设计简介

摘 要

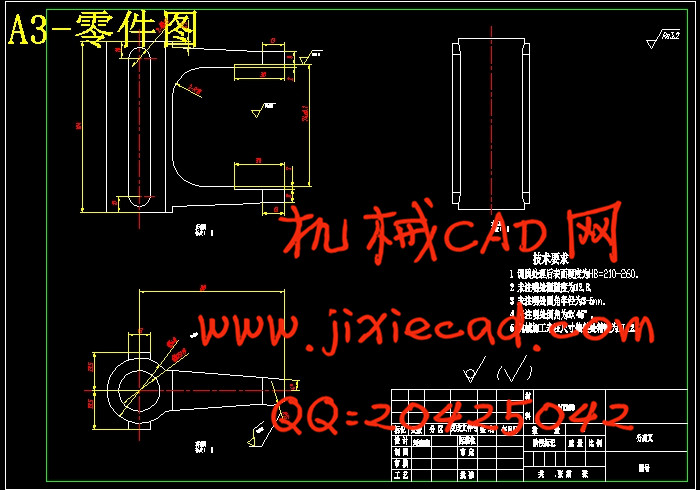

本次设计是对分离叉的加工工艺规程及一些工序的专用夹具设计。分离叉零件的主要加工表面是端面,孔及圆弧加工。由加工工艺原则可知,为了保证零件的精度,同时节约成本縮短加工周期提高生产效率。那么一个良好的工艺安排以及专用夹具的设计必不可少。在工艺的安排下不紧考虑合理的加工要求,还要考虑操作者及加工机械的安全,同时夹具的设计也要考虑拆卸的方便及安全。设计一个良好的工艺工装安排路线必须对加工件的详细分析及周密考虑后才能得出。所以分析问题是解决问题的关键,同时还要反复的调整,来寻求一个最好的方案,这样才能保证工件的加工精度及生产节拍。关键词 分离叉,加工工艺,夹具设计

ABSTRACT

This design is the design of special fixture processing procedure on the separation fork and some work. The main processing surface separation fork parts of the face, hole and arc processing. By the principle known processing, in order to ensure the accuracy of the parts, at the same time, save cost and shorten the processing cycle to improve production efficiency. So the design of a good process arrangement and special fixture is essential. In the process of arrangement is not tight reasonable processing requirements, but also consider the operator and processing machinery safety. At the same time, the fixture design also consider removing the convenience and safety. The design of a good tooling arrangement route must have to process a detailed analysis and careful consideration can reach. So the analysis of the problem is the key to solve the problem. At the same time, repeat adjustment. To seek a better solution. In order to guarantee the processing precision of the workpiece and the production rhythmKey words : Separation fork,Process the craft,special fixture

目 录

摘 要..........................................................................................................................

ABSTRACT...................................................................................................................

目录.............................................................................................................................. I

第一章 前 言.................................................... 1

第二章 机床的夹具概述.............................................................................................. 3

2.1 机床夹具及其作用.....................................................................................................3

2.2 机床夹具的分类及组成............................................................................................3

2.3 夹具装夹工件的方法及特点 ....................................................................................5

2.4工件定位的基本原理.................................................................................................5

2.5 常用定位元件...................................................................................................................7

2.6 定位元件的使用..............................................................................................................9

2.7 定位误差的分析.............................................................................................................11

2.8 工件的夹紧......................................................................................................................13

2.9 工件的组合定位............................................................................................................15

2.10 机床夹具的现状及发展方向....................................................................................17

第三章 分离叉加工工艺规程设计.......................................................... 19

3.1零件的分析...................................................................................................... 19

3.1.1零件的作用............................................................................................... 19

3.1.2零件的工艺分析....................................................................................... 19

3.2工艺过程设计所应采取的相应措施............................................................... 20

3.3分离叉加工定位基准的选择........................................................................... 20

3.3.1确定毛坯的制造形式............................................................................... 20

3.3.2粗基准的选择........................................................................................... 20

3.3.3精基准的选择........................................................................................... 21

3.4 工艺路线的制定................................................................................................... 21

3.4.1 工艺方案一.............................................................................................. 21

3.4.2 工艺方案二.......................................................................................... ....21

3.4.3 工艺方案的比较与分析.......................................................................... 22

3.5机械加工余量、工序尺寸及毛坯尺寸的确定............................................... 22

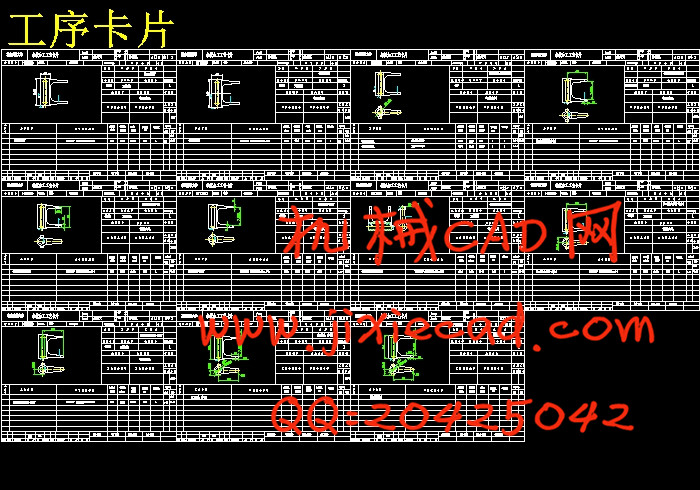

3.6确定切削用量及基本工时(机动时间)....................................................... 23

3.7时间定额计算及生产安排............................................................................... 31

3.8 本章小结.......................................................................................................... 34

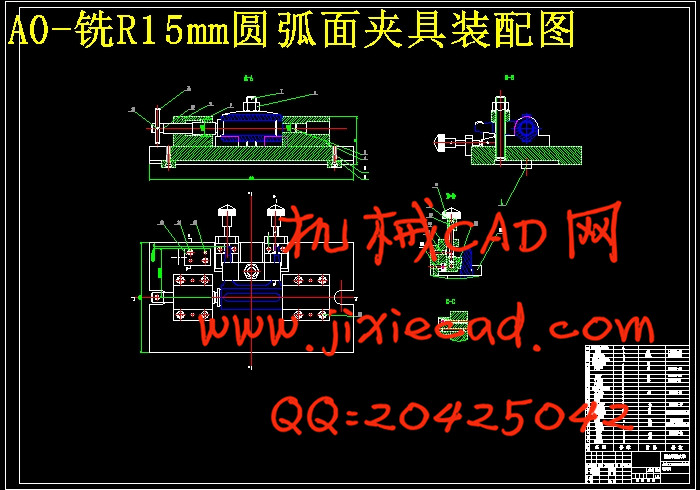

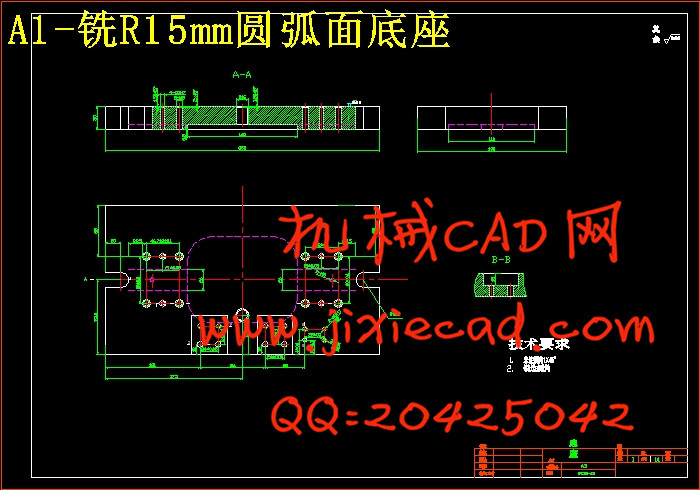

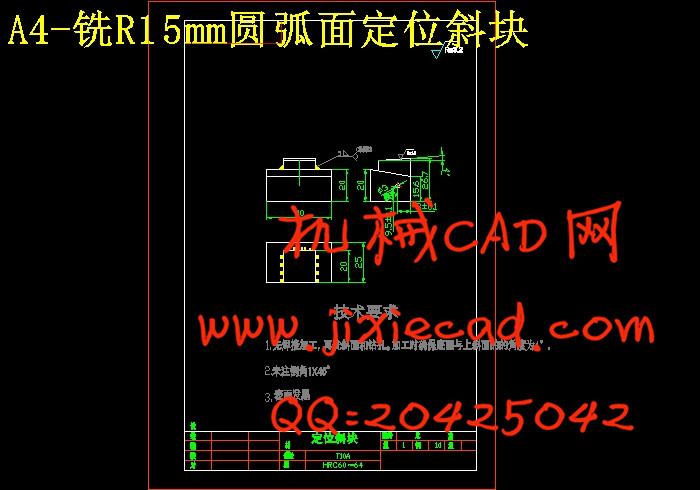

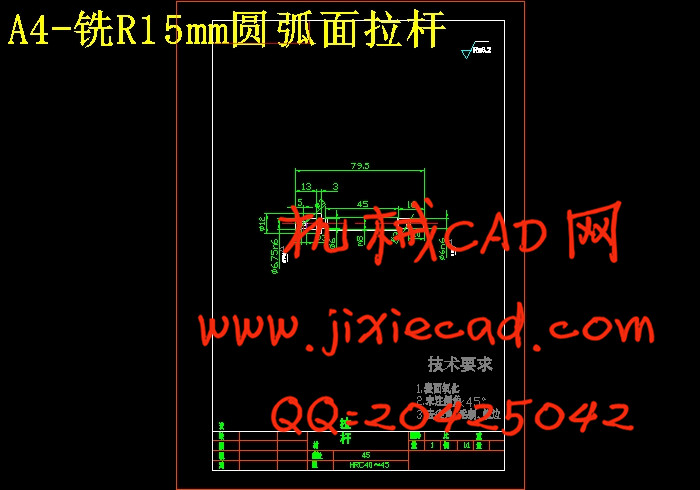

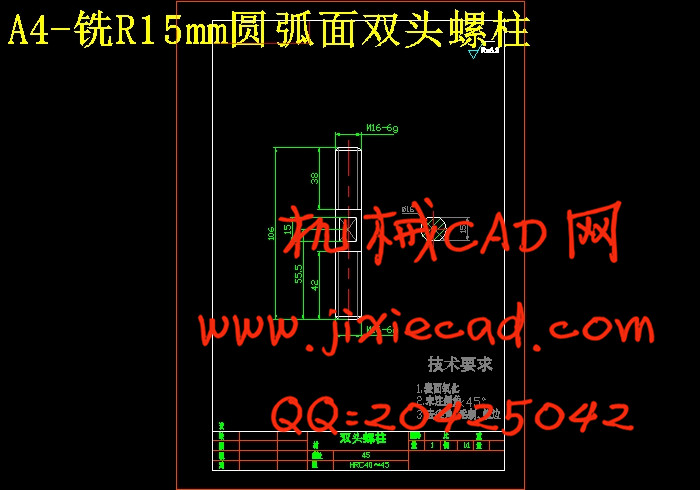

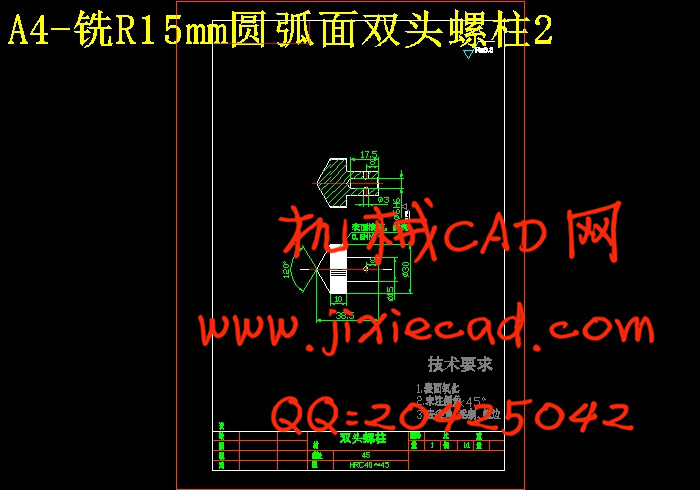

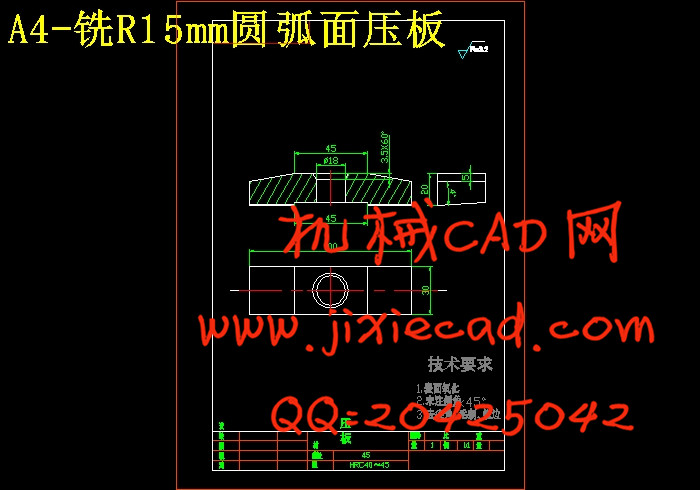

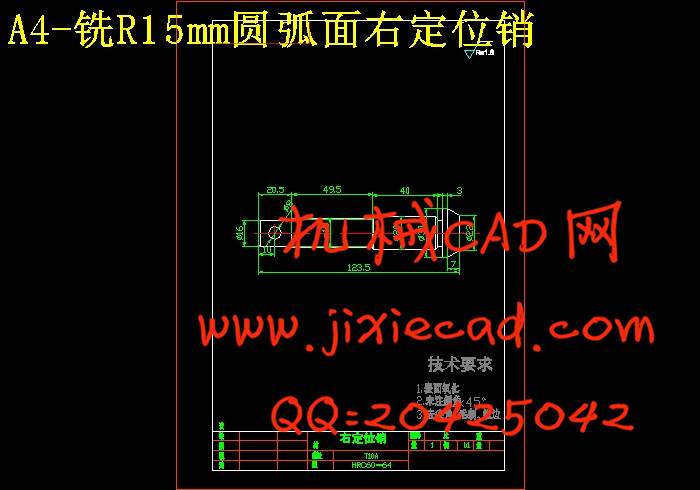

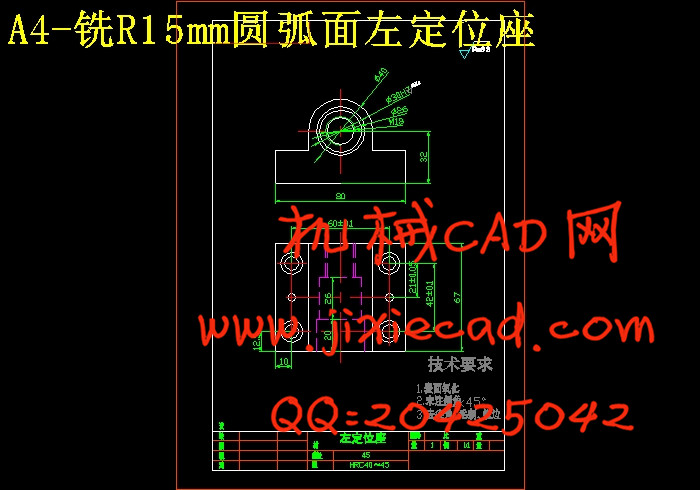

第四章 分离叉铣R15圆弧面夹具设计.................................................. 35

4.1分离叉铣R15圆弧面夹具设计....................................................................... 35

4.2定位方案的分析和定位基准的选择............................................................... 35

4.3铣削力与夹紧力计算....................................................................................... 36

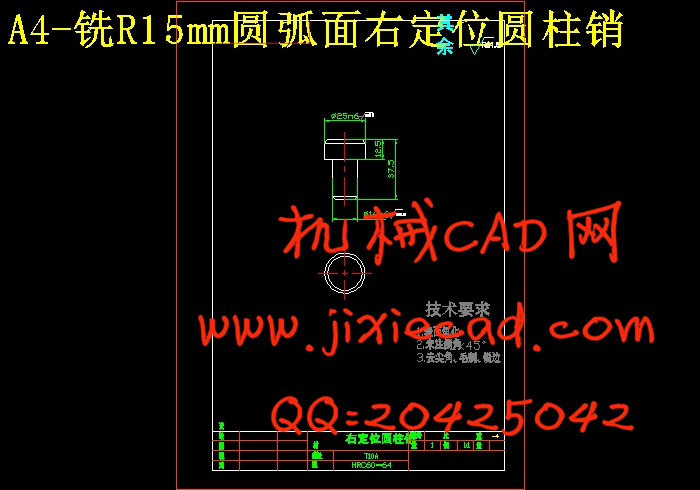

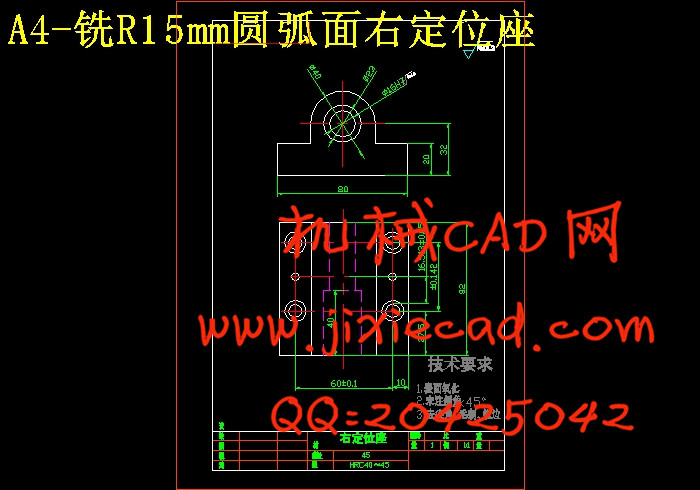

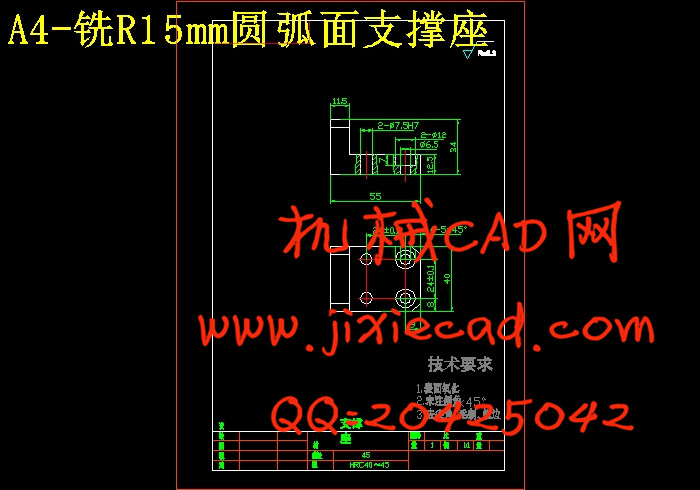

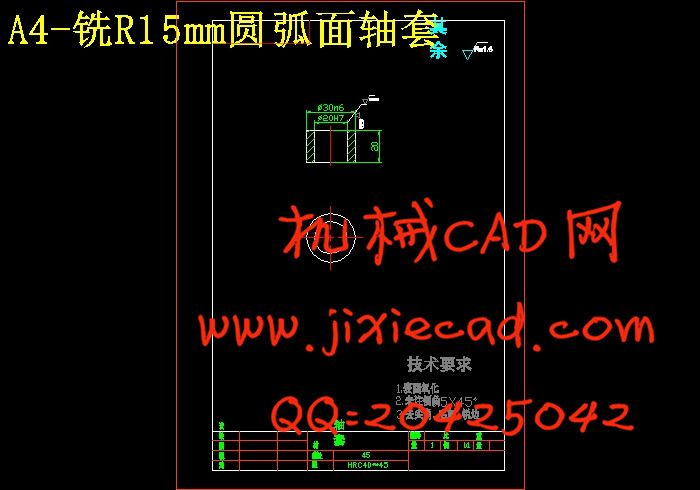

4.4本体和定位销及支撑座的设计....................................................................... 36

4.5夹具精度分析................................................................................................... 38

4.6本章小结...........................................................................................................................38

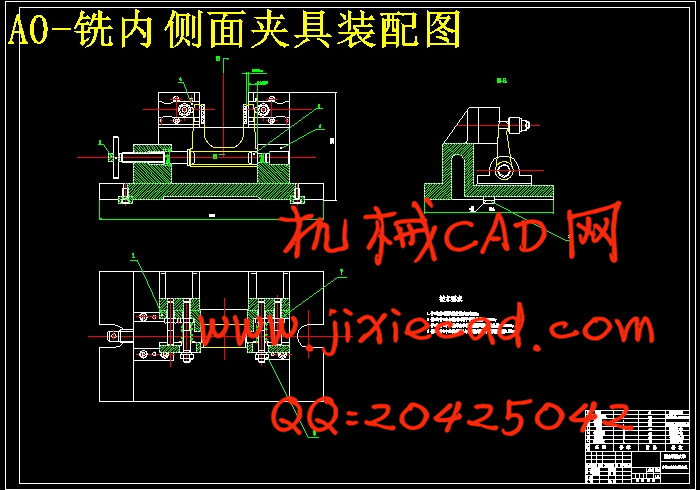

第五章 分离叉内侧面铣夹具设计........................................................................39

5.1定位方案...........................................................................................................39

5.1.1六点定位原理.............................................................................................39

5.1.2应用定位原理几种情况.............................................................................39

5.1.3确定要限制的自由度.................................................................................40

5.1.4定位误差计算.............................................................................................41

5.2夹紧方案................................................................................................................41

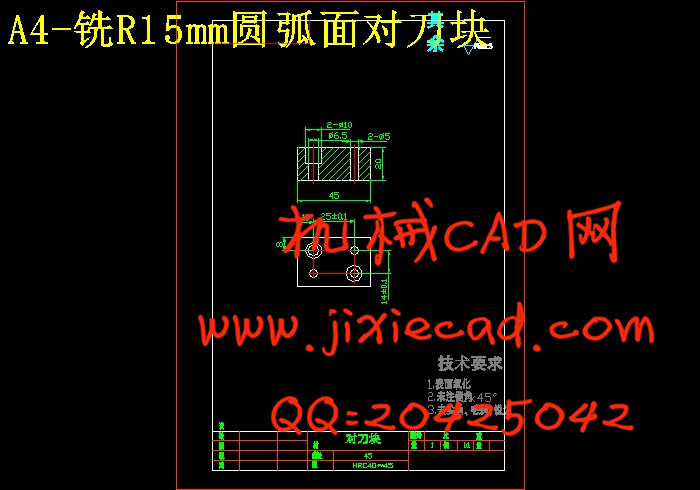

5.3对刀方案................................................................................................................42

5.4夹具体与定位键....................................................................................................43

5.5夹具体总图上的尺寸公差和技术要求................................................................43

5..6夹具精度分析.......................................................................................................43

第六章 结论......................................................................................................................46

参 考 文 献.............................................................................................................. 47

致 谢......................................................................................................................... 48