设计简介

目 录

前 言. 1

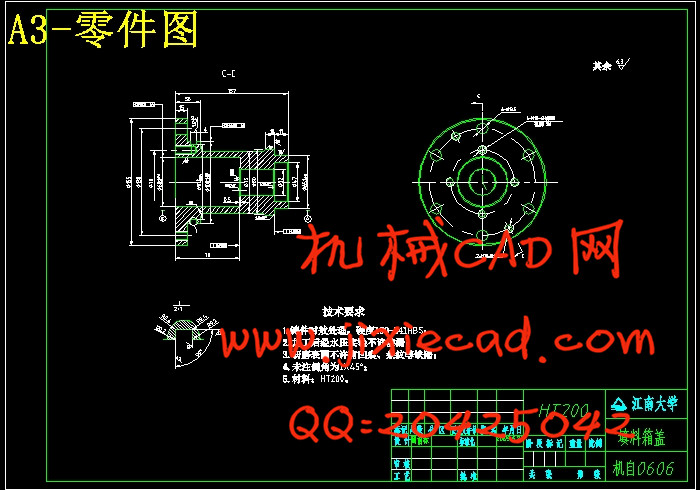

1 零件的分析. 2

1.1 零件的作用. 2

1.2 零件的工艺分析. 3

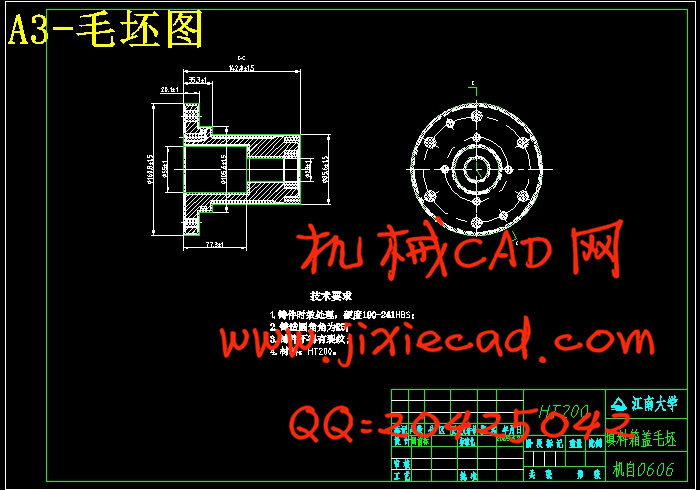

2 工艺规程设计. 3

2.1 毛坯的制造形式. 3

2.2 基准面的选择. 3

2.2.1 粗基准的选择.........................................3

2.2.2 精基准的选择.........................................3

2.3 制订工艺路线. 3

2.3.1 工艺线路方案一.......................................3

2.3.2 工艺路线方案二.......................................4

2.3.3 工艺方案的比较与分析.................................4

2.4 机械加工余量、工序尺寸及毛坯尺寸的确定. 5

2.5 确定切削用量及基本工时. 6

2.5.1 工序Ⅰ:车削端面、外圆...............................6

2.5.2 工序Ⅱ:粗车 65,

65, 80,

80, 75,

75, 100外圆以及槽和倒角......8

100外圆以及槽和倒角......8

2.5.3 工序Ⅲ:钻扩 mm、及锪

mm、及锪 孔。转塔机床C365L....11

孔。转塔机床C365L....11

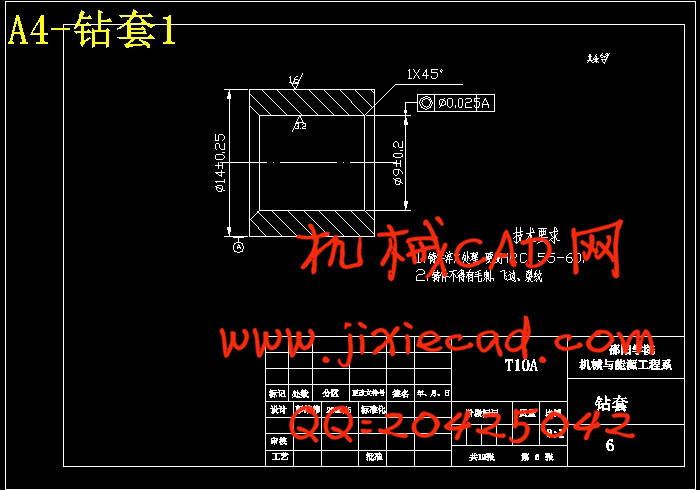

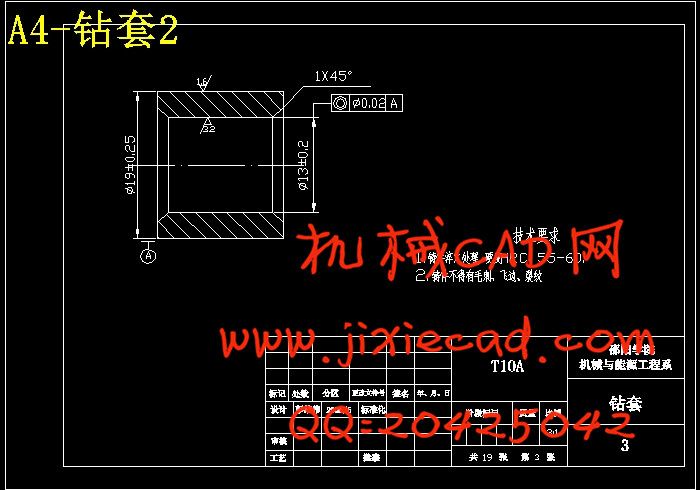

2.5.4 工序Ⅳ:钻6— 13.5, 2-M10-6H, 4-M10-6H深孔深24....12

13.5, 2-M10-6H, 4-M10-6H深孔深24....12

2.5.5 工序Ⅴ:精车Φ65mm的外圆及与Φ80mm相接的端面.......15

2.5.6 工序Ⅵ:精、粗、细镗 mm孔...............17

mm孔...............17

2.5.7 工序Ⅶ:铣Φ60孔底面...............................18

2.5.8 工序Ⅷ:磨Φ60孔底面...............................18

2.5.9 工序Ⅸ:镗Φ60mm孔底沟槽.......................... 19

2.5.10 工序Ⅹ:研磨Φ60mm孔底面.......................... 19

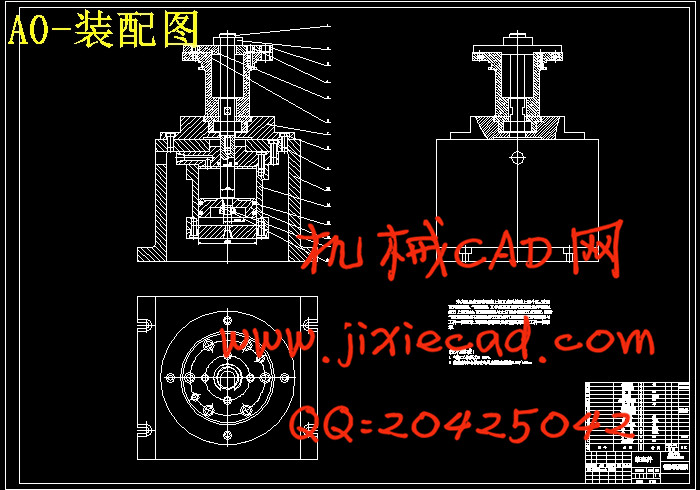

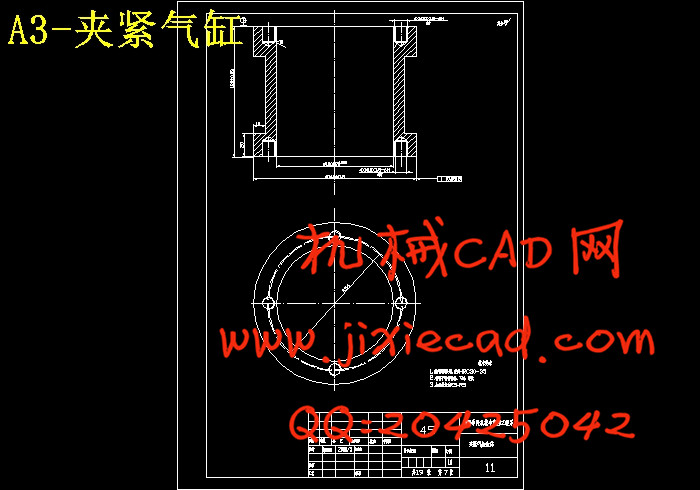

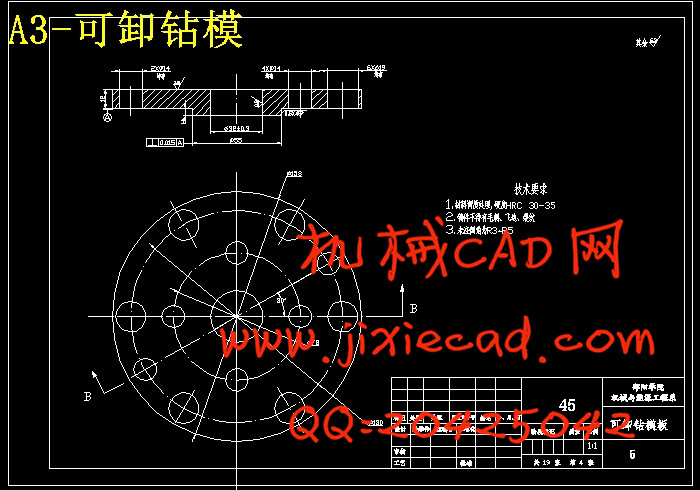

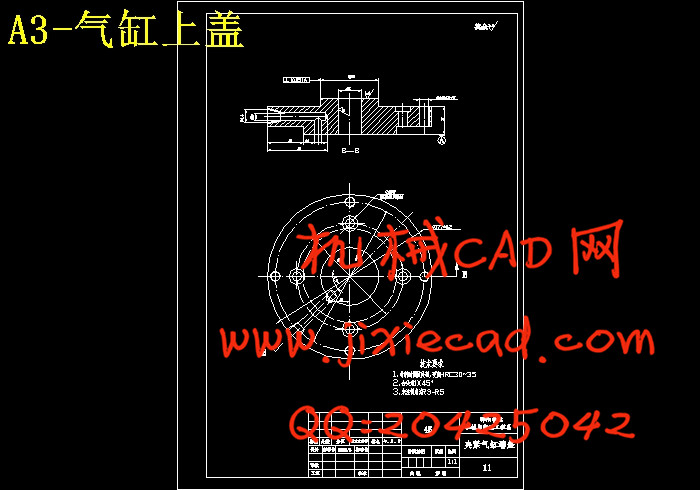

3专用夹具设计. 20

3.1 问题的指出. 20

3.2 夹具设计. 20

3.2.1 定位基准的选择......................................20

3.2.2 切削力及夹紧力的计算................................20

3.3 定位误差的分析. 21

3.4 夹具设计及操作的简要说明. 21

参考资料. 22

致 谢. 23

附 录. 24

摘 要

在机械制造的机械加工,检验,装配,焊接和热处理等冷热工艺过程中,使用着大量的夹具,用以安装加工对象,使之占有正确的位置,以保证零件和工件的质量。

本次设计主要是进行填料箱盖零件的专用夹具的设计,是对我们以往所学知识的总结和对我们所掌握知识的一次扩展。本文主要从工艺规程的指定与夹具的设计两方面出发。根据零件本身的特点,生产类型以及零件在具体工作时的作用选择工艺规程和夹具。在工艺规程方面:确定生产类型,综合考虑其准确度高,生产效率高,消耗经济少等方面,选择一个最优方案;在夹具设计方面,因为是盖体类零件,加工Ф13.5孔,选择钻床加工,考虑诸多因素拟订最优方案,最终完成本次设计。

关键字:填料箱盖; 工艺; 夹具

Abstract

The machine made in the machine processes, examining, assembling, welding with heat handle to wait cold and hot craft process in, use a great deal of tongs, in order to the gearing process object, making it occupy right position to promise the quality of spare parts and work piece.

This design is mainly the design of appropriation tongs which carries Stuffing box cover spare parts, is tally up the knowledge that we learn before and to the once expanding of the knowledge that we control.This text mainly sets out from the design both side of the specifying of craft rules distance and the tongs.According to the characteristics of spare parts, the function produced type and spare parts while concretely working choice the craft rules distance and tongs.In the craft rules distance aspect:Assurance produce a type, comprehensive consider its ccurate degree high, produce an efficiency is high, consume economy little etc. aspect, choose the superior project;Design aspect in the tongs, because of is cover body spare parts, process Ф 13.5 bores, the choice drills a bed to process, considering many factors to draw up the superior project, end completion originally time design.

Key words: stuffing box cover; craft; jig

前 言. 1

1 零件的分析. 2

1.1 零件的作用. 2

1.2 零件的工艺分析. 3

2 工艺规程设计. 3

2.1 毛坯的制造形式. 3

2.2 基准面的选择. 3

2.2.1 粗基准的选择.........................................3

2.2.2 精基准的选择.........................................3

2.3 制订工艺路线. 3

2.3.1 工艺线路方案一.......................................3

2.3.2 工艺路线方案二.......................................4

2.3.3 工艺方案的比较与分析.................................4

2.4 机械加工余量、工序尺寸及毛坯尺寸的确定. 5

2.5 确定切削用量及基本工时. 6

2.5.1 工序Ⅰ:车削端面、外圆...............................6

2.5.2 工序Ⅱ:粗车

2.5.3 工序Ⅲ:钻扩

2.5.4 工序Ⅳ:钻6—

2.5.5 工序Ⅴ:精车Φ65mm的外圆及与Φ80mm相接的端面.......15

2.5.6 工序Ⅵ:精、粗、细镗

2.5.7 工序Ⅶ:铣Φ60孔底面...............................18

2.5.8 工序Ⅷ:磨Φ60孔底面...............................18

2.5.9 工序Ⅸ:镗Φ60mm孔底沟槽.......................... 19

2.5.10 工序Ⅹ:研磨Φ60mm孔底面.......................... 19

3专用夹具设计. 20

3.1 问题的指出. 20

3.2 夹具设计. 20

3.2.1 定位基准的选择......................................20

3.2.2 切削力及夹紧力的计算................................20

3.3 定位误差的分析. 21

3.4 夹具设计及操作的简要说明. 21

参考资料. 22

致 谢. 23

附 录. 24

摘 要

在机械制造的机械加工,检验,装配,焊接和热处理等冷热工艺过程中,使用着大量的夹具,用以安装加工对象,使之占有正确的位置,以保证零件和工件的质量。

本次设计主要是进行填料箱盖零件的专用夹具的设计,是对我们以往所学知识的总结和对我们所掌握知识的一次扩展。本文主要从工艺规程的指定与夹具的设计两方面出发。根据零件本身的特点,生产类型以及零件在具体工作时的作用选择工艺规程和夹具。在工艺规程方面:确定生产类型,综合考虑其准确度高,生产效率高,消耗经济少等方面,选择一个最优方案;在夹具设计方面,因为是盖体类零件,加工Ф13.5孔,选择钻床加工,考虑诸多因素拟订最优方案,最终完成本次设计。

关键字:填料箱盖; 工艺; 夹具

Abstract

The machine made in the machine processes, examining, assembling, welding with heat handle to wait cold and hot craft process in, use a great deal of tongs, in order to the gearing process object, making it occupy right position to promise the quality of spare parts and work piece.

This design is mainly the design of appropriation tongs which carries Stuffing box cover spare parts, is tally up the knowledge that we learn before and to the once expanding of the knowledge that we control.This text mainly sets out from the design both side of the specifying of craft rules distance and the tongs.According to the characteristics of spare parts, the function produced type and spare parts while concretely working choice the craft rules distance and tongs.In the craft rules distance aspect:Assurance produce a type, comprehensive consider its ccurate degree high, produce an efficiency is high, consume economy little etc. aspect, choose the superior project;Design aspect in the tongs, because of is cover body spare parts, process Ф 13.5 bores, the choice drills a bed to process, considering many factors to draw up the superior project, end completion originally time design.

Key words: stuffing box cover; craft; jig