设计简介

摘 要

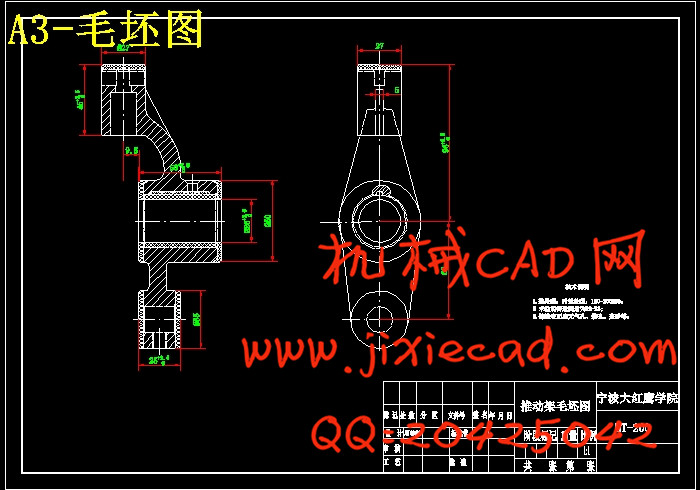

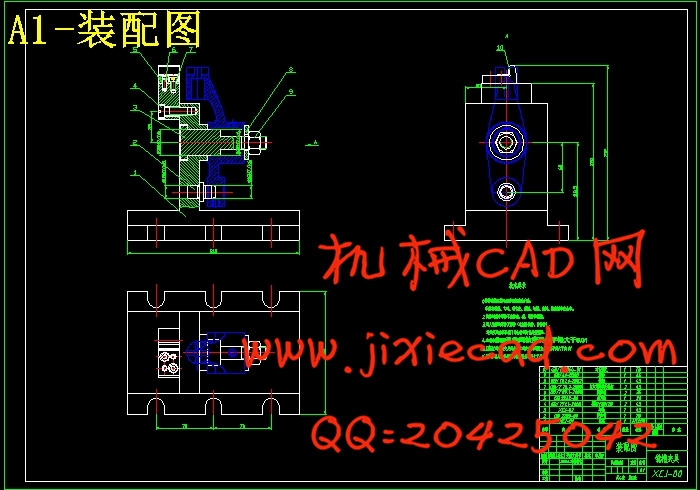

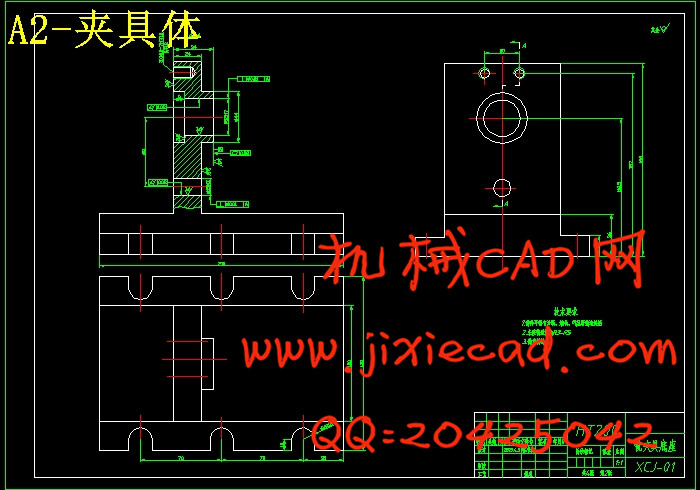

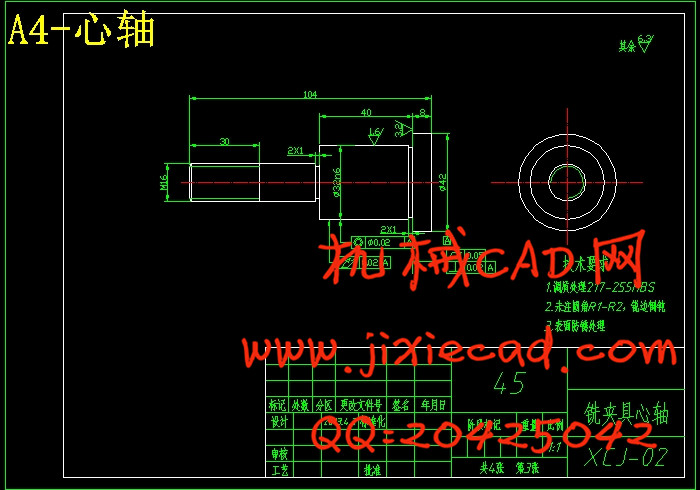

机械加工工艺规程设计和机床专用夹具设计在零件生产制造中有着很重要的作用。制定可行的机械加工工艺路线和设计合理的夹具才可确保零件的加工质量,生产出合格的产品。本设计的内容可分为机械加工工艺规程设计和机床专用夹具设计两大部分。先对B6065刨床推动架零件进行了详细的分析,了解其作用及加工要求。制定了两套工艺路线,通过分析、比较,最终确定了工艺路线方案,确定出加工余量和工序尺寸,选择了合适的加工设备,确定出了切削用量,计算了加工所需的基本工时。又运用夹具设计的基本原理和方法,拟定夹具设计的方案,针对零件加工中的铣槽工序和钻孔工序设计了三套专用夹具。本设计的加工工艺合理,夹具可行、高效、省力,能满足零件的加工要求,保证其加工质量。

关键词:机械加工;工艺规程;专用夹具;推动架

Abstract

The machining process planning design and machine tool fixture design plays a very important role in parts manufacturing. Make feasible machining technology route and design reasonable fixture can ensure machining quality, product qualified. The design of the content can be divided into design for mechanical machining and machine fixture design two parts. First the B6065 planer promote frame parts are analyzed in detail, understanding the role and requirements of the processing, formulation, analysis, comparison and determine the process scheme, machining allowance and the process dimensions were determined, choose suitable processing equipment, to determine the cutting parameters, calculate the basic work processing required. And by using the basic principle and method of fixture design, fixture design scheme proposed, aiming at the slot milling machining process and drilling process three sets of special fixture design. Processing technology of the design is reasonable, feasible, high efficiency, labor saving fixture, can meet the processing requirements of parts, ensure the machining quality.

Key Words: Mechanical processing; process planning; special fixture; promote

frame

目 录

1绪论................................................................................................................... 1

1.1题目背景及研究意义..................................................................................... 1

1.2国内外相关研究情况..................................................................................... 1

1.3本课题主要内容............................................................................................. 4

2零件的分析.................................................................................................... 5

2.1零件的作用和结构......................................................................................... 5

2.2零件的工艺分析............................................................................................. 5

2.3零件的生产纲领............................................................................................. 7

3机械加工工艺规程设计........................................................................... 8

3.1零件表面加工方法的选择............................................................................. 8

3.2制定机械加工工艺路线................................................................................. 8

3.3工艺方案的比较与分析................................................................................. 9

3.4工序尺寸的确定........................................................................................... 11

3.5加工余量的确定........................................................................................... 12

3.6选择加工设备与工艺设备........................................................................... 13

3.7切削用量及基本时间的确定....................................................................... 14

4钻ϕ16孔专用夹具设计......................................................................... 38

4.1夹具的相关知识........................................................................................... 38

4.2问题的提出................................................................................................... 39

4.3研究原始质料............................................................................................... 39

4.4定位基准的选择........................................................................................... 39

4.5夹紧方案的选择........................................................................................... 40

4.6其他重要零件选择....................................................................................... 40

4.7切削力和夹紧力计算................................................................................... 40

4.8定位误差分析............................................................................................... 41

4.9夹具设计及操作的简要说明....................................................................... 42

5铣槽专用夹具设计................................................................................... 43

5.1问题的提出................................................................................................... 43

5.2研究原始质料............................................................................................... 43

5.3定位基准的选择........................................................................................... 43

5.4夹紧方案的选择........................................................................................... 44

5.5切削力和夹紧力计算................................................................................... 44

5.6定位误差分析............................................................................................... 45

5.7夹具设计及操作的简要说明....................................................................... 45

6钻ϕ6孔专用夹具设计............................................................................ 46

6.1问题的提出................................................................................................... 46

6.2研究原始质料............................................................................................... 46

6.3定位基准的选择........................................................................................... 46

6.4夹紧方案的选择........................................................................................... 47

6.5其他重要零件选择....................................................................................... 47

6.6切削力和夹紧力计算................................................................................... 47

6.7定位误差分析............................................................................................... 48

6.8夹具设计及操作的简要说明....................................................................... 48

7结论................................................................................................................. 49

参考文献........................................................................................................... 50

致谢..................................................................................................................... 51

机械加工工艺规程设计和机床专用夹具设计在零件生产制造中有着很重要的作用。制定可行的机械加工工艺路线和设计合理的夹具才可确保零件的加工质量,生产出合格的产品。本设计的内容可分为机械加工工艺规程设计和机床专用夹具设计两大部分。先对B6065刨床推动架零件进行了详细的分析,了解其作用及加工要求。制定了两套工艺路线,通过分析、比较,最终确定了工艺路线方案,确定出加工余量和工序尺寸,选择了合适的加工设备,确定出了切削用量,计算了加工所需的基本工时。又运用夹具设计的基本原理和方法,拟定夹具设计的方案,针对零件加工中的铣槽工序和钻孔工序设计了三套专用夹具。本设计的加工工艺合理,夹具可行、高效、省力,能满足零件的加工要求,保证其加工质量。

关键词:机械加工;工艺规程;专用夹具;推动架

Abstract

The machining process planning design and machine tool fixture design plays a very important role in parts manufacturing. Make feasible machining technology route and design reasonable fixture can ensure machining quality, product qualified. The design of the content can be divided into design for mechanical machining and machine fixture design two parts. First the B6065 planer promote frame parts are analyzed in detail, understanding the role and requirements of the processing, formulation, analysis, comparison and determine the process scheme, machining allowance and the process dimensions were determined, choose suitable processing equipment, to determine the cutting parameters, calculate the basic work processing required. And by using the basic principle and method of fixture design, fixture design scheme proposed, aiming at the slot milling machining process and drilling process three sets of special fixture design. Processing technology of the design is reasonable, feasible, high efficiency, labor saving fixture, can meet the processing requirements of parts, ensure the machining quality.

Key Words: Mechanical processing; process planning; special fixture; promote

frame

目 录

1绪论................................................................................................................... 1

1.1题目背景及研究意义..................................................................................... 1

1.2国内外相关研究情况..................................................................................... 1

1.3本课题主要内容............................................................................................. 4

2零件的分析.................................................................................................... 5

2.1零件的作用和结构......................................................................................... 5

2.2零件的工艺分析............................................................................................. 5

2.3零件的生产纲领............................................................................................. 7

3机械加工工艺规程设计........................................................................... 8

3.1零件表面加工方法的选择............................................................................. 8

3.2制定机械加工工艺路线................................................................................. 8

3.3工艺方案的比较与分析................................................................................. 9

3.4工序尺寸的确定........................................................................................... 11

3.5加工余量的确定........................................................................................... 12

3.6选择加工设备与工艺设备........................................................................... 13

3.7切削用量及基本时间的确定....................................................................... 14

4钻ϕ16孔专用夹具设计......................................................................... 38

4.1夹具的相关知识........................................................................................... 38

4.2问题的提出................................................................................................... 39

4.3研究原始质料............................................................................................... 39

4.4定位基准的选择........................................................................................... 39

4.5夹紧方案的选择........................................................................................... 40

4.6其他重要零件选择....................................................................................... 40

4.7切削力和夹紧力计算................................................................................... 40

4.8定位误差分析............................................................................................... 41

4.9夹具设计及操作的简要说明....................................................................... 42

5铣槽专用夹具设计................................................................................... 43

5.1问题的提出................................................................................................... 43

5.2研究原始质料............................................................................................... 43

5.3定位基准的选择........................................................................................... 43

5.4夹紧方案的选择........................................................................................... 44

5.5切削力和夹紧力计算................................................................................... 44

5.6定位误差分析............................................................................................... 45

5.7夹具设计及操作的简要说明....................................................................... 45

6钻ϕ6孔专用夹具设计............................................................................ 46

6.1问题的提出................................................................................................... 46

6.2研究原始质料............................................................................................... 46

6.3定位基准的选择........................................................................................... 46

6.4夹紧方案的选择........................................................................................... 47

6.5其他重要零件选择....................................................................................... 47

6.6切削力和夹紧力计算................................................................................... 47

6.7定位误差分析............................................................................................... 48

6.8夹具设计及操作的简要说明....................................................................... 48

7结论................................................................................................................. 49

参考文献........................................................................................................... 50

致谢..................................................................................................................... 51