设计简介

风罩成形工艺及模具设计

摘要:冷冲压加工在我国已有很长的历史,封建社会时期我国劳动人民纯手工打造金、银和铜饰品,制作各种日用品,就已显示出精巧的工艺技术,但那时人们劳动强度大,制作时间长,不宜生产大量的生活用品供生活所需,随着现今科技的进步,工业发展,模具在工业生产中引起了人们的重视。冲压模具生产产品效率高,能保证工件的精度,实现了自动化,适合大批量生产。未来模具将向全面推广CAD/CAE/CAM,模具优质材料及表面处理技术,特种加工,模具扫描及数字化系统,模具研磨抛光将自动化、智能化,模具自动加工系统方向发展。

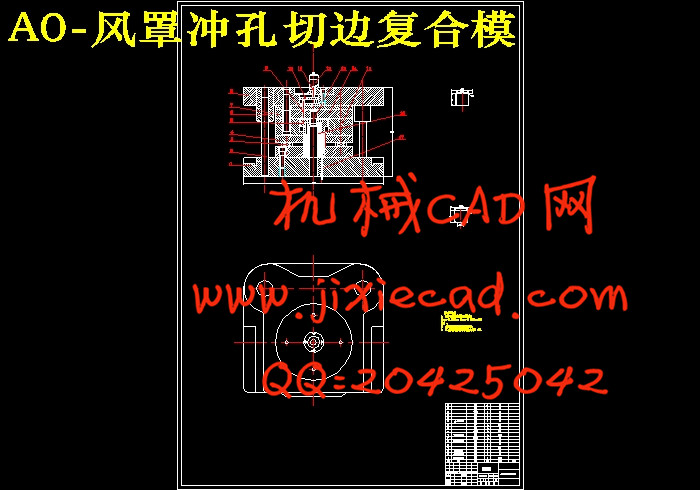

本设计是对风罩的落料、冲孔、切边的设计,完成的内容为:对模具在工业生产中的作用,模具发展历史与现状,未来模具的发展前景做了概述。进行零件的形状、尺寸、精度工艺分析,确定合理的工艺方案,确定工序数目。确定拉深凸、凹模间隙,计算落料、冲孔的凸、凹模刃口尺寸。确定凸、凹模结构,并绘制零件图,设计定位零件,压料、卸料、出件零部件,设计固定零件,选择模架标注紧固件,最后绘制模具非标准零件图。

本设计运用模具使钢料产生塑性变形,获得最终需要的零件,这是一种少切削、无切削、多工序重合的生产方法,并且生产零件,提高了生产效率,对相似工件的大批量生产具有参考的作用。

关键词:风罩; 落料; 冲孔; 切边; 复合膜

The wind cover forming technology and die design

Abstract:Cold stamping has a long history in China. The period of feudal society, our working people handmade gold, silver and copper jewelry, production of daily necessities, Already shows a sophisticated technology, But then the people to the labor intensity of production a long time, should not produce large amounts of daily necessities for living expenses. With today's advances in technology, industrial development, attracted the attention of people die in industrial production. Stamping mold products, high efficiency, to ensure the precision of the workpiece, automated, suitable for mass production. The mold will comprehensively promote the automation of CAD / CAE / CAM, mold-quality materials and surface treatment techniques, special machining, mold scanning and digitizing systems, mold grinding polishing, intelligent, mold automatic processing system direction.

This design is to wind a cover the design of the blanking, punching and trimming, to complete the content as follows: to die in the role of industrial production, mold development history and present situation, future development prospects of the overview of the mould. Components of the shape, size, precision process analysis, to determine the reasonable processing plan, determine the number of process. Determine the drawing convex and concave die clearance, calculation of blanking, punching convex and concave die cutting edge dimension. Determine the convex and concave die structure, and draw the part drawing, design positioning parts, pressure, discharge, the components, design of fixed parts, choose to die set with fasteners, the final map die non-standard parts.

The use of design mold steel material of the plastic deformation, to obtain the final parts, this is a little cutting, cutting, process production methods overlap, and progressive die production parts, improve production efficiency, similar to the workpiece high-volume production with reference to the role.

Keywords:fan cowl ;Blanking. Punching; Trimming; Composite membrane.

目录

第一章 绪论 1

1.1 模具的发展历史与现状 1

1.2 冲压模具的发展趋势 1

1.2.1 模具自动加工系统的发展 2

1.2.2 优质材料及先进表面处理技术 2

1.2.3 特种加工技术的发展 2

1.2.4全面推广CAD/CAM/CAE技术 2

1.2.5 模具扫描及数字化系统 2

1.3 本论文研究的内容 3

第二章 风罩冲压工艺的分析 4

2.1 零件的工艺性分析 4

2.1.1 工件的设计要求 4

2.1.2 零件工艺性分析 4

2.1.3冲压工艺方案的确定 5

2.2 冲裁过程中的相关计算问题 5

2.2.1 冲裁力的计算 5

2.2.2 工作零件刃口尺寸计算 5

2.2.3 冲裁刃口尺寸计算原则 6

2..2.4 冲裁凸凹模刃口尺寸计算 6

2.2.5 冲孔力 8

2.2.6 推件力.8

2.2.7 顶件力.9

第三章 模具的结构设计 10

3.1冲压设备类型的选择 10

3.1.1 冲压设备规格的确定 10

3.2 凸凹模固定板 11

3.3 导柱导套 13

3.4垫板 13

3.5 紧固件连接件 14

3.6 模柄和模架的选择 14

3.7 其它零件.15

3.8 模具总体结构的设计 16

第四章 模具零件的加工工艺19

设计总结 21

参考文献 22

致谢 23

摘要:冷冲压加工在我国已有很长的历史,封建社会时期我国劳动人民纯手工打造金、银和铜饰品,制作各种日用品,就已显示出精巧的工艺技术,但那时人们劳动强度大,制作时间长,不宜生产大量的生活用品供生活所需,随着现今科技的进步,工业发展,模具在工业生产中引起了人们的重视。冲压模具生产产品效率高,能保证工件的精度,实现了自动化,适合大批量生产。未来模具将向全面推广CAD/CAE/CAM,模具优质材料及表面处理技术,特种加工,模具扫描及数字化系统,模具研磨抛光将自动化、智能化,模具自动加工系统方向发展。

本设计是对风罩的落料、冲孔、切边的设计,完成的内容为:对模具在工业生产中的作用,模具发展历史与现状,未来模具的发展前景做了概述。进行零件的形状、尺寸、精度工艺分析,确定合理的工艺方案,确定工序数目。确定拉深凸、凹模间隙,计算落料、冲孔的凸、凹模刃口尺寸。确定凸、凹模结构,并绘制零件图,设计定位零件,压料、卸料、出件零部件,设计固定零件,选择模架标注紧固件,最后绘制模具非标准零件图。

本设计运用模具使钢料产生塑性变形,获得最终需要的零件,这是一种少切削、无切削、多工序重合的生产方法,并且生产零件,提高了生产效率,对相似工件的大批量生产具有参考的作用。

关键词:风罩; 落料; 冲孔; 切边; 复合膜

The wind cover forming technology and die design

Abstract:Cold stamping has a long history in China. The period of feudal society, our working people handmade gold, silver and copper jewelry, production of daily necessities, Already shows a sophisticated technology, But then the people to the labor intensity of production a long time, should not produce large amounts of daily necessities for living expenses. With today's advances in technology, industrial development, attracted the attention of people die in industrial production. Stamping mold products, high efficiency, to ensure the precision of the workpiece, automated, suitable for mass production. The mold will comprehensively promote the automation of CAD / CAE / CAM, mold-quality materials and surface treatment techniques, special machining, mold scanning and digitizing systems, mold grinding polishing, intelligent, mold automatic processing system direction.

This design is to wind a cover the design of the blanking, punching and trimming, to complete the content as follows: to die in the role of industrial production, mold development history and present situation, future development prospects of the overview of the mould. Components of the shape, size, precision process analysis, to determine the reasonable processing plan, determine the number of process. Determine the drawing convex and concave die clearance, calculation of blanking, punching convex and concave die cutting edge dimension. Determine the convex and concave die structure, and draw the part drawing, design positioning parts, pressure, discharge, the components, design of fixed parts, choose to die set with fasteners, the final map die non-standard parts.

The use of design mold steel material of the plastic deformation, to obtain the final parts, this is a little cutting, cutting, process production methods overlap, and progressive die production parts, improve production efficiency, similar to the workpiece high-volume production with reference to the role.

Keywords:fan cowl ;Blanking. Punching; Trimming; Composite membrane.

目录

第一章 绪论 1

1.1 模具的发展历史与现状 1

1.2 冲压模具的发展趋势 1

1.2.1 模具自动加工系统的发展 2

1.2.2 优质材料及先进表面处理技术 2

1.2.3 特种加工技术的发展 2

1.2.4全面推广CAD/CAM/CAE技术 2

1.2.5 模具扫描及数字化系统 2

1.3 本论文研究的内容 3

第二章 风罩冲压工艺的分析 4

2.1 零件的工艺性分析 4

2.1.1 工件的设计要求 4

2.1.2 零件工艺性分析 4

2.1.3冲压工艺方案的确定 5

2.2 冲裁过程中的相关计算问题 5

2.2.1 冲裁力的计算 5

2.2.2 工作零件刃口尺寸计算 5

2.2.3 冲裁刃口尺寸计算原则 6

2..2.4 冲裁凸凹模刃口尺寸计算 6

2.2.5 冲孔力 8

2.2.6 推件力.8

2.2.7 顶件力.9

第三章 模具的结构设计 10

3.1冲压设备类型的选择 10

3.1.1 冲压设备规格的确定 10

3.2 凸凹模固定板 11

3.3 导柱导套 13

3.4垫板 13

3.5 紧固件连接件 14

3.6 模柄和模架的选择 14

3.7 其它零件.15

3.8 模具总体结构的设计 16

第四章 模具零件的加工工艺19

设计总结 21

参考文献 22

致谢 23