设计简介

摘 要

在机床上加工工件时,为了使工件在该工序所加工的表面能达到规定的尺寸和位置公差要求,在开动机床进行加工之前,必须首先使工件占有一正确位置。通常把确定工件在机床上或夹具中占有正确位置的过程,称为定位。当工件定位后,为了避免在加工中受到切削力、重力等的作用而破坏定位,还应该用一定的机构或装置将工件加以固定。工件定位后即将其固定,使其在加工过程中保持定位位置不便的操作,称为夹紧。

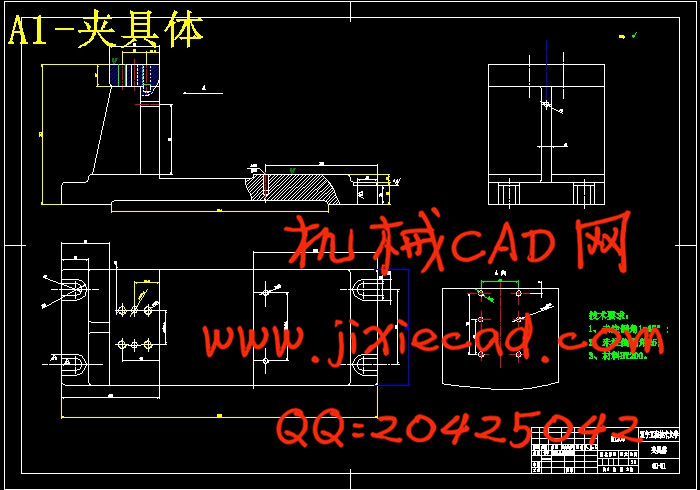

通过以杠杆Φ20H7孔和其左端面为精基准,运用一面两销来限制工件的6个自由度,在实现中批生产的前提下,采用液压缸来对工件进行夹紧。满足了该杠杆工件的生产要求。

由于本夹具配合面,连接孔较多,因此,夹具的零件对精度比较高,操作时要注意夹具各螺纹是否拧紧;还有就是夹具操作时,要防止定位零件有过大的磨损,若有较大磨损,要注意及时更换,以保证零件加工精度。

夹具上装有对钻套,可以使夹具在一批零件的加工之前很好的对刀,同时,夹具体上底面有一对定位键,可使夹具工作台上在很好的定位。

工件装夹是否正确、迅速、方便和可靠,将直接影响工件的加工质量、生产效率、制造成本和操作安全。在成批、大量生产中,工件的装夹是通过机床夹具来实现的。机床夹具在生产中应用十分广泛。

关键词:机械制造 夹具 定位 夹紧元件

Abstract

In the processing machine parts, in order to enable the workpiece in the process by processing the surface can achieve the required size and location of tolerance requirements, starting in the machine for processing before, we must first make a correct position of the workpiece possession. The workpiece is usually identified in the machine tool or fixture in the possession of the correct location of the process, known as the location. When the workpiece positioning, in order to avoid being in the processing of cutting force, gravity, and so undermine the role and positioning, but also should use a certain body parts or devices will be fixed. After positioning the workpiece to be fixed, in the process to maintain the target of inconvenience in the operation, known as the clamp.

Φ20H7 to leverage through the hole and its fine base for the extreme left side, use a pin to limit the two parts of six degrees of freedom, in the realization of the grant under the premise of the production, use of hydraulic cylinders to the workpiece to clamp. Parts of the lever to meet the production requirements.

As the fixture with face, connecting more holes, so the fixture parts of the relatively high precision, the operation of the fixture should pay attention to whether the tightening thread; fixture is still in operation, to prevent the positioning is too large parts of wear and tear, if Have greater wear and tear, attention should be paid timely replacement to ensure that the precision machining parts.

Fixture is equipped with sets of drilling, so that the fixture in a number of processing before the good parts of the knife, at the same time, specific folder on the underside of a pair of targeting key fixture will work on stage in a very good location.

Workpiece clamping is correct, rapid, convenient and reliable, will directly affect parts of the processing quality, productivity, manufacturing costs and operational safety. In bulk, mass production, part of the fixture through the machine to achieve the fixture. Fixture for the production of machine tools in the application of a very wide range.

Keywords: Machinofacture Fixture Location Clamping components

目 录

中文摘要................................................. I

英文摘要.................................................Ⅱ

1.CA1340自动车床杠杆工艺分析......................... 1

1.1泵体工艺分析及生产类型确定......................... 1

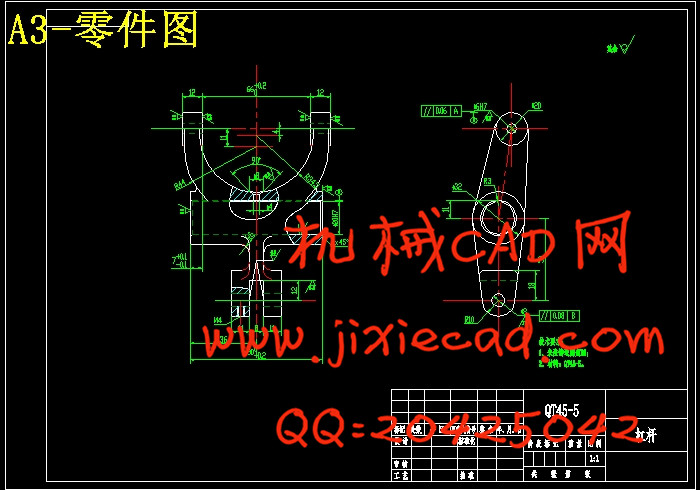

1.1.1杠杆的技术要求.................................. 1

1.1.2审查杠杆的工艺.................................. 1

1.1.3确定杠杆的生产类型.............................. 2

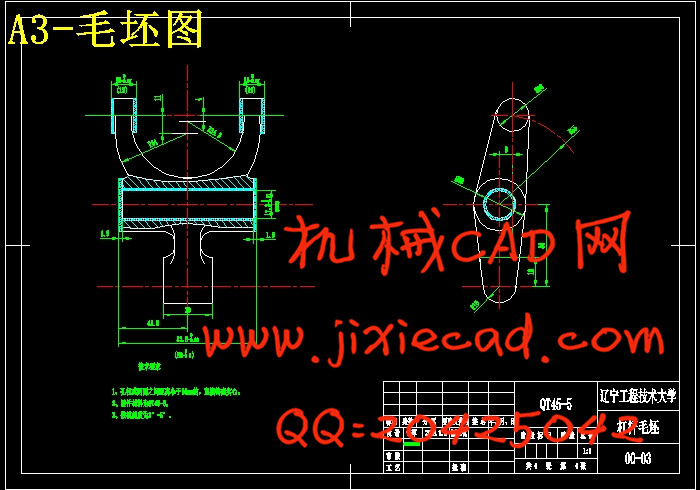

1.2确定毛坯、绘制毛坯简图............................ 2

1.2.1选择毛坯........................................ 2

1.2.2确定毛坯的尺寸公差和机械加工余量................. 2

1.3拟定杠杆的工艺路线................................ 2

1.3.1定位基准的选择.................................. 2

1.3.2表面加工方法确定................................ 3

1.3.3加工阶段划分.................................... 4

1.3.4工序的集中与分散................................ 4

1.3.5工序顺序安排.................................... 5

1.3.6确定工艺路线.................................... 5

1.4加工余量、工序尺寸和公差的确定..................... 6

1.5切削用量、时间额定的计算........................... 9

1.5.1切削用量的计算.................................. 9

1.5.2时间额定的计算.................................. 9

2.专用夹具设计...................................... 10

2.1 基本定位原理分析................................. 10

2.2 定位基准的选择................................... 10

2.3 定位误差分析.................................... 10

2.4夹具操作简要说明................................. 12

2.5 夹具使用注意事项、保养及维护..................... 12

3.方案综合评价与结论................................. 12

4.体会与展望........................................ 13

参考文献............................................ 14

附录1:机械加工工艺过程卡...............................15

附录2:机械加工工序卡...................................16

在机床上加工工件时,为了使工件在该工序所加工的表面能达到规定的尺寸和位置公差要求,在开动机床进行加工之前,必须首先使工件占有一正确位置。通常把确定工件在机床上或夹具中占有正确位置的过程,称为定位。当工件定位后,为了避免在加工中受到切削力、重力等的作用而破坏定位,还应该用一定的机构或装置将工件加以固定。工件定位后即将其固定,使其在加工过程中保持定位位置不便的操作,称为夹紧。

通过以杠杆Φ20H7孔和其左端面为精基准,运用一面两销来限制工件的6个自由度,在实现中批生产的前提下,采用液压缸来对工件进行夹紧。满足了该杠杆工件的生产要求。

由于本夹具配合面,连接孔较多,因此,夹具的零件对精度比较高,操作时要注意夹具各螺纹是否拧紧;还有就是夹具操作时,要防止定位零件有过大的磨损,若有较大磨损,要注意及时更换,以保证零件加工精度。

夹具上装有对钻套,可以使夹具在一批零件的加工之前很好的对刀,同时,夹具体上底面有一对定位键,可使夹具工作台上在很好的定位。

工件装夹是否正确、迅速、方便和可靠,将直接影响工件的加工质量、生产效率、制造成本和操作安全。在成批、大量生产中,工件的装夹是通过机床夹具来实现的。机床夹具在生产中应用十分广泛。

关键词:机械制造 夹具 定位 夹紧元件

Abstract

In the processing machine parts, in order to enable the workpiece in the process by processing the surface can achieve the required size and location of tolerance requirements, starting in the machine for processing before, we must first make a correct position of the workpiece possession. The workpiece is usually identified in the machine tool or fixture in the possession of the correct location of the process, known as the location. When the workpiece positioning, in order to avoid being in the processing of cutting force, gravity, and so undermine the role and positioning, but also should use a certain body parts or devices will be fixed. After positioning the workpiece to be fixed, in the process to maintain the target of inconvenience in the operation, known as the clamp.

Φ20H7 to leverage through the hole and its fine base for the extreme left side, use a pin to limit the two parts of six degrees of freedom, in the realization of the grant under the premise of the production, use of hydraulic cylinders to the workpiece to clamp. Parts of the lever to meet the production requirements.

As the fixture with face, connecting more holes, so the fixture parts of the relatively high precision, the operation of the fixture should pay attention to whether the tightening thread; fixture is still in operation, to prevent the positioning is too large parts of wear and tear, if Have greater wear and tear, attention should be paid timely replacement to ensure that the precision machining parts.

Fixture is equipped with sets of drilling, so that the fixture in a number of processing before the good parts of the knife, at the same time, specific folder on the underside of a pair of targeting key fixture will work on stage in a very good location.

Workpiece clamping is correct, rapid, convenient and reliable, will directly affect parts of the processing quality, productivity, manufacturing costs and operational safety. In bulk, mass production, part of the fixture through the machine to achieve the fixture. Fixture for the production of machine tools in the application of a very wide range.

Keywords: Machinofacture Fixture Location Clamping components

目 录

中文摘要................................................. I

英文摘要.................................................Ⅱ

1.CA1340自动车床杠杆工艺分析......................... 1

1.1泵体工艺分析及生产类型确定......................... 1

1.1.1杠杆的技术要求.................................. 1

1.1.2审查杠杆的工艺.................................. 1

1.1.3确定杠杆的生产类型.............................. 2

1.2确定毛坯、绘制毛坯简图............................ 2

1.2.1选择毛坯........................................ 2

1.2.2确定毛坯的尺寸公差和机械加工余量................. 2

1.3拟定杠杆的工艺路线................................ 2

1.3.1定位基准的选择.................................. 2

1.3.2表面加工方法确定................................ 3

1.3.3加工阶段划分.................................... 4

1.3.4工序的集中与分散................................ 4

1.3.5工序顺序安排.................................... 5

1.3.6确定工艺路线.................................... 5

1.4加工余量、工序尺寸和公差的确定..................... 6

1.5切削用量、时间额定的计算........................... 9

1.5.1切削用量的计算.................................. 9

1.5.2时间额定的计算.................................. 9

2.专用夹具设计...................................... 10

2.1 基本定位原理分析................................. 10

2.2 定位基准的选择................................... 10

2.3 定位误差分析.................................... 10

2.4夹具操作简要说明................................. 12

2.5 夹具使用注意事项、保养及维护..................... 12

3.方案综合评价与结论................................. 12

4.体会与展望........................................ 13

参考文献............................................ 14

附录1:机械加工工艺过程卡...............................15

附录2:机械加工工序卡...................................16