设计简介

摘 要

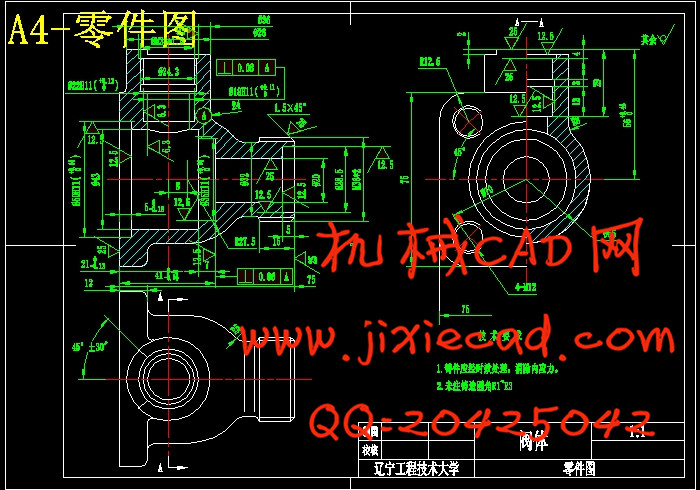

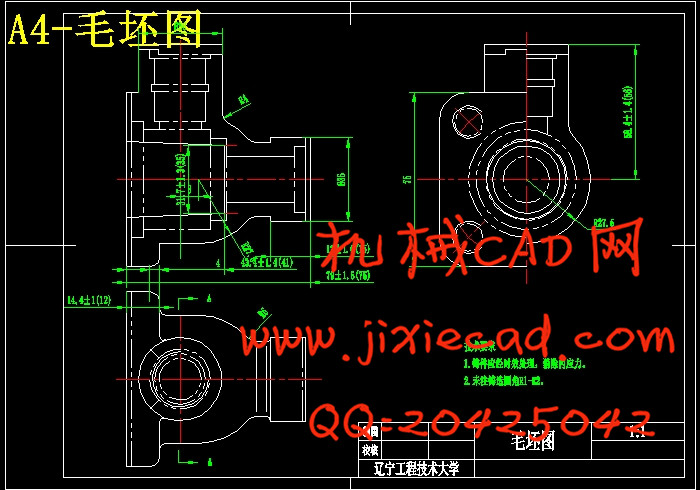

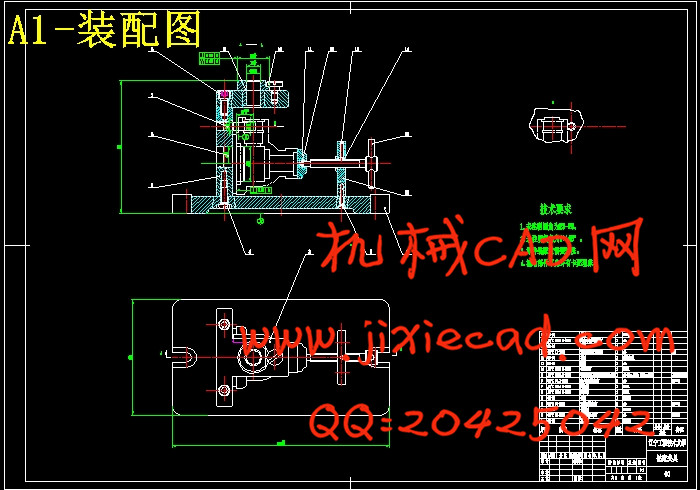

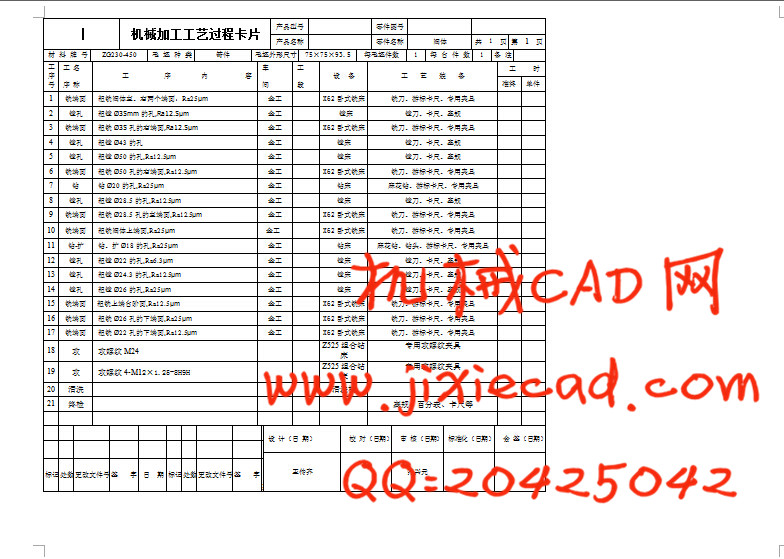

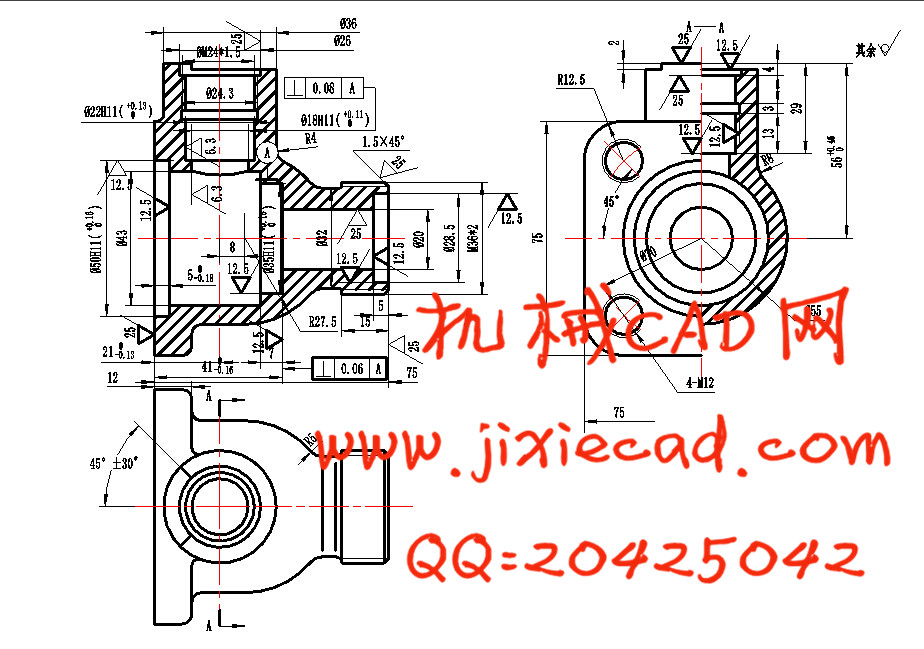

阀体的机械加工及Φ18H11孔加工的工艺装备设计。并绘制阀体的零件图,毛坯图,夹具装配图和夹具零件图,填写机械加工工艺过程综合卡片和工序卡片。并编写设计说明书。

阀体零件的机械加工工艺规程及工艺装备事通过对阀体零件工艺问题的理解分析,完成工艺规程的设计和夹具的设计。次设计为阀体零件工艺规程和夹具设计提供了方法,改进了以往设计的不足,提高了劳动生产率。对于阀体零件的生产具有很重要的意义。

Abstract

The machine of valve body process and the Φ 18 H11 the bore process of craft material design.Combine draw the spare parts diagram of valve body, semi-finished product diagram, the tongs assemble diagram and tongs spare parts diagram and fill in a machine to process the comprehensive card of the craft process and work preface card.Combine write design manual.

The machine of valve body spare parts process craft regulations and craft material matter to pass the comprehension toward the valve body spare parts craft problem analysis, completion craft regulations of design and tongs of design.The time design was regulations and tongs of the valve body spare parts craft design to provide a method, improvement former design of shortage, exaltation labor rate of production.Have very important meaning to the produce of valve body spare parts.

阀体的机械加工及Φ18H11孔加工的工艺装备设计。并绘制阀体的零件图,毛坯图,夹具装配图和夹具零件图,填写机械加工工艺过程综合卡片和工序卡片。并编写设计说明书。

阀体零件的机械加工工艺规程及工艺装备事通过对阀体零件工艺问题的理解分析,完成工艺规程的设计和夹具的设计。次设计为阀体零件工艺规程和夹具设计提供了方法,改进了以往设计的不足,提高了劳动生产率。对于阀体零件的生产具有很重要的意义。

Abstract

The machine of valve body process and the Φ 18 H11 the bore process of craft material design.Combine draw the spare parts diagram of valve body, semi-finished product diagram, the tongs assemble diagram and tongs spare parts diagram and fill in a machine to process the comprehensive card of the craft process and work preface card.Combine write design manual.

The machine of valve body spare parts process craft regulations and craft material matter to pass the comprehension toward the valve body spare parts craft problem analysis, completion craft regulations of design and tongs of design.The time design was regulations and tongs of the valve body spare parts craft design to provide a method, improvement former design of shortage, exaltation labor rate of production.Have very important meaning to the produce of valve body spare parts.

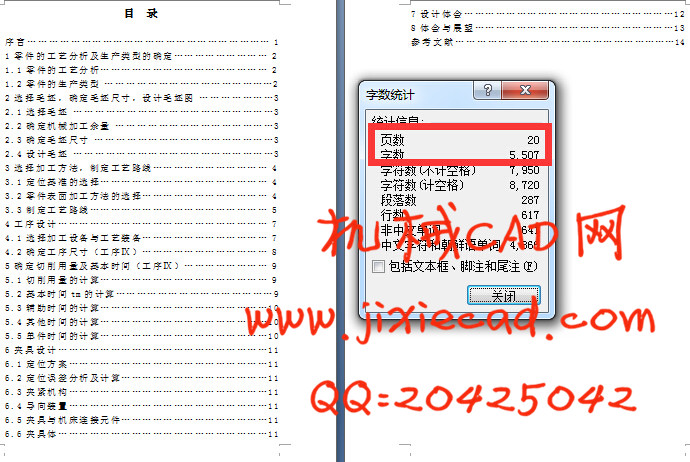

目 录

序言…………………………………………………………… 1

1零件的工艺分析及生产类型的确定……………………… 2

1.1零件的工艺分析………………………………………… 2

1.2零件的生产类型 …………………………………………2

2选择毛坯,确定毛坯尺寸,设计毛坯图 …………………3

2.1选择毛坯 …………………………………………………3

2.2确定机械加工余量 ………………………………………3

2.3确定毛坯尺寸 ……………………………………………3

2.4设计毛坯 …………………………………………………3

3选择加工方法,制定工艺路线…………………………… 4

3.1定位基准的选择………………………………………… 4

3.2零件表面加工方法的选择……………………………… 4

3.3制定工艺路线…………………………………………… 5

4工序设计…………………………………………………… 7

4.1选择加工设备与工艺装备……………………………… 7

4.2确定工序尺寸(工序Ⅸ)……………………………… 8

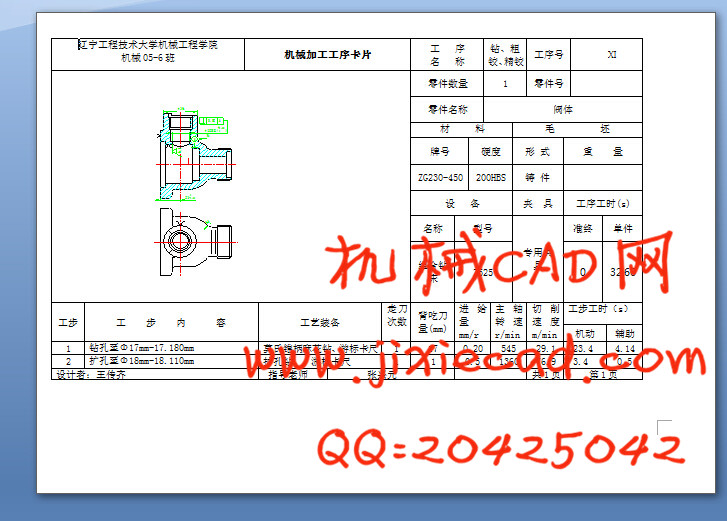

5确定切削用量及基本时间(工序Ⅸ)…………………… 9

5.1切削用量的计算………………………………………… 9

5.2基本时间tm的计算………………………………………9

5.3辅助时间的计算…………………………………………10

5.4其他时间的计算…………………………………………10

5.5单件时间的计算…………………………………………10

6夹具设计……………………………………………………11

6.1定位方案…………………………………………………11

6.2定位误差分析及计算……………………………………11

6.3夹紧机构…………………………………………………11

6.4导向装置…………………………………………………11

6.5夹具与机床连接元件……………………………………11

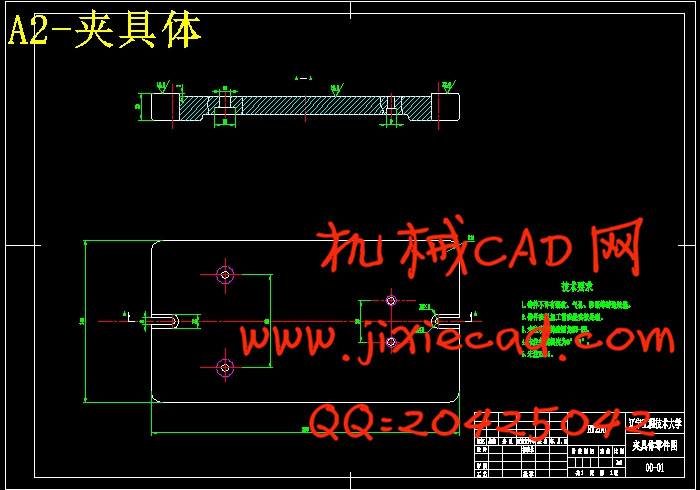

6.6夹具体……………………………………………………11

7设计体会……………………………………………………12

8体会与展望…………………………………………………13

参考文献………………………………………………………14

序言…………………………………………………………… 1

1零件的工艺分析及生产类型的确定……………………… 2

1.1零件的工艺分析………………………………………… 2

1.2零件的生产类型 …………………………………………2

2选择毛坯,确定毛坯尺寸,设计毛坯图 …………………3

2.1选择毛坯 …………………………………………………3

2.2确定机械加工余量 ………………………………………3

2.3确定毛坯尺寸 ……………………………………………3

2.4设计毛坯 …………………………………………………3

3选择加工方法,制定工艺路线…………………………… 4

3.1定位基准的选择………………………………………… 4

3.2零件表面加工方法的选择……………………………… 4

3.3制定工艺路线…………………………………………… 5

4工序设计…………………………………………………… 7

4.1选择加工设备与工艺装备……………………………… 7

4.2确定工序尺寸(工序Ⅸ)……………………………… 8

5确定切削用量及基本时间(工序Ⅸ)…………………… 9

5.1切削用量的计算………………………………………… 9

5.2基本时间tm的计算………………………………………9

5.3辅助时间的计算…………………………………………10

5.4其他时间的计算…………………………………………10

5.5单件时间的计算…………………………………………10

6夹具设计……………………………………………………11

6.1定位方案…………………………………………………11

6.2定位误差分析及计算……………………………………11

6.3夹紧机构…………………………………………………11

6.4导向装置…………………………………………………11

6.5夹具与机床连接元件……………………………………11

6.6夹具体……………………………………………………11

7设计体会……………………………………………………12

8体会与展望…………………………………………………13

参考文献………………………………………………………14