设计简介

摘要

工艺规程的原则是优质高产和低成本,即在保证产品质量的前提下缩短生产周期,改变劳动条件,提高劳动生产率,提高经济效益。夹具设计在机械加工中具有重要的作用,它能保证加工精度,提高产品质量,减轻工人的劳动强度,保证安全,提高劳动生产率,能以优质、高效、低耗的工艺去完成零件的加工和产品的装配。而使用了分度钻的好处在于,可采用多工位加工,能使加工工序集中,从而减轻工人的劳动强度和提高生产率。

使用夹具的最根本目的是获得好的经济效益。所以设计夹具也和其它技术工作一样,不仅是一个技术问题,而且是个经济问题。每当设计一套夹具之前,都要进行必要的技术经济分析,使所设计的夹具获得最佳的经济效果。同样组合机床的设计也是很重要的,科学的设计组合机床减少工作时间和工作强度。

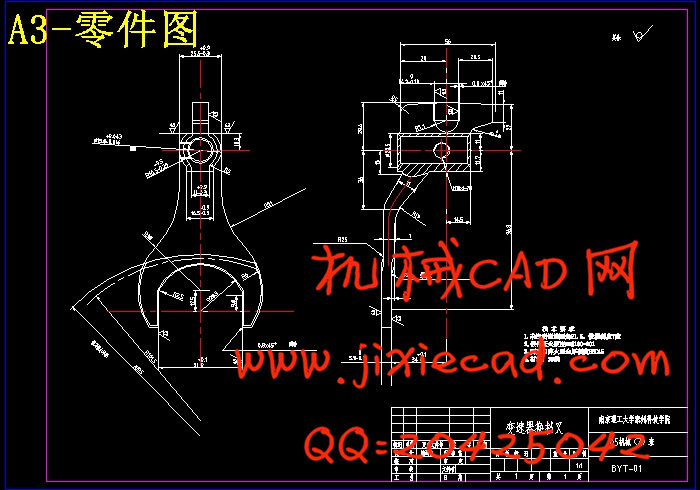

本文对变速器换挡叉的结构进行工艺分析,确定加工工艺路线,根据任务书的要求制定出零件的工艺规程,并设计工序Ⅲ粗铣19 56和2.6

56和2.6 44.6两侧面的专用夹具和组合机床。

44.6两侧面的专用夹具和组合机床。

关键词 工艺规程 夹具设计 工艺分析

Abstract

The technological procedure principle is high grade high yield and low cost , is on the premise of product quality, to shorten a production cycle , to change the condition working , to improve productivity , the improvement of economic results in guarantee. Grip design has the important effect in machine work , it can swear to process accuracy , to raise product quality , lighten worker's labour intensity , swear to safe , to improve productivity, can use high grade , high-effect, the low consumption handicraft goes to accomplish the part treating and the product assembling. But the benefit having used scale division drill lies in, may adopt multistation treating, the working procedure the energy messenger is processed concentrates, thereby, lighten worker's labour intensity and improve efficacy.

Use the basicest clamp purpose to be to gain the good economic effect. Therefore designing that the clamp is also same as other technology job, not only be a technology problem, and be economic problems. Needing to carry out necessary technical economy analysis , make the what be designed that clamp gain optimum economic results before designing a set of clamp everytime. The design constituting a machine tool by the same token is also very important , the science design combination machine tool cuts down on-time and the working strength.

The structure the main body of a book is shifted gears fork to change gear carries out industrial analysis , ascertains the route processing handicraft, the call for according to mission book works out out the part technological procedure , design thick bright metal of working procedure III 19 56 and 2.6 44.6 liang of side special use.

Keywords Technologicalprocedure Gripdesign Industrial analysis

目 录

1 引言............................................................... 1

2 零件分析........................................................... 2

2.1 零件的作用........................................................ 2

2.2零件的工艺分析.................................................... 2

2.3 零件的主要技术条件分析及技术关键问题.............................. 2

3 工艺规程设计....................................................... 4

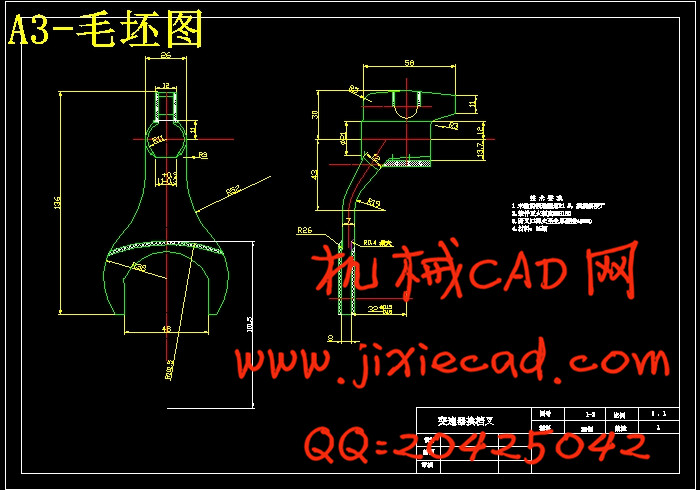

3.1 确定毛坯的制造形式............................................... 4

3.2 基面的选择....................................................... 4

3.3 制订工艺路线..................................................... 5

3.4 机械加工余量、工序尺寸及毛坯尺寸确定............................. 6

3.5 确定切削余量及基本工时.......................................... 10

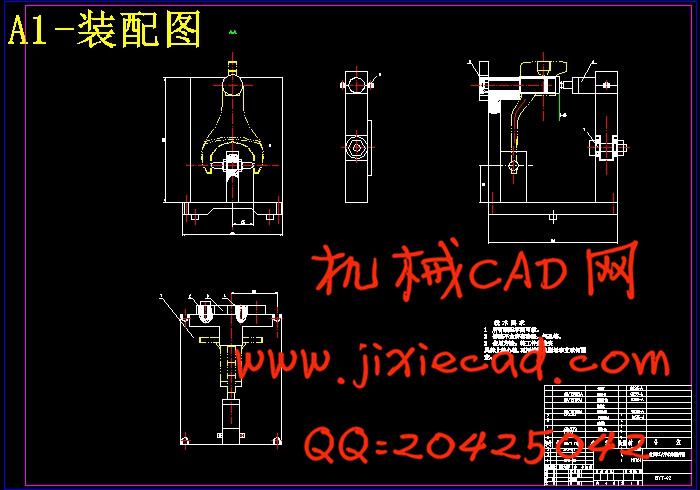

4 夹具设计.......................................................... 21

4.1 问题的提出...................................................... 21

4.2 夹具设计........................................................ 21

4.3 夹具的零件...................................................... 22

4.4 夹具设计及操作说明.............................................. 25

5 组合机床设计...................................................... 26

5.1 组合机床机构方案的确定.......................................... 26

5.2 组合机床通用部件的选择.......................................... 26

5.3 被加工零件工序图................................................ 26

5.4 被加工零件加工示意图............................................ 27

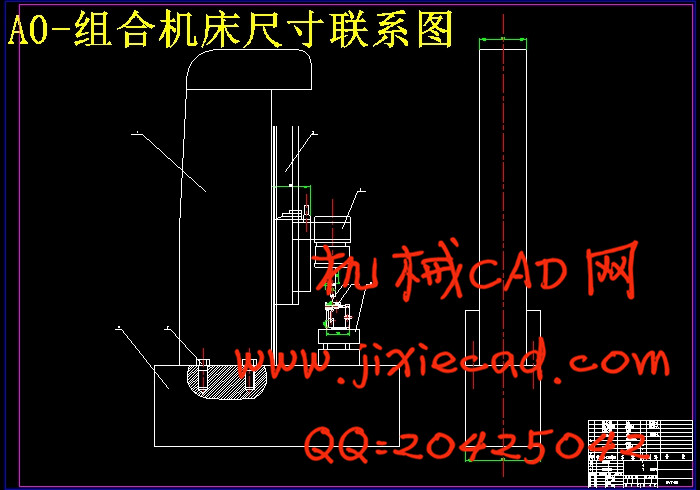

5.5 组合机床联系尺寸图的绘制........................................ 28

结束语............................................................... 29

致 谢............................................................... 30

参考文献............................................................. 31

工艺规程的原则是优质高产和低成本,即在保证产品质量的前提下缩短生产周期,改变劳动条件,提高劳动生产率,提高经济效益。夹具设计在机械加工中具有重要的作用,它能保证加工精度,提高产品质量,减轻工人的劳动强度,保证安全,提高劳动生产率,能以优质、高效、低耗的工艺去完成零件的加工和产品的装配。而使用了分度钻的好处在于,可采用多工位加工,能使加工工序集中,从而减轻工人的劳动强度和提高生产率。

使用夹具的最根本目的是获得好的经济效益。所以设计夹具也和其它技术工作一样,不仅是一个技术问题,而且是个经济问题。每当设计一套夹具之前,都要进行必要的技术经济分析,使所设计的夹具获得最佳的经济效果。同样组合机床的设计也是很重要的,科学的设计组合机床减少工作时间和工作强度。

本文对变速器换挡叉的结构进行工艺分析,确定加工工艺路线,根据任务书的要求制定出零件的工艺规程,并设计工序Ⅲ粗铣19

关键词 工艺规程 夹具设计 工艺分析

Abstract

The technological procedure principle is high grade high yield and low cost , is on the premise of product quality, to shorten a production cycle , to change the condition working , to improve productivity , the improvement of economic results in guarantee. Grip design has the important effect in machine work , it can swear to process accuracy , to raise product quality , lighten worker's labour intensity , swear to safe , to improve productivity, can use high grade , high-effect, the low consumption handicraft goes to accomplish the part treating and the product assembling. But the benefit having used scale division drill lies in, may adopt multistation treating, the working procedure the energy messenger is processed concentrates, thereby, lighten worker's labour intensity and improve efficacy.

Use the basicest clamp purpose to be to gain the good economic effect. Therefore designing that the clamp is also same as other technology job, not only be a technology problem, and be economic problems. Needing to carry out necessary technical economy analysis , make the what be designed that clamp gain optimum economic results before designing a set of clamp everytime. The design constituting a machine tool by the same token is also very important , the science design combination machine tool cuts down on-time and the working strength.

The structure the main body of a book is shifted gears fork to change gear carries out industrial analysis , ascertains the route processing handicraft, the call for according to mission book works out out the part technological procedure , design thick bright metal of working procedure III 19 56 and 2.6 44.6 liang of side special use.

Keywords Technologicalprocedure Gripdesign Industrial analysis

目 录

1 引言............................................................... 1

2 零件分析........................................................... 2

2.1 零件的作用........................................................ 2

2.2零件的工艺分析.................................................... 2

2.3 零件的主要技术条件分析及技术关键问题.............................. 2

3 工艺规程设计....................................................... 4

3.1 确定毛坯的制造形式............................................... 4

3.2 基面的选择....................................................... 4

3.3 制订工艺路线..................................................... 5

3.4 机械加工余量、工序尺寸及毛坯尺寸确定............................. 6

3.5 确定切削余量及基本工时.......................................... 10

4 夹具设计.......................................................... 21

4.1 问题的提出...................................................... 21

4.2 夹具设计........................................................ 21

4.3 夹具的零件...................................................... 22

4.4 夹具设计及操作说明.............................................. 25

5 组合机床设计...................................................... 26

5.1 组合机床机构方案的确定.......................................... 26

5.2 组合机床通用部件的选择.......................................... 26

5.3 被加工零件工序图................................................ 26

5.4 被加工零件加工示意图............................................ 27

5.5 组合机床联系尺寸图的绘制........................................ 28

结束语............................................................... 29

致 谢............................................................... 30

参考文献............................................................. 31