设计简介

摘 要

本文对减速器箱孔的加工工艺进行了详细的分析,就其孔的加工提出了“一次装夹,多工位加工,达到产品图样的精度要求”的思路。根据这一思路设计了钻孔组合机床设计。该组合机床由立柱、立柱底座、中间底座、液压滑台、动力箱、多轴箱等组成。本文对各部分的设计进行了详细的计算和论证。

在工艺制定过程中,通过批量的进行钻底孔的加工方案,并寻求最佳的工艺方案,借此说明了工艺在生产过程中的重要性。本人的设计的主要内容是:进行了机床总体布局设计;对机床的进给和传动部分进行了设计;结合实例,介绍了夹具设计方法;通过此设计,本机床完全能满足设计要求,与传统的机床相比,本机床具有自动化程度高,生产率高,精度高等优点。

关键词:组合机床;钻底孔;夹具设计;手动

本文对减速器箱孔的加工工艺进行了详细的分析,就其孔的加工提出了“一次装夹,多工位加工,达到产品图样的精度要求”的思路。根据这一思路设计了钻孔组合机床设计。该组合机床由立柱、立柱底座、中间底座、液压滑台、动力箱、多轴箱等组成。本文对各部分的设计进行了详细的计算和论证。

在工艺制定过程中,通过批量的进行钻底孔的加工方案,并寻求最佳的工艺方案,借此说明了工艺在生产过程中的重要性。本人的设计的主要内容是:进行了机床总体布局设计;对机床的进给和传动部分进行了设计;结合实例,介绍了夹具设计方法;通过此设计,本机床完全能满足设计要求,与传统的机床相比,本机床具有自动化程度高,生产率高,精度高等优点。

关键词:组合机床;钻底孔;夹具设计;手动

Abstract

This paper makes a detailed analysis on the machining process of the reducer hole, the hole processing put forward "one time clamping, multi station processing, reachthe precision requirement of product pattern" idea. According to this idea, the design of drill hole modular machine tool design. The combined machine tool by the column, column base, base, hydraulic pressure sliding table, the power box, multi axle box etc.. In this paper, the detailed calculation and verification of the design of each part.

In the process of the development process, through the batch drilling bottom hole processing scheme, and to seek the best technology solutions, which illustrates the importance of the process in the production process. The main contents of the design are: the general layout design of machine tool; feed and transmission part of the machine is designed; combined with the example, introduces the design method of fixture; with this design, this machine can meet the design requirements, compared with traditional machine, this machine has a high degree of automation, high productivity, advantages high precision.

Key Words: modular machine tool; drilling bottom hole; fixture design; manual

This paper makes a detailed analysis on the machining process of the reducer hole, the hole processing put forward "one time clamping, multi station processing, reachthe precision requirement of product pattern" idea. According to this idea, the design of drill hole modular machine tool design. The combined machine tool by the column, column base, base, hydraulic pressure sliding table, the power box, multi axle box etc.. In this paper, the detailed calculation and verification of the design of each part.

In the process of the development process, through the batch drilling bottom hole processing scheme, and to seek the best technology solutions, which illustrates the importance of the process in the production process. The main contents of the design are: the general layout design of machine tool; feed and transmission part of the machine is designed; combined with the example, introduces the design method of fixture; with this design, this machine can meet the design requirements, compared with traditional machine, this machine has a high degree of automation, high productivity, advantages high precision.

Key Words: modular machine tool; drilling bottom hole; fixture design; manual

目 录

1 绪论 1

1.1组合机床的概论 1

1.2 组合机床的发展现状与趋势 1

1.3 机床设计意义、内容、要求 2

1.3.1设计的意义 2

1.3.2 设计内容与要求 3

2 组合机床的总体设计 4

2.1 组合机床方案的制定 4

2.1.1 制定工艺方案 4

2.1.2 确定组合机床的配置形式和结构方案 4

2.2 确定切削用量及选择刀具 6

2.2.1 确定工序间余量 6

2.2.2 选择切削用量 6

2.2.3 确定切削力、切削扭矩、切削功率 7

2.2.4 选择刀具结构 7

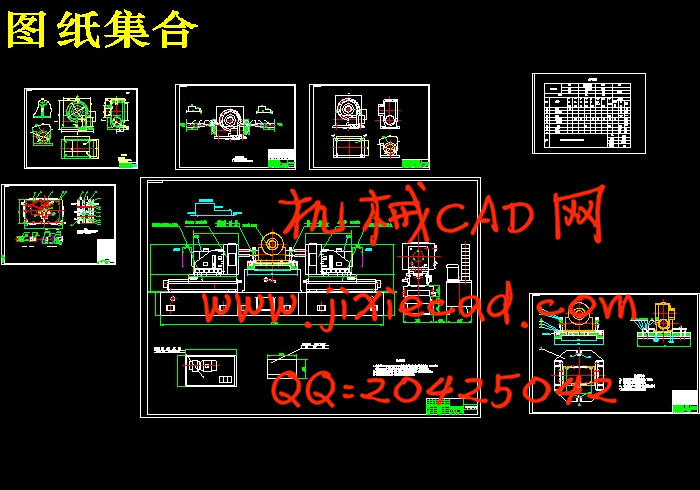

2.3 钻孔组合机床总设计“三图一卡”的编制 8

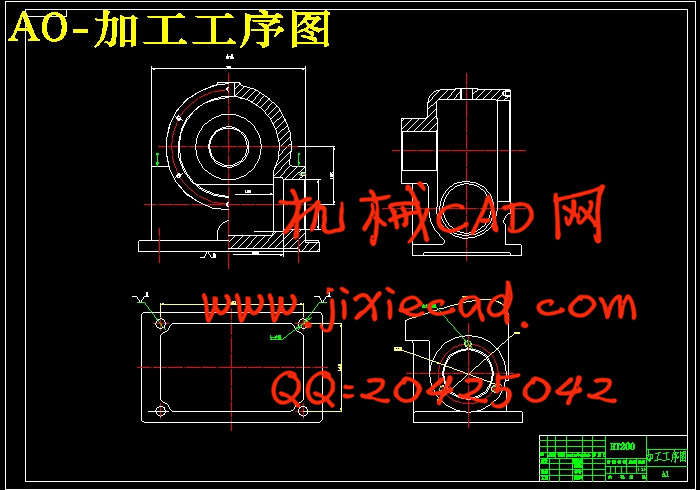

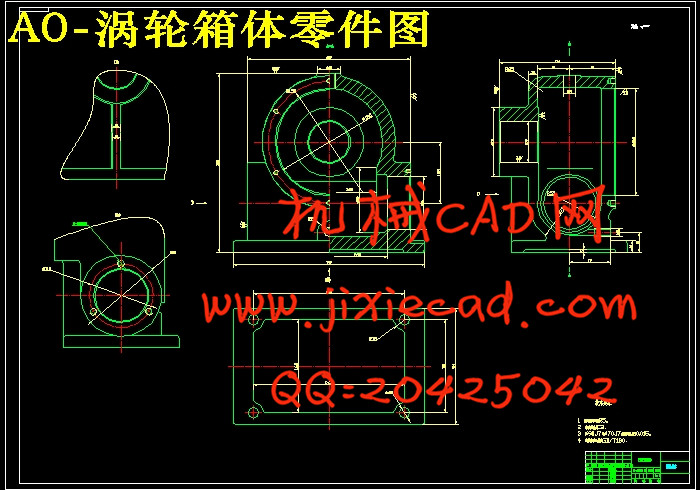

2.3.1 被加工零件工序图 8

2.3.2 加工示意图 9

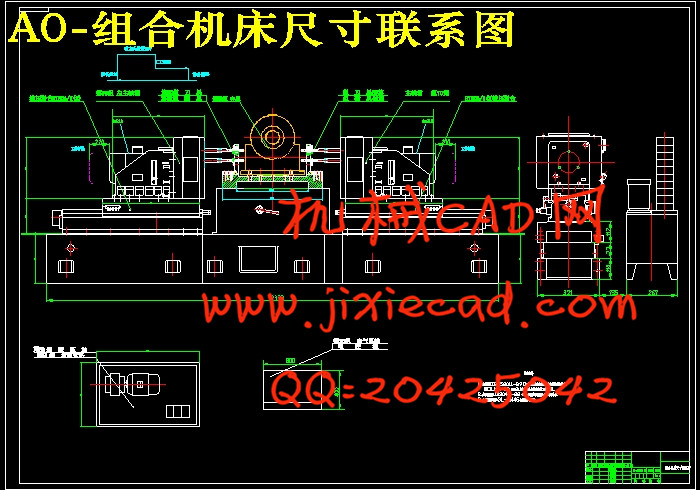

2.3.3 机床联系尺寸图 14

2.3.4 生产率计算卡 17

2.4 多轴箱的设计 19

2.4.1 绘制多轴箱设计原始依据图 19

2.4.2 齿轮模数选择 20

2.4.3 多轴箱的传动设计 20

2.4.4 绘制传动系统图 22

2.4.5 传动零件的校核 23

3 钻孔夹具设计 24

3.1 研究原始质料 24

3.2 定位、夹紧方案的选择 24

3.3切削力及夹紧力的计算 24

3.4 误差分析与计算 26

3.5定位销选用 27

3.6 钻套、衬套、钻模板设计与选用 28

3.7夹具设计及操作的简要说明 29

结论 31

参考文献 32

致 谢 33