设计简介

摘 要

在工艺设计中要首先对零件进行分析,了解零件的工艺再设计出毛坯的结构,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件;计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。关键词:工艺,工序,切削用量,夹紧,定位,误差

Abstract

In the process of design should first of all parts to analyze, understand parts of the process and then design a blank structure, and choose the good parts of the machining datum, designs the process routes of the parts; then the parts each step process dimension calculation, the key is to determine the process equipment and cutting the amount of each working procedure design; then a special fixture, fixture for the various components of a design, such as the connecting part positioning device, clamping element, a guide element, clamp and the machine tool and other components; the positioning error caused calculate fixture when positioning, analysis of the rationality and deficiency of fixture structure, pay attention to improving and will design in.

Keywords: process, process, cutting, clamping, positioning

Keywords: process, process, cutting, clamping, positioning

目 录

摘 要···························································································· II

Abstract························································································· III

第1章 绪论···················································································· 1

第2章 加工工艺规程设计······························································· 2

2.1 零件的分析········································································ 2

2.1.1 零件的作用······································································ 2

2.1.2 零件的工艺分析······························································· 3

2.2 卡板零件加工的主要问题和工艺过程设计所应采取的相应措施 3

2.2.1 孔和平面的加工顺序························································· 3

2.2.2 孔系加工方案选择···························································· 3

2.3 卡板零件加工定位基准的选择·············································· 3

2.3.1 粗基准的选择··································································· 3

2.3.2 精基准的选择··································································· 4

2.4 卡板零件加工主要工序安排················································· 4

2.5 机械加工余量、工序尺寸及毛坯尺寸的确定·························· 6

2.6确定切削用量及基本工时(机动时间)································· 6

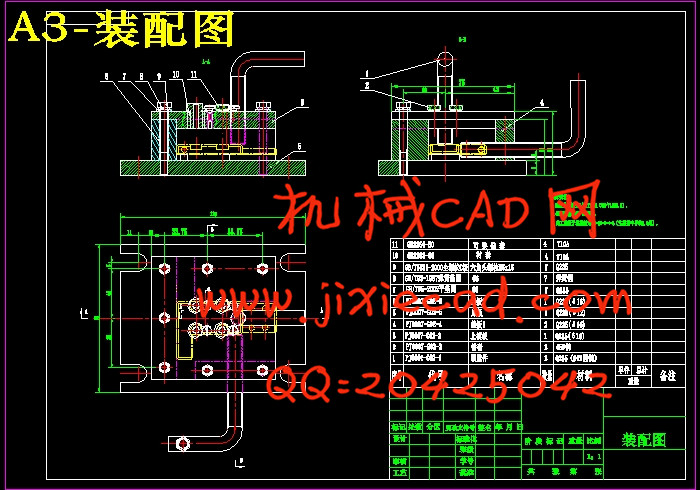

第3章 钻孔专用夹具设计································································ 14

3.1问题的指出········································································ 14

3.2 夹具设计·········································································· 14

3.2.1概述··············································································· 14

3.2.2方案设计········································································ 14

3.2.3定位基准的选择······························································ 14

3.2.4切削力和夹紧力的计算···················································· 15

3.3切削力和夹紧力计算·························································· 15

3.4夹紧力的计算···································································· 16

3.5定位误差分析···································································· 17

3.6零、部件的设计与选用······················································· 17

3.7确定夹具体结构尺寸和总体结构·········································· 20

总 结···························································································· 22

参 考 文 献··················································································· 23

致 谢···························································································· 24