设计简介

摘 要

模具工业是国民经济各部门发展的重要基础产业,具有生产精度高、生产效率高、生产周期短等特点。冲压模具在实际工业生产中应用广泛。冲压模具可以大大的提高劳动生产效率,减轻工人负担,具有重要的技术进步意义和经济价值。

本次设计的主要任务是安装座弯曲模的设计与加工工艺的制订。通过对零件的工艺分析,确定工艺方案,模具的设计与计算,设计冲压力与压力中心,选定压力机,完成了模具的设计,并对主要零部件进行了加工工艺的分析以及加工工艺方案的制订。通过此次设计,掌握了弯曲模具的设计流程、方法以及零部件的加工工艺。

关键词:凸模;凹模;级进模;弯曲模

ABSTRACT

The mold industry is the important base industry each department of national economy develop, possession the precision of production high, the production efficiency is high and produces the periods short and so on the characteristics. Punching die has been widely used in industrial production. Punching die could increase the efficiency of production and could alleviate the work burden,so it has significant meaning in technologic progress and economic value. This paper introduces inflectional of punching die and swell of punching die , and mainly ,and it introduces ,die design and process plan of assmebled bracket. And it including: the process of the parts analysis to determine the process plan, design and calculate of the mould, design stamping press and the pressure Center, selected presses, draw part drawing and assembly drawing. Process plan of assmebled bracket including: analysis of part’s shape, select of blank, the main part’s process has selected and analysised. The dies here discussed can be easily made, conveniently used, and safely operated. And it could be used as the reference in the large scale production of similar workpieces.

Key Words: Punching Die; Core; Cavity; Composite Dies

目录

1 引言 1

1.1冲压的概念、特点及应用 1

1.2冲压的基本工序及模具 2

1.3冲压技术的现代级发展方向 3

2 分析制件的结构工艺性 8

2.1 制件的结构分析 8

2.2 制件的材料分析 9

2.3 确定工艺方案 9

3 冲压模具总体结构分析 11

3.1 模具类型 11

3.2 操作与定位分析 11

3.3 卸料与出件方式 11

3.4 模架类型及精度 11

4 冲压模具工艺 12

4.1 排样设计与计算 13

4.2 弯曲见的展开与计算 13

4.3 确定条料宽度及步距 14

4.4 材料利用率 15

5 设计计算 16

5.1 冲裁件的冲裁力和卸料力 16

5.2 压力中心确定和初选压力机 17

5.3 冲裁刃口尺寸计算 19

5.4 弯曲部分 24

5.5 最小弯曲相对半径 26

5.6 弯曲力计算 27

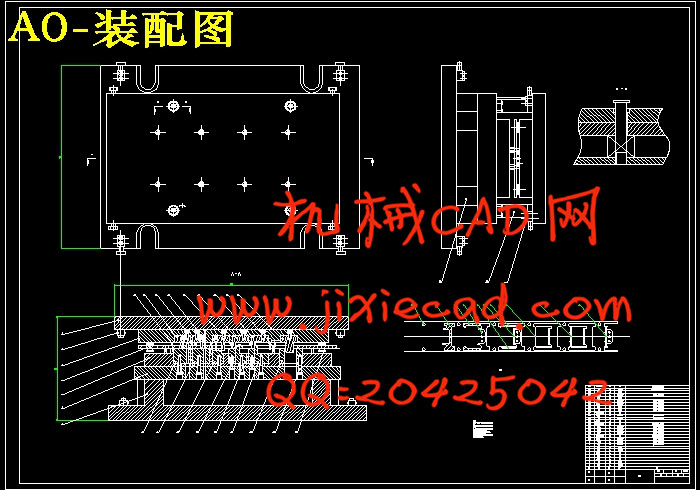

6模具总装图 29

6.1 模具总装图 29

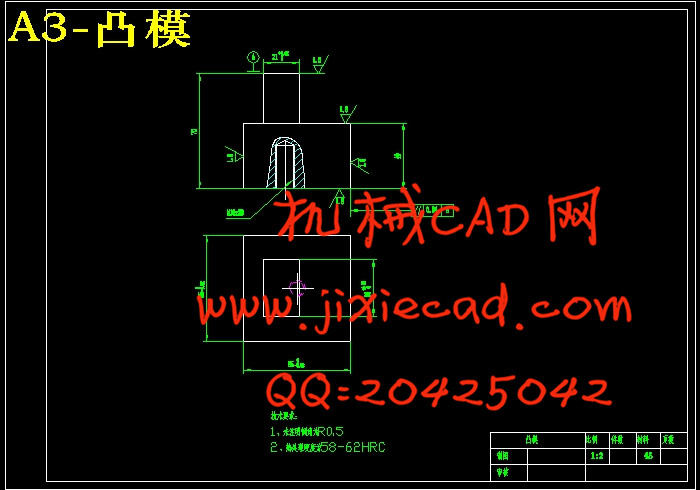

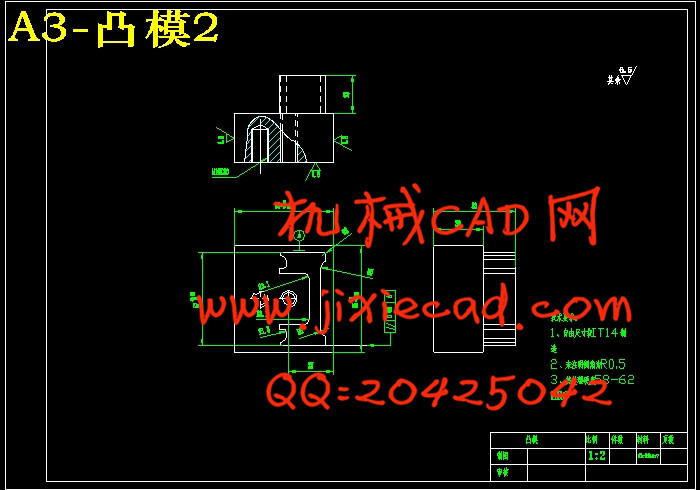

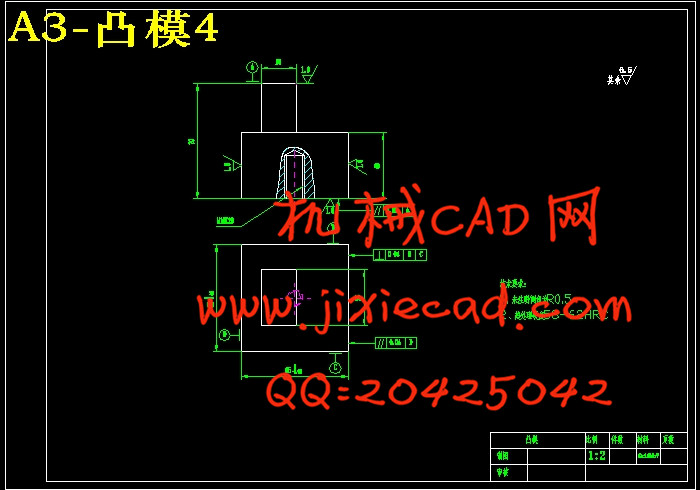

6.2 凸模计算 29

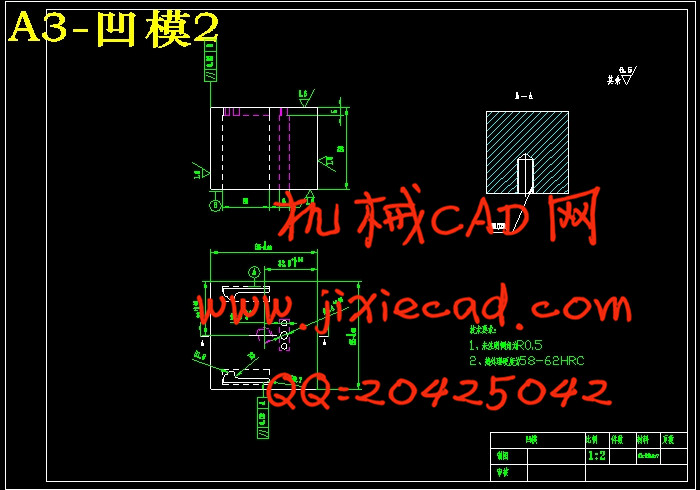

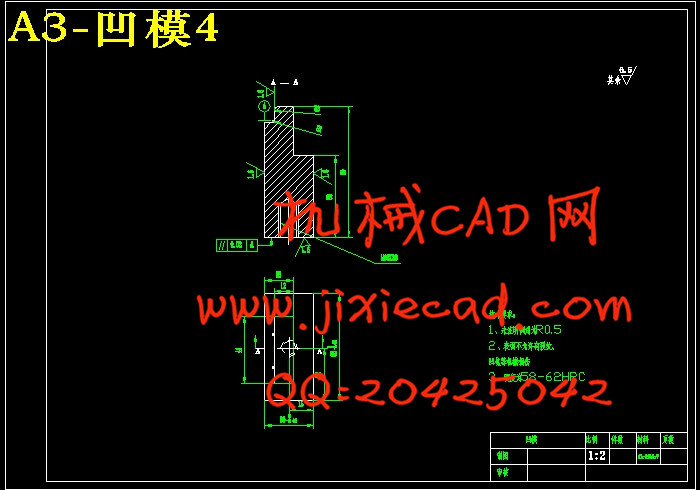

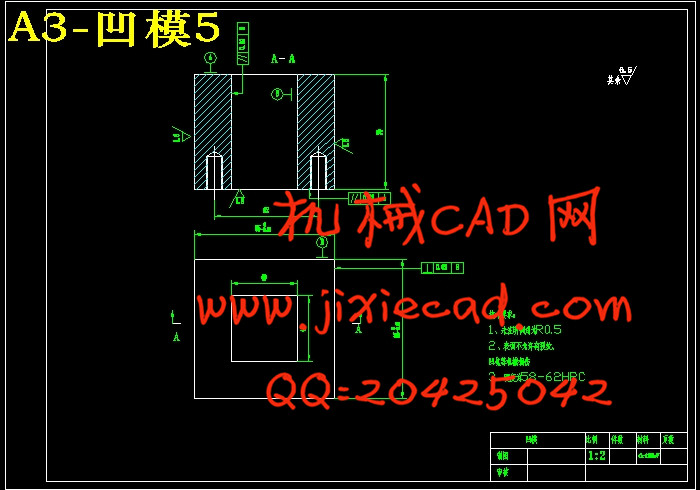

6.3 凹模计算 31

6.4校核冲压机设备基本参数 33

7 冲压模具零件加工工艺的编制 35

7.1凹模固定板加工工艺 35

7.2各凹模加工工艺 35

7.3卸料板加工工艺 36

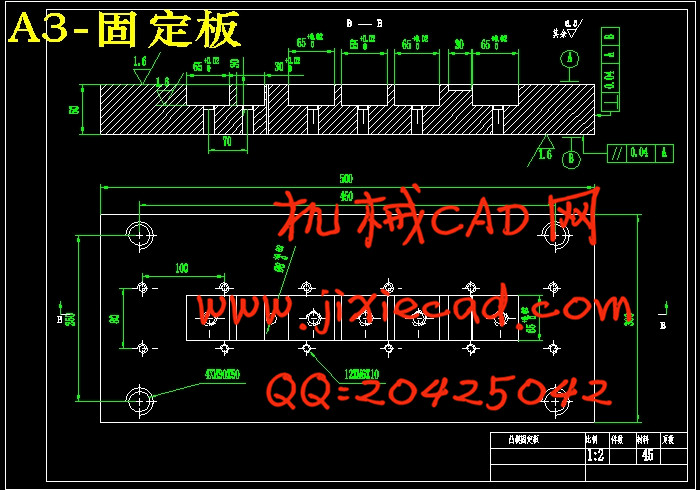

7.4凸模固定板加工工艺 36

7.5 上模座加工工艺 37

7.6冲孔凸模加工工艺 37

7.7冲孔凸模加工工艺 38

8 总结 39

8.1毕业设计感想 9

8.2存在问题与解决设想 39

参考文献 40

致谢 41

模具工业是国民经济各部门发展的重要基础产业,具有生产精度高、生产效率高、生产周期短等特点。冲压模具在实际工业生产中应用广泛。冲压模具可以大大的提高劳动生产效率,减轻工人负担,具有重要的技术进步意义和经济价值。

本次设计的主要任务是安装座弯曲模的设计与加工工艺的制订。通过对零件的工艺分析,确定工艺方案,模具的设计与计算,设计冲压力与压力中心,选定压力机,完成了模具的设计,并对主要零部件进行了加工工艺的分析以及加工工艺方案的制订。通过此次设计,掌握了弯曲模具的设计流程、方法以及零部件的加工工艺。

关键词:凸模;凹模;级进模;弯曲模

ABSTRACT

The mold industry is the important base industry each department of national economy develop, possession the precision of production high, the production efficiency is high and produces the periods short and so on the characteristics. Punching die has been widely used in industrial production. Punching die could increase the efficiency of production and could alleviate the work burden,so it has significant meaning in technologic progress and economic value. This paper introduces inflectional of punching die and swell of punching die , and mainly ,and it introduces ,die design and process plan of assmebled bracket. And it including: the process of the parts analysis to determine the process plan, design and calculate of the mould, design stamping press and the pressure Center, selected presses, draw part drawing and assembly drawing. Process plan of assmebled bracket including: analysis of part’s shape, select of blank, the main part’s process has selected and analysised. The dies here discussed can be easily made, conveniently used, and safely operated. And it could be used as the reference in the large scale production of similar workpieces.

Key Words: Punching Die; Core; Cavity; Composite Dies

目录

1 引言 1

1.1冲压的概念、特点及应用 1

1.2冲压的基本工序及模具 2

1.3冲压技术的现代级发展方向 3

2 分析制件的结构工艺性 8

2.1 制件的结构分析 8

2.2 制件的材料分析 9

2.3 确定工艺方案 9

3 冲压模具总体结构分析 11

3.1 模具类型 11

3.2 操作与定位分析 11

3.3 卸料与出件方式 11

3.4 模架类型及精度 11

4 冲压模具工艺 12

4.1 排样设计与计算 13

4.2 弯曲见的展开与计算 13

4.3 确定条料宽度及步距 14

4.4 材料利用率 15

5 设计计算 16

5.1 冲裁件的冲裁力和卸料力 16

5.2 压力中心确定和初选压力机 17

5.3 冲裁刃口尺寸计算 19

5.4 弯曲部分 24

5.5 最小弯曲相对半径 26

5.6 弯曲力计算 27

6模具总装图 29

6.1 模具总装图 29

6.2 凸模计算 29

6.3 凹模计算 31

6.4校核冲压机设备基本参数 33

7 冲压模具零件加工工艺的编制 35

7.1凹模固定板加工工艺 35

7.2各凹模加工工艺 35

7.3卸料板加工工艺 36

7.4凸模固定板加工工艺 36

7.5 上模座加工工艺 37

7.6冲孔凸模加工工艺 37

7.7冲孔凸模加工工艺 38

8 总结 39

8.1毕业设计感想 9

8.2存在问题与解决设想 39

参考文献 40

致谢 41