设计简介

空气开关固定卡冲压成形工艺与模具设计

摘 要:本设计题目为空气开关固定卡冲压成形工艺与模具设计,体现了板类冲压零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冲压模具设计的基础知识,为设计更复杂的冲压模具做好了铺垫并吸取了更深刻的经验。

本设计运用冲孔落料弯曲成形工艺及模具设计的基础知识,首先分析了工件的成形工艺及模具成形结构对制件质量的影响。介绍了空气开关固定卡冲压成形工艺与模具设计时要注意的要点,通过对制件进行工艺分析,可确定制件的成形加工用两套模具即冲孔落料正装复合模和一次弯曲成形模具。从控制制件尺寸精度出发,对该冲孔落料弯曲模的各主要尺寸进行了理论计算,以确定各工作零件的尺寸。从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:复合模,工艺分析,模具零部件的加工工艺

THE FONUDATION PUNCH HLOES FALL THE MATERIAL CURVING MOLD THE DESING

ABSTRACT:The topic of this design is the foundation punch holes fall the material to be curvingforming process and die design. The requirement,content and direction of the design of the stamps forming plate parts are embodied on this stamping die design. The designer’s foundation knowledge of the stamping die design is reinforced and is able to design more complex stamping die through the design.

The design of the use of the punch holes fall the material curving forming process and die design of the basic knowledge, First, we analyze the shape of workpiece forming process and die structure of the parts quality. Introduced The foundation punch holes fall the material curving mold design to the main points of attention, through the process of parts for analysis, to determine parts of the forming die with two sets of molds are the punch holes fall the material true thing superposable die and one time form the mold curving. Embarks from the control workpiece size precision, To the foundation punch holes fall the material bending die of the main dimensions of the theoretical calculation to determine the size of the working parts. Parts from the mold design to the processing technology as well as the assembly process, such as described in detail, and the application of CAD for the design of the important parts.

KEY WORD: compound die,process analysis,processing of die parts

目 录

摘 要:本设计题目为空气开关固定卡冲压成形工艺与模具设计,体现了板类冲压零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者冲压模具设计的基础知识,为设计更复杂的冲压模具做好了铺垫并吸取了更深刻的经验。

本设计运用冲孔落料弯曲成形工艺及模具设计的基础知识,首先分析了工件的成形工艺及模具成形结构对制件质量的影响。介绍了空气开关固定卡冲压成形工艺与模具设计时要注意的要点,通过对制件进行工艺分析,可确定制件的成形加工用两套模具即冲孔落料正装复合模和一次弯曲成形模具。从控制制件尺寸精度出发,对该冲孔落料弯曲模的各主要尺寸进行了理论计算,以确定各工作零件的尺寸。从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:复合模,工艺分析,模具零部件的加工工艺

THE FONUDATION PUNCH HLOES FALL THE MATERIAL CURVING MOLD THE DESING

ABSTRACT:The topic of this design is the foundation punch holes fall the material to be curvingforming process and die design. The requirement,content and direction of the design of the stamps forming plate parts are embodied on this stamping die design. The designer’s foundation knowledge of the stamping die design is reinforced and is able to design more complex stamping die through the design.

The design of the use of the punch holes fall the material curving forming process and die design of the basic knowledge, First, we analyze the shape of workpiece forming process and die structure of the parts quality. Introduced The foundation punch holes fall the material curving mold design to the main points of attention, through the process of parts for analysis, to determine parts of the forming die with two sets of molds are the punch holes fall the material true thing superposable die and one time form the mold curving. Embarks from the control workpiece size precision, To the foundation punch holes fall the material bending die of the main dimensions of the theoretical calculation to determine the size of the working parts. Parts from the mold design to the processing technology as well as the assembly process, such as described in detail, and the application of CAD for the design of the important parts.

KEY WORD: compound die,process analysis,processing of die parts

目 录

1 绪 论 1

1.1冲压模具行业发展现状及技术趋势 1

1.2 未来冲压模具制造技术发展趋势 2

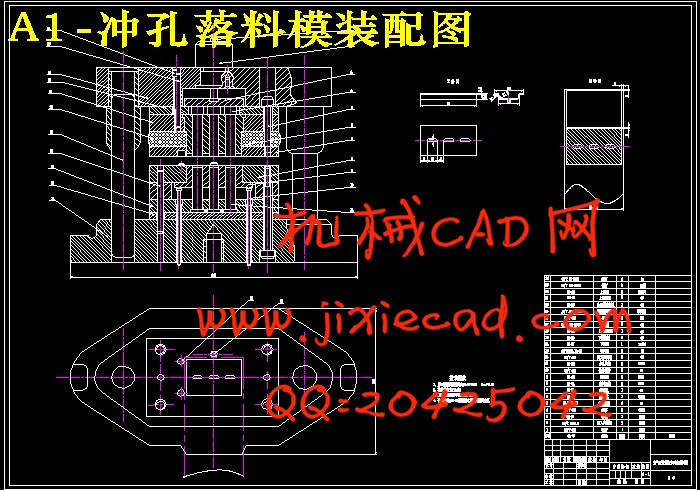

2 冲孔落料复合模 4

2.1 工艺分析 4

2.2 工艺方案确定 5

2.3 主要的工艺计算 6

2.3.1 冲裁件坯料长度的计算 6

2.3.2 冲裁排样方式的确定与相关计算 7

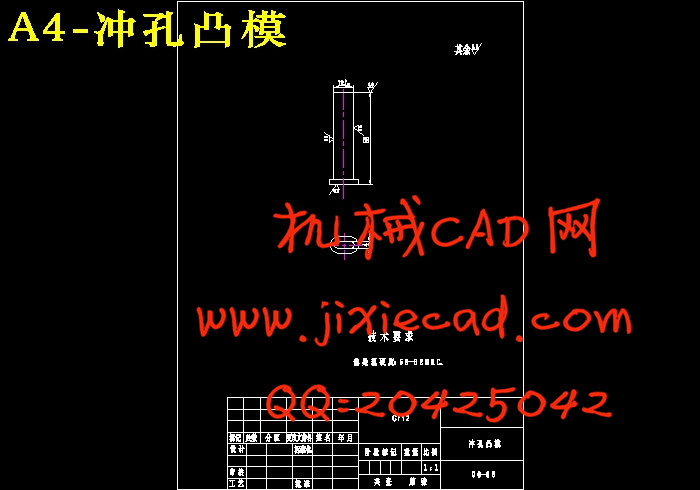

2.4 模具工作零部件刃口尺寸的计算 9

2.5 计算冲压力和初选压力机 11

2.6 模具总体设计 13

2.6.1 模具的类型选择 13

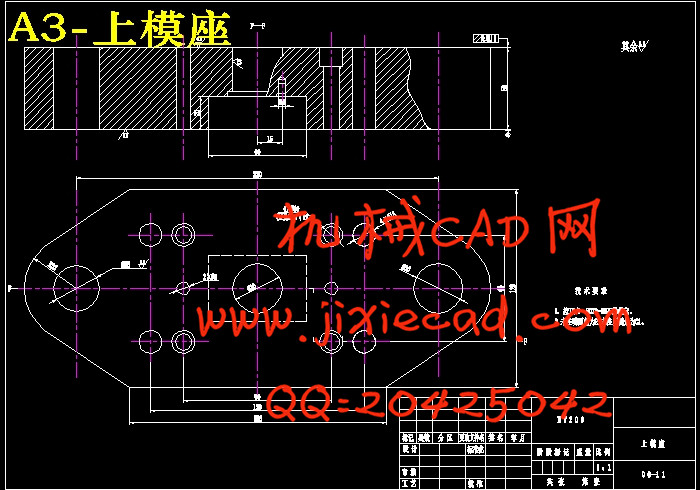

2.6.2 模具主要零部件的结构设计 14

2.7 冲压设备的的选用及安装 17

2.7.1 冲压设备的选定 17

2.7.2 冲孔落料正装复合模冲压设备的安装 18

2.7.3 模具装配的技术要求 19

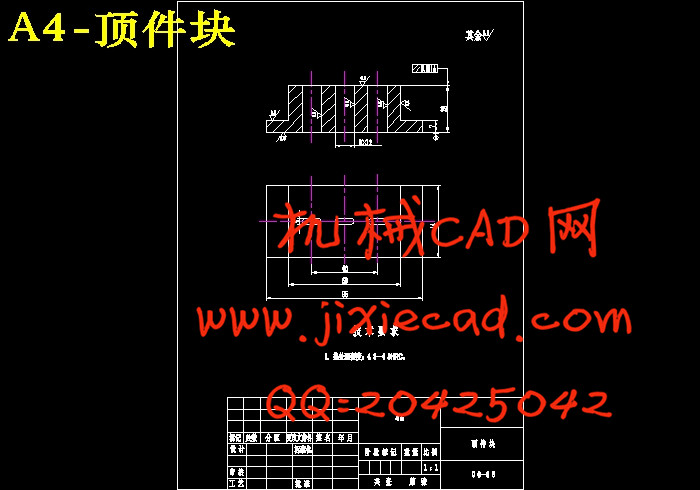

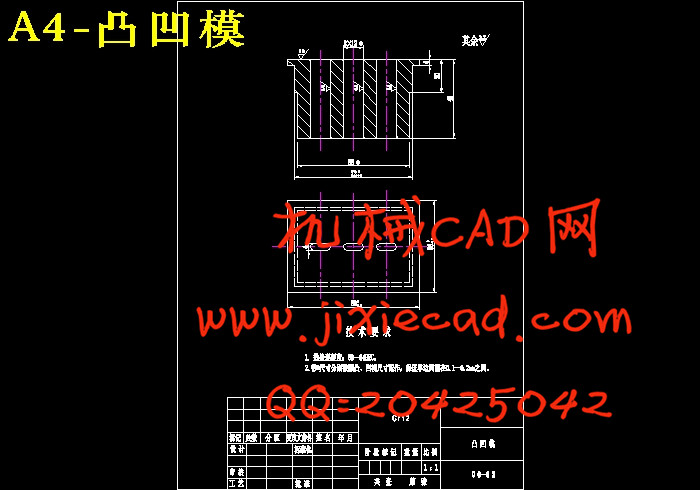

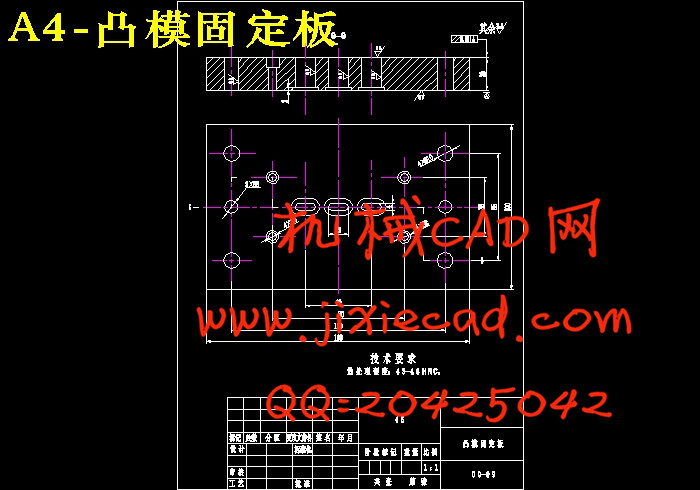

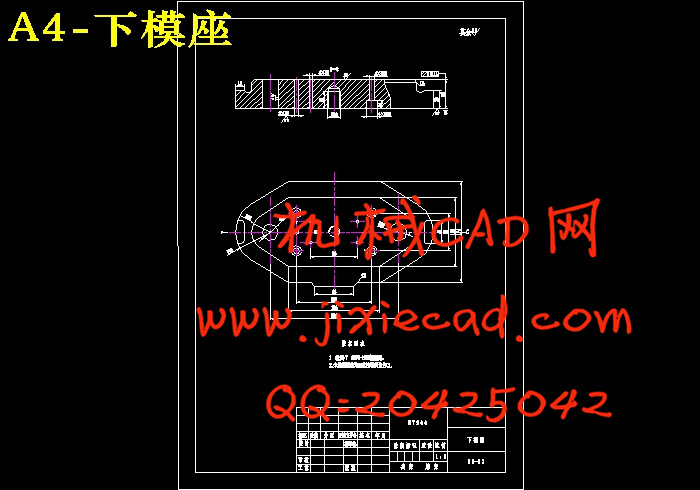

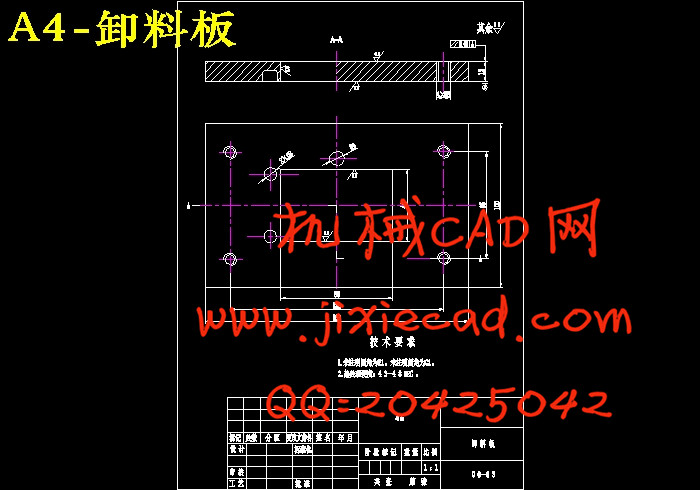

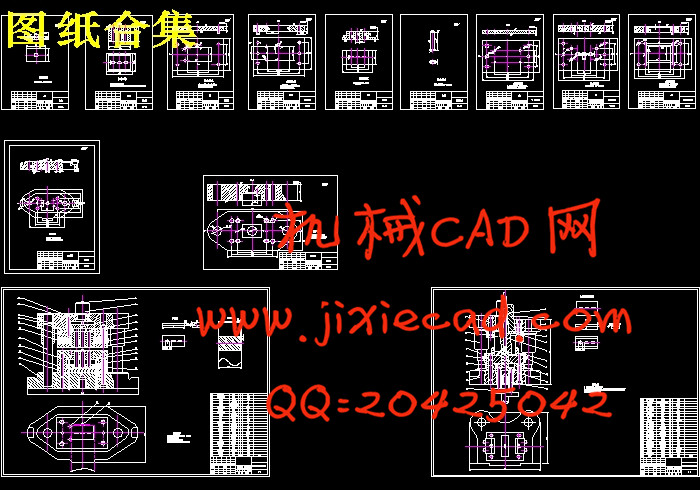

2.8 模具总装图 19

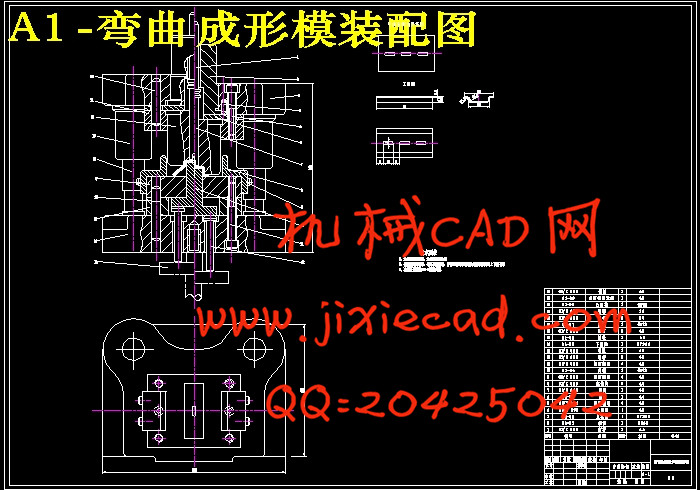

3 弯曲模的设计 22

3.1 弯曲模具的相关计算 22

3.1.1 弯曲模工作部分尺寸计算 22

3.1.2 弯曲模部分其他相关计算 24

3.2 初选压力机 26

3.3 压力中心的确定和冲压力的计算 27

3.4 一次弯曲成形模的设计 29

3.5. 一次弯曲成形模冲压设备的选定及安装 32

3.6 模具的总装图 33

总 结 36

致谢 38

参考文献 39

1.1冲压模具行业发展现状及技术趋势 1

1.2 未来冲压模具制造技术发展趋势 2

2 冲孔落料复合模 4

2.1 工艺分析 4

2.2 工艺方案确定 5

2.3 主要的工艺计算 6

2.3.1 冲裁件坯料长度的计算 6

2.3.2 冲裁排样方式的确定与相关计算 7

2.4 模具工作零部件刃口尺寸的计算 9

2.5 计算冲压力和初选压力机 11

2.6 模具总体设计 13

2.6.1 模具的类型选择 13

2.6.2 模具主要零部件的结构设计 14

2.7 冲压设备的的选用及安装 17

2.7.1 冲压设备的选定 17

2.7.2 冲孔落料正装复合模冲压设备的安装 18

2.7.3 模具装配的技术要求 19

2.8 模具总装图 19

3 弯曲模的设计 22

3.1 弯曲模具的相关计算 22

3.1.1 弯曲模工作部分尺寸计算 22

3.1.2 弯曲模部分其他相关计算 24

3.2 初选压力机 26

3.3 压力中心的确定和冲压力的计算 27

3.4 一次弯曲成形模的设计 29

3.5. 一次弯曲成形模冲压设备的选定及安装 32

3.6 模具的总装图 33

总 结 36

致谢 38

参考文献 39