设计简介

摘 要

机械制造工艺是实现产品设计、保证产品质量、节约能源、降低消耗的重要手段,是企业进行生产准备、计划调度、加工操作、技术检查、安全生产和健全劳动组织的依据,也是企业上品种、上质量、上水平,加速产品改进,提高经济效益的技术保证,因而编制一套合理的加工工艺是影响产品制造效益,企业发展进步的重要法码 。这次毕业设计主要是对转速器盘进行加工工艺和夹具的设计,以求在工艺的设计中能找到提高经济效益的新的加工方法。而本次设计主要内容是对零件的分析、毛坯件的铸造、加工的工艺路线以及夹具部分的设计,为提高经济精度,本次设计更是进行了大量的计算。希望对转速器盘的加工工艺有一些帮助。

关键词:机械制造工艺;转速器盘;加工工艺。

ABSTRACT

Machinery manufacturing technology is to implement product design, an important means to ensure the product quality, save energy and reduce consumption, is the enterprise is ready for production, planning and scheduling, processing operations, technical inspection, production safety and sound according to the labor organization, and enterprises on the variety, quality, level, accelerate product improvement, and improve the economic benefits of the technology guarantee, thus preparing a set of reasonable processing technology is affecting the product manufacturing efficiency, enterprise development and progress of the important weights. This graduation design mainly carries on the processing craft and the jig design to the speed wheel, in order to find the new processing method which can improve the economic efficiency in the process design. And the design of the main content is on the part of the analysis, blank casting, machining process and fixture design, in order to improve the precision of the economy, this design is the calculation of a large amount of. I hope that the speed of the processing technology to help the disc.

Keywords: mechanical manufacturing process; rotating speed machining; processing technology.

目 录

第一章 零件分析........................................................................................ 1

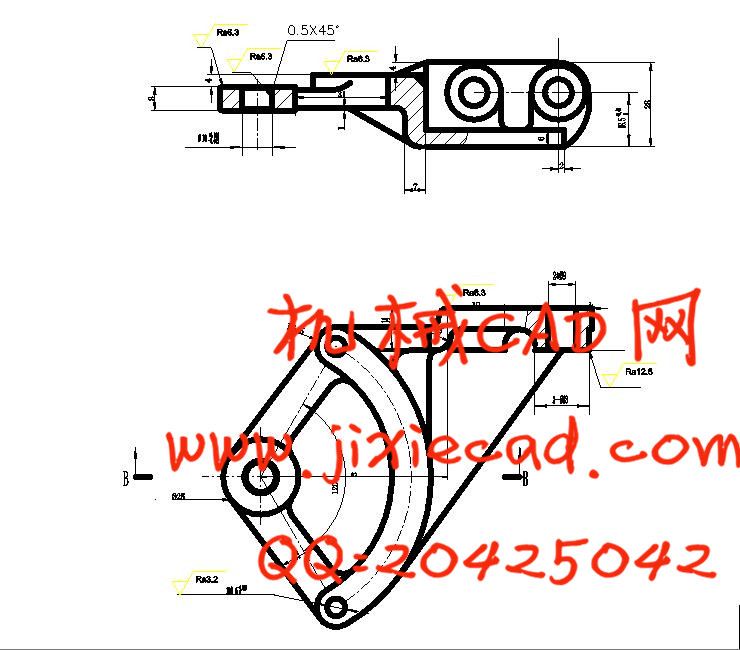

1.1零件的作用................................................................................................................... 1

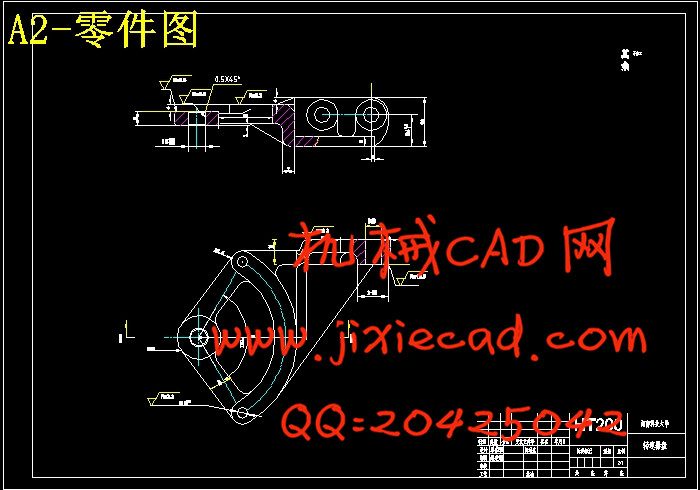

1.2零件的工艺性分析和零件图的审查........................................................................... 2

1.3零件的生产纲领及生产类型 ...................................................................................... 3

1.4零件的加工工艺分析 .................................................................................................. 3

1.5零件主要技术条件分析及技术关键问题 .................................................................. 3

第二章 选择毛坯............................................................................................................... 5

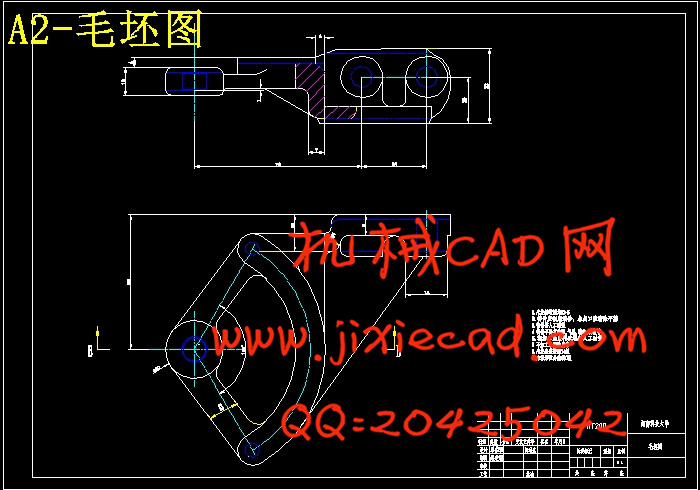

2.1 确定毛坯的成形方法.................................................................................................. 5

2.2 铸件结构工艺性分析.................................................................................................. 5

2.3 铸造工艺方案的确定.................................................................................................. 5

2.3.1铸造方法的选择........................................................................................................ 5

2.4 铸造工艺参数的确定.................................................................................................. 6

2.4.1加工余量的确定................................................................................................. 6

2.4.2拔模斜度的确定................................................................................................. 6

2.4.3分型负数的确定................................................................................................. 6

2.4.4收缩率的确定..................................................................................................... 6

2.4.5不铸孔的确定..................................................................................................... 6

2.4.6铸造圆角的确定................................................................................................. 6

2.5 型芯设计...................................................................................................................... 6

第三章 工艺规程设计..................................................................................................... 8

3.1定位基准的选择........................................................................................................... 8

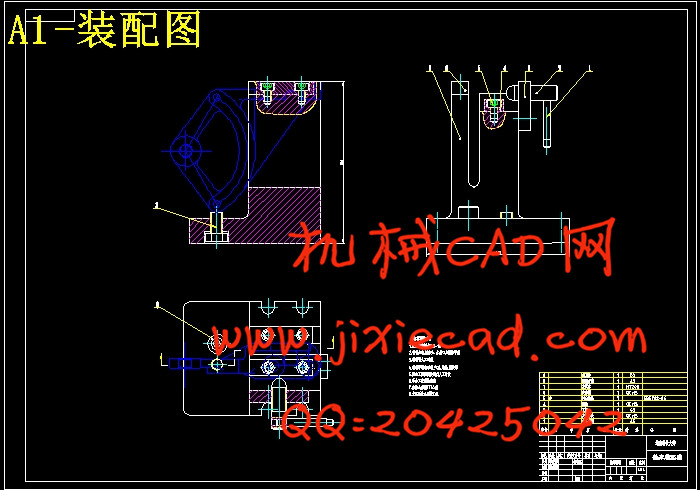

3.2制订工艺路线............................................................................................................... 9

3.3确定机械加工余量及工序尺寸.................................................................................. 11

3.4确定切削用量及基本工时......................................................................................... 15

3.4.1 工序40:粗、精铣Φ9端两端面.......................................................................... 15

第四章 夹具设计............................................................................................................. 37

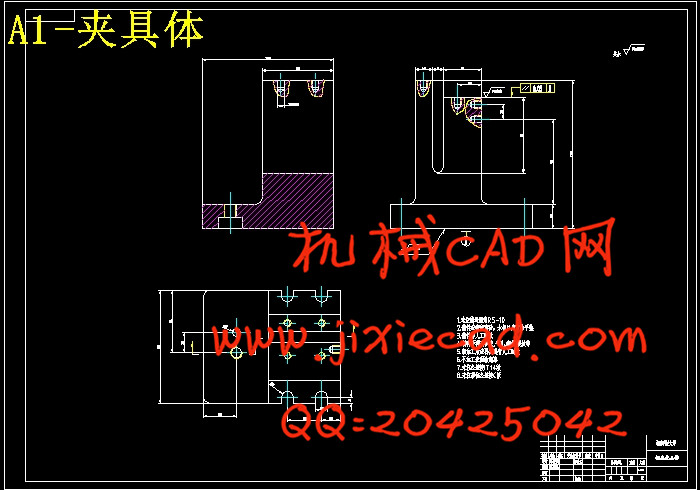

4.1定位基准的选择......................................................................................................... 37

4.2切削力及夹紧力计算:............................................................................................. 37

4.3定位误差分析............................................................................................................. 38

第五章 结论....................................................................................................................... 40

参 考 文 献....................................................................................................................... 41

致 谢.............................................................................................................................. 42

机械制造工艺是实现产品设计、保证产品质量、节约能源、降低消耗的重要手段,是企业进行生产准备、计划调度、加工操作、技术检查、安全生产和健全劳动组织的依据,也是企业上品种、上质量、上水平,加速产品改进,提高经济效益的技术保证,因而编制一套合理的加工工艺是影响产品制造效益,企业发展进步的重要法码 。这次毕业设计主要是对转速器盘进行加工工艺和夹具的设计,以求在工艺的设计中能找到提高经济效益的新的加工方法。而本次设计主要内容是对零件的分析、毛坯件的铸造、加工的工艺路线以及夹具部分的设计,为提高经济精度,本次设计更是进行了大量的计算。希望对转速器盘的加工工艺有一些帮助。

关键词:机械制造工艺;转速器盘;加工工艺。

ABSTRACT

Machinery manufacturing technology is to implement product design, an important means to ensure the product quality, save energy and reduce consumption, is the enterprise is ready for production, planning and scheduling, processing operations, technical inspection, production safety and sound according to the labor organization, and enterprises on the variety, quality, level, accelerate product improvement, and improve the economic benefits of the technology guarantee, thus preparing a set of reasonable processing technology is affecting the product manufacturing efficiency, enterprise development and progress of the important weights. This graduation design mainly carries on the processing craft and the jig design to the speed wheel, in order to find the new processing method which can improve the economic efficiency in the process design. And the design of the main content is on the part of the analysis, blank casting, machining process and fixture design, in order to improve the precision of the economy, this design is the calculation of a large amount of. I hope that the speed of the processing technology to help the disc.

Keywords: mechanical manufacturing process; rotating speed machining; processing technology.

目 录

第一章 零件分析........................................................................................ 1

1.1零件的作用................................................................................................................... 1

1.2零件的工艺性分析和零件图的审查........................................................................... 2

1.3零件的生产纲领及生产类型 ...................................................................................... 3

1.4零件的加工工艺分析 .................................................................................................. 3

1.5零件主要技术条件分析及技术关键问题 .................................................................. 3

第二章 选择毛坯............................................................................................................... 5

2.1 确定毛坯的成形方法.................................................................................................. 5

2.2 铸件结构工艺性分析.................................................................................................. 5

2.3 铸造工艺方案的确定.................................................................................................. 5

2.3.1铸造方法的选择........................................................................................................ 5

2.4 铸造工艺参数的确定.................................................................................................. 6

2.4.1加工余量的确定................................................................................................. 6

2.4.2拔模斜度的确定................................................................................................. 6

2.4.3分型负数的确定................................................................................................. 6

2.4.4收缩率的确定..................................................................................................... 6

2.4.5不铸孔的确定..................................................................................................... 6

2.4.6铸造圆角的确定................................................................................................. 6

2.5 型芯设计...................................................................................................................... 6

第三章 工艺规程设计..................................................................................................... 8

3.1定位基准的选择........................................................................................................... 8

3.2制订工艺路线............................................................................................................... 9

3.3确定机械加工余量及工序尺寸.................................................................................. 11

3.4确定切削用量及基本工时......................................................................................... 15

3.4.1 工序40:粗、精铣Φ9端两端面.......................................................................... 15

第四章 夹具设计............................................................................................................. 37

4.1定位基准的选择......................................................................................................... 37

4.2切削力及夹紧力计算:............................................................................................. 37

4.3定位误差分析............................................................................................................. 38

第五章 结论....................................................................................................................... 40

参 考 文 献....................................................................................................................... 41

致 谢.............................................................................................................................. 42