设计简介

摘 要

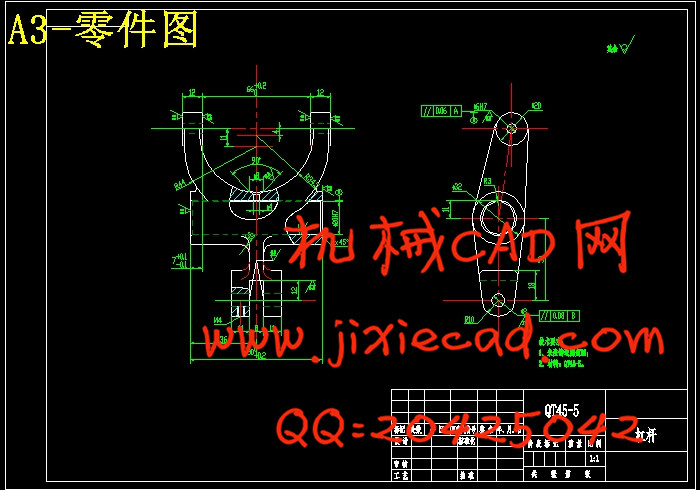

针对在大学中对机械制造工艺学这门基础课的学习成果的验收,在这次的毕业设计选题中,选择了针对杠杆(CA1340自动车床)加工工艺规程及其夹具设计的题目,通过对杠杆在CA1340自动车床上作用的分析、杠杆加工工艺的分析、杠杆的生产类型的分析,来确定杠杆(CA1340自动车床)的工艺工程和其加工夹具的设计方案。进而巩固所学知识,同时为日后的实践应用做一个良好的开端。关键词: 机械工艺;加工工艺规程;夹具;杠杆

Abstract

In connection with Machinery Manufacturing Technology at the university to learn this basic course learning outcomes acceptance, in this graduation design topics, selected for the subject of the leverage (CA1340 Automatic Lathe) process planning, fixture design topic, leverage in the role of the CA1340 automatic lathe of analysis, analysis of the leverage process, analysis of the leverage type of production, leverage (CA1340 Automatic Lathe) technology to determine the engineering and design of machining fixtures. Thereby strengthening the knowledge, at the same time, this has a good start for future practical application.Keywords: Mechanical process; Process planning; Fixture; Leverage

目 录

摘 要.......................................................................................................................... I

第1章 绪论............................................................................................................. 1

1.1 机械制造工艺简介...................................................................................... 1

1.2 零件加工过程简介...................................................................................... 2

第2章 零件的工艺分析及生产类型的确定......................................................... 4

2.1 零件的作用.................................................................................................. 4

2.2 零件的工艺分析.......................................................................................... 4

2.3 零件的生产类型.......................................................................................... 5

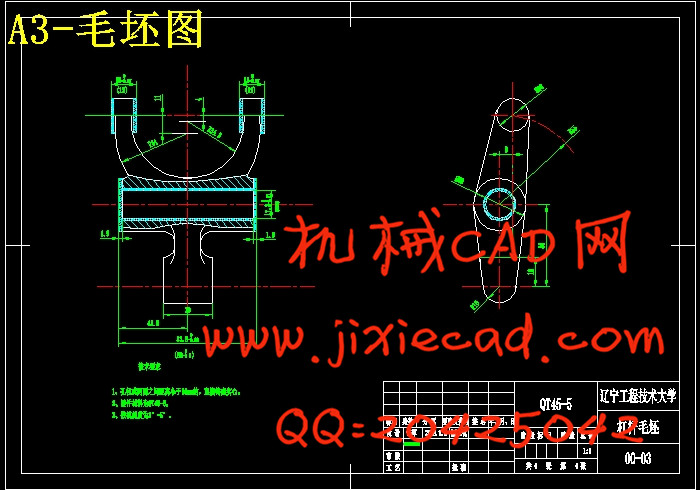

第3章 选择及确定毛坯,设计毛坯..................................................................... 6

3.1 选择毛坯...................................................................................................... 6

3.2 确定毛坯尺寸和公差.................................................................................. 6

第4章 选择加工方法,制定工艺路线................................................................. 8

4.1 基面的选择.................................................................................................. 8

4.2 零件表面加工方法的选择.......................................................................... 8

4.3 工艺过程制定.............................................................................................. 9

第5章 工序设计................................................................................................... 11

5.1 选择机床.................................................................................................... 11

5.2 选择夹具.................................................................................................... 11

5.3 根据不同工序选择刀具............................................................................ 12

5.4 选择量具.................................................................................................... 13

5.5 确定工序尺寸............................................................................................ 15

第6章 确定切削用量及基本时间....................................................................... 19

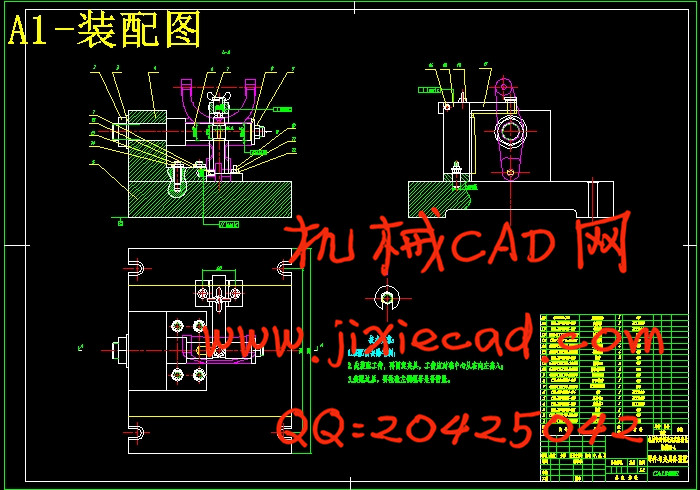

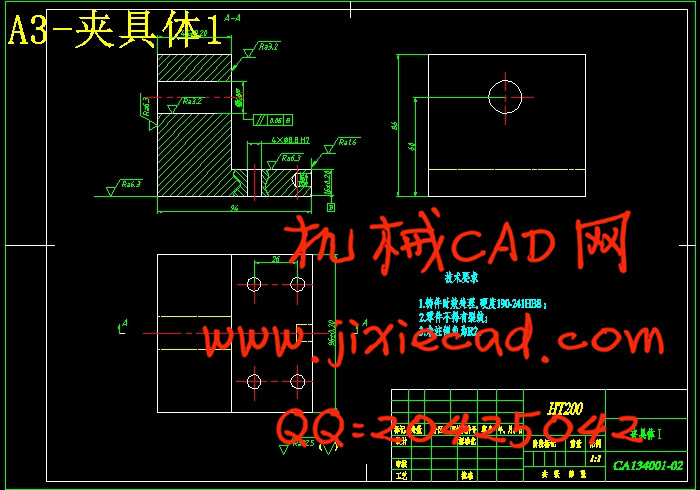

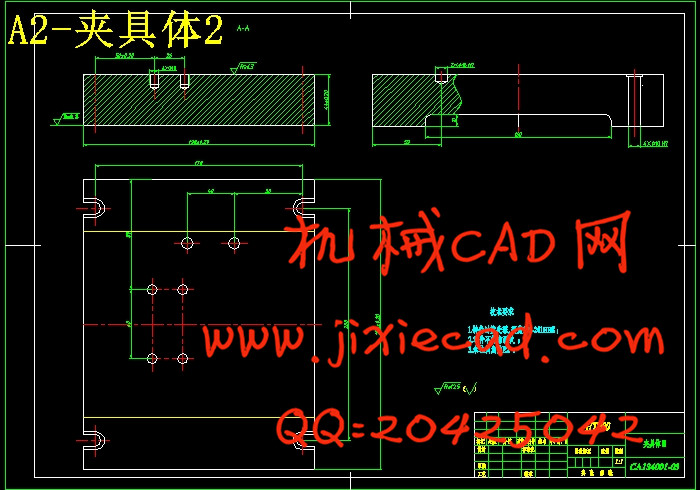

第7章 夹具设计................................................................................................... 36

7.1 设计钻Φ4mm的油孔及锪Φ8mm圆锥沉头孔专用夹具...................... 36

7.1.1定位方案............................................................................................. 36

7.1.2 装夹设计要求.................................................................................... 37

7.1.3切削力和夹紧力的计算..................................................................... 37

7.1.4 导向元件........................................................................................... 38

7.1.5 夹具与机床连接元件....................................................................... 38

7.1.6 装夹说明........................................................................................... 38

7.1.7 夹具特点........................................................................................... 39

结 论....................................................................................................................... 41

致 谢....................................................................................................................... 42

参考文献................................................................................................................... 43