设计简介

筒形件冲压成形工艺与模具设计

摘 要 : 此次设计为落料—拉深—冲孔复合模,设计本模具充分利用了网上资源,图书馆藏书,更重要的是老师的谆谆教导,才成就了此模具。

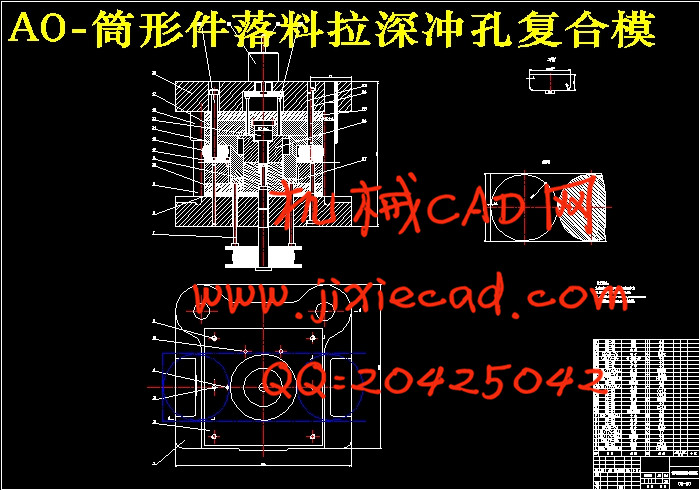

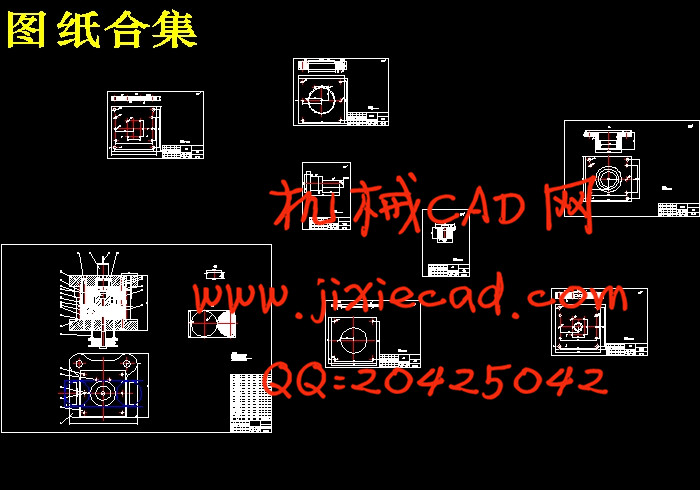

在模具的设计过程中,首先,简要地概述了冲压模具的特点和在社会发展领域中的作用及其以后的发展前途,点明了模具的设计意义;其次进行工件的工艺分析;进而确定了工艺方案,计算出了模具工作部分的尺寸公差,设计出零部件,然后依据设计要求选择各个标准件,最后设计出模具的总装配图。在设计过程中需要计算冲压力,落料力,拉深力及推件力,卸料力,从而判断模具各部件是否能承受压力机的作用,更重要的是模具工作零件的设计,以此为核心的问题,工作零件的误差将直接影响制件的质量。最后利于绘图工具AutoCAD制作了装配图和零件图,而节省了许多时间。

通过此次设计使我不仅掌握了冲压模具设计的一般流程,更好的学习好多在课本上没有学习的知识。

关键词 : 冲孔,拉深,计算机绘图,工艺分析

THE CYLINDRICAL PARTS

FORMING TECHNOLOGY AND DIE DESIGN

ABSTRACT :This time design for fall to anticipate- pull deep- blunt bore compound mold, design originally the molding tool made use of the on-line resources well, the library library, the more important teacher earnestly instruct, just achieving this molding tool.

In the design process of the molding tool, first, the synopsis ground says to hurtle the characteristics of press the molding tool all and after society develop the function in the realm and it of development prospect, order the design meaning of understand the molding tool;Carry on the craft analysis of the work piece the next in order;Then made sure the craft project, compute the molding tool work the size business trip of the part, design zero partses of, then request to choose the each standard piece according to the design, designing a total assemble diagram of molding tool finally.The demand computes the blunt pressure in design process, falling to anticipate the dint, pulling the deep dint and pushing a dint, unloading to anticipate the dint, thus judging whether each parts of molding tool can bear the function of the pressure machine or not, the design of the more important molding tool work spare parts, with this for core of problem, the error margin of the work spare parts will affect the quantity of make the piece directly.Finally the benefit manufactures to assemble the diagram and the spare parts diagrams in the painting tool .

Pass this time design make me not only controled to hurtle the general process of press the molding tool design, the better study is a lot of in the lesson originally up have no knowledge of study.

KEY WORDS: Blunt bore ,Pull deeply ,The calculator painting,The craft analysis

目录

1.绪论 1

1.1 冲压模具水平状况 1

1.2 冷冲压的应用 1

1.3 冲压模具的发展重点与展望 2

1.3.1 冲压模具产品发展重点 2

1.3.2 冲压模具技术发展重点 2

2.制件工艺分析及工艺方案确定 4

2.1 工艺分析 5

2.2 工艺方案的确定 6

2.3 制件排样及相关的计算 6

3.冲压模具设计 8

3.1 确定冲模类型及结构形式 8

3.2 计算工序压力,选择压力机 8

3.3 计算压力中心 11

3.4 计算模具零件主要工作部分的刃口尺寸 11

3.4.1 凸、凹模刃口尺寸的确定 11

3.4.2 凸、凹模配合加工时的工作部分尺寸 11

3.5 弹性元件的设计计算 14

3.6 模具主要零部件的结构设计 15

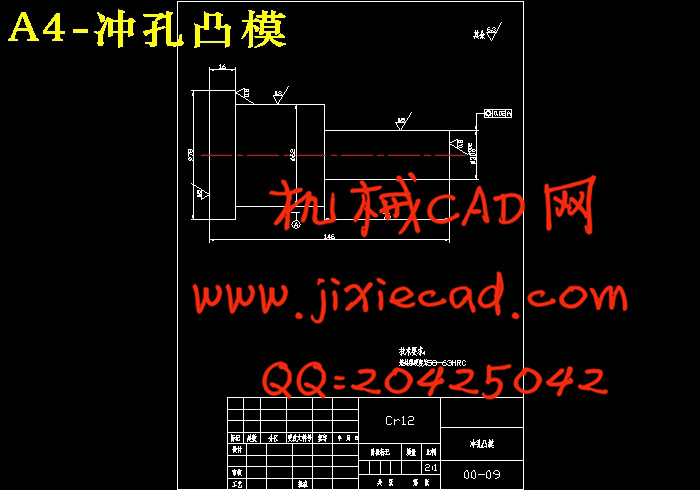

3.6.1 凸模、凹模、凸凹模的结构设计 15

3.6.2 卸料装置的设计与标准化 16

3.6.3 标准模架的选用 17

3.6.4 挡料销、导料销的的选用 18

3.6.5 螺钉与销钉的选择 18

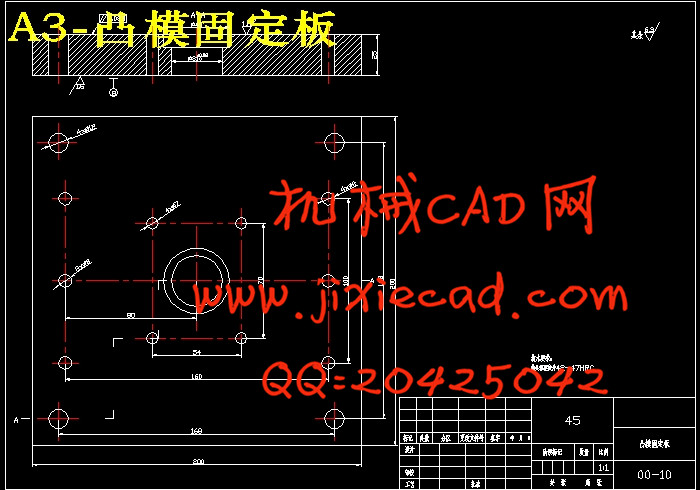

3.6.6 模具中各板的尺寸 19

3.6.7 推件装置的选择 19

3.6.8 顶件装置的选用 19

3.6.9 压边装置的选择 19

4.筒形件复合模装配和注意事项 20

4.1 冲压模具装配的技术要求 20

4.2 筒形件复合模装配的特点 21

4.3 试冲与调整 21

4.4 模具零件的制造需要注意的事项 22

4.5 复合模具总装配 22

总结 24

致谢 26

参考文献 27

摘 要 : 此次设计为落料—拉深—冲孔复合模,设计本模具充分利用了网上资源,图书馆藏书,更重要的是老师的谆谆教导,才成就了此模具。

在模具的设计过程中,首先,简要地概述了冲压模具的特点和在社会发展领域中的作用及其以后的发展前途,点明了模具的设计意义;其次进行工件的工艺分析;进而确定了工艺方案,计算出了模具工作部分的尺寸公差,设计出零部件,然后依据设计要求选择各个标准件,最后设计出模具的总装配图。在设计过程中需要计算冲压力,落料力,拉深力及推件力,卸料力,从而判断模具各部件是否能承受压力机的作用,更重要的是模具工作零件的设计,以此为核心的问题,工作零件的误差将直接影响制件的质量。最后利于绘图工具AutoCAD制作了装配图和零件图,而节省了许多时间。

通过此次设计使我不仅掌握了冲压模具设计的一般流程,更好的学习好多在课本上没有学习的知识。

关键词 : 冲孔,拉深,计算机绘图,工艺分析

THE CYLINDRICAL PARTS

FORMING TECHNOLOGY AND DIE DESIGN

ABSTRACT :This time design for fall to anticipate- pull deep- blunt bore compound mold, design originally the molding tool made use of the on-line resources well, the library library, the more important teacher earnestly instruct, just achieving this molding tool.

In the design process of the molding tool, first, the synopsis ground says to hurtle the characteristics of press the molding tool all and after society develop the function in the realm and it of development prospect, order the design meaning of understand the molding tool;Carry on the craft analysis of the work piece the next in order;Then made sure the craft project, compute the molding tool work the size business trip of the part, design zero partses of, then request to choose the each standard piece according to the design, designing a total assemble diagram of molding tool finally.The demand computes the blunt pressure in design process, falling to anticipate the dint, pulling the deep dint and pushing a dint, unloading to anticipate the dint, thus judging whether each parts of molding tool can bear the function of the pressure machine or not, the design of the more important molding tool work spare parts, with this for core of problem, the error margin of the work spare parts will affect the quantity of make the piece directly.Finally the benefit manufactures to assemble the diagram and the spare parts diagrams in the painting tool .

Pass this time design make me not only controled to hurtle the general process of press the molding tool design, the better study is a lot of in the lesson originally up have no knowledge of study.

KEY WORDS: Blunt bore ,Pull deeply ,The calculator painting,The craft analysis

目录

1.绪论 1

1.1 冲压模具水平状况 1

1.2 冷冲压的应用 1

1.3 冲压模具的发展重点与展望 2

1.3.1 冲压模具产品发展重点 2

1.3.2 冲压模具技术发展重点 2

2.制件工艺分析及工艺方案确定 4

2.1 工艺分析 5

2.2 工艺方案的确定 6

2.3 制件排样及相关的计算 6

3.冲压模具设计 8

3.1 确定冲模类型及结构形式 8

3.2 计算工序压力,选择压力机 8

3.3 计算压力中心 11

3.4 计算模具零件主要工作部分的刃口尺寸 11

3.4.1 凸、凹模刃口尺寸的确定 11

3.4.2 凸、凹模配合加工时的工作部分尺寸 11

3.5 弹性元件的设计计算 14

3.6 模具主要零部件的结构设计 15

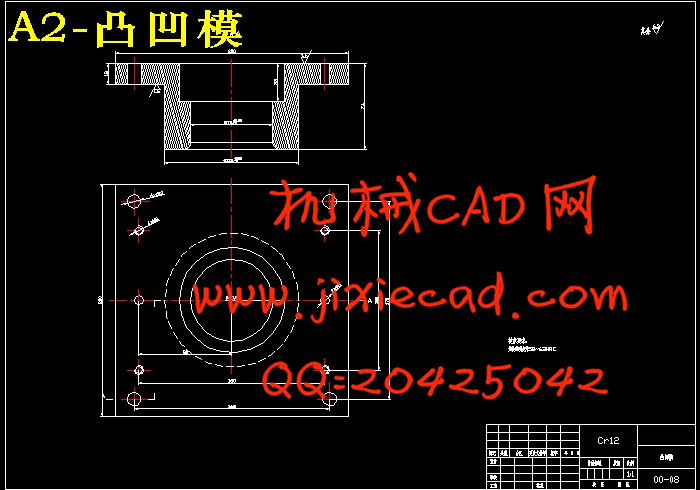

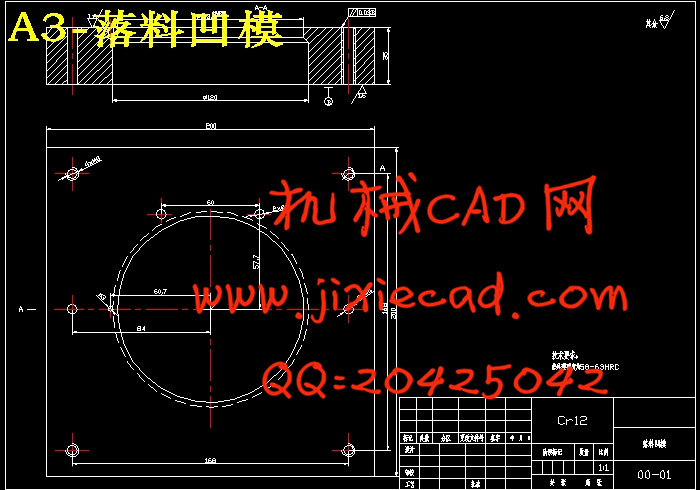

3.6.1 凸模、凹模、凸凹模的结构设计 15

3.6.2 卸料装置的设计与标准化 16

3.6.3 标准模架的选用 17

3.6.4 挡料销、导料销的的选用 18

3.6.5 螺钉与销钉的选择 18

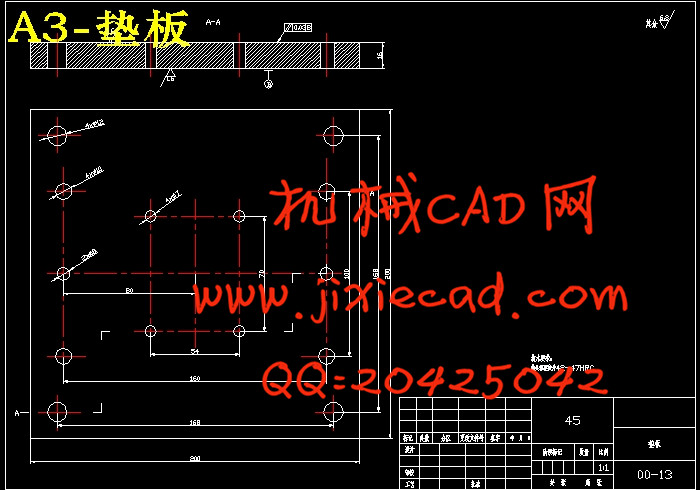

3.6.6 模具中各板的尺寸 19

3.6.7 推件装置的选择 19

3.6.8 顶件装置的选用 19

3.6.9 压边装置的选择 19

4.筒形件复合模装配和注意事项 20

4.1 冲压模具装配的技术要求 20

4.2 筒形件复合模装配的特点 21

4.3 试冲与调整 21

4.4 模具零件的制造需要注意的事项 22

4.5 复合模具总装配 22

总结 24

致谢 26

参考文献 27