. After cutting for parts crowded mouth like the phenomenon of sharp edge, and improve the structure of the mold to eliminate processing defects, sub-stamping process reflects the nature and efficiency, the design of a certain significance. Parts of the process technology and die structure design, the consolidation of knowledge, familiar with the relevant information, establish the correct design to enhance the overall understanding of the mold, to improve their ability to work the actual mold design.

The use of a stamping die design basic knowledge, the first part of understanding the whole analysis process parameters, the performance of stamping process, and then determine the structure of the form of stamping die, the parts of the design and calculation, bending and cutting-edge processes in a completed, the advantages of simple structure, deputy dies compact, easy maintenance processing.

Keywords: Process analysis; Bending; edge; die structure.

目录

1.绪论 ……………………………………………………………………1

2、支撑板工艺分析 ………………………………………………………6

2.1工艺分析 ………………………………………………………………6

2.2工艺方案的确定 ………………………………………………………7

2.3弯曲工艺计算 …………………………………………………………7

2.4弯曲工作部分尺寸计算 ………………………………………………9

2.4.1凸模圆角半径计算 …………………………………………………9

2.4.2凹模圆角半角计算 …………………………………………………9

2.4.3凹模工作部分深度的设计计算……………………………………10

2.4.4凸凹模间隙的确定…………………………………………………10

2.5弯曲件回弹值的计算…………………………………………………10

2.6弯曲力计算……………………………………………………………10

2.7冲孔φ10mm凸、凹刃口尺寸的计算…………………………………11

2.8外形落料凸、凹刃口尺寸的计算……………………………………12

2.9冲压力计算……………………………………………………………13

2.10压力中心的计算 ……………………………………………………13

2.11橡皮的选择 …………………………………………………………13

3、模架与压力机的选用 ………………………………………………16

3.1模架的选择 …………………………………………………………16

3.2压力机的选择 ………………………………………………………17

3.3压力机的校核 ………………………………………………………18

4、模具主要零部件的设计 ………………………………………………19

4.1冲孔Φ10凸模设计……………………………………………………19

4.2落料凹模的设计 ………………………………………………………20

4.3凸凹模的设计 …………………………………………………………21

4.4凸模固定板的设计 ……………………………………………………21

4.5垫板的设计 ……………………………………………………………22

4.6模座的设计 ……………………………………………………………22

4.7模柄的设计 ……………………………………………………………22

4.8导柱、导套的选择 ……………………………………………………23

5、绘制模具总装配图………………………………………………………24

6、结束语……………………………………………………………………26