设计简介

摘 要

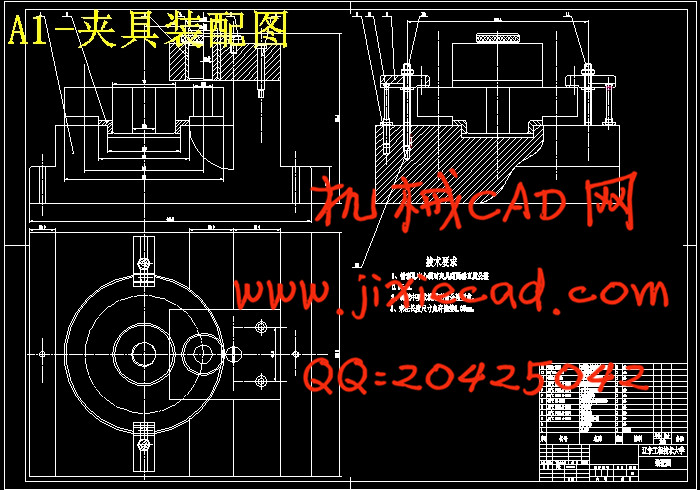

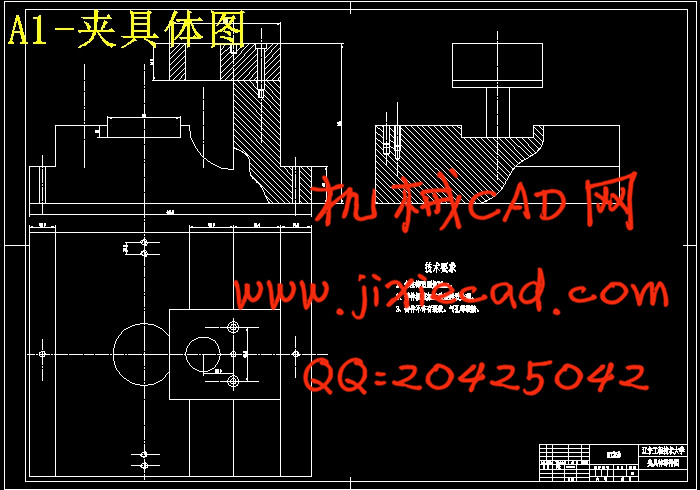

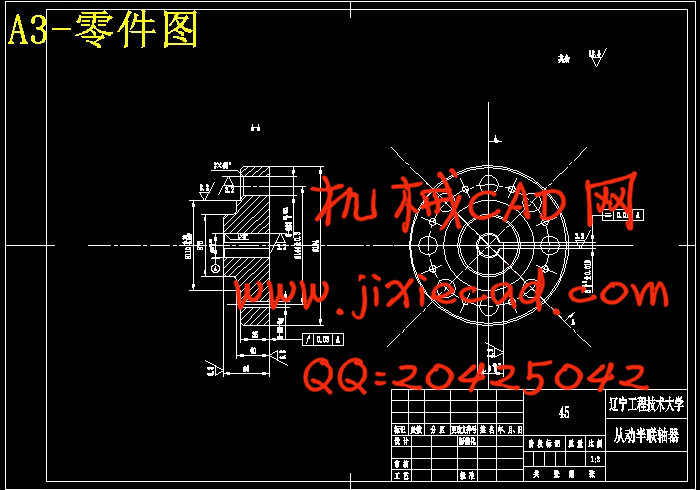

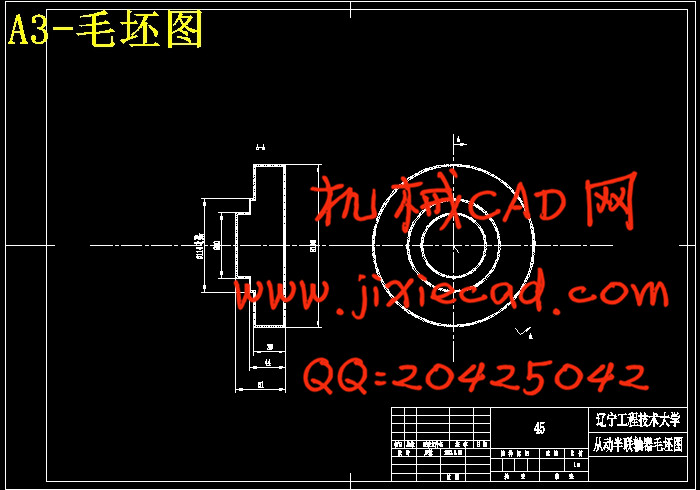

这次课程设计设计的是从动半联轴器的夹具设计,包括零件图、毛坯图、装配图、夹具体零件图各一张,机械加工工艺过程卡片和与工序卡片各一张。首先我们要熟悉零件和了解其作用。然后,根据零件的性质和零件图上各端面的粗糙度确定毛坯的尺寸和机械加工余量。最后拟定从动半联轴器的工艺路线图,制定该工件的夹紧方案,画出夹具装配图。

此次课程设计我了解并认识一般机器零件的生产工艺过程,巩固和加深已学过的技术基础课和专业课的知识,理论联系实际,从中锻炼自己分析问题、解决问题的能力,为今后的工作打下一个良好的基础,并且为后续课程的学习打好基础。对我们动手动脑的能力有了提高。

Abstract

What this design is the Driven half-coupling, include spare parts diagram, semi-finished product diagram and assemble diagram one for each, the machine processes craft process card with and work preface the card be an one for each.We want to acquaint with spare parts and understand its function first.Then, process amount of remaining according to size and Xie which makes sure semi-finished product of each rough degree which carry noodles of property and the top of the spare parts diagram of spare parts. Finally proposed driven half-coupling technology roadmap, formulate the workpiece clamping scheme, draw the fixture assembly drawing.

This time course design I understand and know general machine parts of production craft process, make stronger and deepen have already learned of the knowledge of the lesson and professional lesson of the technique foundation, theories contact actual, toughen from it oneself analysis problem, problem-solving ability, lay the next and good foundation for aftertime's work, and for follow-up course of the study lay good foundation.Began ability of move the brain to have an exaltation to us.

目录

1机械加工工艺规程设计 6

1.1零件的工艺性分析及生产类型的确定 7

1.1.1从动半联轴器的用途 7

1.1.2从动半联轴器的技术要求 7

1.2确定毛坯、绘制毛坯简图 8

1.2.1选择毛坯 8

1.2.2确定毛坯的尺寸公差和机械加工余量 8

1.2.3绘制从动半联轴器毛坯简图 9

1.3拟定从动半联轴器工艺路线 10

1.3.1定位基准的选择 10

1.3.2表面加工方法的确定 10

1.3.3加工阶段的划分 11

1.3.4工序的集中与分散 11

1.3.5工序顺序的安排 11

1.3.6确定工艺路线 12

1.4加工余量、工序尺寸和公差的确定 13

1.5切削用量、时间定额的计算 15

1.5.1切削用量的计算 15

1.5.2时间定额的计算 21

2夹具设计 25

2.1设计思想 25

2.2夹具设计 25

2.2.1定位分析 25

2.2.2切削力与夹紧力的计算 26

2.3夹具操作说明 27

2.4确定导向装置 27

方案综合评价与结论 28

体会与展望 29

这次课程设计设计的是从动半联轴器的夹具设计,包括零件图、毛坯图、装配图、夹具体零件图各一张,机械加工工艺过程卡片和与工序卡片各一张。首先我们要熟悉零件和了解其作用。然后,根据零件的性质和零件图上各端面的粗糙度确定毛坯的尺寸和机械加工余量。最后拟定从动半联轴器的工艺路线图,制定该工件的夹紧方案,画出夹具装配图。

此次课程设计我了解并认识一般机器零件的生产工艺过程,巩固和加深已学过的技术基础课和专业课的知识,理论联系实际,从中锻炼自己分析问题、解决问题的能力,为今后的工作打下一个良好的基础,并且为后续课程的学习打好基础。对我们动手动脑的能力有了提高。

Abstract

What this design is the Driven half-coupling, include spare parts diagram, semi-finished product diagram and assemble diagram one for each, the machine processes craft process card with and work preface the card be an one for each.We want to acquaint with spare parts and understand its function first.Then, process amount of remaining according to size and Xie which makes sure semi-finished product of each rough degree which carry noodles of property and the top of the spare parts diagram of spare parts. Finally proposed driven half-coupling technology roadmap, formulate the workpiece clamping scheme, draw the fixture assembly drawing.

This time course design I understand and know general machine parts of production craft process, make stronger and deepen have already learned of the knowledge of the lesson and professional lesson of the technique foundation, theories contact actual, toughen from it oneself analysis problem, problem-solving ability, lay the next and good foundation for aftertime's work, and for follow-up course of the study lay good foundation.Began ability of move the brain to have an exaltation to us.

目录

1机械加工工艺规程设计 6

1.1零件的工艺性分析及生产类型的确定 7

1.1.1从动半联轴器的用途 7

1.1.2从动半联轴器的技术要求 7

1.2确定毛坯、绘制毛坯简图 8

1.2.1选择毛坯 8

1.2.2确定毛坯的尺寸公差和机械加工余量 8

1.2.3绘制从动半联轴器毛坯简图 9

1.3拟定从动半联轴器工艺路线 10

1.3.1定位基准的选择 10

1.3.2表面加工方法的确定 10

1.3.3加工阶段的划分 11

1.3.4工序的集中与分散 11

1.3.5工序顺序的安排 11

1.3.6确定工艺路线 12

1.4加工余量、工序尺寸和公差的确定 13

1.5切削用量、时间定额的计算 15

1.5.1切削用量的计算 15

1.5.2时间定额的计算 21

2夹具设计 25

2.1设计思想 25

2.2夹具设计 25

2.2.1定位分析 25

2.2.2切削力与夹紧力的计算 26

2.3夹具操作说明 27

2.4确定导向装置 27

方案综合评价与结论 28

体会与展望 29