设计简介

摘 要

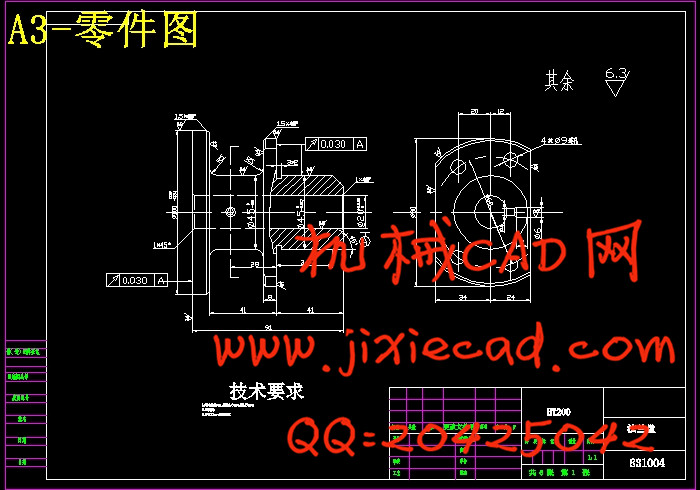

法兰盘是指在一个类似盘状的金属体的周边开几个固定用的孔用于连接其它东西的一种零件。主要用来使管子与管子相互连接,连接于管端。法兰盘上有孔眼,可穿螺栓,使使两法兰紧连。法兰间用衬垫密封。它可由浇铸而成,也可由螺纹连接或焊接构成。法兰联接由一对法兰、一个垫片及若干个螺栓螺母组成,垫片放在法兰密封面之间,拧紧螺母后,垫片表面上的比压达到一定数值后产生变形,并填满密封面上的凹凸不平处,使联接严密补漏。法兰连接使用方便,能够承受较大的压力,是管道施工的重要连接方式。关键词:法兰盘,工艺设计,夹具设计

Abstract

The flange is defined in a similar disc shaped metal body peripheral opening several fixing holes for connection to a part of something else. Mainly used to make the pipes are connected to each other, connected to the tube end. The flange plate with holes, can be worn bolt, make the two flange connect. The flange gasket seal. It can be formed by casting, also can be connected by threads or welding. Flange connected by a flange, a gasket and a nut composed of a number of bolts, the sealing surface of the flange gasket is placed in between, fastening nut, the gasket on the surface pressure reaches a certain value after the deformation, and filled with dense cover on the uneven, so closely linked traps. Flange connection is convenient to use, can withstand greater pressure, pipeline construction an important connection.Key Words: flange, process design, fixture design

目 录

摘 要... IIAbstract III

目 录... IV

第1章 序言... 1

1.1 机械加工工艺概述... 1

1.2机械加工工艺流程... 1

1.3夹具概述... 2

1.4机床夹具的功能... 2

1.5机床夹具的发展趋势... 3

1.5.1机床夹具的现状... 3

1.5.2现代机床夹具的发展方向... 4

第2章 零件的分析... 5

2.1零件的作用... 5

2.2零件的工艺分析... 5

第3章 工艺规程设计... 1

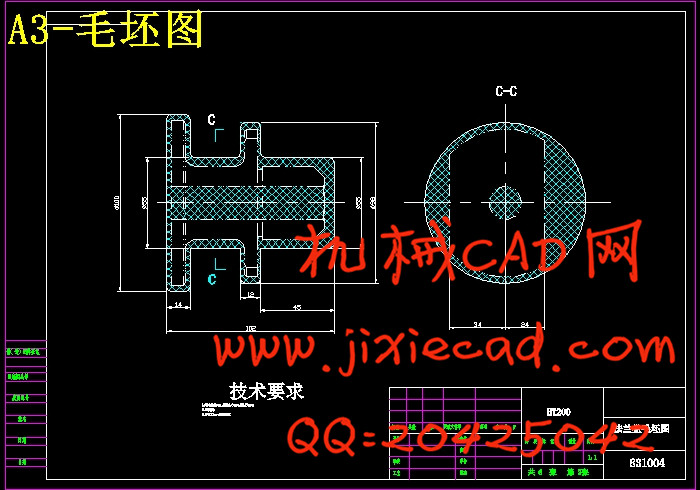

3.1确定毛坯制造方法,初步确定毛坯形状... 1

3.2基准的选择... 1

3.3制定工艺路线... 1

3.3.1工艺路线方案一... 2

3.3.2 工艺路线方案二... 2

3.3.3 工艺方案的比较与分析... 3

3.4 机械加工余量、工序尺寸及毛坯尺寸的确定... 3

3.5 确定切削用量及基本工时... 5

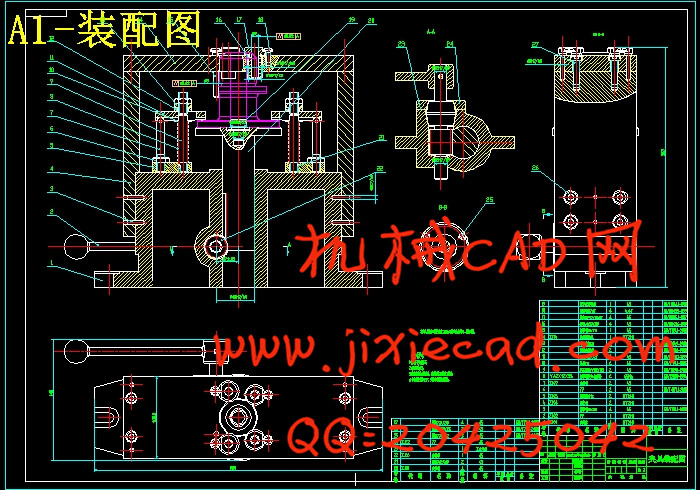

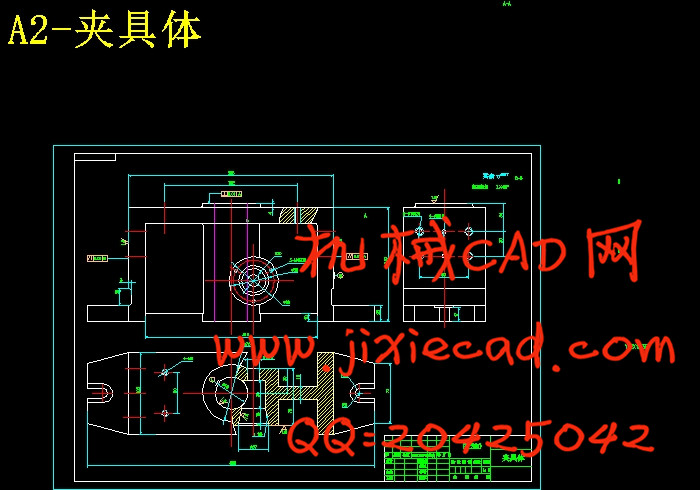

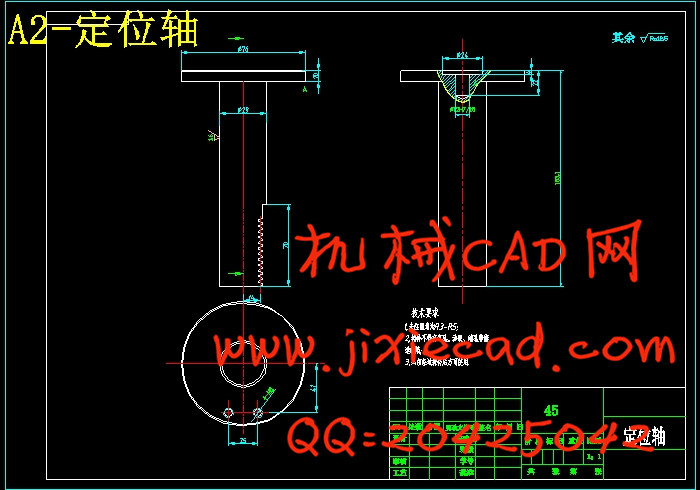

第4章 钻4- Ø9透孔的钻床夹具设计... 23

4.1 定位基准的选择... 23

4.2 切削力及夹紧力计算... 23

4.3 定位误差分析... 24

4.4 钻套选择... 24

4.5 夹具设计及操作说明... 24

总 结... 26

参 考 文 献... 27

致 谢... 28