设计简介

摘 要

支架A是用来支撑轴承的,支架A的概念就是轴承和箱体的集合体,以便于应用,这样的好处是可以有更好的配合,更方便的使用,减少了使用厂家的成本.至于形状,多种多样,通常是一个箱体,轴承可以安装在其中。随着科学技术的不断进步,它在国民经济中占有越来越重要的地位,发展前景十分广阔,尤其是在汽车和电子电器等高速发展的领域。本次课程设计设计的课题就是支架A的设计,是在学完制造工艺学后进行的一项教学环节;在老师的指导下,要求在设计中能初步学会综合运用以前所学过的全部课程,并且独立完成的一项工程基本训练。关键词:支架A 工艺规格设计 夹具设计 工序 工艺性

Abstract

The bearing seat is used to support the bearing outer ring, inner ring for fixing the bearing outer ring rotation, let alone, keep still, always keep consistent with the direction of transmission (such as motor rotation direction), and keep the balance; and aggregate concept is bearing and the bearing seat, in order to facilitate the application, so that the benefits of cooperation can be better, more convenient to use, to reduce the use of cost for manufacturers. As for the shape, variety, is usually a box can be installed in the bearing. With the continuous progress of science and technology, it plays a more and more important role in the national economy, the development prospect is very wide, especially in the automotive and electronic appliances such as the rapid development of the field. The course design is the subject of the bearing seat design, is a teaching link in the completion of the manufacturing technology of automobile; under the guidance of the teacher, to a full course of primary learn the integrated use of previously learned in the design, the basic training and independence completion of an engineering.Keywords: bearing process specifications for design of fixture design process.

目 录

摘 要 I

Abstract II

第1章 序言 1

1.1 机械加工工艺概述 1

1.2机械加工工艺流程 1

1.3夹具概述 2

1.4机床夹具的功能 3

1.5机床夹具的发展趋势 3

1.5.1机床夹具的现状 3

1.5.2现代机床夹具的发展方向 4

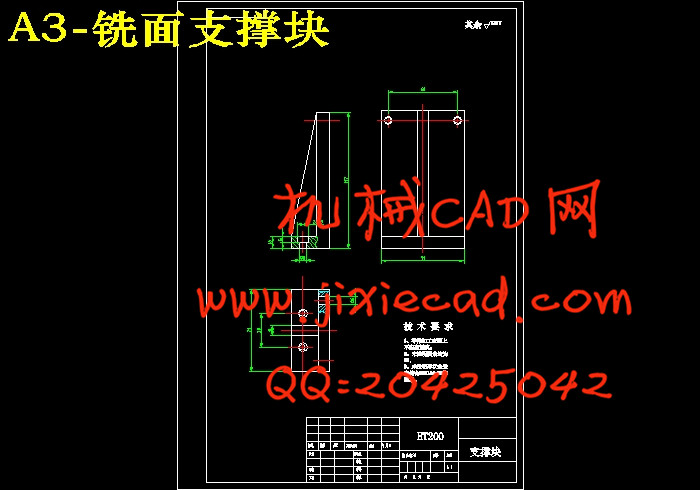

第2 章 工艺性分析 6

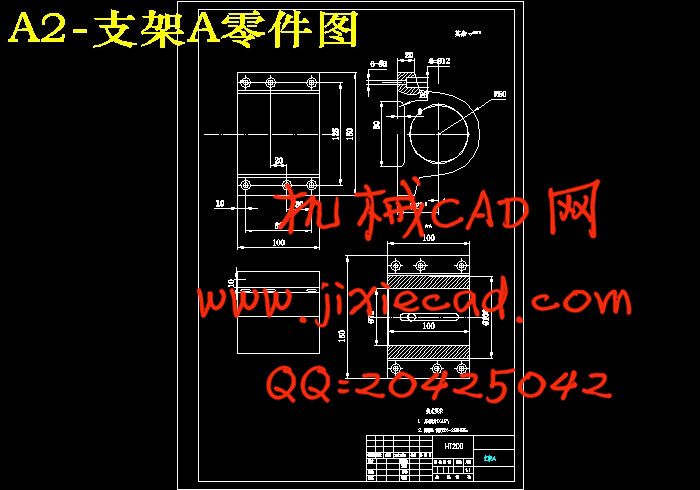

2.1零件作用 6

2.2零件工艺性分析 6

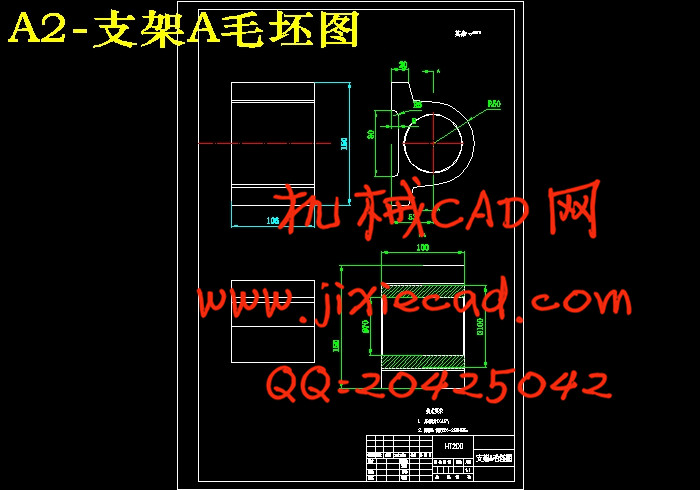

第3章 工艺规程设计 8

3.1零件材料 8

3.2毛坯选择 8

3.2.1确定毛坯的类型及制造方法 8

3.2.3毛坯加工余量、工序尺寸及公差的确定 8

3.3.1粗基准的选择 9

3.3.2精基准的选择 9

3.4制订工艺路线 9

3.5机械加工余量、工序尺寸及公差 11

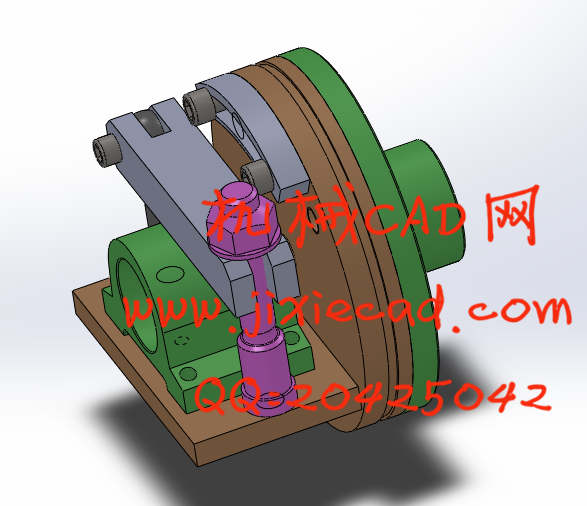

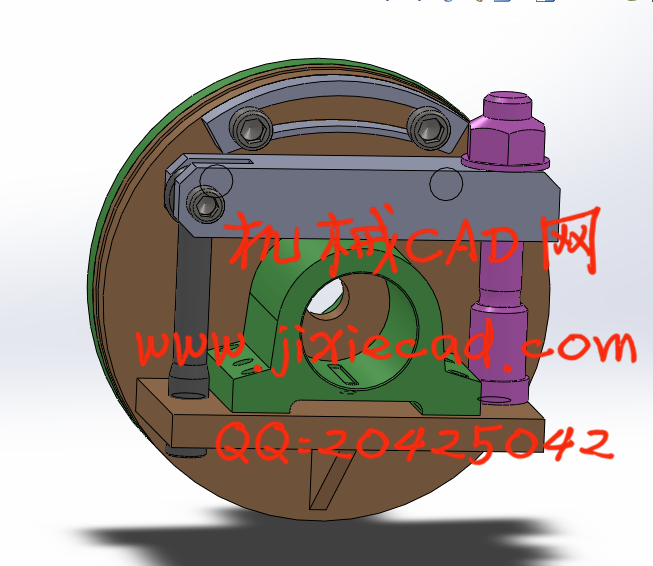

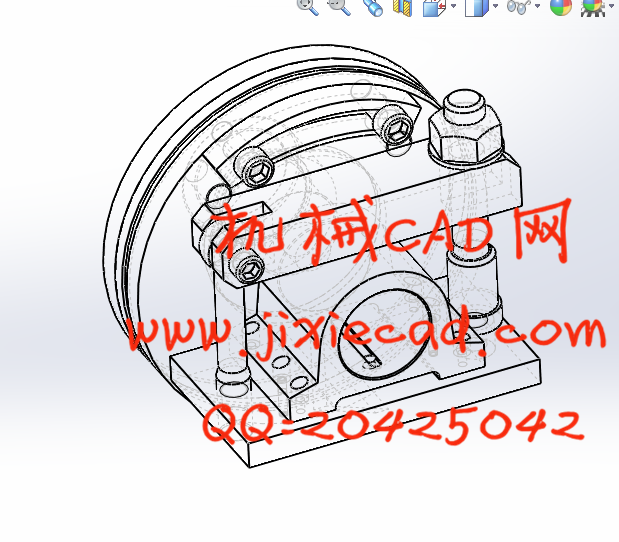

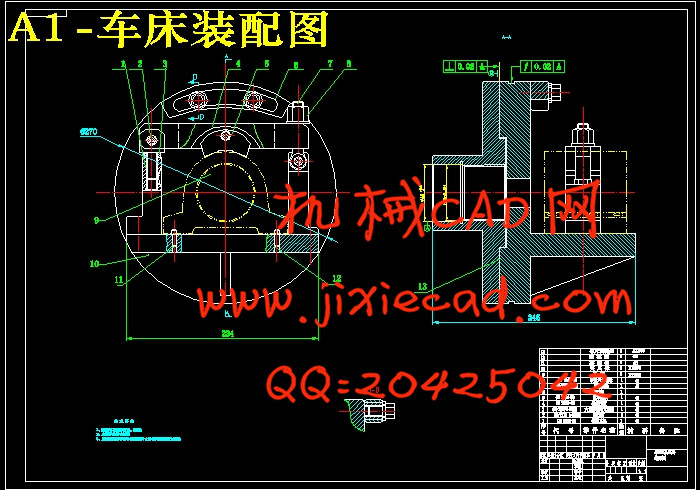

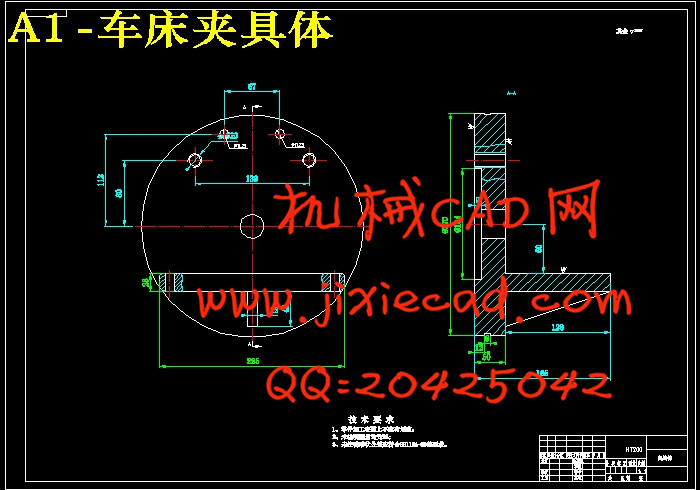

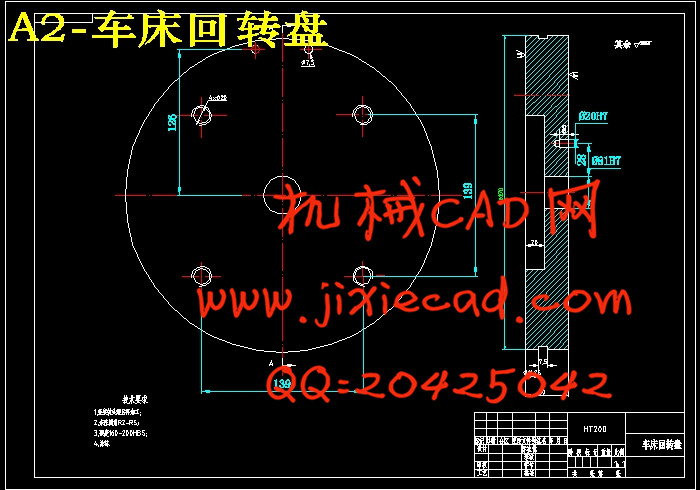

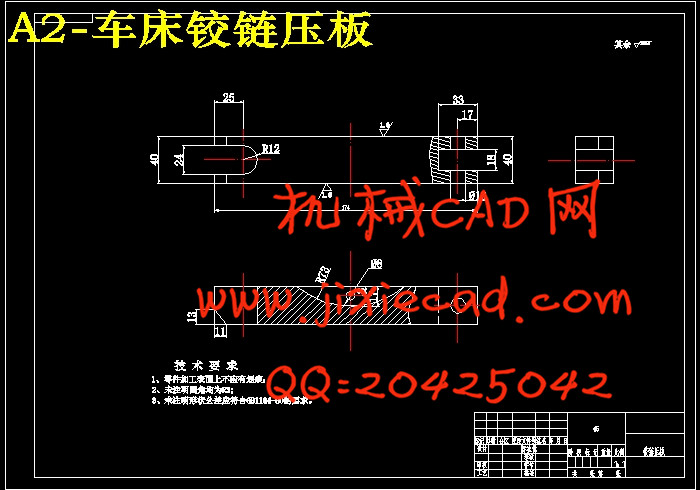

第4章 车φ70孔夹具设计 18

4.1问题的提出 18

4.2夹具的设计 18

4.2.1定位基准的选择 18

4.2.2定位元件的设计 19

4.2.3切削力及夹紧力的计算 19

4.2.4加紧元件的设计 20

4.2.5紧固元件的选择 20

4.2.6夹具操作说明 20

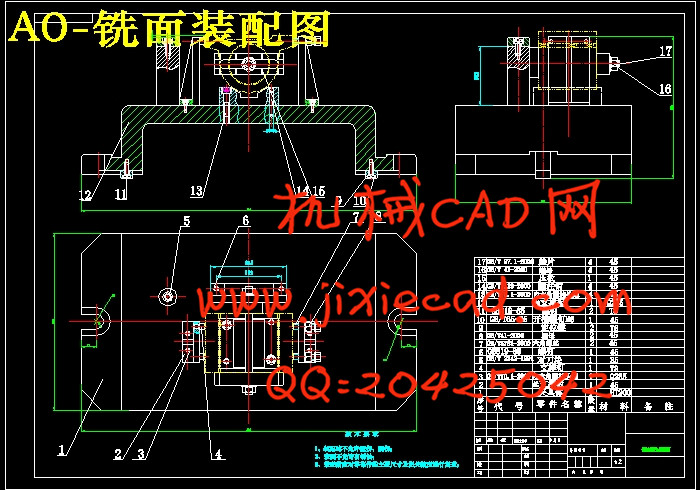

第5章 铣底面夹具设计 21

5.1 机床夹具概述 21

5.2研究原始质料 22

5.3定位基准的选择 22

5.3 切削力及夹紧分析计算 22

5.4 误差分析与计算 25

5.5 零、部件的设计与选用 25

5.6 夹具操作步骤分析和可靠性预测 26

总 结 27

参 考 文 献 28

致谢 29