设计简介

目录

摘要................................................................................................. 3

引 言............................................................................................ 4

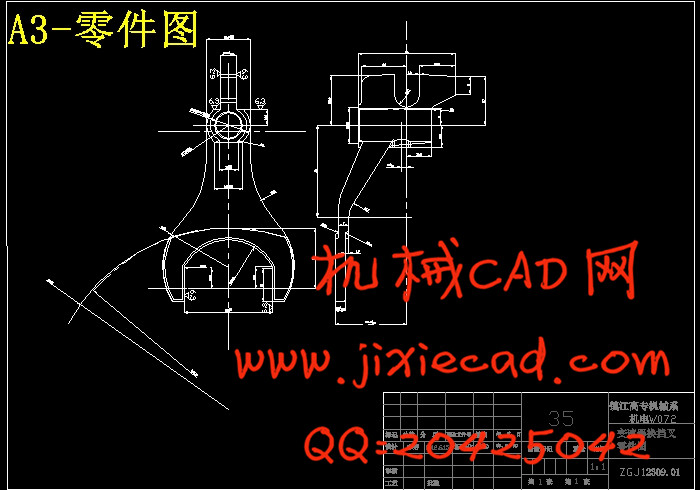

第一章 零件的分析....................................................................... 5

第二章 工艺规程的设计............................................................... 6

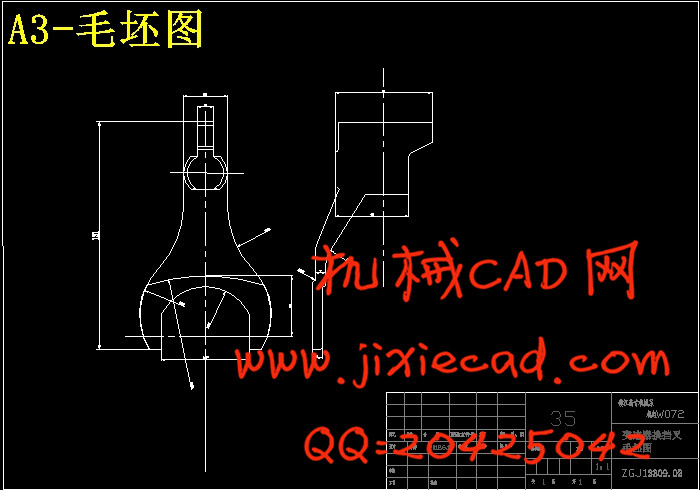

2.1确定毛坯的的制造形式.................................................................... 6

2.2基准的选择.................................................................................... 6

2.3制订工艺路线................................................................................. 6

2.4机械加工余量、工序尺寸及毛坯尺寸的确定....................................... 8

2.5确定切削用量及基本工时................................................................. 9

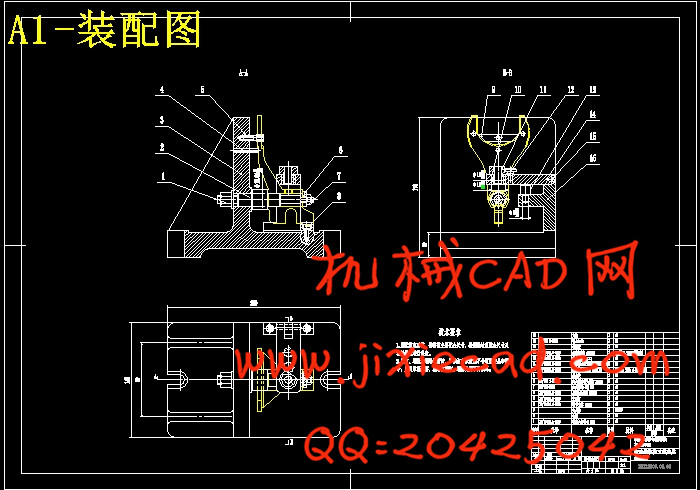

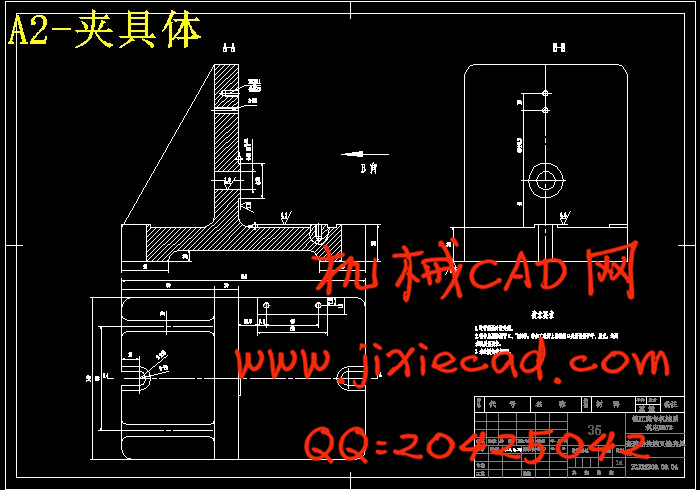

第三章 专用夹具的设计............................................................. 19

3.1钻、攻M10螺纹的夹具设计........................................................... 19

3.1.1问题提出................................................................................... 19

3.1.2 定位基准的选择......................................................................... 19

3.1.3定位元件的设计......................................................................... 19

3.1.4切削力及夹紧力计算................................................................... 19

3.1.5 夹具设计及操作简要说明............................................................ 19

3.2铣拨叉宽51面的夹具设计............................................................. 21

3.2.1 问题的提出............................................................................... 21

3.2.2 定位基准的选择......................................................................... 21

3.2.3定位元件的设计......................................................................... 21

3.2.4 切削力及夹紧力计算.................................................................. 21

3.2.5 定向键与对刀装置设计............................................................... 23

3.2.6 夹具设计及操作简要说明............................................................ 25

总 结........................................................................................ 26

致 谢............................................................................................ 27

参 考 文 献.................................................................................. 28

摘 要:本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。

拨叉的加工工艺规程及其铣叉口面与钻M10螺纹的夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。铣叉口面以Φ15.81F8孔及其端面作为来定位基准,以工件的另外一个端面作为辅助基准,实现工件的完全定位,夹紧则是通过调节螺母来实现;钻M10螺纹以Φ15.81F8孔及其端面作为定位基准,以一削边销作为辅助基准,实现工件的完全定位,夹紧则是由快换垫圈、螺母、心轴等组成。

关键词: 夹紧 定位 基准

ABSTRCT:The design of the content relates to the machinery manufacturing technology and machine tool fixture design, metal cutting machine tool, tolerance and measuring and other aspects of knowledge.

Fork processing procedures and milling fork and drill M10 threads of fixture design is including machining process design, process design and fixture design in three parts. Milling fork with diameter 15.81F8hole and end as to the locating datum to the workpiece, another end as auxiliary reference, realize the workpiece positioning, clamping is realized through adjusting nut; screw thread hole drilling M10than 15.81F8and its face as a positioning reference, to an edge cutting pin as auxiliary reference, to achieve workpiece positioning, clamping is fast changing washer, nut, the mandrel.

Key words: clamping positioning datum

摘要................................................................................................. 3

引 言............................................................................................ 4

第一章 零件的分析....................................................................... 5

第二章 工艺规程的设计............................................................... 6

2.1确定毛坯的的制造形式.................................................................... 6

2.2基准的选择.................................................................................... 6

2.3制订工艺路线................................................................................. 6

2.4机械加工余量、工序尺寸及毛坯尺寸的确定....................................... 8

2.5确定切削用量及基本工时................................................................. 9

第三章 专用夹具的设计............................................................. 19

3.1钻、攻M10螺纹的夹具设计........................................................... 19

3.1.1问题提出................................................................................... 19

3.1.2 定位基准的选择......................................................................... 19

3.1.3定位元件的设计......................................................................... 19

3.1.4切削力及夹紧力计算................................................................... 19

3.1.5 夹具设计及操作简要说明............................................................ 19

3.2铣拨叉宽51面的夹具设计............................................................. 21

3.2.1 问题的提出............................................................................... 21

3.2.2 定位基准的选择......................................................................... 21

3.2.3定位元件的设计......................................................................... 21

3.2.4 切削力及夹紧力计算.................................................................. 21

3.2.5 定向键与对刀装置设计............................................................... 23

3.2.6 夹具设计及操作简要说明............................................................ 25

总 结........................................................................................ 26

致 谢............................................................................................ 27

参 考 文 献.................................................................................. 28

摘 要:本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。

拨叉的加工工艺规程及其铣叉口面与钻M10螺纹的夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。铣叉口面以Φ15.81F8孔及其端面作为来定位基准,以工件的另外一个端面作为辅助基准,实现工件的完全定位,夹紧则是通过调节螺母来实现;钻M10螺纹以Φ15.81F8孔及其端面作为定位基准,以一削边销作为辅助基准,实现工件的完全定位,夹紧则是由快换垫圈、螺母、心轴等组成。

关键词: 夹紧 定位 基准

ABSTRCT:The design of the content relates to the machinery manufacturing technology and machine tool fixture design, metal cutting machine tool, tolerance and measuring and other aspects of knowledge.

Fork processing procedures and milling fork and drill M10 threads of fixture design is including machining process design, process design and fixture design in three parts. Milling fork with diameter 15.81F8hole and end as to the locating datum to the workpiece, another end as auxiliary reference, realize the workpiece positioning, clamping is realized through adjusting nut; screw thread hole drilling M10than 15.81F8and its face as a positioning reference, to an edge cutting pin as auxiliary reference, to achieve workpiece positioning, clamping is fast changing washer, nut, the mandrel.

Key words: clamping positioning datum