设计简介

目 录

前 言....................................................................................................................................... 1

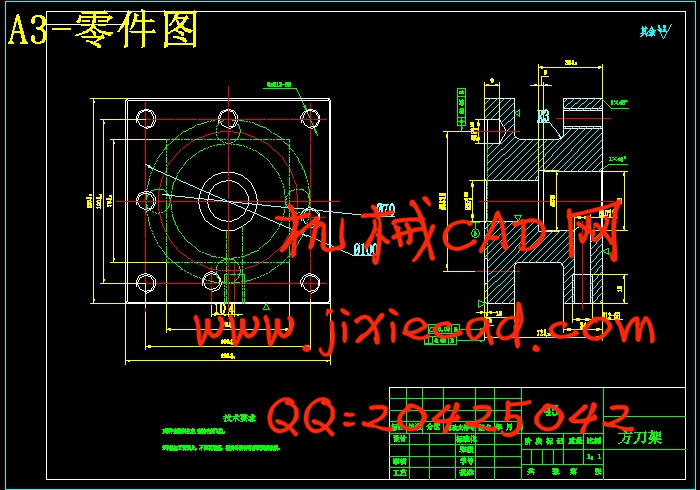

1 零件分析................................................................................................................................. 2

1.1 零件的作用................................................................................................................... 2

1.2 零件的工艺分析............................................................................................................ 2

1.2.1 零件图样分析..................................................................................................... 2

1.2.2 工艺分析............................................................................................................ 2

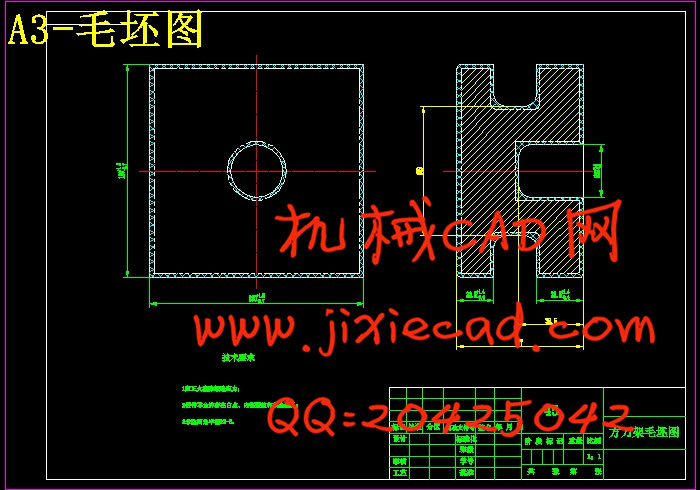

2 确定毛坯、绘制毛坯简图...................................................................................................... 4

2.1 选择毛坯...................................................................................................................... 4

2.2 确定毛坯的尺寸公差和机械加工余量............................................................................ 4

2.3绘制方刀架锻造毛坯简图............................................................................................... 5

3 工艺规程设计........................................................................................................................ 6

3.1 定位基准的选择............................................................................................................ 6

3.1.1 基面的选择........................................................................................................ 6

3.1.2 粗基准的选择..................................................................................................... 6

3.1.3 精基准的选择..................................................................................................... 6

3.2 拟订工艺路线............................................................................................................... 7

3.3 加工余量、工序尺寸和公差的确定.............................................................................. 11

3.4 切削用量的计算.......................................................................................................... 12

3.5 时间定额计算............................................................................................................. 20

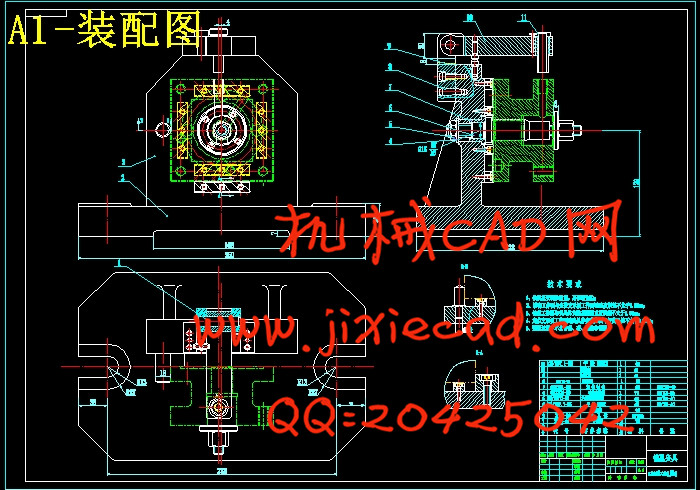

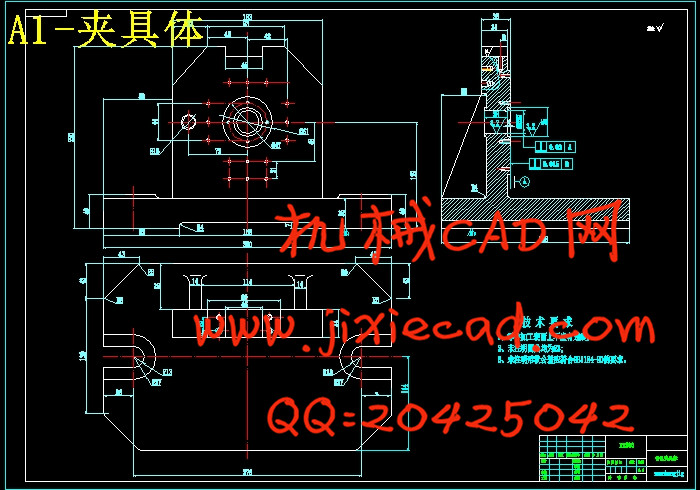

4 钻M12螺纹底孔专用夹具设计.............................................................................................. 25

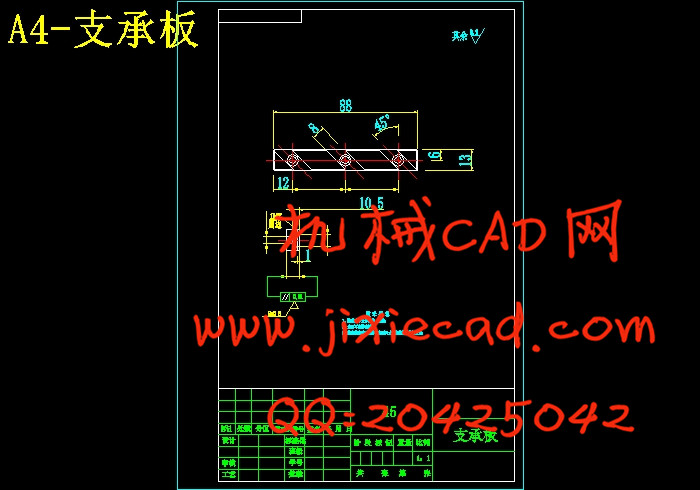

4.1 夹具的夹紧装置和定位装置........................................................................................ 25

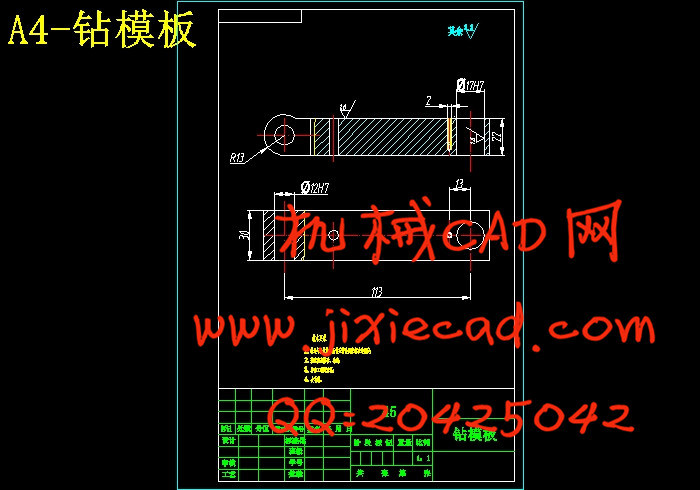

4.2 钻模板与导引元件的设计............................................................................................ 25

4.3 切削力及夹紧力的计算............................................................................................... 26

4.4 钻孔与工件之间的切屑间隙........................................................................................ 28

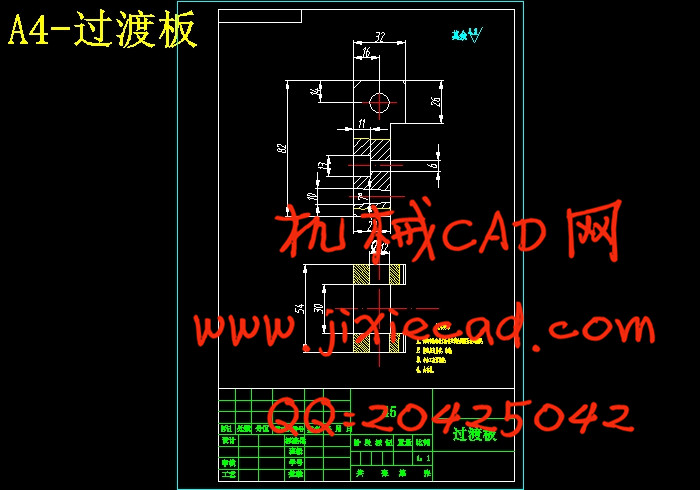

4.5 钻模板........................................................................................................................ 29

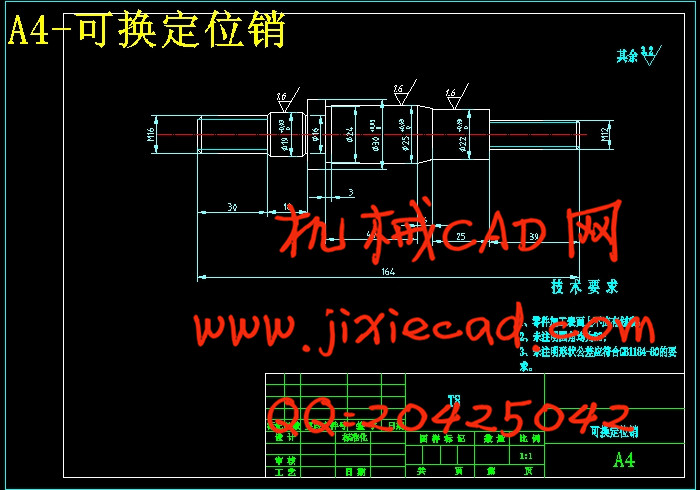

4.6定位误差的分析........................................................................................................... 29

4.7 钻套、衬套、钻模板设计与选用................................................................................. 30

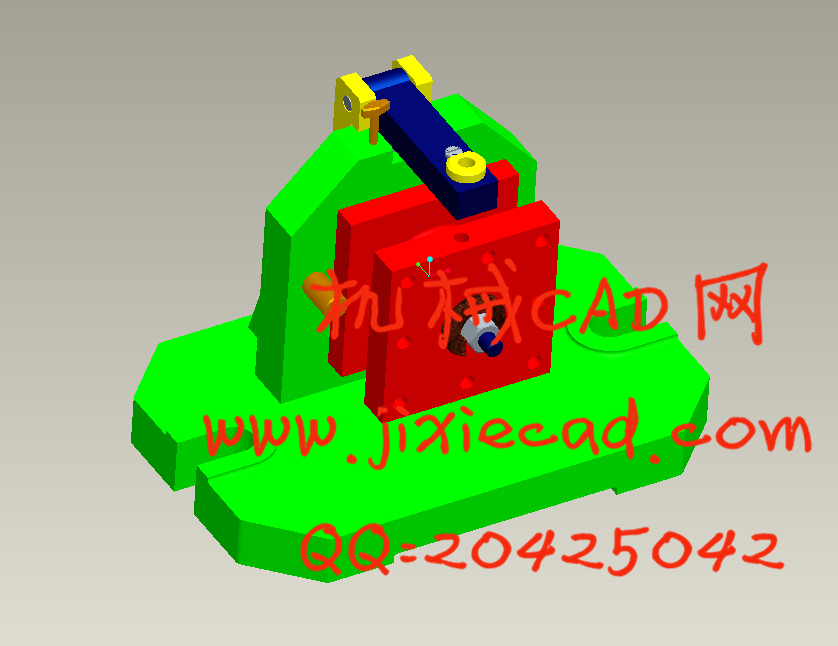

4.8 确定夹具体结构和总体结构........................................................................................ 32

结 论...................................................................................................................................... 34

参考文献.................................................................................................................................. 35

致 谢...................................................................................................................................... 36

方刀架零件加工工艺及夹具设计

摘要:本课题主要是在方刀架零件加工过程的基础上进行的专用夹具设计。主要加工部位是平面和孔。在一般情况下,确保比保证精密加工孔很容易。因此,设计遵循的原则是先加工面后加工孔。孔加工平面分明显的阶段性保证粗加工和加工精度加工孔。通过底面作一个良好的基础过程的基础。主要的流程安排是支持在定位孔过程第一个,然后进行平面和孔定位技术支持上加工孔。在随后的步骤中,除了被定位在平面和孔的加工工艺及其他孔过程。整个过程是一个组合的选择工具。专用夹具夹具的选择,有自锁机构,因此,对于大批量,设计夹具会产生更高的生产力,提高生产效率,满足设计要求。

关键词:方刀架类零件;工艺;夹具;

Abstract: Machining process and fixture design of the lathe tool

This paper mainly is in the process of the processing of the parts of the machine tool, based on the special fixture design. The main parts of the machine is the plane and the hole. In general, it is easy to make sure that the hole is better than the guarantee. Therefore, the design principle is the first processing hole. The hole processing plane is obvious and the phase of the hole is ensured. The foundation of a good foundation is made by the bottom surface. The main process arrangement is to support the first one in the positioning hole, and then carry out the plane and hole positioning technology to support the processing hole. In the subsequent step, the process and other holes are positioned in addition to being positioned in the plane and hole. The whole process is a combination of selection tools. The choice of special fixture fixture, there are self - locking mechanism, therefore, for large quantities, design fixture will produce higher productivity, improve production efficiency, meet the design requirements.

Key words: square frame parts; process; fixture

视产品与技术人员,设备条件和工人的质量等的数量,以确定所使用的过程中,和写在过程的文件,这是所述处理的规划的内容。这是一个比较有针对性。每个工厂可能不一样,因为实际的情况是不同的。

总体来说,该过程是一个程序,过程是对于每个步骤详细参数,工艺规划是基于一个特定工厂编写过程的实际情况。

前 言....................................................................................................................................... 1

1 零件分析................................................................................................................................. 2

1.1 零件的作用................................................................................................................... 2

1.2 零件的工艺分析............................................................................................................ 2

1.2.1 零件图样分析..................................................................................................... 2

1.2.2 工艺分析............................................................................................................ 2

2 确定毛坯、绘制毛坯简图...................................................................................................... 4

2.1 选择毛坯...................................................................................................................... 4

2.2 确定毛坯的尺寸公差和机械加工余量............................................................................ 4

2.3绘制方刀架锻造毛坯简图............................................................................................... 5

3 工艺规程设计........................................................................................................................ 6

3.1 定位基准的选择............................................................................................................ 6

3.1.1 基面的选择........................................................................................................ 6

3.1.2 粗基准的选择..................................................................................................... 6

3.1.3 精基准的选择..................................................................................................... 6

3.2 拟订工艺路线............................................................................................................... 7

3.3 加工余量、工序尺寸和公差的确定.............................................................................. 11

3.4 切削用量的计算.......................................................................................................... 12

3.5 时间定额计算............................................................................................................. 20

4 钻M12螺纹底孔专用夹具设计.............................................................................................. 25

4.1 夹具的夹紧装置和定位装置........................................................................................ 25

4.2 钻模板与导引元件的设计............................................................................................ 25

4.3 切削力及夹紧力的计算............................................................................................... 26

4.4 钻孔与工件之间的切屑间隙........................................................................................ 28

4.5 钻模板........................................................................................................................ 29

4.6定位误差的分析........................................................................................................... 29

4.7 钻套、衬套、钻模板设计与选用................................................................................. 30

4.8 确定夹具体结构和总体结构........................................................................................ 32

结 论...................................................................................................................................... 34

参考文献.................................................................................................................................. 35

致 谢...................................................................................................................................... 36

方刀架零件加工工艺及夹具设计

摘要:本课题主要是在方刀架零件加工过程的基础上进行的专用夹具设计。主要加工部位是平面和孔。在一般情况下,确保比保证精密加工孔很容易。因此,设计遵循的原则是先加工面后加工孔。孔加工平面分明显的阶段性保证粗加工和加工精度加工孔。通过底面作一个良好的基础过程的基础。主要的流程安排是支持在定位孔过程第一个,然后进行平面和孔定位技术支持上加工孔。在随后的步骤中,除了被定位在平面和孔的加工工艺及其他孔过程。整个过程是一个组合的选择工具。专用夹具夹具的选择,有自锁机构,因此,对于大批量,设计夹具会产生更高的生产力,提高生产效率,满足设计要求。

关键词:方刀架类零件;工艺;夹具;

Abstract: Machining process and fixture design of the lathe tool

This paper mainly is in the process of the processing of the parts of the machine tool, based on the special fixture design. The main parts of the machine is the plane and the hole. In general, it is easy to make sure that the hole is better than the guarantee. Therefore, the design principle is the first processing hole. The hole processing plane is obvious and the phase of the hole is ensured. The foundation of a good foundation is made by the bottom surface. The main process arrangement is to support the first one in the positioning hole, and then carry out the plane and hole positioning technology to support the processing hole. In the subsequent step, the process and other holes are positioned in addition to being positioned in the plane and hole. The whole process is a combination of selection tools. The choice of special fixture fixture, there are self - locking mechanism, therefore, for large quantities, design fixture will produce higher productivity, improve production efficiency, meet the design requirements.

Key words: square frame parts; process; fixture

前 言

方刀架加工处理是指改变形状,尺寸,相对位置和取得良好份的全过程的性质的加工坯料的方法,该方法是基于所述工作者的处理。例如,该处理流程粗加工的共用部分 - 精加工 - 装配 - 检验 - 包装,是一般方法的过程。如上面所述原油处理可以包括空白的制造,研磨等,可被分成轿厢精加工,钳工,铣床,等等,必要的每个步骤进行了详细的数据,如粗糙度,以实现得多,公差来实现。视产品与技术人员,设备条件和工人的质量等的数量,以确定所使用的过程中,和写在过程的文件,这是所述处理的规划的内容。这是一个比较有针对性。每个工厂可能不一样,因为实际的情况是不同的。

总体来说,该过程是一个程序,过程是对于每个步骤详细参数,工艺规划是基于一个特定工厂编写过程的实际情况。