设计简介

端罩的冲压成形工艺及冲压模具设计

摘要:本设计题目为端罩的设计,体现了深薄壁类零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冷冲模设计的基础知识,为设计更复杂的冷冲模具做好了铺垫和吸取了更深刻的经验。

本设计运用薄板类零件成型工艺及模具设计的基础知识,首先分析了零件的成分及性能要求,为设计拉深及冲裁模的数据指标做好了准备;然后计算了零件的体积,便于设计落料模的刃口尺寸;最后设计了模具的结构特征,确定了模具的设计参数、设计要点及推出装置的设计。

冲压加工分为分离工序和成形工序两大类。落料、打孔属于分离工序,拉深属于成形工序。设计任务是指导老师指定加工的零件为有孔拉深件,材料为铝L3,厚度为2mm,大批量生产,其他具体要求参照零件图。根据零件形状,需要采用落料、拉深、冲孔3个工序,为提高成倍提高生产效率,提高冲压件的质量,可采用落料和拉深过程集中于一套模具来完成,冲孔工序用简单模完成。

关键词:落料 拉深 冲孔

The drop-cylinder-shaped pieces of material, drawing, punching, trimming the compound die design

Abstract:The design of the sets of topics for the long injection mold design, reflects the deep thin wall plastic parts of the design, content and direction of a certain design significance. Parts of the mold through the design, the designer has been further strengthened by the injection mold design based on knowledge, for the design of more complex injection molds made and lessons foreshadowing a more profound experience

The use of thin design parts molding process and die design of the basic knowledge, first of all parts of the composition and performance requirements for the design and drawing Die data prepared for the target and then calculate the size of the parts, for design Blanking the edge-size; final design of the structure of the mold, a mold determine the design parameters, design elements and the introduction of the device design.

Cutting and piercing belong to separating , pulling and stretching belong to calendering. The spare parts fall to cut material-pull and stretch compound die and multiple hole punched die to process.The job is in order to process the multiple hole punched die and pull-stretch die design which is given by the tutor , the material is AL L3 , the thickness is a 2 mm, the large quantity quantity produce, other request to according to the spare parts diagram in a specific way. According to the spare parts’ shape,it need to to cut material,to pull and stretch,to punched hole 3 work, become for the exaltation to raise the production efficiency doubly, raise to the quantity of part, to cut material and to pull and stretch adopt to compound die to complete, to punched hole adopt to pierce die to complete.

Keywords:cut material ;pull and stretch ; piercing

目录

1 绪论 1

1.1 冲压模具市场情况 1

1.2 冲压模具水平状况 1

1.2.1 模具设计与制造能力状况 1

1.2.2 专业化程度及分布状况 2

1.3 冲压模具的发展重点与展望 2

1.3.1 冲压模具产品发展重点 2

1.3.2 冲压模具技术发展重点 3

2 成形制品的工艺性分析 4

2.1冲裁件的结构工艺性 4

2.2模具结构选择 4

2.3确定工艺方案 5

3 加工工艺的设计 7

3.1拉深工艺的设计 7

3.1.1外形毛坯尺寸的确定 7

3.1.2拉深模工作部分参数 7

3.1.3工作部分尺寸的确定 9

3.1.4 工艺力的计算 10

3.2 冲压工艺设计 12

3.2.1模具间隙的设计 12

3.2.2凸凹模刃口尺寸计算 13

3.2.3排样的设计 15

4 模具结构的设计 17

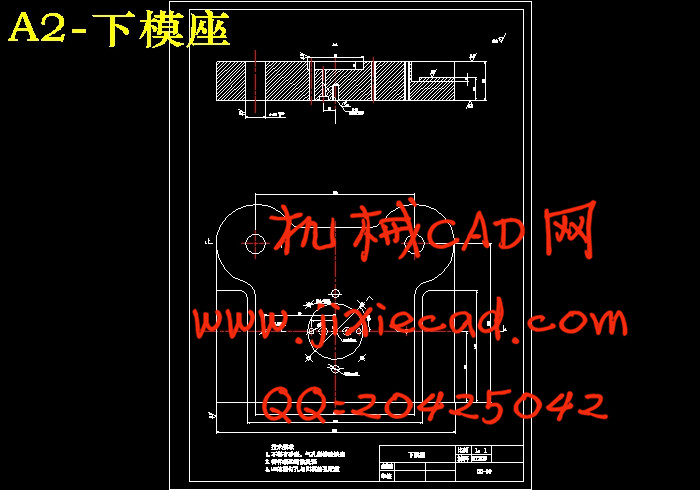

4.1落料,拉深工序的结构设计 17

4.2冲孔、切边工序的结构设计 17

4.3模具工作过程 19

5 模具主要零件的结构 20

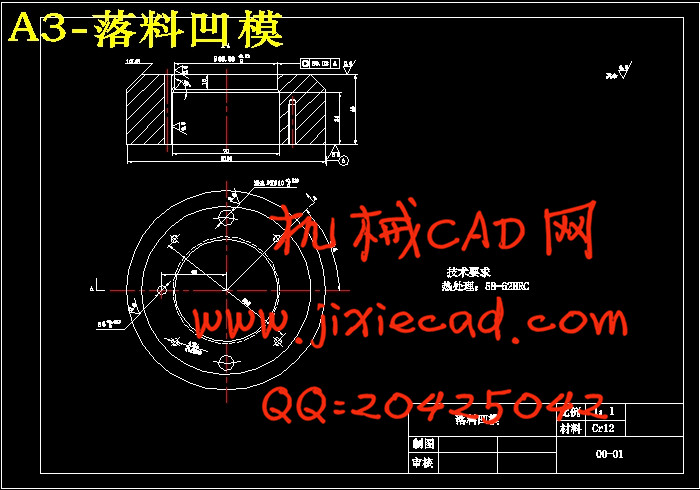

5.1落料凹模 20

5.2拉深凸模 20

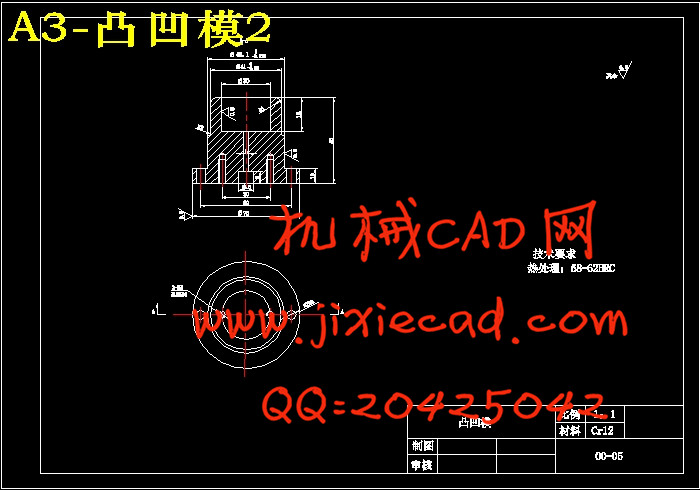

5.3凸凹模 21

5.4弹性卸料板 22

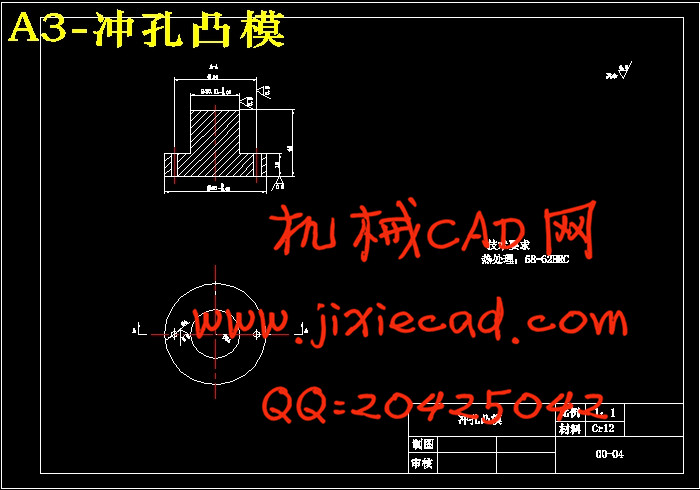

5.5冲孔凸模 23

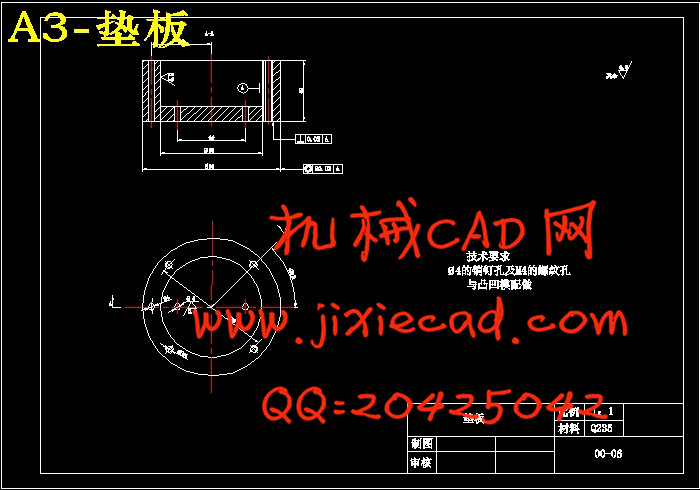

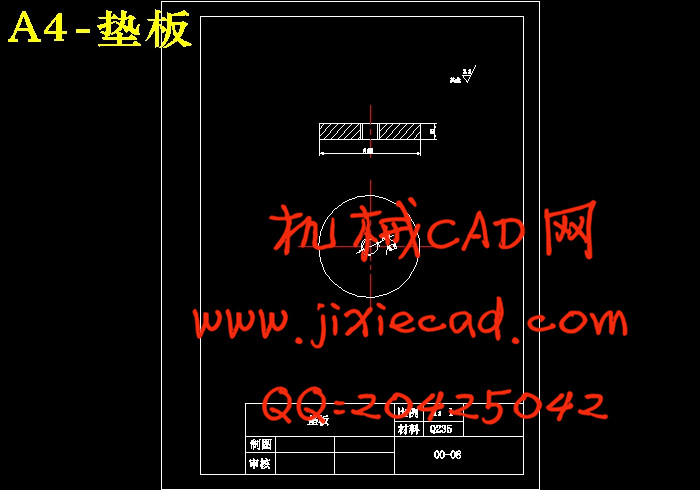

5.6垫板 24

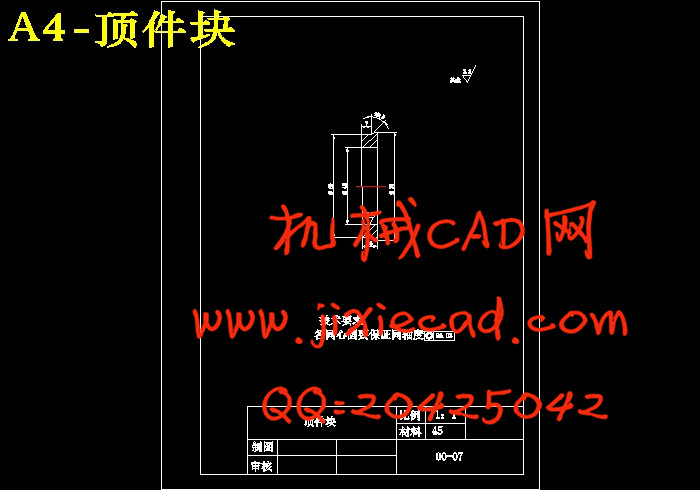

5.7其它零件 25

6 零件的加工 28

结束语 29

致 谢 30

参考文献 31

摘要:本设计题目为端罩的设计,体现了深薄壁类零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冷冲模设计的基础知识,为设计更复杂的冷冲模具做好了铺垫和吸取了更深刻的经验。

本设计运用薄板类零件成型工艺及模具设计的基础知识,首先分析了零件的成分及性能要求,为设计拉深及冲裁模的数据指标做好了准备;然后计算了零件的体积,便于设计落料模的刃口尺寸;最后设计了模具的结构特征,确定了模具的设计参数、设计要点及推出装置的设计。

冲压加工分为分离工序和成形工序两大类。落料、打孔属于分离工序,拉深属于成形工序。设计任务是指导老师指定加工的零件为有孔拉深件,材料为铝L3,厚度为2mm,大批量生产,其他具体要求参照零件图。根据零件形状,需要采用落料、拉深、冲孔3个工序,为提高成倍提高生产效率,提高冲压件的质量,可采用落料和拉深过程集中于一套模具来完成,冲孔工序用简单模完成。

关键词:落料 拉深 冲孔

The drop-cylinder-shaped pieces of material, drawing, punching, trimming the compound die design

Abstract:The design of the sets of topics for the long injection mold design, reflects the deep thin wall plastic parts of the design, content and direction of a certain design significance. Parts of the mold through the design, the designer has been further strengthened by the injection mold design based on knowledge, for the design of more complex injection molds made and lessons foreshadowing a more profound experience

The use of thin design parts molding process and die design of the basic knowledge, first of all parts of the composition and performance requirements for the design and drawing Die data prepared for the target and then calculate the size of the parts, for design Blanking the edge-size; final design of the structure of the mold, a mold determine the design parameters, design elements and the introduction of the device design.

Cutting and piercing belong to separating , pulling and stretching belong to calendering. The spare parts fall to cut material-pull and stretch compound die and multiple hole punched die to process.The job is in order to process the multiple hole punched die and pull-stretch die design which is given by the tutor , the material is AL L3 , the thickness is a 2 mm, the large quantity quantity produce, other request to according to the spare parts diagram in a specific way. According to the spare parts’ shape,it need to to cut material,to pull and stretch,to punched hole 3 work, become for the exaltation to raise the production efficiency doubly, raise to the quantity of part, to cut material and to pull and stretch adopt to compound die to complete, to punched hole adopt to pierce die to complete.

Keywords:cut material ;pull and stretch ; piercing

目录

1 绪论 1

1.1 冲压模具市场情况 1

1.2 冲压模具水平状况 1

1.2.1 模具设计与制造能力状况 1

1.2.2 专业化程度及分布状况 2

1.3 冲压模具的发展重点与展望 2

1.3.1 冲压模具产品发展重点 2

1.3.2 冲压模具技术发展重点 3

2 成形制品的工艺性分析 4

2.1冲裁件的结构工艺性 4

2.2模具结构选择 4

2.3确定工艺方案 5

3 加工工艺的设计 7

3.1拉深工艺的设计 7

3.1.1外形毛坯尺寸的确定 7

3.1.2拉深模工作部分参数 7

3.1.3工作部分尺寸的确定 9

3.1.4 工艺力的计算 10

3.2 冲压工艺设计 12

3.2.1模具间隙的设计 12

3.2.2凸凹模刃口尺寸计算 13

3.2.3排样的设计 15

4 模具结构的设计 17

4.1落料,拉深工序的结构设计 17

4.2冲孔、切边工序的结构设计 17

4.3模具工作过程 19

5 模具主要零件的结构 20

5.1落料凹模 20

5.2拉深凸模 20

5.3凸凹模 21

5.4弹性卸料板 22

5.5冲孔凸模 23

5.6垫板 24

5.7其它零件 25

6 零件的加工 28

结束语 29

致 谢 30

参考文献 31