设计简介

摘要

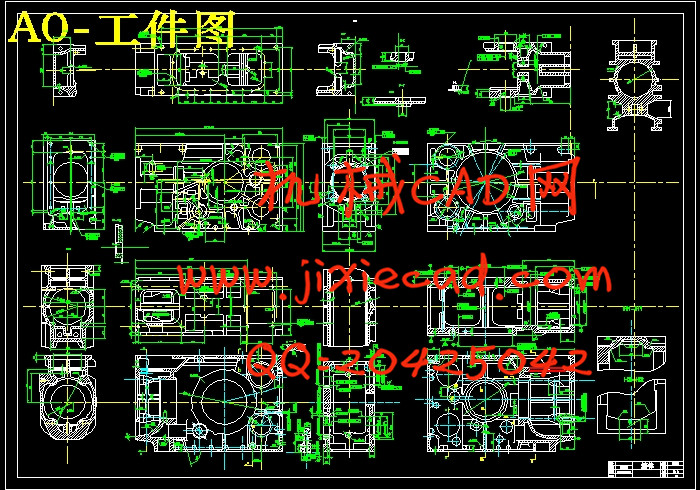

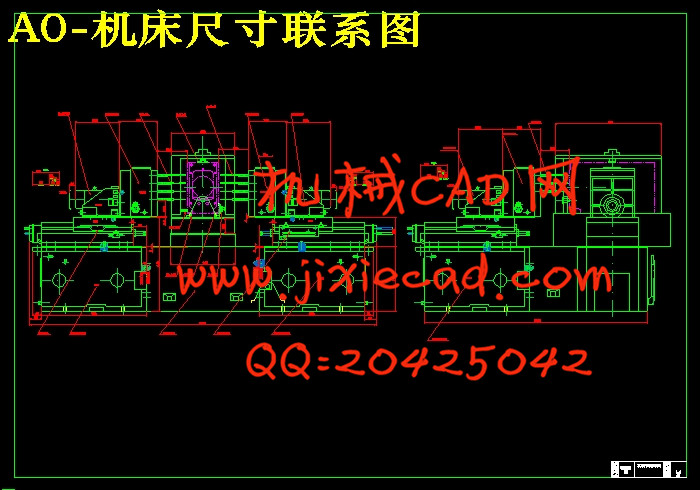

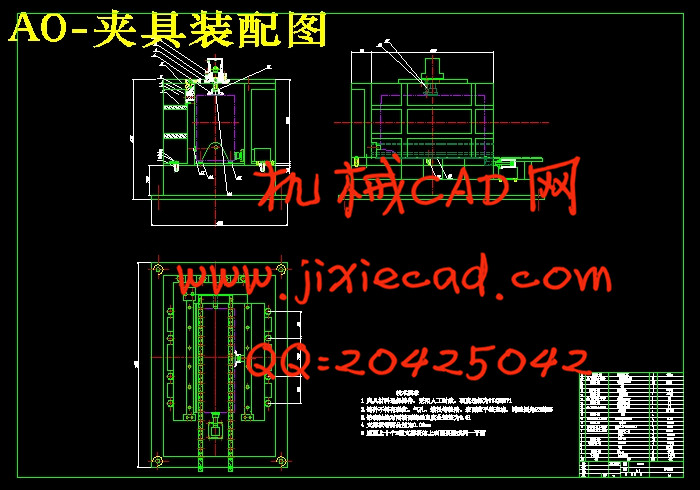

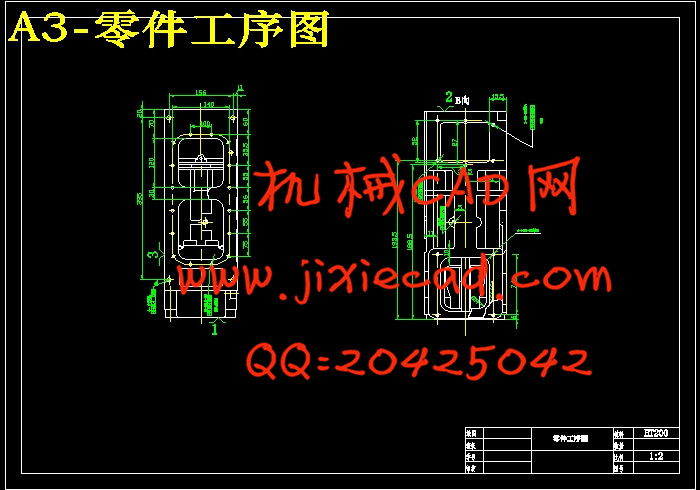

本次设计任务是S1105柴油机箱体制造工艺规程及专用钻床设计,主要内容是:首先对箱体零件工艺设计,在分析了S1105柴油机箱体的具体结构及加工技术要求的基础上,通过批量生产的分析确定箱体各部位的加工方案,并找寻最适合的工艺方案。根据每道工序的技术要求,选定每道工序的背吃刀量、进给量、切削速度以及所采用的机床、刀具、夹具等,确定每道工序的时间,从而绘制工艺过程卡片。然后是对专用钻床夹具体进行设计,根据被加工零件的结构特点、加工尺寸和精度要求,确定组合钻床的配置方案,对专机进行总体设计即三图一卡的设计,三图一卡包括零件工序图、加工示意图、机床联系尺寸图和机床生产率计算卡。其次绘制其装配图和相关的零件图。

整个加工过程均选用组合机床,夹具选用专用夹具,夹紧方式一般都选用液压夹紧,夹紧方式可靠。因此生产效率比较高。适用于大批量、流水线生产加工。能够满足设计的要求。

关键词 工艺设计;组合机床;钻床夹具

Abstract

This design task is the design of the S1105 diesel chassis manufacturing process specifications and the special drilling machine, the main elements are: First, the analysis on the basis of cabinet parts, S1105 diesel cabinet structure and processing requirements of the process design by massanalysis to determine if the processing box programvarious parts, and find the most appropriate technology solutions. According to the requirements of each process technology, the choice, each process of the back of the cutting, feed rate, cutting speed and machine tools, cutting tools, jigs, etc., to determine the time of each process, thereby drawing process card. Then have to deal with the parts of the structure characteristics, the design of a special drilling machine specific file folder, processing size and accuracy requirements, determine the drilling machine configuration combined, the overall design of the three cards, graphic design, three-card, including parts processing diagram, process chart, machine contact, dimensional drawings and machine productivity calculation card. Secondly, the assembly drawing and parts diagrams.

The whole process of the special fixture, machine tool and fixture selection, selection, clamp commonly used hydraulic clamping, the clamping style is reliable. Therefore, it has the relatively high production efficiency. It is suitable for high-volume, assembly line production and processing. So it is able to meet the design requirements.

Keywords process design combination machine Drill press fixture.

本次设计任务是S1105柴油机箱体制造工艺规程及专用钻床设计,主要内容是:首先对箱体零件工艺设计,在分析了S1105柴油机箱体的具体结构及加工技术要求的基础上,通过批量生产的分析确定箱体各部位的加工方案,并找寻最适合的工艺方案。根据每道工序的技术要求,选定每道工序的背吃刀量、进给量、切削速度以及所采用的机床、刀具、夹具等,确定每道工序的时间,从而绘制工艺过程卡片。然后是对专用钻床夹具体进行设计,根据被加工零件的结构特点、加工尺寸和精度要求,确定组合钻床的配置方案,对专机进行总体设计即三图一卡的设计,三图一卡包括零件工序图、加工示意图、机床联系尺寸图和机床生产率计算卡。其次绘制其装配图和相关的零件图。

整个加工过程均选用组合机床,夹具选用专用夹具,夹紧方式一般都选用液压夹紧,夹紧方式可靠。因此生产效率比较高。适用于大批量、流水线生产加工。能够满足设计的要求。

关键词 工艺设计;组合机床;钻床夹具

Abstract

This design task is the design of the S1105 diesel chassis manufacturing process specifications and the special drilling machine, the main elements are: First, the analysis on the basis of cabinet parts, S1105 diesel cabinet structure and processing requirements of the process design by massanalysis to determine if the processing box programvarious parts, and find the most appropriate technology solutions. According to the requirements of each process technology, the choice, each process of the back of the cutting, feed rate, cutting speed and machine tools, cutting tools, jigs, etc., to determine the time of each process, thereby drawing process card. Then have to deal with the parts of the structure characteristics, the design of a special drilling machine specific file folder, processing size and accuracy requirements, determine the drilling machine configuration combined, the overall design of the three cards, graphic design, three-card, including parts processing diagram, process chart, machine contact, dimensional drawings and machine productivity calculation card. Secondly, the assembly drawing and parts diagrams.

The whole process of the special fixture, machine tool and fixture selection, selection, clamp commonly used hydraulic clamping, the clamping style is reliable. Therefore, it has the relatively high production efficiency. It is suitable for high-volume, assembly line production and processing. So it is able to meet the design requirements.

Keywords process design combination machine Drill press fixture.

目 录

摘要 II

Abstract III

1 绪论 1

2 S1105柴油机简介 2

2.1 S1105 柴油机箱体的作用 2

2.2零件的工艺分析 2

2.3确定箱体的生产类型 2

2.4确定箱体毛坯制造形式和尺寸 2

2.4.1确定毛坯的制造种类和制造方法 2

2.5定位基准的选择 2

2.5.1粗基准的选择 2

2.5.2精基准的选择 3

3 箱体工艺分析与设计 4

3.1 箱体工艺的分析 4

3.2 工艺规程设计 7

3.2.2确定工艺方案的原则及注意问题 7

3.2.3确定工艺方案的原则及注意问题 8

3.2.4工艺路线确定 9

3.3 切削各表面的切削用量和基本工时 10

3.3.1 切削用量的选择原则 10

3.3.2切削用量基本工时 11

4 组合机床总体设计 23

4.1组合机床总体设计 23

4.1.1 被加工零件工序图 23

4.1.2 加工示意图 24

4.1.3 机床联系尺寸图 26

4.1.4 生产率计算卡 28

5 专用夹具的设计 30

5.1 机床夹具的作用 30

5.2 对组合钻床夹具的要求 30

5.3 箱体类零件定位基准 30

5.4专用夹具的设计步骤 30

5.4.1研究原始资料 30

5.4.2绘制夹具总装配图 30

5.4.3标注夹具总装配图上各部分尺寸和技术要求: 31

5.5 夹具公差配合的制订 32

5.7 夹具整体方案设计 32

5.7.1 夹具元件的选择与设计 32

5.7.2钻削夹紧力的计算 34

5.8钻模板设计 35

5.9夹具设计和操作的简要说明 35

结 论 36

致 谢 37

参考文献 38