设计简介

摘 要

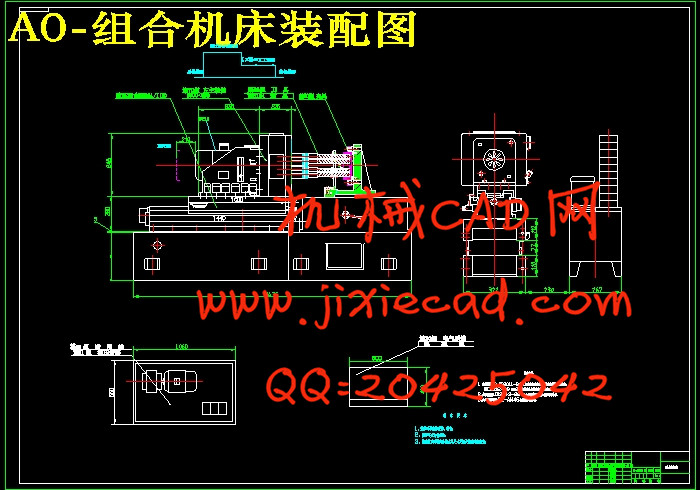

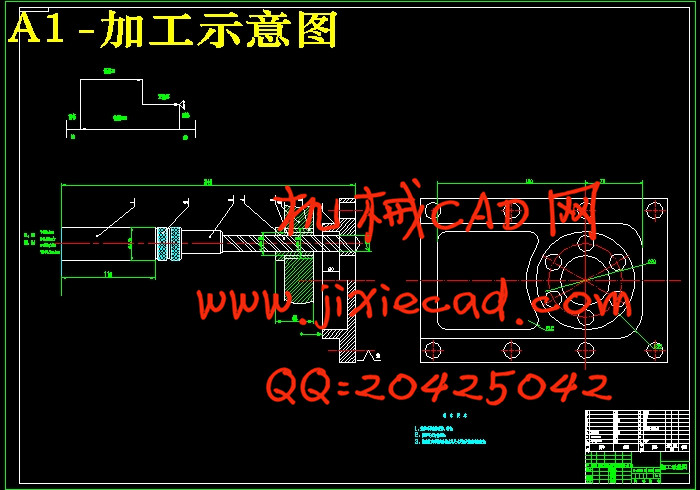

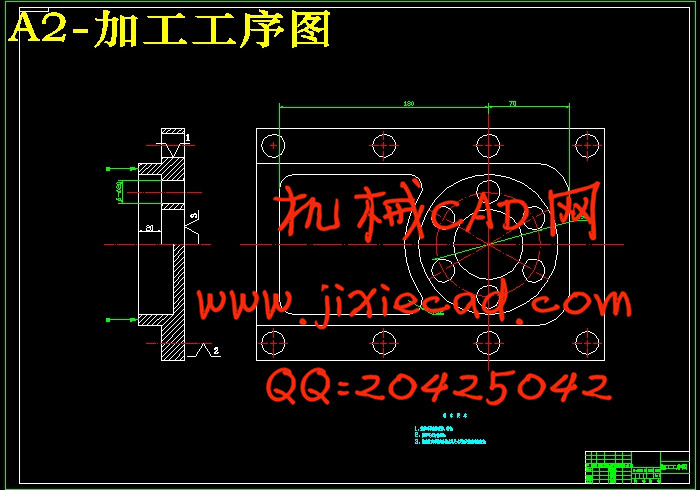

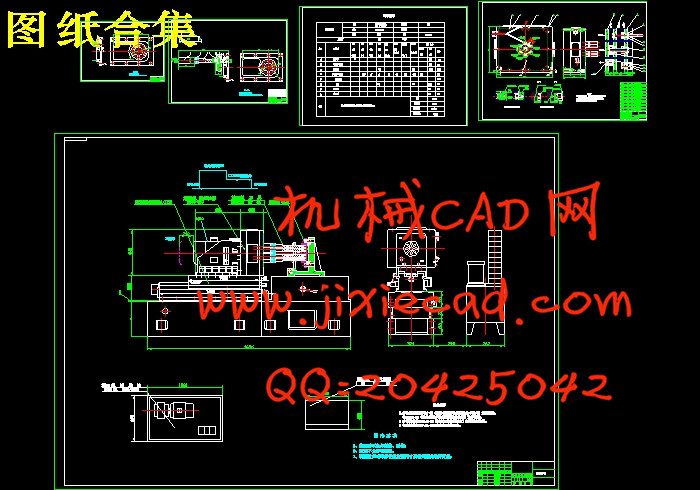

应用组合机床加工大批量零件,快捷高效,生产效率高是机械加工的发展方向。本次毕业设计的题目是“凹形侧支承板 钻铰6-Φ20孔组合机床设计”。在工艺制定过程中,通过批量的进行钻底孔的加工方案,并寻求最佳的工艺方案,借此说明了工艺在生产过程中的重要性。本人的设计的主要内容是:进行了机床总体布局设计;对机床的进给和传动部分进行了设计;结合实例,介绍了夹具设计方法;通过此设计,本机床完全能满足设计要求,与传统的机床相比,本机床具有自动化程度高,生产率高,精度高等优点。关键词:组合机床;钻底孔;夹具设计;手动

Abstract

Application of combined high-volume machining parts, high efficiency, high productivity is the development direction of machining. The topic of this graduation design is a "design machine tools for processing the pump body bottom hole drilling 8-M10 modular machine tool design". Making process in the process, with a mass of bottom hole drilling processing scheme, and to seek the best technology solutions, which illustrates the importance of process in the production process. The main content of my design is: on the overall layout of machine tools; on the machine feed and transmission parts of the design; combined with the example, introduces the fixture design method; with this design, this machine can meet the design requirements, compared with traditional machine, this machine has high automation, high productivity, advantages higher accuracy.Key Words: modular machine tool; drilling bottom hole; fixture design; manual

目 录

摘 要 II

Abstract III

1 绪论 1

1.1 组合机床的简介 1

1.2本课题国内外研究概况 2

2 组合机床的总体设计 4

2.1 组合机床方案的制定 4

2.1.1 制定工艺方案 4

2.1.2 确定组合机床的配置形式和结构方案 4

2.2 确定切削用量及选择刀具 6

2.2.1 确定工序间余量 6

2.2.2 选择切削用量 6

2.2.3 确定切削力、切削扭矩、切削功率 6

2.2.4 选择刀具结构 7

2.3 钻孔组合机床总设计“三图一卡”的编制 7

2.3.1 被加工零件工序图 7

2.3.2 加工示意图 8

2.3.3 机床联系尺寸图 12

2.3.4 生产率计算卡 15

2.4 多轴箱的设计 17

2.4.1 绘制多轴箱设计原始依据图 17

2.4.2 齿轮模数选择 18

2.4.3 多轴箱的传动设计 18

2.4.4 绘制传动系统图 20

2.4.5 传动零件的校核 20

结论 22

致 谢 23

参考文献 24