设计简介

滤清器固定架 冲压模具设计

冲压模具设计

摘 要 冲压成形是一个涉及领域极其广泛的行业,深入到制造业的每个方面,冲压成形加工主要是通过冲压模具来实现。冲压模具是大批量生产同类产品的工具,是冲压成形的常用工艺装备。本设计首先根据空气滤清器固定架冲压件的结构特点、生产批量、加工精度进行冲压工艺性分析,确定冲压工艺方案。空气滤清器固定架成型工序包括两个大的部分:一部分是板材的冲孔落料,另一部分为材料的弯曲工艺。因此,由冲压工艺性分析所确定的冲压工艺方案是设计四套模具,分别是冲孔、落料复合模、中间弯曲单工序模、外角弯曲单工序模,外角弯曲单工序模。然后对这四套冲压模具进行工艺计算并设计每套模具所用的零部件:凸模、凹模、凹模固定板、卸料板、弯曲模等。按照冲压模具的设计的步骤,对各套冲压模具选用合适的导柱、导套、模柄及模架等标准件。最终完成空气滤清器固定架冲压件的模具设计。

关键词:冲压工艺;复合模;弯曲模;空气滤清器固定架

ABSTRACT

Abstract: The stamping is a very wide range of the areas of industry, into all aspects of manufacturing, stamping forming processing to achieve through the stamping die. The stamping dies are the tools of mass production of similar products is the main process of stamping equipment.The design is first based on the structural characteristics of the air filter holder stampings, production volume, processing precision stamping process analysis to determine the program of stamping process. The air filter holder molding processes, including punching, blanking, bending, stamping process determined by the stamping process analysis program is to design three sets of mold, namely, punching, blanking, bending single-process mode, punching down composite material, bending mode, punching and blanking, bending the middle, both ends of the curved composite mode. And then punching, blanking, bending single-process mode, punching and blanking, bending composite mold, punching and blanking the middle bend, both ends of the curved composite mode, three sets of stamping die process calculation and design of each mold parts: punch, die, punch fixed plate and the fixed plate of the die, stripper plate, bending modulus and so on. In accordance with the steps of stamping die design different sets of stamping dies, the appropriate choice of guide posts, guide sleeve, die handle and mold standard parts. The final completion of the air filter holder of stamping mold design.

Key words: Stamping process;Punching blanking the composite modulus;Bending mode

目录

1 绪 论 1

1.1国内模具的现状和发展趋势 2

1.1.1国内模具的现状 3

1.1.2国内模具的发展趋势 3

1.1.3国外模具的现状和发展趋势 3

2 滤清器固定架的工艺方案的制定 5

2.1滤清器固定架的工艺性分析 5

2.1.1滤清器固定架的精度和粗糙度 6

2.1.2滤清器固定架毛坯尺寸的计算 6

2.1.3零件的排样图 8

2.2计算冲压力和初选压力机 10

2.2.1冲裁力计算 10

2.2.2冲压设备的初选 12

2.2.3 模具压力中心的确定 12

3 冲孔、落料复合模的设计 13

3.1冲孔、落料复合模主要零部件的结构设计 13

3.1.1 落料凹模 13

3.1.2 冲孔凸模 14

3.1.3 冲孔凹模的设计 15

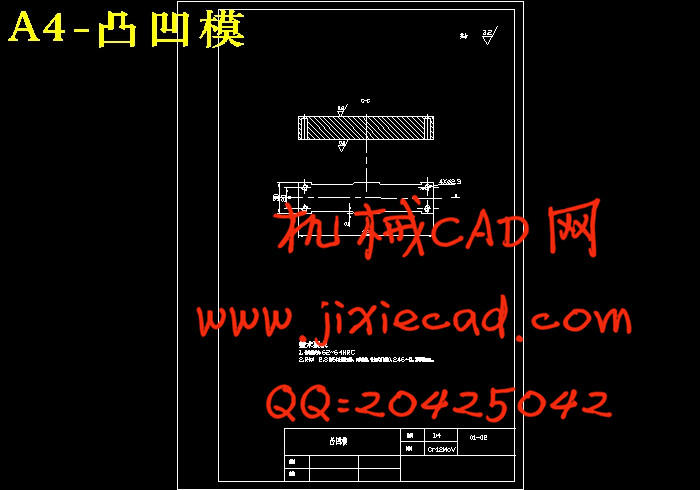

3.1.4 凸凹模 16

3.1.5凸、凹模间隙值的确定 16

3.1.6 凸、凹模刃口尺寸的确定 17

3.2模具总体结构方案 22

3.2.1模具结构 23

3.2.2操作与定位方式 23

3.2.3卸料方式 23

3.2.4模架类型的选择 23

3.2.5 螺钉与圆柱销的设计与选用 23

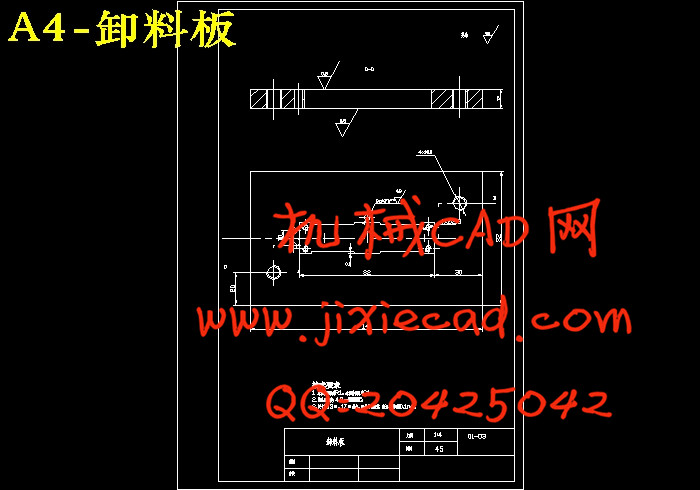

3.2.6 卸料板 25

3.2.7 挡料装置 25

3.2.8 模座 25

3.2.9 模柄 25

3.2.10推杆 25

3.2.11 导柱、导套 26

3.2.12冲模闭合高度的确定 26

3.3压力机的校核 27

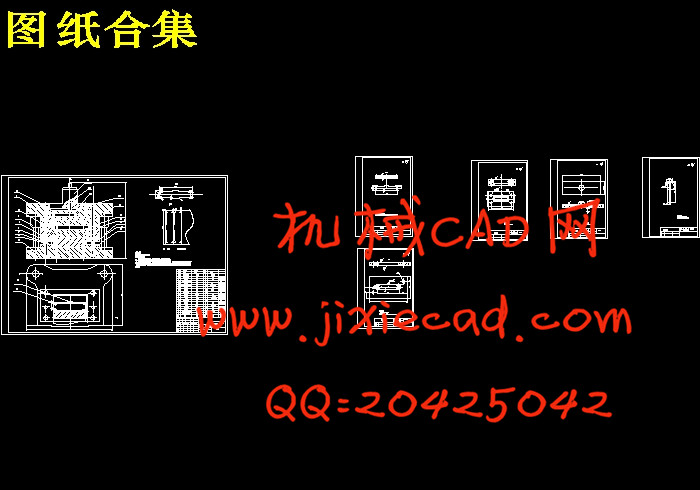

4模具总装图 28

5 结束语 29

6 致 谢 30

7 参考文献 31