设计简介

摘要

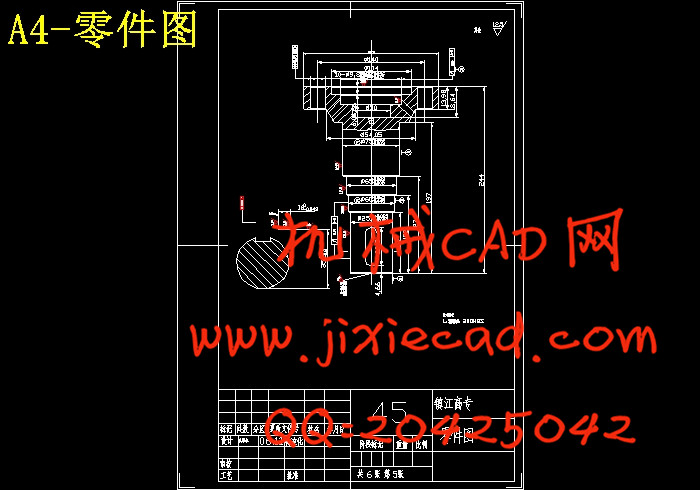

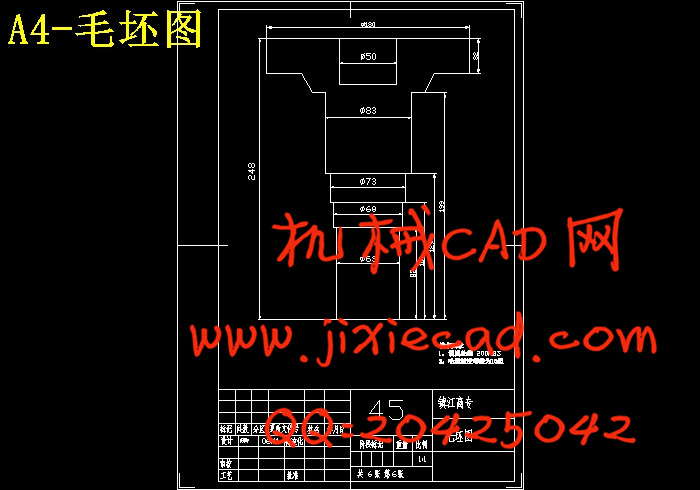

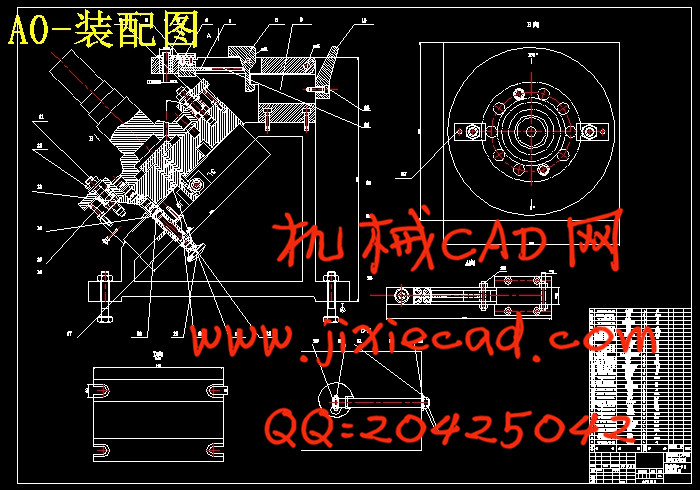

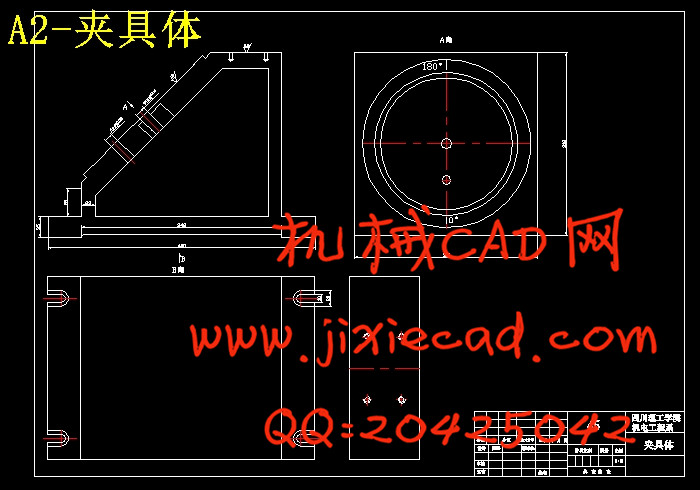

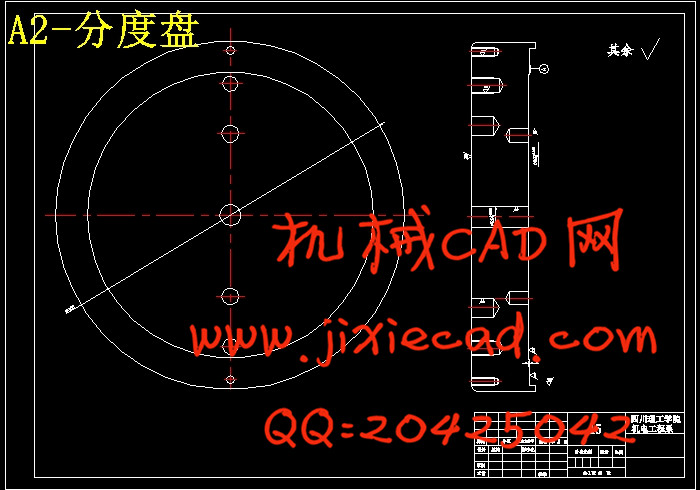

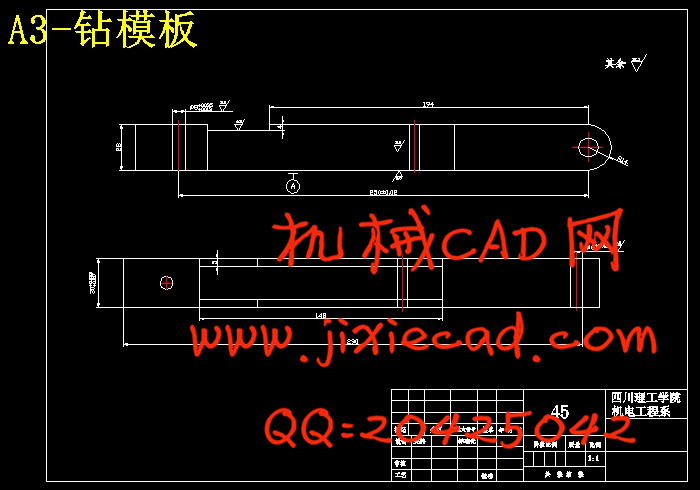

机械制造业是一个国家技术进步和社会发展的支柱产业之一,无论是传统产业,还是新兴产业,都离不开各式各样的机械设备。而各种机器零部件的加工的核心问题是工艺。这次毕业设计就是选择了这样一个课题——对动力输出轴的数控加工工艺及斜孔的夹具设计进行研究。在机加工工艺编制方面,主要通过仔细分析产品零件图和相关技术要求,查阅箱体类零件相关资料,结合暑假实习经历等等,考虑了的工艺结构要求、批量要求、经济性、可行性等多方面因素,最终安排了19个工序来完成变速箱体的加工,其中包括各道工序的加工方法,机床、刀具、夹具、辅具、量具的选择,基准面的选取,定位和夹紧方案的拟定,并通过反复推敲、比较,最终确定了最佳方案,并将其编入工序卡,清晰明了的表达出了整个加工过程。另外,在夹具设计方面,主要就钻斜孔这个工序进行了夹具方案的分析,计算和最终敲定,并用一张装配图和两张零件图来表达设计出的夹具方案。

关键字: 斜孔,一面双销,平行度,输出轴,工序卡

ABSTRACT

The mechanical manufacturing industry is one of pillar industrieswhich a country technology advancement and the society develops,regardless of is the traditional industry, or the emerging industry,all cannot leave all kinds of mechanical device. But each kind ofmachine spare part processing core question is a craft. Thisgraduation project was has chosen this kind of topic - conducts theresearch to the power output shaft numerical control processing craftand the slanting hole jig design. In the machining craft establishmentaspect, mainly through the careful analysis product detail drawing andthe related specification, consults the box body class componentscorrelation data, the union summer vacation practises experience andso on, had considered craft structure request, batch request,efficiency, feasible and so on various factor, finally arranged 19working procedures to complete the gear box body the processing,including each working procedure processing method, engine bed,cutting tool, jig, auxiliary, measuring instrument choice, reducedplane selection, located and clamps the plan drawing up, and throughrepeatedly deliberated, the comparison, finally had determined thepreferred plan, and enrolled it the working procedure card, Clearbright expression entire processing process. Moreover, in the jigdesign aspect, mainly drilled slanting Kong Zheige the workingprocedure to carry on the jig plan analysis, the computation andfinally makes a final decision, and expressed the jig plan with anassembly drawing and two detail drawings which designed。

Key word:Slanting hole ,At the same time double sells ,Parallelism ,Output shaft,Working procedure card

目 录

中文摘要.................................................................................................................... Ⅰ

英文摘要.................................................................................................................... Ⅱ

第1章 前言.............................................................................................................. 1

1.1 零件的作用......................................................................................................... 1

1.2 划分阶段............................................................................................................. 1

1.3 零件的工艺分析................................................................................................. 2

第2章 工艺规程设计............................................................................................. 3

2.1 确定毛坯的制造形式.......................................................................................... 3

2.2 制定工艺路线 .................................................................................................... 3

2.3 加工方法的选择.................................................................................................. 4

2.4 机械加工余量、工序尺寸及毛坯尺寸的确定..................................................... 4

2.5 确定切削用量及基本工时……………………………………………………… 5

第3章 夹具的设计............................................................................................... 24

3.1 夹具的作用及设计条件.................................................................................... 24

3.2 夹具设计计算.................................................................................................... 24

3.2.1 确定工件定位方式、分析定位误差............................................................. 24

3.2.2 确定刀具导引方式和导引文件.................................................................... 25

3.2.3 确定工件夹紧方式、选择夹紧机构、计算夹紧力........................................ 25

3.3 分度机构的设计................................................................................................ 27

3.4 分度装置机构的选定........................................................................................ 28

第4章 数控工艺与编程......................................................................................... 31

第5章 结论.............................................................................................................. 32

参考文献.................................................................................................................... 33

致谢............................................................................................................................. 34

附录 A:钻孔 20程序.............................................................................................. 35

20程序.............................................................................................. 35

附录 B:钻孔 8程序................................................................................................ 35

8程序................................................................................................ 35

机械制造业是一个国家技术进步和社会发展的支柱产业之一,无论是传统产业,还是新兴产业,都离不开各式各样的机械设备。而各种机器零部件的加工的核心问题是工艺。这次毕业设计就是选择了这样一个课题——对动力输出轴的数控加工工艺及斜孔的夹具设计进行研究。在机加工工艺编制方面,主要通过仔细分析产品零件图和相关技术要求,查阅箱体类零件相关资料,结合暑假实习经历等等,考虑了的工艺结构要求、批量要求、经济性、可行性等多方面因素,最终安排了19个工序来完成变速箱体的加工,其中包括各道工序的加工方法,机床、刀具、夹具、辅具、量具的选择,基准面的选取,定位和夹紧方案的拟定,并通过反复推敲、比较,最终确定了最佳方案,并将其编入工序卡,清晰明了的表达出了整个加工过程。另外,在夹具设计方面,主要就钻斜孔这个工序进行了夹具方案的分析,计算和最终敲定,并用一张装配图和两张零件图来表达设计出的夹具方案。

关键字: 斜孔,一面双销,平行度,输出轴,工序卡

ABSTRACT

The mechanical manufacturing industry is one of pillar industrieswhich a country technology advancement and the society develops,regardless of is the traditional industry, or the emerging industry,all cannot leave all kinds of mechanical device. But each kind ofmachine spare part processing core question is a craft. Thisgraduation project was has chosen this kind of topic - conducts theresearch to the power output shaft numerical control processing craftand the slanting hole jig design. In the machining craft establishmentaspect, mainly through the careful analysis product detail drawing andthe related specification, consults the box body class componentscorrelation data, the union summer vacation practises experience andso on, had considered craft structure request, batch request,efficiency, feasible and so on various factor, finally arranged 19working procedures to complete the gear box body the processing,including each working procedure processing method, engine bed,cutting tool, jig, auxiliary, measuring instrument choice, reducedplane selection, located and clamps the plan drawing up, and throughrepeatedly deliberated, the comparison, finally had determined thepreferred plan, and enrolled it the working procedure card, Clearbright expression entire processing process. Moreover, in the jigdesign aspect, mainly drilled slanting Kong Zheige the workingprocedure to carry on the jig plan analysis, the computation andfinally makes a final decision, and expressed the jig plan with anassembly drawing and two detail drawings which designed。

Key word:Slanting hole ,At the same time double sells ,Parallelism ,Output shaft,Working procedure card

目 录

中文摘要.................................................................................................................... Ⅰ

英文摘要.................................................................................................................... Ⅱ

第1章 前言.............................................................................................................. 1

1.1 零件的作用......................................................................................................... 1

1.2 划分阶段............................................................................................................. 1

1.3 零件的工艺分析................................................................................................. 2

第2章 工艺规程设计............................................................................................. 3

2.1 确定毛坯的制造形式.......................................................................................... 3

2.2 制定工艺路线 .................................................................................................... 3

2.3 加工方法的选择.................................................................................................. 4

2.4 机械加工余量、工序尺寸及毛坯尺寸的确定..................................................... 4

2.5 确定切削用量及基本工时……………………………………………………… 5

第3章 夹具的设计............................................................................................... 24

3.1 夹具的作用及设计条件.................................................................................... 24

3.2 夹具设计计算.................................................................................................... 24

3.2.1 确定工件定位方式、分析定位误差............................................................. 24

3.2.2 确定刀具导引方式和导引文件.................................................................... 25

3.2.3 确定工件夹紧方式、选择夹紧机构、计算夹紧力........................................ 25

3.3 分度机构的设计................................................................................................ 27

3.4 分度装置机构的选定........................................................................................ 28

第4章 数控工艺与编程......................................................................................... 31

第5章 结论.............................................................................................................. 32

参考文献.................................................................................................................... 33

致谢............................................................................................................................. 34

附录 A:钻孔

附录 B:钻孔