设计简介

摘 要

本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。

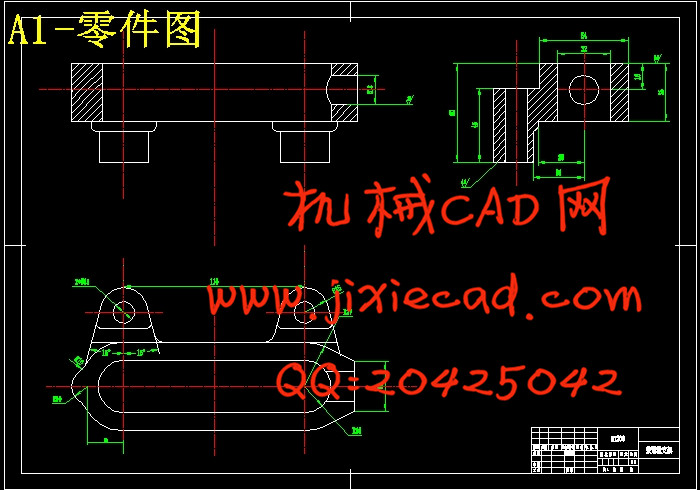

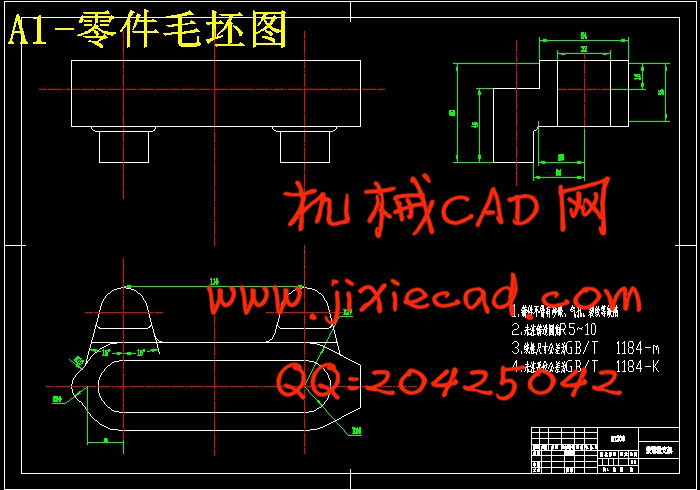

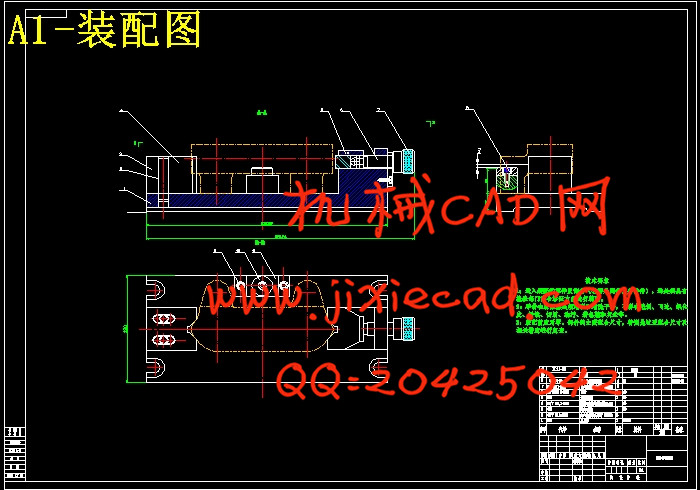

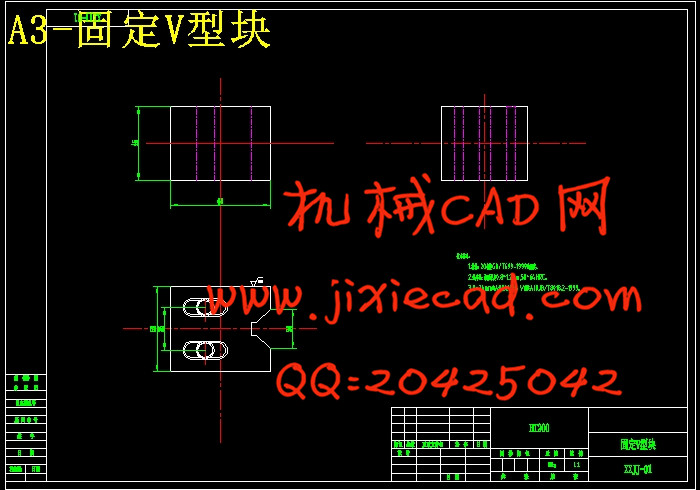

张紧轮支架加工工艺规程及夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

关键词:工艺、工序、切削用量、夹紧、定位、误差。

ABSTRCT

This design content has involved the machine manufacture craft and the engine bed jig design, the metal-cutting machine tool, the common difference coordination and the survey and so on the various knowledge.

The reduction gear box body components technological process and its the processing hole jig design is includes the components processing the technological design, the working procedure design as well as the unit clamp design three parts. Must first carry on the analysis in the technological design to the components, understood the components the craft redesigns the semi finished materials the structure, and chooses the good components the processing datum, designs the components the craft route; After that is carrying on the size computation to a components each labor step of working procedure, the key is decides each working procedure the craft equipment and the cutting specifications; Then carries on the unit clamp the design, the choice designs the jig each composition part, like locates the part, clamps the part, guides the part, to clamp concrete and the engine bed connection part as well as other parts; Position error which calculates the jig locates when produces, analyzes the jig structure the rationality and the deficiency, and will design in later pays attention to the improvement.

Keywords: The craft, the working procedure, the cutting specifications, clamp, the localization, the error

目 录

1 绪 论 1

2 张紧轮支架的分析 2

2.1张紧轮支架的工艺分析 2

2.2生产类型的确定 2

2.3毛坯的选择2

3 工艺规程设计4

3.1 加工方法的选择4

3.2确定定位基准 4

3.2.1粗基准的选择 4

3.2.2精基准的选择 5

3.3 工序的合理组合 6

3.4工序的人集中与分散 6

3.5加工阶段的划分 6

3.6工艺路线的拟订 7

3.7加工工艺路线方案的比较7

3.8张紧轮支架的偏差计算 9

4 确定加工余量和尺寸工序 9

5确定切削用量及基本工时(机动时间) 10

6铣底部平面夹具设计 17

1问题的提出 17

2切削力和夹紧力的计算 17

3定位误差分析 18

4夹具设计及简单的操作说明 19

参考文献 20

致谢 20

本次设计内容涉及了机械制造工艺及机床夹具设计、金属切削机床、公差配合与测量等多方面的知识。

张紧轮支架加工工艺规程及夹具设计是包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

关键词:工艺、工序、切削用量、夹紧、定位、误差。

ABSTRCT

This design content has involved the machine manufacture craft and the engine bed jig design, the metal-cutting machine tool, the common difference coordination and the survey and so on the various knowledge.

The reduction gear box body components technological process and its the processing hole jig design is includes the components processing the technological design, the working procedure design as well as the unit clamp design three parts. Must first carry on the analysis in the technological design to the components, understood the components the craft redesigns the semi finished materials the structure, and chooses the good components the processing datum, designs the components the craft route; After that is carrying on the size computation to a components each labor step of working procedure, the key is decides each working procedure the craft equipment and the cutting specifications; Then carries on the unit clamp the design, the choice designs the jig each composition part, like locates the part, clamps the part, guides the part, to clamp concrete and the engine bed connection part as well as other parts; Position error which calculates the jig locates when produces, analyzes the jig structure the rationality and the deficiency, and will design in later pays attention to the improvement.

Keywords: The craft, the working procedure, the cutting specifications, clamp, the localization, the error

目 录

1 绪 论 1

2 张紧轮支架的分析 2

2.1张紧轮支架的工艺分析 2

2.2生产类型的确定 2

2.3毛坯的选择2

3 工艺规程设计4

3.1 加工方法的选择4

3.2确定定位基准 4

3.2.1粗基准的选择 4

3.2.2精基准的选择 5

3.3 工序的合理组合 6

3.4工序的人集中与分散 6

3.5加工阶段的划分 6

3.6工艺路线的拟订 7

3.7加工工艺路线方案的比较7

3.8张紧轮支架的偏差计算 9

4 确定加工余量和尺寸工序 9

5确定切削用量及基本工时(机动时间) 10

6铣底部平面夹具设计 17

1问题的提出 17

2切削力和夹紧力的计算 17

3定位误差分析 18

4夹具设计及简单的操作说明 19

参考文献 20

致谢 20