设计简介

中铰链垫片模具设计

摘 要:本设计的题目为中铰链垫片模具设计,体现了薄板类冲压零件的要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了本人冲压模设计的基础知识,为设计更复杂的冲压模具做好了铺垫和吸取更深刻的经验。

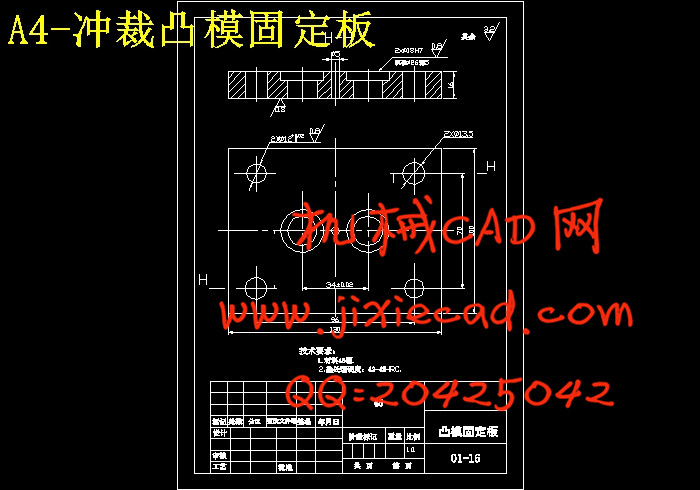

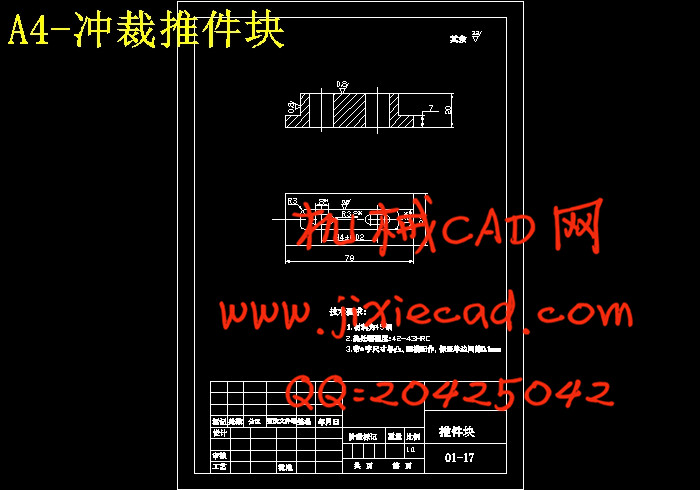

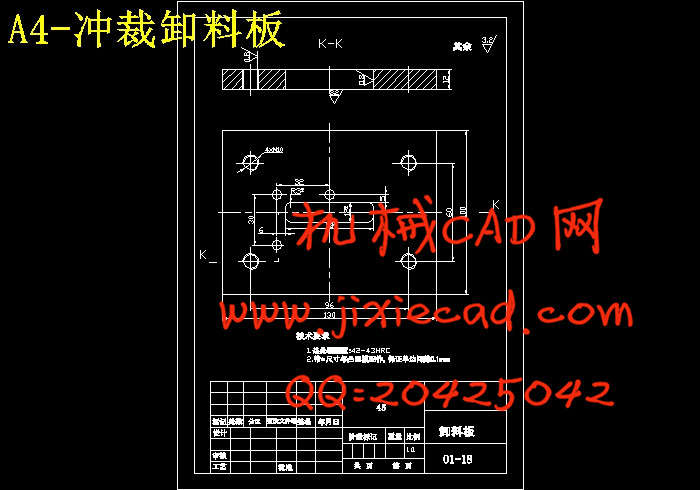

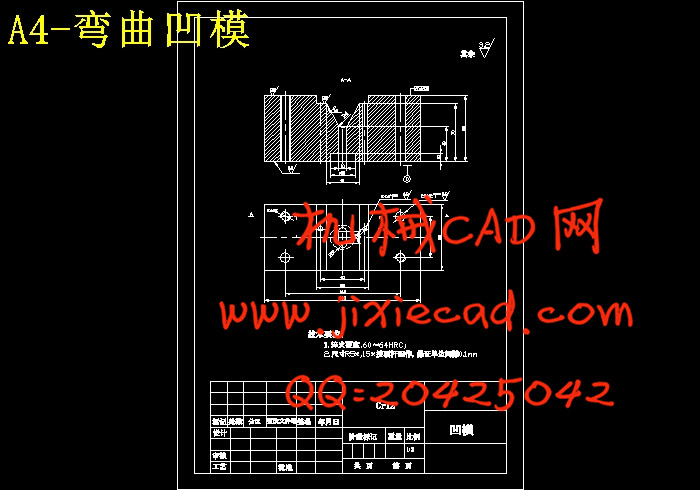

本设计运用冲压成形工艺及模具设计的基础知识,首先分析了冲裁件的冲压工艺性,为确定冲裁工艺方案做好了准备;然后计算冲裁力和模具刃口尺寸,便于选取压力机及确定工作零件的尺寸和结构;最后分析了制件的特征,确定模具的设计参数、设计要点及推件装置的选取。为了方便制件的取出,冲裁时模具采用倒装结构形式,为了简化模具结构,弯曲模采用了弹性顶件装置。本设计从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:冲压模具,倒装复合,弯曲模,弹性顶件,

The design of mold in the gasket hinge

Abstract :The design was entitled mold in the gasket hinge, reflects the thin parts like punching the request, the contents and direction of a certain design significance. Parts of the mold through the design, has further strengthened my stamping die design of the basic knowledge for the design of more complex stamping die to pave the way and the lessons more profound experience.

The use of the design process and die stamping forming the basis of design knowledge and analysis of the first blanking of the stamping process, to determine blanking of the programme prepared for and then calculating punching power and size Die Cutting Edge, For selected press and determine the size and structure of parts of the last parts of the characteristics of the design parameters established mold, design features and pushing the select pieces of equipment. This design designs from the mold to the spare part processing craft as well as the assembly craft and so on carries on the detailed elaboration, and carries on each important components using CAD the design.

Key word: stamping die,flip-composite,bending dies,flexible pieces of pushing

目 录

1 绪论………………………………………………………………………………1

1.1国内模具的现状和发展趋势………………………………………………1

1.1.1国内模具的现状………………………………………………………1

1.1.2国内模具的发展趋势…………………………………………………3

1.2国外模具的现状和发展趋势………………………………………………5

1.3中铰链垫片的模具设计与制造方面………………………………………6

1.3.1中铰链垫片模具设计的设计思路……………………………………6

1.3.2中铰链垫片模具设计的进度…………………………………………6

2 中铰链垫片的工艺分析…………………………………………………………7

2.1工件的工艺性分析…………………………………………………………7

2.2 工艺方案的确定……………………………………………………………8

2.2.1工艺方案分析…………………………………………………………8

2.2.2 排样设计………………………………………………………………8

2.3 必要的尺寸计算……………………………………………………………10

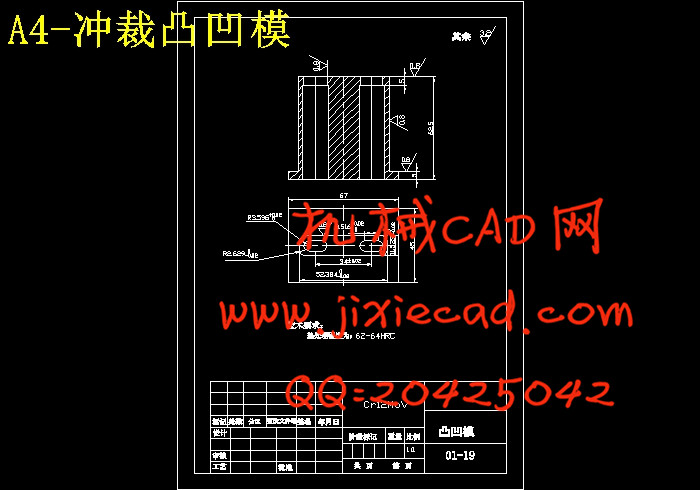

2.3.1冲孔落料凸凹模刃口尺寸计算………………………………………10

2.3.2计算压力及初选冲床…………………………………………………12

2.3.3弯曲模工作部分尺寸计算……………………………………………13

2.3.4弯曲力的计算…………………………………………………………17

3 模具的总体设计…………………………………………………………………19

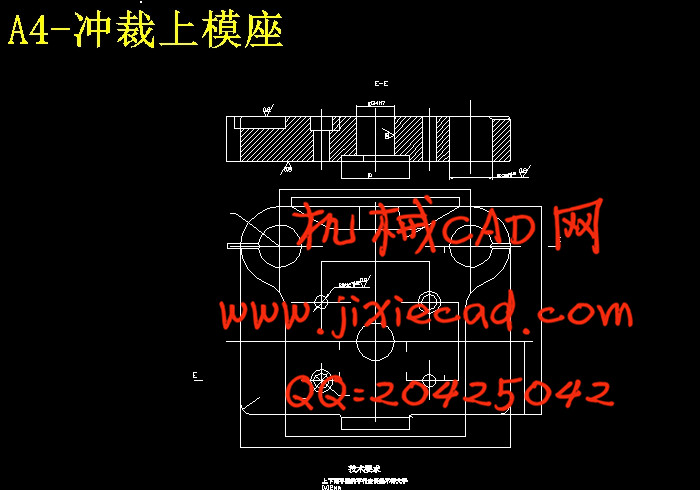

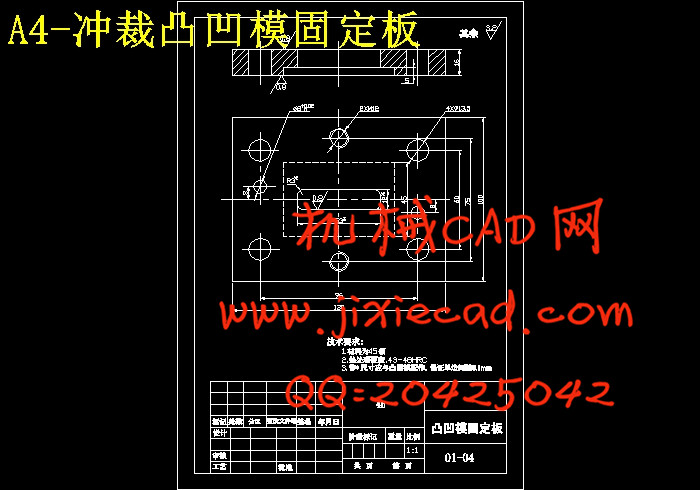

3.1冲孔落料模具总体设计……………………………………………………19

3.2弯曲模具总体设计…………………………………………………………20

4. 冲压设备的选定…………………………………………………………………21

4.1冲孔落料模具冲压设备的选定……………………………………………21

4.2弯曲模具冲压设备的选定……………………………………………21

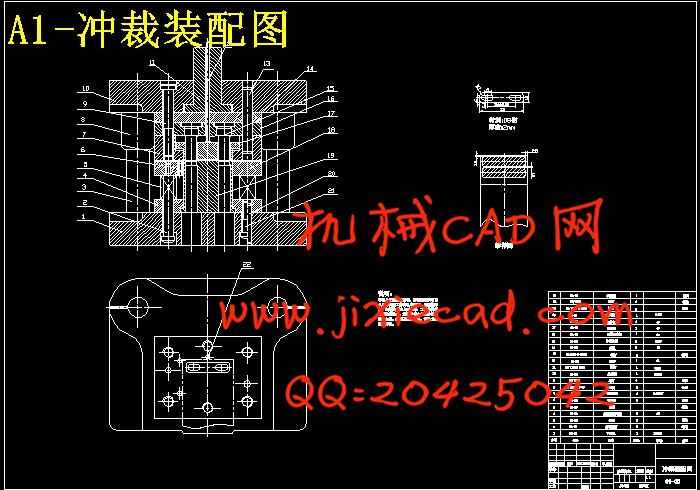

5. 绘制模具装配图……………………………………………………………23

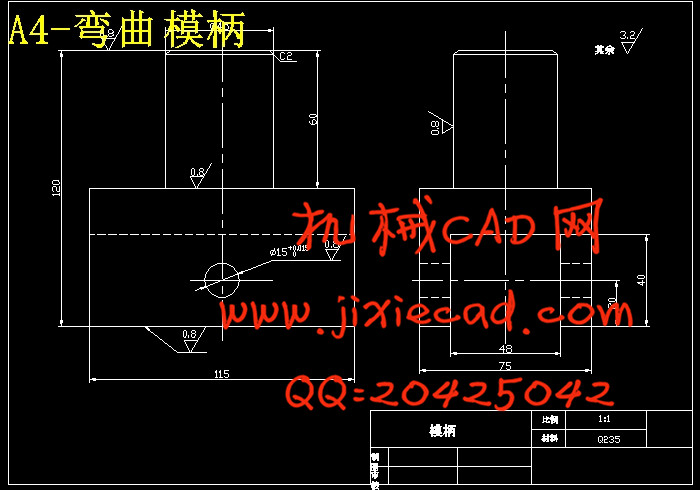

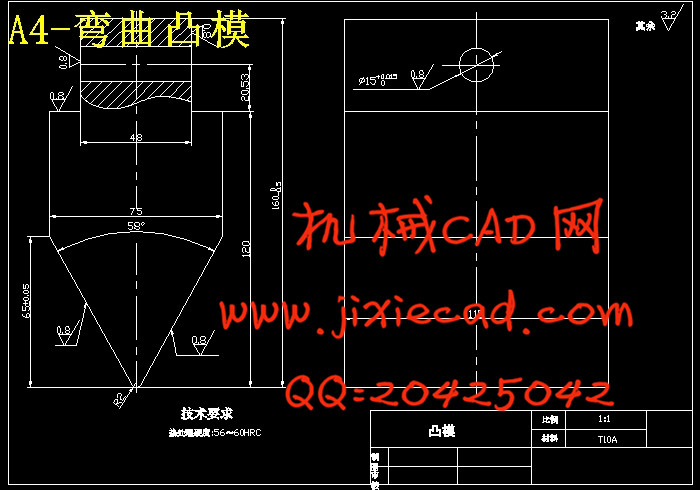

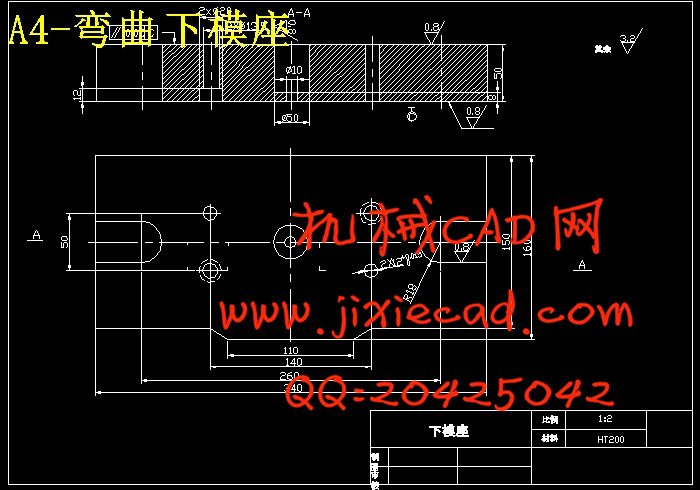

6. 弯曲模工作零件的制造……………………………………………………26

7.结束语………………………………………………………………………28

致谢 ……………………………………………………………………………29

参考文献…………………………………………………………………………30

摘 要:本设计的题目为中铰链垫片模具设计,体现了薄板类冲压零件的要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了本人冲压模设计的基础知识,为设计更复杂的冲压模具做好了铺垫和吸取更深刻的经验。

本设计运用冲压成形工艺及模具设计的基础知识,首先分析了冲裁件的冲压工艺性,为确定冲裁工艺方案做好了准备;然后计算冲裁力和模具刃口尺寸,便于选取压力机及确定工作零件的尺寸和结构;最后分析了制件的特征,确定模具的设计参数、设计要点及推件装置的选取。为了方便制件的取出,冲裁时模具采用倒装结构形式,为了简化模具结构,弯曲模采用了弹性顶件装置。本设计从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:冲压模具,倒装复合,弯曲模,弹性顶件,

The design of mold in the gasket hinge

Abstract :The design was entitled mold in the gasket hinge, reflects the thin parts like punching the request, the contents and direction of a certain design significance. Parts of the mold through the design, has further strengthened my stamping die design of the basic knowledge for the design of more complex stamping die to pave the way and the lessons more profound experience.

The use of the design process and die stamping forming the basis of design knowledge and analysis of the first blanking of the stamping process, to determine blanking of the programme prepared for and then calculating punching power and size Die Cutting Edge, For selected press and determine the size and structure of parts of the last parts of the characteristics of the design parameters established mold, design features and pushing the select pieces of equipment. This design designs from the mold to the spare part processing craft as well as the assembly craft and so on carries on the detailed elaboration, and carries on each important components using CAD the design.

Key word: stamping die,flip-composite,bending dies,flexible pieces of pushing

目 录

1 绪论………………………………………………………………………………1

1.1国内模具的现状和发展趋势………………………………………………1

1.1.1国内模具的现状………………………………………………………1

1.1.2国内模具的发展趋势…………………………………………………3

1.2国外模具的现状和发展趋势………………………………………………5

1.3中铰链垫片的模具设计与制造方面………………………………………6

1.3.1中铰链垫片模具设计的设计思路……………………………………6

1.3.2中铰链垫片模具设计的进度…………………………………………6

2 中铰链垫片的工艺分析…………………………………………………………7

2.1工件的工艺性分析…………………………………………………………7

2.2 工艺方案的确定……………………………………………………………8

2.2.1工艺方案分析…………………………………………………………8

2.2.2 排样设计………………………………………………………………8

2.3 必要的尺寸计算……………………………………………………………10

2.3.1冲孔落料凸凹模刃口尺寸计算………………………………………10

2.3.2计算压力及初选冲床…………………………………………………12

2.3.3弯曲模工作部分尺寸计算……………………………………………13

2.3.4弯曲力的计算…………………………………………………………17

3 模具的总体设计…………………………………………………………………19

3.1冲孔落料模具总体设计……………………………………………………19

3.2弯曲模具总体设计…………………………………………………………20

4. 冲压设备的选定…………………………………………………………………21

4.1冲孔落料模具冲压设备的选定……………………………………………21

4.2弯曲模具冲压设备的选定……………………………………………21

5. 绘制模具装配图……………………………………………………………23

6. 弯曲模工作零件的制造……………………………………………………26

7.结束语………………………………………………………………………28

致谢 ……………………………………………………………………………29

参考文献…………………………………………………………………………30