设计简介

摘要

机械制造工艺学课程设计是我们学完了大学的全部基础课、技术基础课以及大部分专业课之后进行的.这是我们在进行毕业设计之前对所学各课程的一次深入的综合性的总复习,也是一次理论联系实际的训练,因此,它在我们四年的大学生活中占有重要的地位。设计意义:本课程设计是重要的实践教学环节之一。是在完成生产实习,学完机械制造技术基础和其它专业课程之后进行的。通过该课程设计,将所学理论与生产实践相结合, 锻炼了自己分析问题、解决问题的能力,在这个过程中我独立地分析和解决了零件机械制造的工艺问题,设计了机床专用夹具这一典型的工艺装备,提高了结构设计能力,为今后的毕业设计及对自己未来将从事的工作进行了一次适应性训练,从而打下了良好的基础。

Machinery Manufacturing Technology curriculum design is finished we learn all the basic course of the University, technology and the most basic course after the specialized, which is our graduation project before conducting the various courses of study by an in-depth comprehensive review of the total, is also a Theory with practical training, therefore, in our four years of university life occupy an important position.

This is the cover design, parts map, rough map, one of the assembly, machining process with the card and the

Design significance: the design of this course is an important aspect of the practice of teaching. Completed internship in the production, completion of machinery manufacturing and technological foundation and other professional courses conducted. The adoption of the curriculum design, will learn theory and practice of combining production, tempered his analysis, problem-solving abilities, in the process I am an independent analysis and solution of the manufacture of mechanical parts of the problem, design a machine for this fixture A typical technology equipment, improved structural design capability for future graduates to design their own future and will be engaged in the work of an adaptation training, thus laying a good foundation.

Key words: ram; curriculum design, technology point of order, technology and equipment;

目录

1摘要 1

1、零件的分析 3

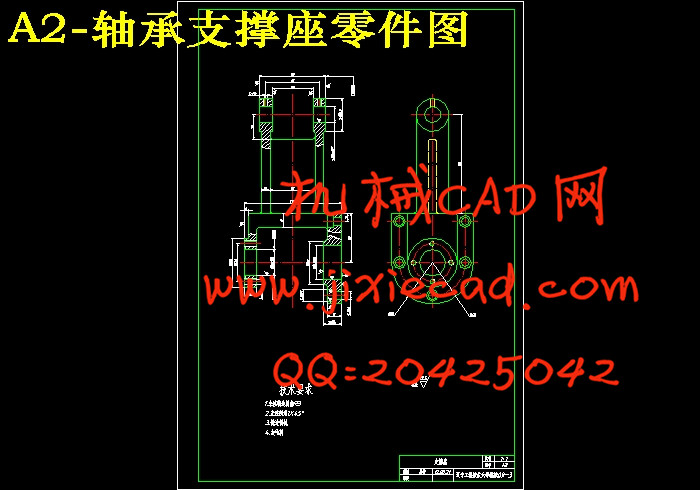

1.1绘制和分析零件图 3

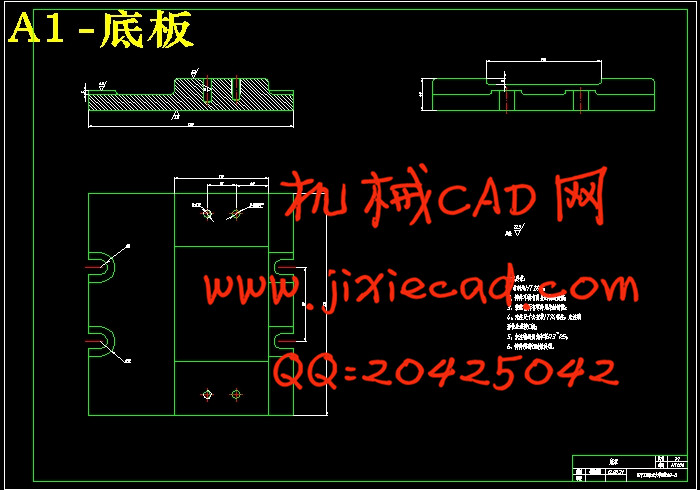

2、工艺规程设计 5

2.1.毛坯的选择 5

2.2. 确定主要加工余量 6

2.3.基面的选择 7

2.3.1.粗基面的选择 7

2.3.2.精基面的选择 7

2.4.制定工艺路线 7

2.5填写工艺过程卡 7

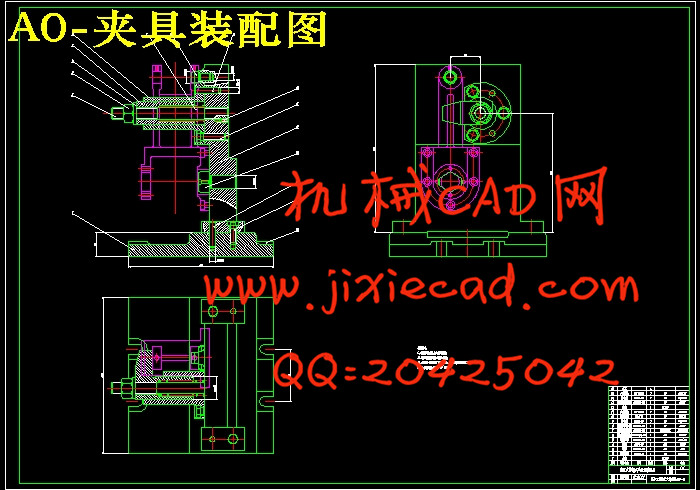

3、夹具的设计 10

3.1.确定加工部位,分析技术要求 10

3.2确定定位方案 10

3.3.确定夹紧方案,选择夹紧元件和夹紧结构 11

4、夹具结构设计 13

4.1夹具体及其他零件设计,确定夹具详细结构 13

4.2定位误差分析 13

5、夹具体绘制 14

6体会与展望 14

7、参考文献 14