设计简介

摘 要

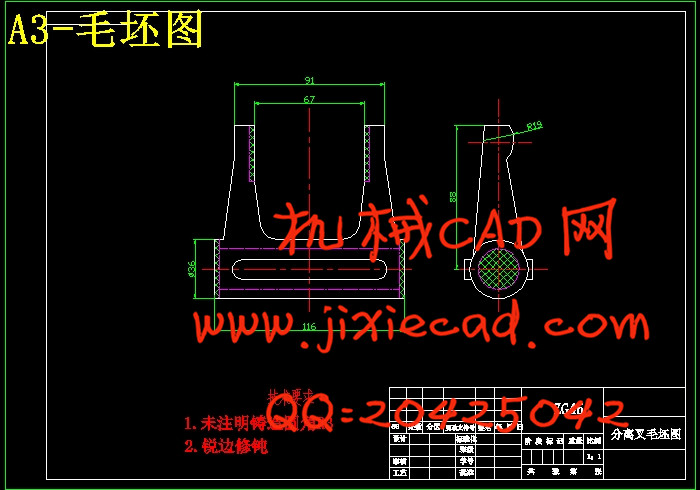

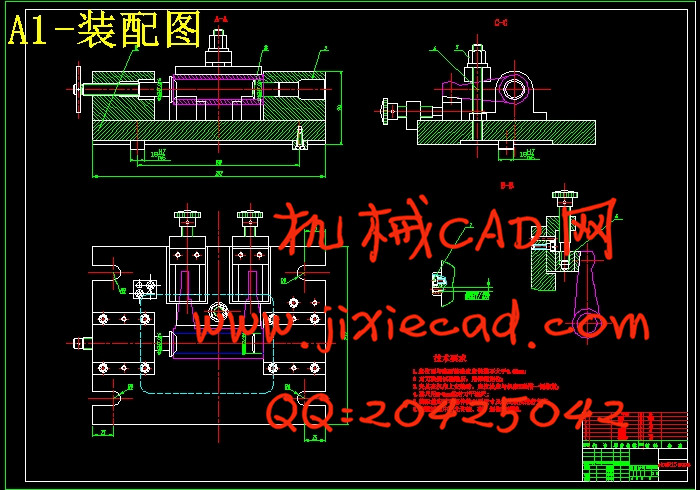

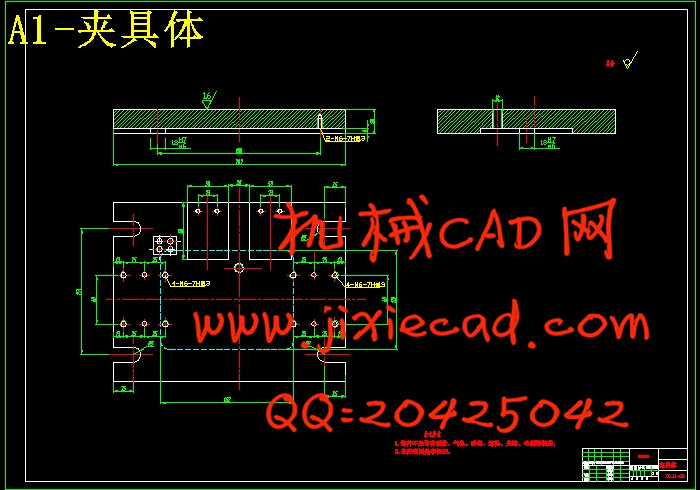

本设计是基于分离叉零件的加工工艺规程及一些工序的专用夹具设计。分离叉零件的主要加工表面是平面和孔系。一般来说,保证平面的加工精度要比保证加工精度容易。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段,以保证加工精度。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。关键词:分离叉类零件;工艺;夹具;

ABSTRACT

The design of special fixture process separation fork parts and process design based on. The main processing surface separation fork parts is the plane and hole. In general, guarantee the working accuracy of the plane is easier than to ensure accuracy. Therefore, the design follows the principle of the surface after the first hole. And the hole and the plane processingclearly divided into roughing and finishing stages of processing to ensure accuracy. First on the part of the analysis, understand parts of the process and then design a blank in the process design of structure, and choose the good parts machining reference to design parts of the process route; then the various parts of the process we will calculate the size, the key is to determine every step of the craft equipment and the cutting dosage; then special fixture design, choice designs the jig each component, such as element positioning, clamping element, a guide element, clip with the machine specific connection components, and other components; calculate fixture positioning error analysis rationality and deficiency of fixture structure, and in later design should be improved.

Keywords: chemical pipe parts; technology; fixture;

目 录

摘 要······················································································ II

ABSTRACT············································································· III

第1章 机械加工工艺规程设计·················································· 1

1.1 零件的分析································································· 1

1.1.1 零件的作用····························································· 1

1.1.2 零件的工艺分析······················································· 1

1.2 分离叉加工的主要问题和工艺过程设计所应采取的相应措施 1

1.2.1 孔和平面的加工顺序················································ 2

1.2.2 孔系加工方案选择··················································· 2

1.3 分离叉加工定位基准的选择·········································· 2

1.3.1 粗基准的选择·························································· 2

1.3.2 精基准的选择·························································· 3

1.4 分离叉加工主要工序安排············································· 3

1.5 机械加工余量、工序尺寸及毛坯尺寸的确定·················· 4

1.6 毛坯种类的选择·························································· 5

1.7 选择加工设备和工艺装备············································· 6

1.7.1 机床选用································································ 6

1.7.2 选择刀具································································ 6

1.7.3 选择量具································································ 6

1.8 机械加工余量、工序尺寸及毛坯尺寸的确定·················· 6

1.9确定切削用量及基本工时(机动时间)·························· 8

1.10 时间定额计算及生产安排·········································· 14

第2章分离叉铣R15圆弧面夹具设计········································ 16

2.1研究原始质料······························································ 16

2.2定位基准的选择··························································· 16

2.3 切削力及夹紧分析计算················································· 16

2.4 误差分析与计算·························································· 18

2.5 零、部件的设计与选用················································· 19

2.5.1定位销选用···························································· 19

2.5.2 定向键装置设计····················································· 19

2.6 夹具设计及操作的简要说明·········································· 21

总结························································································ 22

参 考 文 献············································································· 23

致谢························································································ 24